Professional Documents

Culture Documents

Mechanical Package Design Quality Checklist

Uploaded by

ulfat100%(1)100% found this document useful (1 vote)

251 views1 pagecheck list for piping

Original Title

Check List Rev-04

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentcheck list for piping

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

251 views1 pageMechanical Package Design Quality Checklist

Uploaded by

ulfatcheck list for piping

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

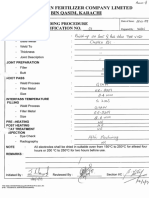

Form# PTU-001-Rev-04

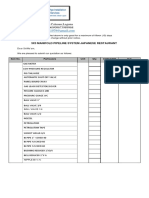

MECHANICAL PACKAGE DESIGN QUALITY CHECKLIST

Unit/ Section: Projects /PTE Department: Engineering Department

MOC Subject : MOC #

Peer

PREPR'D CHK'D APPR'D REMARKS

Review

SN DESCRIPTION D/F man Proj. Engr Proj. Engr UM/SH

A DRAWING TITLE BLOCK & PROCESS / INSPECTION DATA CHECKS

1 Drawing Latest Template & Revision Number, Rev Cloud / Rev Mark

2 Title Block Information & MOC# , RT/ DPT/Hydro Test / Service Test

3 Drawing Notes & Legends/Spellings,

4 North Arrow/Wind Direction/ Line weight & line Types as per STD

5 Check Line Number/Reference Data/Drawing Presentation/ ITP&WPS

B EQUIPMENT & PIPING LAYOUT CHECKS

6 Site verification as per layout drawings

7 P&ID and Process Requirements/Notes/Demolition (DWG Self Explanatory)

Equipment Location from Existing, Tag#, Coordinates & Nozzle Elevation/ Nozzle #/

8

Size & Rating

9 Layout Dimension and Elevations and Interference/Clash Check

Optimum Design Checks (Access/Operation/Maintenance

/Construction,Crane/Piping Flexibility/Routing & grouping

10

/Existing & New PS/Fitting & welding savings /Equipment

removal/Overhead & man-way clearance/Future space)

11 Compliance with Project relevant Specifications

12 Valve and in-Line Components / CV Dimension/ FT's Straight length

13 Process / HT Vents and Drains / Flow Direction Arrow

14 E&I cable Tray, E&I connection/Orientation and Access

15 Stress Critical lines Analysis & B31.3/SEC VIII DIV-I Calculation

16 Sectional views details provided where required

17 U/G Pipe Burial Depth/Sleeve requirement/Insulation Gasket

C PIPING ISOMETRIC CHECKS

18 Check Dimensional, Elevations as per layout & site verification

19 BOM-Bill of material completion & verification, Gasket Space

Operating & Design data, reference dwgs#, PID #, Insulation,

20 Painting,heat treatment,RT,/DPT Pipeline number/Check Process

data from line list

21 Minimum space b/w welds (100mm)/Field weld indication

Bolt Withdrawal space, flange clearance (where valves joined

22

with equipment)/Min line size for thermo well installation

23 Tapping Points/Orientation in orifice flange/PT-PI' (Gas/Liquid)

24 Process & Hyro. test vents/Low Points Drains /PSV Set Pressure & weep hole

25 All HOLDS & Notes to be recorded / HOLD list attached

26 Check Material Specs Description & Mark Spec. Breaks

27 Break out Spool & Hook-up details, if any

28 Brace Small Bore Branches / Control valve Actuator support

29 ECC Reducers (T/B Flat) shown/Suction Lines are short

D CIVIL/ SUPPORTS CHECKS

Da Metalic Piping. CS and SS:

Foundation Loading and height of Supports info drawing prepared for Civil Plant to

30

design Civil structure.

Referance drawing and dimensions form existing civil structure, Steel Structure and

31

anchor Bolts details provided.

Maximun pipes support added with minimum recommended span for horizenal

32

piping on Pipe Sleepers and Racks.

Db Non Metalic Piping, PVC, UPVC and HDPE

Maximum pipe support added on manufacturer recommended with minimum span

33 for horizontal and vertical piping around equipment and on Pipe Sleepers/Racks for

non metal piping.

E Piping / Equipment Re-rating

34 Piping / Equipment old calcuations checked and new calcuations performed

35 Name plate drawing revised

36 WPS to be developed & Welding details updated

Peer

Legends: RC: Recommended Checkk / (Optional for SH)

PREPR'D CHK'D Review APPR'D

N/A : Not Applicable

Signature

PREPARED BY APPROVED BY REFERENCE

You might also like

- Piping Design Checklist: How To UseDocument2 pagesPiping Design Checklist: How To Usekarpakki100% (1)

- CLASS 600 Weld Neck Flanges WeightDocument1 pageCLASS 600 Weld Neck Flanges WeightAwais IftikharNo ratings yet

- Pipe Fitter Job DescriptionDocument2 pagesPipe Fitter Job DescriptionuemaaplNo ratings yet

- Detailed Design and Engineering Deliverable List (Sample)Document9 pagesDetailed Design and Engineering Deliverable List (Sample)mohan babuNo ratings yet

- Saes L 100Document12 pagesSaes L 100samsurendran_mech4020No ratings yet

- PEEC-A023 - Checklist - Single Line Diagram PDFDocument2 pagesPEEC-A023 - Checklist - Single Line Diagram PDFRisharto YustitiardiNo ratings yet

- Piping Layout and Equipment Location ChecklistDocument3 pagesPiping Layout and Equipment Location Checklistmithoon_021068100% (1)

- Cable Ladder TrayDocument80 pagesCable Ladder TrayrocketvtNo ratings yet

- Design Document CHCKLSTDocument41 pagesDesign Document CHCKLSTAndile CeleNo ratings yet

- Piping Basic: by Aries ChandraDocument18 pagesPiping Basic: by Aries ChandraAries Chandra Abu HasanNo ratings yet

- Inspection and Test Plan Piping Work ActivitiesDocument2 pagesInspection and Test Plan Piping Work ActivitiesAbram Berkat100% (2)

- PipingDocument7 pagesPipingfarhanyazdaniNo ratings yet

- ValvesDocument26 pagesValvesSatyam KalraNo ratings yet

- Engineering Piping Drawing Index SheetsDocument181 pagesEngineering Piping Drawing Index SheetsAde FaruroziNo ratings yet

- Design Review On Fpso-Belanak: Kerjasama Antara: FT. Kelautan - ITS Dan Direktorat Teknik - Dirjen MIGASDocument47 pagesDesign Review On Fpso-Belanak: Kerjasama Antara: FT. Kelautan - ITS Dan Direktorat Teknik - Dirjen MIGASNur Syahroni100% (1)

- Notes Process DiagramDocument42 pagesNotes Process DiagramDinesh guhanNo ratings yet

- Process Plant Project Sequence ChartDocument10 pagesProcess Plant Project Sequence ChartGeetha_jagadish30No ratings yet

- MSS SP-112-2010Document9 pagesMSS SP-112-2010Денис ПекшуевNo ratings yet

- Bleed Ring - ANSI Class 150-2500 (In)Document2 pagesBleed Ring - ANSI Class 150-2500 (In)ulfatNo ratings yet

- Welding MapDocument10 pagesWelding MapWiwik HaryadiNo ratings yet

- Drawing Check PrintDocument2 pagesDrawing Check PrintSRINKAL1999No ratings yet

- PID Check ListDocument6 pagesPID Check ListArunachalam KaliyaperumalNo ratings yet

- 3DP-G04-00034 - Off Project Design ReviewDocument22 pages3DP-G04-00034 - Off Project Design ReviewtavenegasNo ratings yet

- 3D Modeling (Inputs&Outputs) 1514 20140622Document2 pages3D Modeling (Inputs&Outputs) 1514 20140622Abhiyan Anala ArvindNo ratings yet

- Project Quality Plan and Loop Testing ProceduresDocument3 pagesProject Quality Plan and Loop Testing ProceduresOwais MalikNo ratings yet

- BS EN 744 1996 Cracked PDFDocument16 pagesBS EN 744 1996 Cracked PDFZeeshan Khan100% (1)

- Instrument Diagrams ChecklistDocument3 pagesInstrument Diagrams ChecklistrahulNo ratings yet

- P&id SeminarDocument30 pagesP&id SeminaryasirvazhikkadavuNo ratings yet

- Checklist for Piping Model LayoutDocument1 pageChecklist for Piping Model LayoutJorge Santos RomeroNo ratings yet

- Energy Systems P&ID GuideDocument4 pagesEnergy Systems P&ID GuideLucky Cham AguilaNo ratings yet

- Format SEI-HC-PS-C403: Check List For Hvac Duct LayoutDocument3 pagesFormat SEI-HC-PS-C403: Check List For Hvac Duct Layoutarunima04No ratings yet

- Rack Piping For A Piping Stress EngineerDocument4 pagesRack Piping For A Piping Stress EngineerFaizal Khan100% (2)

- Piping Department Flow ChartDocument2 pagesPiping Department Flow ChartFrancisco José Hernández Gómez100% (1)

- Piping GuideDocument18 pagesPiping GuideEr Moosa Mohammed100% (1)

- Asme B16.15-1985 PDFDocument37 pagesAsme B16.15-1985 PDFRuben Dario Mamani ArellanoNo ratings yet

- Develop Plot Plans for Piping ProjectsDocument9 pagesDevelop Plot Plans for Piping ProjectsTom0% (1)

- Draft: MGE XXX XXX MBR XXX XXXDocument5 pagesDraft: MGE XXX XXX MBR XXX XXXAgus LengoletaNo ratings yet

- C2C BrochureDocument8 pagesC2C BrochureDarla ChavezNo ratings yet

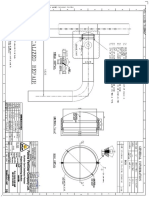

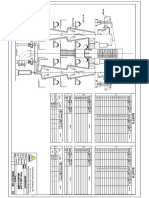

- Piping Support Standards for OFON Phase 2 ProjectDocument136 pagesPiping Support Standards for OFON Phase 2 ProjectCHUKUDINo ratings yet

- Abbreviations in PipingDocument12 pagesAbbreviations in PipingADITYA_PATHAKNo ratings yet

- PDMS Vs SmartPlantDocument24 pagesPDMS Vs SmartPlantrmm99rmm990% (1)

- Lecture 2 Process Engineering-1Document95 pagesLecture 2 Process Engineering-1ahmed.ayoob.abdNo ratings yet

- 1 SS Ci 004Document26 pages1 SS Ci 004chells.sakthiNo ratings yet

- Piping ISO Check SheetDocument3 pagesPiping ISO Check Sheetkulasera100% (2)

- ALLSource Solutions - Engineering ProfileDocument17 pagesALLSource Solutions - Engineering ProfileNikhil JohnNo ratings yet

- Presentation - HPGR Maintenance (17-Sep-10) Rev1Document36 pagesPresentation - HPGR Maintenance (17-Sep-10) Rev1amilkar100% (1)

- PIPING PROCEDURESDocument9 pagesPIPING PROCEDURESippon_osotoNo ratings yet

- FS PipingDocument317 pagesFS PipingOthman RejabNo ratings yet

- LGDD ZZ ITTDSXS 00 45671233 0 Instrument DatasheetDocument37 pagesLGDD ZZ ITTDSXS 00 45671233 0 Instrument DatasheetuyaiekanemNo ratings yet

- Inventor Content Center Authoring & Publishing GuideDocument29 pagesInventor Content Center Authoring & Publishing GuideLÊ VĂN ĐỨCNo ratings yet

- Orifice Plate Flow Meter Data SheetDocument4 pagesOrifice Plate Flow Meter Data SheetTaimoor KhanNo ratings yet

- Saudi Arabian Oil Company: Equipment Inspection ScheduleDocument1 pageSaudi Arabian Oil Company: Equipment Inspection ScheduleBachir GeageaNo ratings yet

- Procedure For Fire Water Max. Demand Calculation: Quality Management System DocumentDocument4 pagesProcedure For Fire Water Max. Demand Calculation: Quality Management System DocumentmNo ratings yet

- Flowchart Piping Stress AnalysisDocument1 pageFlowchart Piping Stress AnalysisSeptian FirdausNo ratings yet

- 3D G.ADocument14 pages3D G.Aeke23No ratings yet

- D7029 - Inspection Release Note FormatDocument2 pagesD7029 - Inspection Release Note Formatnisha_khanNo ratings yet

- TMG Hold & Check Points 16.11.17Document54 pagesTMG Hold & Check Points 16.11.17anjnaNo ratings yet

- DS Pressure Transmitter PDFDocument3 pagesDS Pressure Transmitter PDFadrian bargasNo ratings yet

- (Package-2-Mech Works) : Clean Fuels ProjectDocument17 pages(Package-2-Mech Works) : Clean Fuels ProjectsarangpuneNo ratings yet

- Shafi CV Jan2020 - Project EngineerDocument2 pagesShafi CV Jan2020 - Project EngineerMudasir MughalNo ratings yet

- Op-3-27. Checklist For Information Required Before Cpt/Cptu TestsDocument5 pagesOp-3-27. Checklist For Information Required Before Cpt/Cptu Testsjinwook75No ratings yet

- PSV For Testing Calibration Form (Empty)Document1 pagePSV For Testing Calibration Form (Empty)Jorge GarciaNo ratings yet

- PVRVDocument4 pagesPVRVbkkbrazil100% (1)

- Piping Isometric Checklist - 40 Essential ItemsDocument2 pagesPiping Isometric Checklist - 40 Essential ItemsPaulo SousaNo ratings yet

- NTF in DS LG 001 Data Sheet Level GaugeDocument4 pagesNTF in DS LG 001 Data Sheet Level GaugeRicardo NapitupuluNo ratings yet

- Satr W 2012Document1 pageSatr W 2012Mohammed Hamed BaganNo ratings yet

- Freshmen Electrical Engineering Training CourseDocument20 pagesFreshmen Electrical Engineering Training CourseFadlur RahmanNo ratings yet

- 3 OEE 3 144 Mechanical Design Check ListsDocument13 pages3 OEE 3 144 Mechanical Design Check ListsAnonymous HDlK5cXc8No ratings yet

- Type of Drgs and IDC Draft 4-6-19Document31 pagesType of Drgs and IDC Draft 4-6-19Zahoor AhmedNo ratings yet

- Upvc Pipe Class DDocument4 pagesUpvc Pipe Class DnaagshreeNo ratings yet

- Trolley Aera: Concrete Road New Proposed TST RoadDocument1 pageTrolley Aera: Concrete Road New Proposed TST RoadulfatNo ratings yet

- IN NSA AAF FG GR OU UP: N Nomi Inee Es Ar ReDocument1 pageIN NSA AAF FG GR OU UP: N Nomi Inee Es Ar ReulfatNo ratings yet

- Pm-mg-d-01-1497 RB (Repair For F-101 Inlet Line)Document1 pagePm-mg-d-01-1497 RB (Repair For F-101 Inlet Line)ulfatNo ratings yet

- Boxup CalculationDocument8 pagesBoxup CalculationulfatNo ratings yet

- CCRI LayoutDocument1 pageCCRI LayoutulfatNo ratings yet

- FC CF: During Engineering It Is Recommended by SSW To Replace Inlet Lines With Improved ThicknessDocument1 pageFC CF: During Engineering It Is Recommended by SSW To Replace Inlet Lines With Improved ThicknessulfatNo ratings yet

- Installation of isolation valves for safety showers networkDocument3 pagesInstallation of isolation valves for safety showers networkulfatNo ratings yet

- MOR For FurnitureDocument1 pageMOR For FurnitureulfatNo ratings yet

- AMMONIA FURNACE F-10 ModelDocument1 pageAMMONIA FURNACE F-10 ModelulfatNo ratings yet

- Comments Sheet For IFC CirculationDocument1 pageComments Sheet For IFC CirculationulfatNo ratings yet

- Testing & Repair Form ELE-029Document1 pageTesting & Repair Form ELE-029ulfatNo ratings yet

- V370Document30 pagesV370ulfatNo ratings yet

- Birthday Card For MazharDocument1 pageBirthday Card For MazharulfatNo ratings yet

- BOM (AMMONIA-2018-141) IV Provision Upstream of PSVsDocument5 pagesBOM (AMMONIA-2018-141) IV Provision Upstream of PSVsulfatNo ratings yet

- Velan Pressure Seal Valve CatalogDocument4 pagesVelan Pressure Seal Valve CatalogulfatNo ratings yet

- Velan Pressure Seal Valve CatalogDocument4 pagesVelan Pressure Seal Valve CatalogulfatNo ratings yet

- Stress Analysis List: Rev. Stress Sketch Line Number (S) Remarks Stress Calculation NoDocument5 pagesStress Analysis List: Rev. Stress Sketch Line Number (S) Remarks Stress Calculation NoulfatNo ratings yet

- 01Document1 page01ulfatNo ratings yet

- Oisd STD-226Document76 pagesOisd STD-226rsb72100% (1)

- HIFIT Industries Machining and Forging CapabilitiesDocument6 pagesHIFIT Industries Machining and Forging Capabilitiesprakash 3No ratings yet

- Dasco HvacDocument35 pagesDasco HvacrafaelNo ratings yet

- Jacketed PipesDocument11 pagesJacketed PipesvuongNo ratings yet

- Standard materials for CS900 piping systemDocument5 pagesStandard materials for CS900 piping systemCristobal Leal ArandaNo ratings yet

- Reverse Osmosis SystemDocument28 pagesReverse Osmosis SystemFreddy Enrique Luna MirabalNo ratings yet

- SD-100 VibrocompactadorDocument384 pagesSD-100 VibrocompactadorMIGUELNo ratings yet

- Instrumentation Fittings, Valves & Accessories GuideDocument12 pagesInstrumentation Fittings, Valves & Accessories GuideGloria HamiltonNo ratings yet

- ISO 10628-2 2012 Symbols Sheet 6Document1 pageISO 10628-2 2012 Symbols Sheet 6Nguyễn Đức ÝNo ratings yet

- Letlok Tube Fitting Catalog 2017Document94 pagesLetlok Tube Fitting Catalog 2017chipulinoNo ratings yet

- ASME B16.9 InterpretationsDocument13 pagesASME B16.9 InterpretationsamerNo ratings yet

- Copper Pipe, Fittings & Flanges Manufacturer WebsiteDocument15 pagesCopper Pipe, Fittings & Flanges Manufacturer Websitedenil zNo ratings yet

- BC Plumbing Code UpdateDocument87 pagesBC Plumbing Code UpdateSusheel GuptaNo ratings yet

- PIPING SPECIFICATIONSDocument49 pagesPIPING SPECIFICATIONSkasvikrajNo ratings yet

- Catalog 21Document120 pagesCatalog 21Rodamientos y Representaciones Industriales, S.A. de C.V. - Suc. QueretaroNo ratings yet

- Dixon 3501 Catalog PDFDocument780 pagesDixon 3501 Catalog PDFSharrife JNo ratings yet

- Ground Investigation Works BQDocument51 pagesGround Investigation Works BQMohamedNo ratings yet

- Quotation - Japanese RestaurantDocument2 pagesQuotation - Japanese RestaurantMark Angelo “Gelo” RoxasNo ratings yet

- Ccad-Aed-Sp - G-211300 - 0 - Fre Suppression SprinklersDocument9 pagesCcad-Aed-Sp - G-211300 - 0 - Fre Suppression SprinklersArun UdayabhanuNo ratings yet

- Aaaa 4Document1 pageAaaa 4ravi rajNo ratings yet

- Microfast 0.90 Fast UnitDocument4 pagesMicrofast 0.90 Fast UnitJelena KalcNo ratings yet