Professional Documents

Culture Documents

Wafer Style, Uni-Directional Knifegate Valves

Uploaded by

Daniel BorgesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wafer Style, Uni-Directional Knifegate Valves

Uploaded by

Daniel BorgesCopyright:

Available Formats

Knifegate Valves – Figure 951

50 - 300mm

Wafer style, uni-directional Knifegate valves.

Features

• Compact design.

• Self-aligning gland box.

• Both S.G. Iron and 316 S/S valves

available.

• One piece integral cast body

and chest.

• Integral cast in gate wedges

minimize flow obstructions.

• High quality gate finish for optimum

sealing.

• Gate guides to support gate.

• Integral RTFE gate scraper.

• Complies with MSS SP-81

face-to-face dimensions.

• High flow rates with low pressure

drops.

• All valves are pressure tested to

MSS SP-81

• Maintenance friendly.

General Applications Technical Data

The Keystone K-Nife is designed for a Pressure Rating:

wide range of applications such as: 1000 kPa (10 bar) @ Cold Working

• Pulp & paper Pressure (Non-shock)

• Mining Temperature Rating:

• Effluent handling plants 150°C RTFE seated

• Chemical plants 150°C Viton seated

• Food and beverage 230°C 316 S/S seated

• Fly ash handling plants 230°C S.G. Iron seated

• Bulk conveying

• Corrosive environments

© Copyright by Tyco International Ltd. F951/12/99

A.C.N. 000922690

Keystone reserves the right to change product designs and specifications without notice.

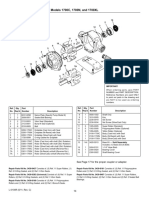

Knifegate Valves – Figure 951

50 - 300mm

14

13

12

14

5

7 8

13

12

17

7

8

5

15,16

9

3 6

11

2

3 9 10

6

11

10

2

4

1 1

4

Note: Note:

50 - 200mm valve illustrated. 250 - 300mm valve illustrated.

Parts List Options

No. Description Material • F459 Manual handwheel or quick

acting levers

1 Body 316 S/S or S.G. Iron

2 Gate 316 S/S, SAF 2205 or 304S/S*# • F738 Pneumatic actuators

3 Gland Box 304 S/S or S.G. Iron • F77C Electric actuators

4 Seat RTFE, Metal or Viton • Bevel gear operators

5 Spindle 303 S/S • Chainwheels

6 Gland Packing K-LON• • F791 Solenoid valves

7 Bridge (50 - 200mm) 304 S/S or S.G. Iron • Limit switches

Upstand (250 - 300mm) 304 S/S • F793 Positioners

8 Pillar 304 S/S • F493 Pneumatic failsafe

9 Glandbox Washer Nylon • Deflection cones, both 28%

Chrome Iron and Polyurethane

10 Gate guide S/S RTFE tipped

11 Gate scraper RTFE • Safety guards and shrouds

12 Handwheel Nut Leaded Gunmetal

13 Thrust Washer Nylon

14 Handwheel S/S or S.G Iron

15 Clevis Pin (50 - 200mm) 304 S/S

16 Split Pin (50 - 200mm) 304 S/S

17 Clevis (250 - 300mm) 304 S/S

18 All Fasteners 304 S/S

Note:

* 304 S/S gate is standard with S.G. Iron bodied valves.

# Gate is PTFE coated when used with Viton seat.

• Other packing Materials available on request.

© Copyright by Tyco International Ltd. F951/12/99

Keystone reserves the right to change product designs and specifications without notice.

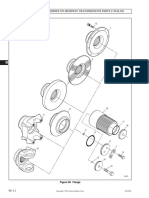

Knifegate Valves – Figure 951

50 - 300mm

C1

C1

C

C

B A

D

B A D

E E

Note: Note:

50 - 200mm valve illustrated. 250 - 300mm valve illustrated.

Dimensions (mm) Standard seat details

Valve A B Rising spindle Non- D E F Nom. mass Kv @

size bore C C1 rising manual full

(closed) (open) C (kg) open*

50 50 92 284 295 N/A 49 159 200 7 223

65 65 108 284 316 N/A 49 172 200 8 368

80 80 127 331 391 N/A 52 190 200 10 557

100 100 157 358 425 N/A 52 210 200 11 909

RTFE seat

125 125 186 450 579 N/A 58 254 300 16 1416

150 150 212 487 580 N/A 58 285 300 20 2112

200 200 270 602 746 N/A 71 338 300 32 4065

250 248 326 651 908 693 71 326 400 46 6850

300 298 380 750 1057 792 76 418 400 71 9863

Notes:

Dimension D = The face to face dimension

Dimension E = The maximum valve or upstand clearance dimension for installation.

*Kv = The flow rate of water in m3/hr that will pass through a valve with a differential Metal seat

pressure of 1 bar (100 kPa) @ 20°C

Cv = 1.155 Kv

Dimensions are nominal.

Viton seat

© Copyright by Tyco International Ltd. F951/12/99

Keystone reserves the right to change product designs and specifications without notice.

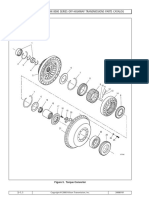

Knifegate Valves – Figure 951

50 - 300mm

Pressure/temperature graph Pressure/temperature ratings

RTFE seated

Temperature °F 1000 kPa/(10 bar) @ 20°C

100 200 300 400 500 770 kPa/(7.7 bar) @ 150°C

1500

(15)

AN

JIS-1

0

AS SI

TM 150

AS

21

200 Viton seated

A1 29

05 E 1000 kPa/(10 bar) @ 20°C

770 kPa/(7 bar) @ 150°C

Pressure kPa/(baar)

1000 150

Pressure psi

(10) Metal seated

1000 kPa/(10 bar) @ 20°C

100 700 kPa/(7 bar) @ 230°C

1 2

500

(5)

50

0

0 50 100 150 200 230 250 300

Temperature °C

1 RTFE seated valve trim code numbers are 176, 177 & 182.

Viton seated valve trim code number is 180

2 Metal -S.G. Iron seated valve trim code number is 170, 172.

-316 S/S seated valve trim code numbers are 170, 171.

Typical specifying sequence F951

150 F951 172 AS 2129 E

Valve size Figure number Trim code End connections

Size range: 50-300mm

Figure No: F951 - Wafer style rising spindle uni-directional valve.

Trim Body Gate Seat Gland Bridge Spindle Packing

No. box

172 S.G. Iron 304 S/S S.G. Iron S.G. Iron S.G. Iron 303 S/S K-LON

182 S.G. Iron 304 S/S RTFE S.G. Iron S.G. Iron 303 S/S K-LON

170* 316 S/S 316 S/S 316 S/S 304 S/S 304 S/S 303 S/S K-LON

171* 316 S/S 316 S/S 316 S/S S.G. Iron S.G. Iron 303 S/S K-LON

176* 316 S/S 316 S/S RTFE 304 S/S 304 S/S 303 S/S K-LON

177* 316 S/S 316 S/S RTFE S.G. Iron S.G. Iron 303 S/S K-LON

180* 316 S/S 316 S/S/PTFE# Viton 304 S/S 304 S/S 303 S/S K-LON

Note:

# Gates are 316 S/S, coated with PTFE.

* 65 and 125mm sizes are currently unavailable in stainless steel F951 wafer style valves.

Subject to material availability and delivery obligations, Keystone reserves the right to supply

higher grade materials for any component, eg. 316 S/S in lieu of 304 S/S.

Non-rising spindle design is available upon request.

End connections • AS 2129 Table C,D,E metric threads • JIS B2210 Table 5, 10

(to suit): • ANSI B16.5 Class 125 & 150 UNC threads • DIN 2501 Table 10, 16

• BS 4504 PN 10 and 16 • ANSI B16.5 Class 125 and 150 metric threads (for N.Z.)

© Copyright by Tyco International Ltd. F951/12/99

Keystone reserves the right to change product designs and specifications without notice.

You might also like

- The F637 Is A Medium Duty Slurry Control Valve, Short Body Style With Replaceable Body SleeveDocument4 pagesThe F637 Is A Medium Duty Slurry Control Valve, Short Body Style With Replaceable Body SleeveCapacitacion TodocatNo ratings yet

- Eaton Rtlo 11610b t2 Transmission Illustrated Parts List en UsDocument46 pagesEaton Rtlo 11610b t2 Transmission Illustrated Parts List en UsJavier Estrada ColindresNo ratings yet

- 716-50-001 - Flange Gate Valve - ANSIDocument2 pages716-50-001 - Flange Gate Valve - ANSIImtiyaz KhanNo ratings yet

- Three Piece Heavy Duty Reduced FDocument12 pagesThree Piece Heavy Duty Reduced Fzuhd1pNo ratings yet

- Llustrated Arts Anual: Transmatic Lawn Tractor - Model Series 700Document48 pagesLlustrated Arts Anual: Transmatic Lawn Tractor - Model Series 700Michael RapinoNo ratings yet

- Pressure Sustaining Valve (PSV) /relief, With Solenoid VALVE PN10/PN16 859/006HDocument3 pagesPressure Sustaining Valve (PSV) /relief, With Solenoid VALVE PN10/PN16 859/006HAgieYogaswaraNo ratings yet

- Safety and Relief ProductsDocument4 pagesSafety and Relief ProductsSamuel OlmosNo ratings yet

- Hidrant Exterior 15 Ls PDFDocument3 pagesHidrant Exterior 15 Ls PDFNicolae CretuNo ratings yet

- Eng Akrapovic Spec S-Y125SO4-HRSSDocument2 pagesEng Akrapovic Spec S-Y125SO4-HRSSclinic carsNo ratings yet

- Llustrated Arts Anual: Transmatic Lawn Tractor - Model Series 700Document48 pagesLlustrated Arts Anual: Transmatic Lawn Tractor - Model Series 700BoM36040100% (1)

- Globe ValvesDocument16 pagesGlobe ValvesafazazissaNo ratings yet

- Cryogenic LNG LPG Type Product Group 800Document16 pagesCryogenic LNG LPG Type Product Group 800Thiên KhánhNo ratings yet

- Illustrated Parts List: T-11607A November 2008Document26 pagesIllustrated Parts List: T-11607A November 2008gestada023No ratings yet

- 1700 Roller Pump Parts BreakdownDocument1 page1700 Roller Pump Parts Breakdownrndslickbar 2021No ratings yet

- Fireloock31 80Document7 pagesFireloock31 80Jorge Alberto Velazquez CortesNo ratings yet

- Check ValvesDocument12 pagesCheck ValvesafazazissaNo ratings yet

- Knife DesignDocument4 pagesKnife DesignE. Manuel Cerrón AngelesNo ratings yet

- Gate ValvesDocument12 pagesGate ValvesafazazissaNo ratings yet

- Danfoss FiltroDeshidratador DCRDocument16 pagesDanfoss FiltroDeshidratador DCROswaldo GomezNo ratings yet

- Ciat FilterDocument16 pagesCiat FilternicolasNo ratings yet

- Cast Iron Sectional Boiler For Heating and Production Domestic Hot WaterDocument20 pagesCast Iron Sectional Boiler For Heating and Production Domestic Hot Waterr_cristiNo ratings yet

- 702 10 103 - enDocument3 pages702 10 103 - enkad-7No ratings yet

- Toyota x888 RM Section 2 3Document190 pagesToyota x888 RM Section 2 3ssinokrotNo ratings yet

- Sentron Molded Case Circuit BreakersDocument6 pagesSentron Molded Case Circuit BreakersEdemirNo ratings yet

- ALU Series Service Parts List: 24 Volt Alternator Replacement ListDocument3 pagesALU Series Service Parts List: 24 Volt Alternator Replacement ListJacksonNo ratings yet

- MODELOS 1500, 2510, 2750 & 2850 Manuales: Manual de ServicioDocument12 pagesMODELOS 1500, 2510, 2750 & 2850 Manuales: Manual de ServicioClaudio Fica RamirezNo ratings yet

- Null 2Document10 pagesNull 2Brayan NohNo ratings yet

- Sellos Cadervall - Aft Stern-Tube Seal Type SeaqualDocument2 pagesSellos Cadervall - Aft Stern-Tube Seal Type SeaqualMarlon Alejandro Arboleda TapiaNo ratings yet

- High Density Mono Perc Module: CS1H-325 - 330 - 335 - 340MSDocument2 pagesHigh Density Mono Perc Module: CS1H-325 - 330 - 335 - 340MSMicu RãzvanNo ratings yet

- Allison 5000/6000 Series Off-Highway Transmissions Parts CatalogDocument4 pagesAllison 5000/6000 Series Off-Highway Transmissions Parts CatalogMaya OlmecaNo ratings yet

- Allison MD/B 300/B 400 Series On-Highway Transmissions Parts CatalogDocument16 pagesAllison MD/B 300/B 400 Series On-Highway Transmissions Parts CatalogZafiro Feliz GalanNo ratings yet

- UT08017L Thru UT080119Document12 pagesUT08017L Thru UT080119Andreas ChristakosNo ratings yet

- The Hydraulic System, Gear Pump AssemblyDocument11 pagesThe Hydraulic System, Gear Pump AssemblyTrần Đức PhiNo ratings yet

- Wiring Diagrams: Section 4A - Single Engine Application Typical DiagramsDocument12 pagesWiring Diagrams: Section 4A - Single Engine Application Typical DiagramsZêkri SäbriNo ratings yet

- Allison 8000 Series Off-Highway Transmissions Parts CatalogDocument5 pagesAllison 8000 Series Off-Highway Transmissions Parts CatalogMETİN100% (1)

- SAW D ManualDocument16 pagesSAW D ManualjlmansillaNo ratings yet

- Steering Unit: EH Electro Proportional Hydraulic Valve In-Line VersionDocument20 pagesSteering Unit: EH Electro Proportional Hydraulic Valve In-Line VersionbrunosamaeianNo ratings yet

- OM. K 970 III, K 970 III Rescue, K 970 SmartGuard. 2021-11Document152 pagesOM. K 970 III, K 970 III Rescue, K 970 SmartGuard. 2021-11SamossyzNo ratings yet

- 701, 702 Oil Burners: Replacement PartsDocument2 pages701, 702 Oil Burners: Replacement PartsHerbert Quispe RjsNo ratings yet

- B2-Borehole Pumps - 2009Document522 pagesB2-Borehole Pumps - 2009Berlian Putra WicaksanaNo ratings yet

- 7 Cooling UnitsDocument2 pages7 Cooling UnitsPANCHVEER ENGINEERINGNo ratings yet

- Catalog of Replacement Parts: CL44e AND CL54e Series DishwashersDocument40 pagesCatalog of Replacement Parts: CL44e AND CL54e Series DishwashersAndres RiveraNo ratings yet

- Avk Flanged Gate Valve, PN 10/16 06/34: DIN F4, AISI 316 Stem, CTC 0035Document3 pagesAvk Flanged Gate Valve, PN 10/16 06/34: DIN F4, AISI 316 Stem, CTC 0035AgieYogaswaraNo ratings yet

- Keeping The World Flowing: IW Quarter-Turn Gear SeriesDocument6 pagesKeeping The World Flowing: IW Quarter-Turn Gear SeriesGourav SharmaNo ratings yet

- 702-50-003 Avki 23072014Document3 pages702-50-003 Avki 23072014bre brilianNo ratings yet

- Aeroad CF SLX - R28-15: TORQUE 4.5Nm TORQUE 4.5NmDocument1 pageAeroad CF SLX - R28-15: TORQUE 4.5Nm TORQUE 4.5NmAntoine MdzNo ratings yet

- Group 2 Electrical CircuitDocument18 pagesGroup 2 Electrical CircuitTaha RdmanNo ratings yet

- FORM 6351002 - SleeveDocument2 pagesFORM 6351002 - SleeverafaelNo ratings yet

- Section 6 Electrical SystemDocument3 pagesSection 6 Electrical SystemSaidi JalelNo ratings yet

- AlgapdfDocument22 pagesAlgapdfDaniel BahamondeNo ratings yet

- CC Plug-ValveDocument2 pagesCC Plug-ValveNtolo Ongene DimitriNo ratings yet

- Parts Details LPG Compressors 3Document40 pagesParts Details LPG Compressors 3mohsen17183No ratings yet

- SP100Document8 pagesSP100Javier Flores CortesNo ratings yet

- Model ES-660-HF Thief HatchDocument2 pagesModel ES-660-HF Thief HatchjayarajNo ratings yet

- Varec Sistem Masurare LichidTEC012 - 6700Document4 pagesVarec Sistem Masurare LichidTEC012 - 6700stroiebogdanNo ratings yet

- Plug Switch 2D PDFDocument5 pagesPlug Switch 2D PDFAdy PurnamaNo ratings yet

- Gate Valves Data SheetDocument3 pagesGate Valves Data SheetRaied AyeshNo ratings yet

- Axial AOF AOF: DimensionsDocument2 pagesAxial AOF AOF: DimensionsAblayeNo ratings yet

- The Toyota Kata Practice Guide: Practicing Scientific Thinking Skills for Superior Results in 20 Minutes a DayFrom EverandThe Toyota Kata Practice Guide: Practicing Scientific Thinking Skills for Superior Results in 20 Minutes a DayRating: 4.5 out of 5 stars4.5/5 (7)

- One Bold Move a Day: Meaningful Actions Women Can Take to Fulfill Their Leadership and Career PotentialFrom EverandOne Bold Move a Day: Meaningful Actions Women Can Take to Fulfill Their Leadership and Career PotentialNo ratings yet

- ETF Presentation May 2011Document43 pagesETF Presentation May 2011Daniel BorgesNo ratings yet

- Para WeldDocument2 pagesPara WeldDaniel BorgesNo ratings yet

- Technical Presentation May 2011Document49 pagesTechnical Presentation May 2011Daniel BorgesNo ratings yet

- ETF Assembling PicturesDocument12 pagesETF Assembling PicturesDaniel BorgesNo ratings yet

- Close ApproachDocument2 pagesClose ApproachDaniel BorgesNo ratings yet

- BELTANDPULLEYDocument1 pageBELTANDPULLEYDaniel BorgesNo ratings yet

- S2 EN1513 A - M5AF M5AF1 Vane Motor Service InstructionsDocument31 pagesS2 EN1513 A - M5AF M5AF1 Vane Motor Service InstructionsDaniel BorgesNo ratings yet

- Apostila CADWorxDocument101 pagesApostila CADWorxDaniel BorgesNo ratings yet

- Bomba Weir AHDocument6 pagesBomba Weir AHDaniel BorgesNo ratings yet

- Bomba Abs RobustaDocument4 pagesBomba Abs RobustaDaniel BorgesNo ratings yet

- Non-Return Valve: ClasarDocument4 pagesNon-Return Valve: ClasarDaniel BorgesNo ratings yet

- Keymc 0025 UsDocument4 pagesKeymc 0025 UssaypionNo ratings yet

- Apostila CADWorxDocument101 pagesApostila CADWorxDaniel BorgesNo ratings yet

- Análisis Sísmico No Lineal de Edificio Con Aislación de BaseDocument15 pagesAnálisis Sísmico No Lineal de Edificio Con Aislación de BaseDieggo100% (1)

- Index For SAP2000 A To Z Problems: Item ProblemDocument2 pagesIndex For SAP2000 A To Z Problems: Item ProblemDaniel BorgesNo ratings yet

- Montagem MonoviaDocument1 pageMontagem MonoviaDaniel BorgesNo ratings yet

- Problem B: Concrete Wall ConcreteDocument10 pagesProblem B: Concrete Wall ConcreteluizmasieroNo ratings yet

- Arruela Lisa Padrão Din 125 A: Ø d1 d2 S Qtd. Peças A Cada 01 KG Nominal Mín. Máx. Mín. Máx. Mín. MáxDocument2 pagesArruela Lisa Padrão Din 125 A: Ø d1 d2 S Qtd. Peças A Cada 01 KG Nominal Mín. Máx. Mín. Máx. Mín. MáxDaniel BorgesNo ratings yet

- Sizing A PV SystemDocument58 pagesSizing A PV SystemNicholas Valdez100% (1)

- Winner Hydraulics - Price List: Index and Part Number Interchange ListDocument23 pagesWinner Hydraulics - Price List: Index and Part Number Interchange ListSHANENo ratings yet

- Suzuki Baleno Workshop ManualDocument2,167 pagesSuzuki Baleno Workshop Manualandrew0% (1)

- Kalyani Powertrain Ltd-4Nov2022Document32 pagesKalyani Powertrain Ltd-4Nov2022Sreekanth DevarasettyNo ratings yet

- (SENR3981-03) Systems Operation - Fluid Power and Electrical Symbols - Electrical Power Graphic SymbolsDocument6 pages(SENR3981-03) Systems Operation - Fluid Power and Electrical Symbols - Electrical Power Graphic SymbolsEdin raul Yalle rafaelNo ratings yet

- Fuji IGBT Module V Series Technical NotesDocument7 pagesFuji IGBT Module V Series Technical NotesManikanta SwamyNo ratings yet

- Datasheet 20611Document2 pagesDatasheet 20611Lilibeth YáñezNo ratings yet

- 1 SINGER Panoramic (Mod. 650 - 670G) PDFDocument89 pages1 SINGER Panoramic (Mod. 650 - 670G) PDFmaria brito100% (2)

- IEEE-GIS PresentationDocument41 pagesIEEE-GIS PresentationRon Daz0% (1)

- Walker Service Manual MB MC MT MS MW MTDocument256 pagesWalker Service Manual MB MC MT MS MW MTLoganNo ratings yet

- Manitou 2001 Magnum Service ManualDocument12 pagesManitou 2001 Magnum Service ManualEdha AliNo ratings yet

- Calibration Volume Lab ReportDocument4 pagesCalibration Volume Lab ReportJason OwiaNo ratings yet

- AUTOMATIC RAILWAY GATE CONTROLLER-reportDocument57 pagesAUTOMATIC RAILWAY GATE CONTROLLER-reportAnarsinh Solanki75% (8)

- Testing and AdjustingDocument12 pagesTesting and AdjustingSergio Reyes100% (1)

- Robin Ex13 Parts ManualDocument42 pagesRobin Ex13 Parts ManualkatilicousNo ratings yet

- 2015 F150 SpecsDocument2 pages2015 F150 SpecsSufian MahadinNo ratings yet

- Projeto Antena Direcional PXDocument4 pagesProjeto Antena Direcional PXalissonalexNo ratings yet

- Renr5807renr5807 01 Sis PDFDocument2 pagesRenr5807renr5807 01 Sis PDFLeonardo Romero JimenezNo ratings yet

- Boca Semiconductor Corp. BSC: Continental Device India LimitedDocument3 pagesBoca Semiconductor Corp. BSC: Continental Device India LimitedNadia Ayelen GonzalezNo ratings yet

- Basic PLC 1Document21 pagesBasic PLC 1Yogi wimi syaputraNo ratings yet

- Crj-700 Fom ManualDocument843 pagesCrj-700 Fom ManualFernando Martínez100% (5)

- Symbols of Transistors MOSFET and IGFET: Go To WebsiteDocument2 pagesSymbols of Transistors MOSFET and IGFET: Go To Websitemhs madiunNo ratings yet

- Cubex 6200 Spec Sheet PDFDocument4 pagesCubex 6200 Spec Sheet PDFtharciocidreira0% (1)

- Dual Range 7 & 8 Speed Transmission - Gears & Related Parts - 5600, 6600, 7600, 5700, 6700, 7700Document8 pagesDual Range 7 & 8 Speed Transmission - Gears & Related Parts - 5600, 6600, 7600, 5700, 6700, 7700Cristian Ivan Grageda YocupicioNo ratings yet

- Auto Start & Auto Mains Failure Control Modules: GensetDocument3 pagesAuto Start & Auto Mains Failure Control Modules: Gensetrazaq athabNo ratings yet

- DXR75 1000 June 1996Document2 pagesDXR75 1000 June 1996SergiSerranoNo ratings yet

- Single-Phase Controller With Integrated Driver For VR12.1 Mobile CPU Core Power SupplyDocument47 pagesSingle-Phase Controller With Integrated Driver For VR12.1 Mobile CPU Core Power SupplykiryanoffNo ratings yet

- University of Zakho College of Engineering Mechanical DepartmentDocument14 pagesUniversity of Zakho College of Engineering Mechanical DepartmentDilshad S FaisalNo ratings yet

- Masterplug Catalogue PDFDocument140 pagesMasterplug Catalogue PDFjdcarnNo ratings yet

- BMC HiaceDocument396 pagesBMC HiaceJerome Maminta100% (1)