Professional Documents

Culture Documents

702-50-003 Avki 23072014

Uploaded by

bre brilianOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

702-50-003 Avki 23072014

Uploaded by

bre brilianCopyright:

Available Formats

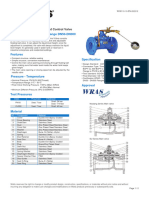

AVK KNIFE GATE VALVE, PN 10, CTC 702/50

ISO top flange for mounting of electric actuator 003

AVK lug/wafer knife gate valves are bi-directional with full and plain bore. The protected sealings and high quality

materials bring about a great performance and a long service life. The valves can be re-tightened during service.

AVK knife gate valves are available with lever, non-rising stem and handwheel, rising stem and handwheel,

pneumatic actuator, ISO top flange for actuator or complete with electric actuator.

Product Description:

Knife gate valve with ISO flange prepared for el-act. and rising stem for wastewater treatment 0°C to +80°C

Standards:

• Face to face according to DIN/EN 558-1, series 20 (K1), up to and incl. DN 350

• Standard flange drilling to EN1092-2 (ISO 7005-2), PN 10/16

Features:

• Bi-directional, can be installed independent of the flow direction

• Full bore with no reduction of the flow

• Plain bottom prevents sediment from being accumulated

• No cavity in the body and thus no risk of clogging

• Push rod protects the packing gland as it distributes the load evenly upon re-tightening

• U-shaped one-piece NBR sealing between the body parts makes up for tolerances in coating and casting. It

is reinforced with a steel insert to protect it from being damaged during operation.

• Encaged stem with yokes prepared for mounting of micro switches and inductive censors

• Stem and gate connection is secured with self-locking nuts

• Supports integrated in the body casting protect the gate from deflecting under pressure

• Body of cast iron with 150 μ fusion bonded epoxy coating. Optionally of acid-resistant stainless steel or

duplex.

• Gate, stem, push rod, bolts and nuts of acid-resistant stainless steel

• Washers under the secondary bolts protect the coating

• Slim design and low weight

• The valve is delivered with loose bolts to prevent unnecessary compression of the packing gland before use,

which therefore needs tightening after installation

• The valve is self cleaning as particles will be pushed off the gate when opening the valve. For extra protection

of the packing gland a scraper is available as an optional extra.

• Approved according to the 97/23/CE European Pressure Equipment Directive

• Optionally in higher PN class

COPYRIGHT©AVK GROUP 2014 Version no. 50 - 7-23-2014 11:35

AVK KNIFE GATE VALVE, PN 10, CTC 702/50

ISO top flange for mounting of electric actuator 003

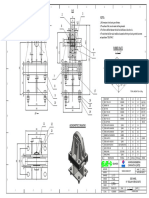

2

12

11

3

13

Ho 5

H3

6

Hc

7

10

Component List:

1. Column Epoxy coated steel St. 52 2. Stem Acid-resistant stainless steel AISI 316

3. Bolts and locking nuts Acid-resistant stainless steel A4 4. Bolt and nut / Washer Acid-resistant stainless steel A4 / PA

5. Push rod Acid-resistant stainless steel AISI 316 6. Packing NBR rubber

7. Body Cast iron GJL-250 (GG-25) 8. Gate Acid-resistant stainless steel AISI 316

9. Body gasket NBR rubber 10. Body bolt Acid-resistant stainless steel A4

11. Washer bearing Acid-resistant stainless steel A4 12. ISO flange Cast iron GJL-250 (GG-25)

13. Bolt and nut Acid-resistant stainless steel A4

Components may be substituted with equivalent or higher class materials without prior notification.

Reference Nos. and Dimensions:

Test

DN Flange L H3 H close H open Working Theoretical

AVK ref. nos pressure

mm drilling mm mm mm mm pressure bar weight kg

bar

702-050-50-13 50 PN10/16 43 448 276 383 10 15 7.0

702-065-50-13 65 PN10/16 46 494 302 422 10 15 8.0

702-080-50-13 80 PN10/16 46 566 332 474 10 15 13

702-100-50-13 100 PN10/16 52 660 369 558 10 15 15

702-125-50-13 125 PN10/16 56 714 409 599 10 15 19

702-150-50-13 150 PN10/16 56 844 487 709 10 15 28

702-200-50-03 200 PN10 60 1026 589 864 8 12 35

702-250-50-03 250 PN10 68 1217 690 1018 7 10 58

702-300-50-03 300 PN10 78 1422 811 1196 7 10 35

702-350-50-03 350 PN10 78 1580 897 1323 6 9 125

702-400-50-03 400 PN10 90 1763 1007 1473 5 8 145

702-450-50-03 450 PN10 90 1925 1062 1612 4 6 245

702-500-50-03 500 PN10 95 2109 1174 1789 4 6 270

702-600-50-03 600 PN10 105 2488 1361 2076 4 6 360

702-700-50-03 700 PN10 110 2956 1633 2507 3 4 550

702-800-50-03 800 PN10 110 3260 1858 2755 3 3 760

702-900-50-03 900 PN10 125 3711 2071 3125 1,5 2,25 1110

702-910-50-03 1000 PN10 125 3184 2406 3568 1 1,5 1160

The designs, materials and specifications shown are subject to change without notice.

This is due to the continuous development of our product programme.

Version no. 50 - 7-23-2014 11:35

Test

DN Flange L H3 H close H open Working Theoretical

AVK ref. nos pressure

mm drilling mm mm mm mm pressure bar weight kg

bar

702-912-50-03 1200 PN10 125 4811 2735 4076 1 1,5 1410

The designs, materials and specifications shown are subject to change without notice.

This is due to the continuous development of our product programme.

Version no. 50 - 7-23-2014 11:35

You might also like

- As 4024.2601-2008 Safety of Machinery Design of Controls Interlocks and Guarding - Two-Hand Control DevicesDocument7 pagesAs 4024.2601-2008 Safety of Machinery Design of Controls Interlocks and Guarding - Two-Hand Control DevicesSAI Global - APACNo ratings yet

- A Practical Guide to Piping and Valves for the Oil and Gas IndustryFrom EverandA Practical Guide to Piping and Valves for the Oil and Gas IndustryRating: 5 out of 5 stars5/5 (3)

- PG800 Cryogenic Butterfly ValvesDocument16 pagesPG800 Cryogenic Butterfly ValvesThiên KhánhNo ratings yet

- SACPCMP Log Book for CandidatesDocument6 pagesSACPCMP Log Book for CandidatesKingsleyModjadji0% (2)

- Eloqua Exam Study Guide 2069112Document18 pagesEloqua Exam Study Guide 2069112gmastro100% (1)

- BS en 12310-2Document12 pagesBS en 12310-2rajivr_ranjan_verma100% (1)

- Electric Service Handbook PDFDocument72 pagesElectric Service Handbook PDFelmerbarrerasNo ratings yet

- Fashioned From NatureDocument4 pagesFashioned From NatureSamantha Valencia LeivaNo ratings yet

- TOP PERFORMANCE UNDER PRESSUREDocument24 pagesTOP PERFORMANCE UNDER PRESSUREDwiki RamadhaniNo ratings yet

- Cedervall aft split oil lubricated stern-tube sealDocument2 pagesCedervall aft split oil lubricated stern-tube sealMarlon Alejandro Arboleda TapiaNo ratings yet

- Steel Slag RecyclingDocument2 pagesSteel Slag RecyclingNickRuiNo ratings yet

- Method Statement For RebarDocument8 pagesMethod Statement For RebarEng hassan hussien100% (1)

- Quality Plus Company ProfileDocument36 pagesQuality Plus Company ProfileMartin Carlo Martinez0% (1)

- BS en 12099Document7 pagesBS en 12099OmerfAtaNo ratings yet

- BOMA 1 Introduction AIADocument70 pagesBOMA 1 Introduction AIAConstantin FlorescuNo ratings yet

- Filters Rexroth PDFDocument564 pagesFilters Rexroth PDFRidha Abbassi100% (1)

- 702 10 103 - enDocument3 pages702 10 103 - enkad-7No ratings yet

- Avk Concentric Loose Liner Butterfly Valve, Pn10/16, DN350-400 76/70Document2 pagesAvk Concentric Loose Liner Butterfly Valve, Pn10/16, DN350-400 76/70bre brilianNo ratings yet

- Avk 555 202 DS131114Document2 pagesAvk 555 202 DS131114mokbelNo ratings yet

- 716-50-001 - Flange Gate Valve - ANSIDocument2 pages716-50-001 - Flange Gate Valve - ANSIImtiyaz KhanNo ratings yet

- Wilo Suction Diffuser / Flow Inverter: Technical BulletinDocument4 pagesWilo Suction Diffuser / Flow Inverter: Technical BulletinilieoniciucNo ratings yet

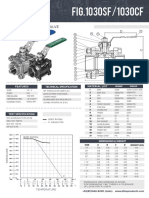

- FIG.1030SF/1030CF: 1000 Psi 3 PC FP Ball ValveDocument1 pageFIG.1030SF/1030CF: 1000 Psi 3 PC FP Ball ValveRodolfo MerazNo ratings yet

- Safety and Relief ProductsDocument4 pagesSafety and Relief ProductsSamuel OlmosNo ratings yet

- Axial AOF AOF: DimensionsDocument2 pagesAxial AOF AOF: DimensionsAblayeNo ratings yet

- ARCODE MRL Gearless Service & Shaft - enDocument51 pagesARCODE MRL Gearless Service & Shaft - enFidan LatifiNo ratings yet

- 76 71-002 AVK026 Eng v1-0Document2 pages76 71-002 AVK026 Eng v1-0bre brilianNo ratings yet

- 11.102aed8 0 - ENDocument2 pages11.102aed8 0 - ENpablo gerardo gil cocaNo ratings yet

- Bimetallic Float Type Steam Trap With Air Vent: General FeaturesDocument2 pagesBimetallic Float Type Steam Trap With Air Vent: General FeaturesprabowopuguhNo ratings yet

- Baydee 1Document2 pagesBaydee 1joseph chungNo ratings yet

- AVK Butterfly 76 SeriesDocument2 pagesAVK Butterfly 76 SeriesBernard Bonnin CervantesNo ratings yet

- Mini indexing plungers in stainless steelDocument2 pagesMini indexing plungers in stainless steelYossiNo ratings yet

- Din 6319Document4 pagesDin 6319PavanNo ratings yet

- Parweld-Plasma - Ultima Pagina Scheme de Conexiuni in Conectorul CPCDocument22 pagesParweld-Plasma - Ultima Pagina Scheme de Conexiuni in Conectorul CPCIonescuTeodoraNo ratings yet

- PCE Main Catalog 2022 23 enDocument376 pagesPCE Main Catalog 2022 23 ensanserg6No ratings yet

- Licad86061000006 L10Document1 pageLicad86061000006 L10Sakeel WagirkhanNo ratings yet

- Avk Flanged Gate Valve, PN 10/16 06/34: DIN F4, AISI 316 Stem, CTC 0035Document3 pagesAvk Flanged Gate Valve, PN 10/16 06/34: DIN F4, AISI 316 Stem, CTC 0035AgieYogaswaraNo ratings yet

- EXS050MRNT01 Collet SystemDocument1 pageEXS050MRNT01 Collet SystemManuel MartinezNo ratings yet

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Document1 pagePesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNo ratings yet

- Avk Gate Valve PN 10 or PN 16 06/30 - 26/00Document2 pagesAvk Gate Valve PN 10 or PN 16 06/30 - 26/00Popescu OctavianNo ratings yet

- Supra Check Valve PN16Document2 pagesSupra Check Valve PN16Emran HaniniNo ratings yet

- DIA5ED2130303EN (Web)Document42 pagesDIA5ED2130303EN (Web)milos ajdacicNo ratings yet

- Swing Check Valve Metal Seated Lever CounterweightDocument3 pagesSwing Check Valve Metal Seated Lever CounterweightEmran HaniniNo ratings yet

- ES - Model W-M110-10.Document2 pagesES - Model W-M110-10.SANRAJ TECHNONo ratings yet

- Wafer Style, Uni-Directional Knifegate ValvesDocument4 pagesWafer Style, Uni-Directional Knifegate ValvesDaniel BorgesNo ratings yet

- 031 PDFDocument1 page031 PDFMarcelo PereiraNo ratings yet

- Prattcheckvalvesupdate f13264 Final-Web-4Document12 pagesPrattcheckvalvesupdate f13264 Final-Web-4Scaramouche SualkNo ratings yet

- 5592F - Válvula de Bola (Roscada)Document1 page5592F - Válvula de Bola (Roscada)Rafael SalazarNo ratings yet

- 02-20 (Old Model)Document3 pages02-20 (Old Model)Anonymous fe5WYXvwNo ratings yet

- AssemblyDocument1 pageAssemblyAnonymous hlRLVcMNo ratings yet

- Plug Valve Drawing - 2Document3 pagesPlug Valve Drawing - 2Akhmad Daudi ShabahainiNo ratings yet

- SH01 spring return handleDocument2 pagesSH01 spring return handleAnil S ChaudharyNo ratings yet

- Hidrant Exterior 15 Ls PDFDocument3 pagesHidrant Exterior 15 Ls PDFNicolae CretuNo ratings yet

- GN 115-NL With KeyDocument3 pagesGN 115-NL With KeyTelxinaNo ratings yet

- D-Me-Ms-152r0 Side Wheel of Spillway Service GateDocument1 pageD-Me-Ms-152r0 Side Wheel of Spillway Service Gateolalekan fatai RotimiNo ratings yet

- Cast Iron Sectional Boiler For Heating and Production Domestic Hot WaterDocument20 pagesCast Iron Sectional Boiler For Heating and Production Domestic Hot Waterr_cristiNo ratings yet

- Ficha Tecnica Valvula Prueba y DrenajeDocument1 pageFicha Tecnica Valvula Prueba y DrenajeGabino CRNo ratings yet

- Avk Extension Spindle, Telescopic 04/04-001: For Gate Valves, Key Adaptor #23-32Document3 pagesAvk Extension Spindle, Telescopic 04/04-001: For Gate Valves, Key Adaptor #23-32Arshad IqbalNo ratings yet

- Canadian Solar Datasheet Hiku Cs3w P High EfficiencyDocument2 pagesCanadian Solar Datasheet Hiku Cs3w P High EfficiencybenicioNo ratings yet

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Document1 pagePesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNo ratings yet

- F1511 Data SheetDocument2 pagesF1511 Data SheetJV Balisi100% (1)

- Armstrong Vertical In-Line PumpsDocument6 pagesArmstrong Vertical In-Line Pumpsrijothomasv777No ratings yet

- CC Plug-ValveDocument2 pagesCC Plug-ValveNtolo Ongene DimitriNo ratings yet

- Remote Reading1Document2 pagesRemote Reading1joseph chungNo ratings yet

- Avk Double Orifice Air Valve Dn25 851/20: MaterialsDocument2 pagesAvk Double Orifice Air Valve Dn25 851/20: Materialsbre brilianNo ratings yet

- Product CatalogueDocument24 pagesProduct CatalogueYamuna InfraNo ratings yet

- Avk Resilient Seated Flanged Gate Valve, PN 10/16, Bs en 1074-2, CTC 55/66Document3 pagesAvk Resilient Seated Flanged Gate Valve, PN 10/16, Bs en 1074-2, CTC 55/66bre brilianNo ratings yet

- Pressure Sustaining Valve (PSV) /relief, With Solenoid VALVE PN10/PN16 859/006HDocument3 pagesPressure Sustaining Valve (PSV) /relief, With Solenoid VALVE PN10/PN16 859/006HAgieYogaswaraNo ratings yet

- CS3W-395 Panel SolarDocument2 pagesCS3W-395 Panel SolarGabriel GonzalezNo ratings yet

- Series WK 70/74: Low Ferrite Tube Bore Clean ValvesDocument8 pagesSeries WK 70/74: Low Ferrite Tube Bore Clean ValvesIsrael BolañosNo ratings yet

- PFI Housing Filter Cartridge High FlowDocument3 pagesPFI Housing Filter Cartridge High Flowbennypartono407No ratings yet

- Aps-243-G2be China PsuDocument3 pagesAps-243-G2be China PsuEgar EduardoNo ratings yet

- Fill Your Glass With Gold-When It's Half-Full or Even Completely ShatteredFrom EverandFill Your Glass With Gold-When It's Half-Full or Even Completely ShatteredNo ratings yet

- 24-90-001 - Avk130 - en 2206 - 478650Document2 pages24-90-001 - Avk130 - en 2206 - 478650bre brilianNo ratings yet

- Avk Resilient Seated Flanged Gate Valve, PN 10/16, Bs en 1074-2, CTC 55/66Document3 pagesAvk Resilient Seated Flanged Gate Valve, PN 10/16, Bs en 1074-2, CTC 55/66bre brilianNo ratings yet

- 76 71-002 AVK026 Eng v1-0Document2 pages76 71-002 AVK026 Eng v1-0bre brilianNo ratings yet

- FOX 3F Water Combination Air Valve 11.2021Document4 pagesFOX 3F Water Combination Air Valve 11.2021bre brilianNo ratings yet

- 701-10-001 2021-12-01 Avkcms en 430686Document2 pages701-10-001 2021-12-01 Avkcms en 430686bre brilianNo ratings yet

- 76-71-012 Avkcms enDocument2 pages76-71-012 Avkcms enbre brilianNo ratings yet

- Avk Resilient Seated Flanged Gate Valve, PN 10/16, Bs en 1074-2, CTC 55/66Document3 pagesAvk Resilient Seated Flanged Gate Valve, PN 10/16, Bs en 1074-2, CTC 55/66bre brilianNo ratings yet

- Avk Resilient Seated Flanged Gate Valve, PN 10/16, Bs en 1074-2, CTC 55/66Document2 pagesAvk Resilient Seated Flanged Gate Valve, PN 10/16, Bs en 1074-2, CTC 55/66bre brilianNo ratings yet

- FM 3059029 Gate Valves, S145Document1 pageFM 3059029 Gate Valves, S145bre brilianNo ratings yet

- UL EX4141 Vol.1, Sec.1, 2, 3, and 4, S25, S45, S145Document4 pagesUL EX4141 Vol.1, Sec.1, 2, 3, and 4, S25, S45, S145bre brilianNo ratings yet

- AVKDocument2 pagesAVKpiscesguy78No ratings yet

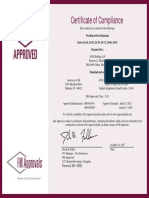

- Certificate of Compliance: Certificate Number Report Reference Issue DateDocument2 pagesCertificate of Compliance: Certificate Number Report Reference Issue DateAlejandro OdeclasNo ratings yet

- Description: STCV - Swing Check ValveDocument2 pagesDescription: STCV - Swing Check Valvebre brilianNo ratings yet

- FM 0003042441 Wet Barrel Fire Hydrants S24Document1 pageFM 0003042441 Wet Barrel Fire Hydrants S24bre brilianNo ratings yet

- Avk Double Orifice Air Valve Dn25 851/20: MaterialsDocument2 pagesAvk Double Orifice Air Valve Dn25 851/20: Materialsbre brilianNo ratings yet

- Avk Centric U-Section Butterfly Valve, Pn10 820/20-028: Loose EPDM Liner For Drinking Water, With Bare ShaftDocument2 pagesAvk Centric U-Section Butterfly Valve, Pn10 820/20-028: Loose EPDM Liner For Drinking Water, With Bare Shaftbre brilianNo ratings yet

- Avk Centric Wafer Butterfly Valve, Pn10/16 820/00-025: Loose EPDM Liner For Drinking Water, With Bare ShaftDocument3 pagesAvk Centric Wafer Butterfly Valve, Pn10/16 820/00-025: Loose EPDM Liner For Drinking Water, With Bare Shaftbre brilianNo ratings yet

- Ed Sarv2 1ph 220 240 50 60 s4 25 enDocument1 pageEd Sarv2 1ph 220 240 50 60 s4 25 enbre brilianNo ratings yet

- Solenoid Valve VSNC: Data SheetDocument2 pagesSolenoid Valve VSNC: Data Sheetbre brilianNo ratings yet

- Rubber Expansion Joint Double Sphere (Flanged End) PN16/25 911/02Document2 pagesRubber Expansion Joint Double Sphere (Flanged End) PN16/25 911/02bre brilianNo ratings yet

- Avk Centric U-Section Butterfly Valve, Pn10/16 820/20-025: Loose EPDM Liner For Drinking Water, With Bare ShaftDocument3 pagesAvk Centric U-Section Butterfly Valve, Pn10/16 820/20-025: Loose EPDM Liner For Drinking Water, With Bare Shaftbre brilianNo ratings yet

- AVK Hydrant Specification WorksheetDocument1 pageAVK Hydrant Specification Worksheetbre brilianNo ratings yet

- Avk Needle Valve, Pn10/16 872/00-004: Gearbox For Modulating Duty, Stainless Steel Trim, DN80-1600Document5 pagesAvk Needle Valve, Pn10/16 872/00-004: Gearbox For Modulating Duty, Stainless Steel Trim, DN80-1600bre brilianNo ratings yet

- Avk Centric Wafer Butterfly Valve, Pn6/10/16 820/00-019: Loose EPDM Liner For Drinking Water, With Electric ActuatorDocument2 pagesAvk Centric Wafer Butterfly Valve, Pn6/10/16 820/00-019: Loose EPDM Liner For Drinking Water, With Electric Actuatorbre brilianNo ratings yet

- Trolley Type: (CG10MPT (Manual Push) CG10CDT (Rope Driven) CG10MT (Motorized)Document3 pagesTrolley Type: (CG10MPT (Manual Push) CG10CDT (Rope Driven) CG10MT (Motorized)Francis BautistaNo ratings yet

- D1-NOSPI-22-085: Engr. Lord Patrick S. Rodriguez Meralco - BatangasDocument1 pageD1-NOSPI-22-085: Engr. Lord Patrick S. Rodriguez Meralco - BatangasSenrick MedranoNo ratings yet

- Guidance Impulse Algorithms For Air Bomb Control: R. GłębockiDocument9 pagesGuidance Impulse Algorithms For Air Bomb Control: R. GłębockiLeiser HartbeckNo ratings yet

- Pengiraan Masa PNP Fb-081-4 (Update)Document6 pagesPengiraan Masa PNP Fb-081-4 (Update)Gee Gbah GurlzNo ratings yet

- Database SystemDocument5 pagesDatabase SystemCaryoo GreenlifeNo ratings yet

- IesDocument7 pagesIesThaungMyintNo ratings yet

- MQP - 1 PDFDocument15 pagesMQP - 1 PDFDoita Dutta ChoudhuryNo ratings yet

- UGRD-MGT6140A Production Operations Management With TQM-Prelim EXAMDocument15 pagesUGRD-MGT6140A Production Operations Management With TQM-Prelim EXAMShaira Dela CruzNo ratings yet

- Herfindahl-Hirschman Index For Passenger Car Segment in IndiaDocument4 pagesHerfindahl-Hirschman Index For Passenger Car Segment in IndiaShreeni YeshodharanNo ratings yet

- Dhs S&T 2011 Long Range Baa 11-03Document37 pagesDhs S&T 2011 Long Range Baa 11-034pavlikNo ratings yet

- Standard Operating Procedure for Hot Works OperationsDocument3 pagesStandard Operating Procedure for Hot Works OperationsShital 2No ratings yet

- Brochure ERU K1 Engl 2 PDFDocument12 pagesBrochure ERU K1 Engl 2 PDFjsenadNo ratings yet

- Lean ThinkingDocument2 pagesLean ThinkingMMFAWZYNo ratings yet

- CNC TrainingDocument19 pagesCNC TrainingMahipal Singh RanawatNo ratings yet

- Quotation: NCC CN# 4400011405 - Al Fara 380kV OHTL AME/08/2021Document3 pagesQuotation: NCC CN# 4400011405 - Al Fara 380kV OHTL AME/08/2021Abdul WaheedNo ratings yet

- Bracing For Wall FormworkDocument4 pagesBracing For Wall FormworkKrm ChariNo ratings yet

- Alewine Wind Turbine Generator Failure ModesDocument5 pagesAlewine Wind Turbine Generator Failure ModesKevin AlewineNo ratings yet

- System Director Sg248141Document554 pagesSystem Director Sg248141ELITEKRISHNo ratings yet