Professional Documents

Culture Documents

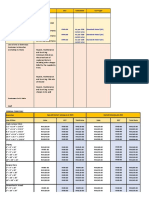

Scheme of Examination: Cylindrical Shell SA516 GR 60 SA516 GR 60 Elliptical Head

Uploaded by

Pand AemonaEonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Scheme of Examination: Cylindrical Shell SA516 GR 60 SA516 GR 60 Elliptical Head

Uploaded by

Pand AemonaEonCopyright:

Available Formats

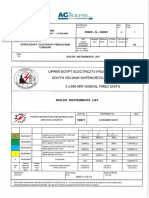

SCHEME OF EXAMINATION

A. EQUIPMENT DATA B. REVISION HISTORY

Equipment No. S8110 Date Issue Rev Description Prepare Sign Reviewed Sign

Description LS Condensate Drum

Mfr. Serial No. TG PMT 6817 Feb-17 1 0 Initial Izzati Shahrul

Func. Location AMKT-T812-S8110 DOSH Reg. No. TG PMT 6817 x YES May-17 1 1 Add sf & hydrojet Izzati Shahrul

Painting

Unit 8000 CF Expiry 18.Aug.21 NO 25.Okt.17 3 2 Remark for history and planning Ameer Shahrul

Section Steam and Condensate Sys. Statutory Inspection x YES NO 01.Jän.20 TA 21 3 Add inspection history ZZ NS/SK

Drawing P&ID 812 Equipment Type Vessel Packed Vessel

Ref. No G.A. J12-PE338-03-01 Orientation Vertical YES

Design Code ASME VIII Div. I Accessibility Intrusive Entry x NO C. RBI SUMMARY Analysis Date: 14.03.2011

Size (mm) 1100 ID 2750 L Extend Full Jacketed Corrosion Loop Remnant Highest

No Component CL Description Risk Rating

No. of Tube N/A Insulation Category YES (CL) Life (Yrs) Risk Rating

Bundle Type Material x NO 1 Vessel 8 Hot Water in CS 13 1A

Shell Side Tube Side Pressure Relief Device 2 Vessel 8 Hot Water in CS 13 1A

1A

Process Medium Water N/A Tag No. 3

Design (min/max) FV/0.5 Set Pres. (min/max), barg

Very Low

Pressure 4

(barg) Operating (min/max) 0.2 5

Temp. Design (min/max) 125 No Damage Mechanism Remarks Overall Summary

(oC) Operating (min/max) 105

1 External corrosion All components

Postweld Heat Treatment No

MATERIAL LIST

2 Other, metal loss All components

Thickness (mm) Internal

Description Material Remarks

Nominal Corr All. Finish

3

Cylindrical Shell SA516 Gr 60

Corrosion

Elliptical Head SA516 Gr 60 4

D. INSPECTION REQUIREMENT (Tick if required)

VISUAL Profile RT

ONSTREAM

UTTM IR

EXTERNAL UTFD PAUT

MPT C-Scan

DPT EMAT

100% coverage on insulation of shell, head, nozzle, support leg,

VISUAL x PMI

painting condition and other external parts

UTTM x As per baseline UT points (24 points) PAUT

UTFD C-Scan

EXTERNAL TOFD PEC

MPT RT

DPT HARDNESS

IR Others

Look for any indication of thinning, localized corrosion inside the

VISUAL x CREEP/PI-TAPE

SHUTDOWN

vessel by internal entry (1MH).

UTTM BOROSCOPE

UTFD VIDEOSCOPE

DPT REPLICA TEST

MPT LOTIS/H-SCAN

INTERNAL RT FTIS

RFET Others

IRIS HYDRO TEST (barg) PNEUMATIC TEST (barg)

ECT SHELL SHELL

MFL TUBE TUBE

HARDNESS

HOLIDAY TEST VACUUM BOX TEST (barg)

E. PREVIOUS FINDING

Year Finding Location Remark Year Finding Location Remark

2016 Shell, top and bottom

No abnormalities Surface corrosion

2018 2016 header

To monitor and measure depth of

Pitting depth <0.5mm Manhole neck

pitting

Localized pitting and hard scale depth

Manhole neck

<0.5mm

2018

Erosion and metal loss depth <0.5mm Nozzle 6N Repaired

External

Internal

Pitting corrosion depth <0.5mm Shell To monitor

F. DISMANTLING (Tick if required)

Open / Refit Insp. Window Open Trays Manways

Remove / Refit Insulation x Open PP at manhole Remove Packing

Open Manhole x 1M for IVI Drop Exch Cover / Channel Hea

EXTERNAL INTERNAL

Open Nozzle Pull Tube Bundle

Remove AFC Plugs Open Demisters / Filters

Others Others

G. CLEANING (Tick if required)

Handtool Handtool

Powertool Powertool

Grit Blasting Grit Blasting

EXTERNAL Degreasing INTERNAL Hydrojet

Others Air Blow

Chemical Cleaning

Not Applicable Others

H. ACCESS REQUIREMENT (Tick if required)

Scaffolding x To access to manhole Scaffolding

Ladder Ladder

Abseiling Abseiling

EXTERNAL INTERNAL

Gondola Gondola

Air Diving Air Diving

Others Others

I. OTHER REQUIREMENT (Tick if required)

Touch up Painting Passivation

Power Supply Power Supply x For lighting

Others Ventilation x For internal entry

EXTERNAL INTERNAL

Lighting x For internal entry

Safe Entry Test x For internal entry

Others

J. REMARKS

You might also like

- A Complete Guide To Volume Price Analysi - A. CoullingDocument242 pagesA Complete Guide To Volume Price Analysi - A. CoullingGiundat Giun Dat97% (129)

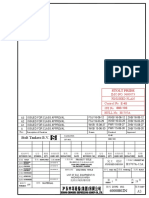

- Ultrasonic Testing Thickness Measurement Report: Component DescriptionDocument2 pagesUltrasonic Testing Thickness Measurement Report: Component DescriptionPand AemonaEon100% (4)

- Ultrasonic Testing Thickness Measurement Report: Component DescriptionDocument2 pagesUltrasonic Testing Thickness Measurement Report: Component DescriptionPand AemonaEon100% (4)

- Ultrasonic Testing Thickness Measurement Report: Component DescriptionDocument2 pagesUltrasonic Testing Thickness Measurement Report: Component DescriptionPand AemonaEon100% (4)

- Ultrasonic Testing Thickness Measurement Report: Component DescriptionDocument2 pagesUltrasonic Testing Thickness Measurement Report: Component DescriptionPand AemonaEon100% (4)

- Ultrasonic Testing Thickness Measurement Report: Component DescriptionDocument2 pagesUltrasonic Testing Thickness Measurement Report: Component DescriptionPand AemonaEon100% (4)

- Ultrasonic Testing Thickness Measurement Report: Component DescriptionDocument2 pagesUltrasonic Testing Thickness Measurement Report: Component DescriptionPand AemonaEon100% (4)

- Ultrasonic Testing Thickness Measurement Report: Component DescriptionDocument2 pagesUltrasonic Testing Thickness Measurement Report: Component DescriptionPand AemonaEon100% (4)

- Ultrasonic Testing Thickness Measurement Report: Component DescriptionDocument2 pagesUltrasonic Testing Thickness Measurement Report: Component DescriptionPand AemonaEon100% (4)

- W 3000Document30 pagesW 3000sarokihNo ratings yet

- SOP For Diesel Generator Set (DG)Document2 pagesSOP For Diesel Generator Set (DG)PADCL100% (4)

- Petrochemical Industry - Production ProcessDocument40 pagesPetrochemical Industry - Production ProcessAyie Arie AyitNo ratings yet

- Pertamina Revitalization Project Expansion Bellow Joints Data SheetDocument14 pagesPertamina Revitalization Project Expansion Bellow Joints Data SheetTommy ArjanggiNo ratings yet

- Calculation Sheet For Slug CatcherDocument12 pagesCalculation Sheet For Slug CatcherchumaNo ratings yet

- VALVE SPECSDocument3 pagesVALVE SPECSazitaggNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Petroleum Development Oman LLC: Appendix-2: Pipe Stress Analysis Checklist-Input/OutputDocument5 pagesPetroleum Development Oman LLC: Appendix-2: Pipe Stress Analysis Checklist-Input/OutputAbhijeetNo ratings yet

- IEC Earthing Types TN, TT, ITDocument5 pagesIEC Earthing Types TN, TT, ITNavneet Singh100% (1)

- Petroleum Development Oman LLC: Appendix-2: Pipe Stress Analysis Checklist-Input/OutputDocument5 pagesPetroleum Development Oman LLC: Appendix-2: Pipe Stress Analysis Checklist-Input/OutputAbhijeetNo ratings yet

- Wolfson Eup3 Ch34 Test BankDocument17 pagesWolfson Eup3 Ch34 Test BankifghelpdeskNo ratings yet

- Cummins: Fault Code: 488 PID: P105 SPN: 105 FMI: 0Document2 pagesCummins: Fault Code: 488 PID: P105 SPN: 105 FMI: 0Enrrique LaraNo ratings yet

- Equalizing Line Mbe 6 WTRDocument2 pagesEqualizing Line Mbe 6 WTRMuhamad Hifni SyahbanaNo ratings yet

- Noris ArrangementDocument59 pagesNoris Arrangementsjsship100% (3)

- 1019 DPP Ele Dts 003 SDV Data SheetDocument2 pages1019 DPP Ele Dts 003 SDV Data SheetJoseNo ratings yet

- Buffer Vessel Data SheetDocument4 pagesBuffer Vessel Data SheetUmair A. KhanNo ratings yet

- WPS PQR XLSXDocument4 pagesWPS PQR XLSXMd Sahabul IslamNo ratings yet

- Manual Book Mov Auma PDFDocument44 pagesManual Book Mov Auma PDFDidi Gunawan100% (1)

- Diesel Tank DSDocument1 pageDiesel Tank DSNurcahyo Djati W0% (1)

- Datasheets For Bucket Type StrainerDocument2 pagesDatasheets For Bucket Type StrainerbecpavanNo ratings yet

- T Header For AFC Calculation (PER UG-34) :, With The Limitation That Z Need Not Be Greater Than 2.5 (UG-34.B3)Document16 pagesT Header For AFC Calculation (PER UG-34) :, With The Limitation That Z Need Not Be Greater Than 2.5 (UG-34.B3)Pand AemonaEonNo ratings yet

- WICSDocument3 pagesWICSmohd as shahiddin jafri100% (1)

- Boiler AccesoriesDocument127 pagesBoiler Accesoriesramnath008100% (1)

- Concepts 2. Smart City 3. Smart Region 4. Smart Port 5. AnnexesDocument97 pagesConcepts 2. Smart City 3. Smart Region 4. Smart Port 5. AnnexesNataliaTeruyaNo ratings yet

- Scheme of Examination: Shell & Head SA516 GR 60Document1 pageScheme of Examination: Shell & Head SA516 GR 60Pand AemonaEonNo ratings yet

- Scheme of Examination: Shell & Head SA516 Gr. 70Document1 pageScheme of Examination: Shell & Head SA516 Gr. 70Pand AemonaEonNo ratings yet

- Scheme of Examination: Shell & Head SA516 Gr. 70Document1 pageScheme of Examination: Shell & Head SA516 Gr. 70Pand AemonaEonNo ratings yet

- Scheme of examination for LS Condensate CondenserDocument1 pageScheme of examination for LS Condensate CondenserPand AemonaEonNo ratings yet

- Scheme of Examination: 1E Medium HighDocument5 pagesScheme of Examination: 1E Medium HighPand AemonaEonNo ratings yet

- 30600-G-G0002 4 Instr ListDocument58 pages30600-G-G0002 4 Instr Listmohamed abourayaNo ratings yet

- Summary Daily ReportDocument10 pagesSummary Daily Reportdidi sudiNo ratings yet

- Instrument ScheduleDocument1 pageInstrument ScheduleSaid Hajril AulizaNo ratings yet

- Instrument ScheduleDocument1 pageInstrument ScheduleSaid Hajril AulizaNo ratings yet

- Branch Line Mbe 6 WTRDocument11 pagesBranch Line Mbe 6 WTRMuhamad Hifni SyahbanaNo ratings yet

- WICS Welding Inspection Control SheetDocument2 pagesWICS Welding Inspection Control Sheetmohd as shahiddin jafriNo ratings yet

- Design Basis For Nht/Unit 02: SnamprogettiDocument2 pagesDesign Basis For Nht/Unit 02: Snamprogettimohsen ranjbarNo ratings yet

- 11.tec-Saukem-Loi003-I01-006 V1 R4Document23 pages11.tec-Saukem-Loi003-I01-006 V1 R4Purushothaman SeenuNo ratings yet

- 01 r0 DPL Gi 150 KV Steel Structure Post 18 M Gid 00010Document3 pages01 r0 DPL Gi 150 KV Steel Structure Post 18 M Gid 00010nisaNo ratings yet

- Refinería de Cartagena Discipline Document Name: Data Sheet Cat Poly Charge Drum Np-D-3020Document3 pagesRefinería de Cartagena Discipline Document Name: Data Sheet Cat Poly Charge Drum Np-D-3020pecosorosaNo ratings yet

- Welding Tracebility Report for MBE-6 Production PipingDocument8 pagesWelding Tracebility Report for MBE-6 Production PipingMuhamad Hifni SyahbanaNo ratings yet

- AnnexureDocument391 pagesAnnexureTommy ArjanggiNo ratings yet

- VIR Hot TapDocument2 pagesVIR Hot TapCak NhassNo ratings yet

- Stolt Tankers electrical equipment listDocument23 pagesStolt Tankers electrical equipment listTrường Bửu TrầnNo ratings yet

- Dehydration and Desalting System Data SheetDocument2 pagesDehydration and Desalting System Data Sheetfiguev2208No ratings yet

- ADMA-OPCO Strainer Data SheetDocument7 pagesADMA-OPCO Strainer Data Sheetvinoj chandranNo ratings yet

- RT Request: Hail Surface Facilities Eps ProjectDocument4 pagesRT Request: Hail Surface Facilities Eps ProjectAnonymous AdofXEYAgENo ratings yet

- E36 Test PanelDocument12 pagesE36 Test PanelGanesa MurthyNo ratings yet

- Ama Uruk RT FWT 002Document5 pagesAma Uruk RT FWT 002Aws AbduljaleelNo ratings yet

- Quick Closing Valve Yoohan (Woosung)Document20 pagesQuick Closing Valve Yoohan (Woosung)Bui Duy ThanhNo ratings yet

- MDR Div-2Document3 pagesMDR Div-2divakar.panigrahiNo ratings yet

- Design Basis For Nht/Unit 02: SnamprogettiDocument2 pagesDesign Basis For Nht/Unit 02: Snamprogettimohsen ranjbarNo ratings yet

- Drain Line Mbe 6 WTRDocument3 pagesDrain Line Mbe 6 WTRMuhamad Hifni SyahbanaNo ratings yet

- Flame Arrestor DatasheetDocument3 pagesFlame Arrestor Datasheetvictor japposanNo ratings yet

- SA - 980 - P - 11405 - Tank Level Transmitter Rev T02Document1 pageSA - 980 - P - 11405 - Tank Level Transmitter Rev T02altipatlarNo ratings yet

- Test Manifold Package No:: Client Saudi Aramco Oil CoDocument7 pagesTest Manifold Package No:: Client Saudi Aramco Oil CosarangpuneNo ratings yet

- Prolong 1 Month BosDocument5 pagesProlong 1 Month BosAl Fitrah EdisonNo ratings yet

- UBL DEB-E-6-M2-DS-MS3-001-G DataSheet Mechanical Steam Separator Rev.A IFRDocument5 pagesUBL DEB-E-6-M2-DS-MS3-001-G DataSheet Mechanical Steam Separator Rev.A IFRAndi Candra IrawanNo ratings yet

- 3827-E10-066 - Knife Gate (On-Off) Control Valve - DDocument2 pages3827-E10-066 - Knife Gate (On-Off) Control Valve - DMohamed Elsaid El ShallNo ratings yet

- BK91-1310-CPF-PIP-MT-0041-5Document1 pageBK91-1310-CPF-PIP-MT-0041-5Panneer SelvamNo ratings yet

- Datasheets For Bucket Type StrainerDocument2 pagesDatasheets For Bucket Type StrainerbecpavanNo ratings yet

- SA 980 P 11401 Flow Switch Rev T02Document1 pageSA 980 P 11401 Flow Switch Rev T02altipatlarNo ratings yet

- Bridge Note Book SampleDocument2 pagesBridge Note Book SampleGerik Almarez100% (1)

- Damper Datasheet: Stack Damper Multiple Stack ControlDocument2 pagesDamper Datasheet: Stack Damper Multiple Stack ControlAjay BaggaNo ratings yet

- IW 50 #150 - Flanged YES - Check (Swing)Document8 pagesIW 50 #150 - Flanged YES - Check (Swing)m 418No ratings yet

- For Additional Detail, Specifications and Charts See:: FeaturesDocument1 pageFor Additional Detail, Specifications and Charts See:: FeaturesFerhat YavasNo ratings yet

- HD-C000628-585-05-762 - 3 (Flujometro)Document2 pagesHD-C000628-585-05-762 - 3 (Flujometro)Patricio AlarconNo ratings yet

- by Pass Line Mbe 6 WTRDocument2 pagesby Pass Line Mbe 6 WTRMuhamad Hifni SyahbanaNo ratings yet

- Rev. Status: Customer Drawing ListDocument9 pagesRev. Status: Customer Drawing ListDebesh ChaudharyNo ratings yet

- MOM Insulation 31jan21Document1 pageMOM Insulation 31jan21Pand AemonaEonNo ratings yet

- Cause of Welding CrackDocument20 pagesCause of Welding CrackPand AemonaEonNo ratings yet

- Damage MechanismDocument2 pagesDamage MechanismPand AemonaEonNo ratings yet

- PRBIv2 Equipment Template - PIPING Rev 2 (00000002)Document144 pagesPRBIv2 Equipment Template - PIPING Rev 2 (00000002)Pand AemonaEonNo ratings yet

- TA Quality PlanDocument5 pagesTA Quality PlanPand AemonaEonNo ratings yet

- Quality Plan Review and UpdatesDocument1 pageQuality Plan Review and UpdatesPand AemonaEonNo ratings yet

- R9621Document3 pagesR9621Pand AemonaEonNo ratings yet

- PipingLineList - 23 05 2019 083842Document54 pagesPipingLineList - 23 05 2019 083842Pand AemonaEonNo ratings yet

- Safe Depo FeesDocument2 pagesSafe Depo FeesPand AemonaEonNo ratings yet

- Report UTTM LCRDocument9 pagesReport UTTM LCRPand AemonaEonNo ratings yet

- The Frequency of Release From Piping: A Case-Study To Compare Approaches Quantifying Organizational and Managerial FactorsDocument6 pagesThe Frequency of Release From Piping: A Case-Study To Compare Approaches Quantifying Organizational and Managerial FactorsPand AemonaEonNo ratings yet

- RJ GPP6Document1,920 pagesRJ GPP6Pand AemonaEonNo ratings yet

- SSI PlanningDocument2,009 pagesSSI PlanningPand AemonaEonNo ratings yet

- Reliability EngineeringDocument6 pagesReliability EngineeringPand AemonaEonNo ratings yet

- Optimal Management of Hydropower Production: Case of Memve'ele Hydropower Reservoir PolicyDocument33 pagesOptimal Management of Hydropower Production: Case of Memve'ele Hydropower Reservoir PolicyAJ JawileouNo ratings yet

- Physics For The Technician-ZhdanovDocument643 pagesPhysics For The Technician-Zhdanovdurant2616No ratings yet

- Wacker Neuson 1404 Compact Excavator StandardsDocument8 pagesWacker Neuson 1404 Compact Excavator StandardsDaniel ModicaNo ratings yet

- Ansi C29 6Document16 pagesAnsi C29 6AlbertoNo ratings yet

- Drilling horizontal wells with electric downhole motorsDocument10 pagesDrilling horizontal wells with electric downhole motorsGregory DemerjiNo ratings yet

- Stycast 2850FTDocument4 pagesStycast 2850FTKhôi NguyênNo ratings yet

- 04 PPT Mine Fan General PresentationDocument52 pages04 PPT Mine Fan General PresentationHeri WibowoNo ratings yet

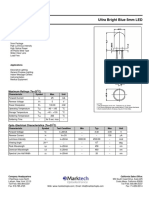

- Ultra Bright Blue 5mm LED: FeaturesDocument2 pagesUltra Bright Blue 5mm LED: FeaturesJhon LaricoNo ratings yet

- SO Short Batch FocusDocument169 pagesSO Short Batch FocusAl Rashedin KawserNo ratings yet

- Clima-8500 Evo - GBDocument2 pagesClima-8500 Evo - GBBig ZevsNo ratings yet

- Department of Physics University of Narowal: Assignment No.2 Assignment Topic: Conservative and Non Conservative ForcesDocument9 pagesDepartment of Physics University of Narowal: Assignment No.2 Assignment Topic: Conservative and Non Conservative ForcesALi HaiderNo ratings yet

- Updated Port Master Plan PDFDocument12 pagesUpdated Port Master Plan PDFRedi SefaNo ratings yet

- Equest For Leed Training: Proposed Building SetupDocument4 pagesEquest For Leed Training: Proposed Building SetupmasoodaeNo ratings yet

- WCAIM2051 - EN - AQ Atomising Air ValveDocument2 pagesWCAIM2051 - EN - AQ Atomising Air ValveMohammed YasinNo ratings yet

- SWV CatalogDocument48 pagesSWV Catalogtpelly7No ratings yet

- Frako Power Factor Control RelaysDocument4 pagesFrako Power Factor Control RelaysTiek Wah TeongNo ratings yet

- Preparation and Characterization of Tungsten Oxynitride NanowiresDocument5 pagesPreparation and Characterization of Tungsten Oxynitride NanowiresimranNo ratings yet

- EssayDocument12 pagesEssayapi-602966374No ratings yet

- Cyclone Separator Design and Working PrinciplesDocument22 pagesCyclone Separator Design and Working PrinciplesVANDINI BANSALNo ratings yet

- Ms Meganorm A2742 8e 3 PDFDocument19 pagesMs Meganorm A2742 8e 3 PDFiamsam869No ratings yet

- Anixter Energy Efficiency and Environmental Considerations For The Data Center White Paper en UsDocument8 pagesAnixter Energy Efficiency and Environmental Considerations For The Data Center White Paper en Ussaba0707No ratings yet

- General Physics ExercisesDocument49 pagesGeneral Physics ExercisesaloNo ratings yet