0% found this document useful (0 votes)

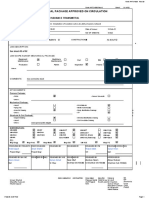

67 views1 pageE-135 B Leakage Analysis and History

1) The document discusses the design, installation, operation, and inspection history of heat exchangers E-135 G and E-135 H at a power plant.

2) It notes that high load operations caused tube ruptures in E-135 G, which was replaced in 2010 and relocated to a bottom location. E-135 H was retubed in 2013.

3) The document outlines inspection and testing activities that have been performed on the exchangers over their operating history to monitor thickness, identify leaks, and assess remaining life.

Uploaded by

ulfatCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLS, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

67 views1 pageE-135 B Leakage Analysis and History

1) The document discusses the design, installation, operation, and inspection history of heat exchangers E-135 G and E-135 H at a power plant.

2) It notes that high load operations caused tube ruptures in E-135 G, which was replaced in 2010 and relocated to a bottom location. E-135 H was retubed in 2013.

3) The document outlines inspection and testing activities that have been performed on the exchangers over their operating history to monitor thickness, identify leaks, and assess remaining life.

Uploaded by

ulfatCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLS, PDF, TXT or read online on Scribd