Professional Documents

Culture Documents

Maximum Over Coating Intervals: Application Guide Jota Armour

Uploaded by

TamerTamerOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Maximum Over Coating Intervals: Application Guide Jota Armour

Uploaded by

TamerTamerCopyright:

Available Formats

Application Guide

Jota Armour

Maximum over coating intervals

Maximum time before thorough surface preparation is required. The surface must be clean and dry and suitable

for over coating. Inspect the surface for chalking and other contamination and if present, remove with an

alkaline detergent. Agitate the surface to activate the cleaner and before it dries, wash the treated area by low-

pressure water jetting to Wa 1 (ISO 8501-4) using fresh water.

If maximum over coating interval is exceeded the surface should in addition be carefully roughened to ensure

good inter coat adhesion.

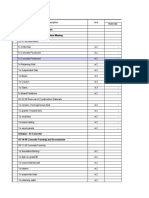

Areas for atmospheric exposure

Average temperature during 0 °C 5 °C 10 °C 23 °C 40 °C

drying/curing

Standard grade

Itself 14 d 7d 2d

epoxy 10 d 7d 5d

epoxy mastic 14 d 7d 2d

polyurethane 7d 5d 1d

Winter grade

Itself 1 mth 14 d 14 d 7d

epoxy 21 d 10 d 10 d 7d

epoxy mastic 1 mth 14 d 14 d 7d

polyurethane 14 d 7d 7d 5d

Other conditions that can affect drying / curing / over coating

Repair of coating system

Damages to the coating layers:

Prepare the area through sandpapering or grinding, followed by thorough cleaning/vacuuming. When the

surface is clean and dry the coating may be over coated by itself or by another product, ref. original

specification.

Always observe the maximum over coating intervals. If the maximum over coating interval is exceeded the

surface should be carefully roughened in order to ensure good intercoat adhesion.

Damages exposing bare substrate:

Remove all rust, loose paint, grease or other contaminants by spot blasting, mechanical grinding, water and/or

solvent washing. Feather edges and roughen the overlap zone of surrounding intact coating. Apply the coating

system specified for repair.

Coating film continuity

When required by the specification, the coating shall be tested for film discontinuity according to ASTM D 5162,

test method A or B as appropriate for the actual dry film thickness.

All recorded defects shall be repaired by best practical means.

Date of issue: 2 February 2017 Page: 8/10

This Application Guide supersedes those previously issued.

The Application Guide (AG) must be read in conjunction with the relevant specification, Technical Data Sheet (TDS) and Safety

Data Sheet (SDS) for all the products used as part of the coating system.

For your nearest local Jotun office, please visit our website at www.jotun.com.

You might also like

- Application Guide Jotamastic 90: Areas For Immersed ExposureDocument1 pageApplication Guide Jotamastic 90: Areas For Immersed ExposureTamerTamerNo ratings yet

- Jotun Epoxy Filler: Technical Data Sheet Application GuideDocument5 pagesJotun Epoxy Filler: Technical Data Sheet Application GuidekajaqcNo ratings yet

- Maximum Over Coating Intervals: Application Guide Tankguard 412Document1 pageMaximum Over Coating Intervals: Application Guide Tankguard 412TamerTamerNo ratings yet

- AG 45382 Pilot QD Topcoat Euk GBDocument6 pagesAG 45382 Pilot QD Topcoat Euk GBFatih GökbuaNo ratings yet

- Maximum Over Coating Intervals: Application Guide Hardtop OneDocument1 pageMaximum Over Coating Intervals: Application Guide Hardtop OneTamerTamerNo ratings yet

- Penguard Clear Sealer: Technical Data Sheet Application GuideDocument7 pagesPenguard Clear Sealer: Technical Data Sheet Application GuideAnonymous 4SFfEmcHmDNo ratings yet

- AG 43362 Alkyd High Gloss QD Euk GBDocument6 pagesAG 43362 Alkyd High Gloss QD Euk GBNurulfazilla YusopNo ratings yet

- Sikagard - 720 Epocem: 3-Part Cement and Epoxy Combination Micro Mortar For Surface SealingDocument5 pagesSikagard - 720 Epocem: 3-Part Cement and Epoxy Combination Micro Mortar For Surface Sealingthe pilotNo ratings yet

- TDS 25740 Jotafloor EP SL Euk GBDocument5 pagesTDS 25740 Jotafloor EP SL Euk GBDavid TumboimbelaNo ratings yet

- Pilot II: Technical Data Sheet Application GuideDocument6 pagesPilot II: Technical Data Sheet Application Guidendt stanleyNo ratings yet

- Chemflake Special: Technical Data SheetDocument5 pagesChemflake Special: Technical Data SheetSalmanNo ratings yet

- Tuf Bond EPDocument2 pagesTuf Bond EPPanruti S SathiyavendhanNo ratings yet

- Application Guide Pilot II: Other Conditions That Can Affect Drying / Curing / Over CoatingDocument1 pageApplication Guide Pilot II: Other Conditions That Can Affect Drying / Curing / Over CoatingTamerTamerNo ratings yet

- Chemflake SpecialDocument5 pagesChemflake SpecialBiju_PottayilNo ratings yet

- Nitocote PE135Document2 pagesNitocote PE135Dejan MicicNo ratings yet

- Jotun Pioner Topcoat Application Guide - AcrylicDocument6 pagesJotun Pioner Topcoat Application Guide - AcrylicChaerul AnwarNo ratings yet

- Jotafloor EP SL Uni - Abrasion & Impact ResistDocument6 pagesJotafloor EP SL Uni - Abrasion & Impact Resistangelito bernalNo ratings yet

- Polycoat RbeDocument2 pagesPolycoat RbejovindhaNo ratings yet

- Nitobond Ep..Document4 pagesNitobond Ep..budhikurniawanNo ratings yet

- Carboguard 703 GFDocument2 pagesCarboguard 703 GFlhanx2100% (2)

- Jotafloor TC EDocument6 pagesJotafloor TC ERidwanSalminNo ratings yet

- Safeguard Universal AGDocument7 pagesSafeguard Universal AGMar PardalesNo ratings yet

- Eco-friendly protective coatingDocument2 pagesEco-friendly protective coatingRaed Naim KhammashNo ratings yet

- Barrier ZEP: Technical Data Sheet Application GuideDocument7 pagesBarrier ZEP: Technical Data Sheet Application GuideNurmalinda SihombingNo ratings yet

- Devran 224HS PdsDocument2 pagesDevran 224HS Pdsjopedro96No ratings yet

- Hardtop f20Document7 pagesHardtop f20nuryati jahariNo ratings yet

- Pilgrim PlasticDocument2 pagesPilgrim Plastichendri sukrisnoNo ratings yet

- PolyguardDocument2 pagesPolyguardJack MayNo ratings yet

- TDS Alkyd High Gross Tahan KimiaDocument7 pagesTDS Alkyd High Gross Tahan Kimiaratnam.ysfNo ratings yet

- TDS Pidifin 2K Eng Rev.09 23 07 19Document3 pagesTDS Pidifin 2K Eng Rev.09 23 07 19Sumit SinhaNo ratings yet

- Jotacote 5Document4 pagesJotacote 5Ridwan BaharumNo ratings yet

- Penguard Topcoat application and repair guideDocument1 pagePenguard Topcoat application and repair guideTamerTamerNo ratings yet

- Crack Bridging Elastomeric PaintDocument3 pagesCrack Bridging Elastomeric PaintMearg NgusseNo ratings yet

- Protect Concrete and Steel with Chemical Resistant Polypoxy EN CoatingDocument2 pagesProtect Concrete and Steel with Chemical Resistant Polypoxy EN CoatingVaittianathan MahavapillaiNo ratings yet

- Application Guide Penguard MidcoatDocument6 pagesApplication Guide Penguard Midcoatadeoye_okunoyeNo ratings yet

- Jotashield Colourlast matt-TDSDocument4 pagesJotashield Colourlast matt-TDSvinnykg_789519104No ratings yet

- JOTUN Jotamastic 80Document5 pagesJOTUN Jotamastic 80Hafiz KamalNo ratings yet

- Resist 78: Technical Data Sheet Application GuideDocument7 pagesResist 78: Technical Data Sheet Application GuideEko Adi PutraNo ratings yet

- Penguard Tie Coat 100: Technical Data Sheet Application GuideDocument7 pagesPenguard Tie Coat 100: Technical Data Sheet Application GuideIrawan FajarNo ratings yet

- Tankguard 412: Technical Data SheetDocument6 pagesTankguard 412: Technical Data SheetMuneer ahmedNo ratings yet

- FLEXICOAT PU (I) LatestDocument3 pagesFLEXICOAT PU (I) Latestmathewsujith31No ratings yet

- Chemflake SpecialDocument5 pagesChemflake Specialmajmor-1No ratings yet

- Jota Floor Top Coat TDSDocument5 pagesJota Floor Top Coat TDSthar gyiNo ratings yet

- Hardtop XPL AGDocument6 pagesHardtop XPL AGHung NGUYEN SYNo ratings yet

- AG 11260 Hardtop XPL Euk GBDocument6 pagesAG 11260 Hardtop XPL Euk GBTamer GamalNo ratings yet

- Jotafloor Coating: Technical Data SheetDocument4 pagesJotafloor Coating: Technical Data SheetArif JoelNo ratings yet

- Jazeera Damp MasticDocument3 pagesJazeera Damp MasticAhmad BougeisNo ratings yet

- Pilot II: Technical Data Sheet Application GuideDocument7 pagesPilot II: Technical Data Sheet Application GuideibrahimNo ratings yet

- Fosroc Dekguard PU: Constructive SolutionsDocument4 pagesFosroc Dekguard PU: Constructive SolutionsganmosesNo ratings yet

- Resist 78: Technical Data Sheet Application GuideDocument7 pagesResist 78: Technical Data Sheet Application GuideMohd YusriNo ratings yet

- Datasheet Jotun-Tankguard StorageDocument5 pagesDatasheet Jotun-Tankguard Storagebudi handoyoNo ratings yet

- 66210-76110-76115 Weathercoat GP. Water ProofingDocument2 pages66210-76110-76115 Weathercoat GP. Water ProofingUpulHettiarachchiNo ratings yet

- Davco Floor Screed ECO_catalogueDocument2 pagesDavco Floor Screed ECO_cataloguepiakhong.cheongNo ratings yet

- Application Guide Jotamastic 90: Stainless SteelDocument1 pageApplication Guide Jotamastic 90: Stainless SteelTamerTamerNo ratings yet

- Jotun - Technical Data Sheet - Tankguard Storage - 09.2019Document5 pagesJotun - Technical Data Sheet - Tankguard Storage - 09.2019Victor PomboNo ratings yet

- Penguard MidcoatDocument4 pagesPenguard MidcoatfirmanNo ratings yet

- AG 24400 Jota Etch Euk GBDocument5 pagesAG 24400 Jota Etch Euk GBchusnadiantyNo ratings yet

- Pds Hempadur Pro Zinc 17380 En-GbDocument2 pagesPds Hempadur Pro Zinc 17380 En-GbThines Kumar0% (1)

- Hardtop CA Technical Data SheetDocument6 pagesHardtop CA Technical Data SheetSam JoseNo ratings yet

- Drying and Curing Time: Technical Data Sheet Hardtop AlfaDocument1 pageDrying and Curing Time: Technical Data Sheet Hardtop AlfaTamerTamerNo ratings yet

- Condition During Application: Other SurfacesDocument1 pageCondition During Application: Other SurfacesTamerTamerNo ratings yet

- Technical Data Sheet Hardtop AlfaDocument1 pageTechnical Data Sheet Hardtop AlfaTamerTamerNo ratings yet

- Film Thickness Per Coat: Technical Data Sheet Jotafloor TopcoatDocument1 pageFilm Thickness Per Coat: Technical Data Sheet Jotafloor TopcoatTamerTamerNo ratings yet

- Packaging (Typical) : Technical Data Sheet Hardtop AlfaDocument1 pagePackaging (Typical) : Technical Data Sheet Hardtop AlfaTamerTamerNo ratings yet

- No Way Part1Document1 pageNo Way Part1TamerTamerNo ratings yet

- Technical Data Sheet Jotafloor Topcoat: Version Will PrevailDocument1 pageTechnical Data Sheet Jotafloor Topcoat: Version Will PrevailTamerTamerNo ratings yet

- Surface Preparation: Technical Data Sheet Hardtop AlfaDocument1 pageSurface Preparation: Technical Data Sheet Hardtop AlfaTamerTamerNo ratings yet

- Quality Assurance: Application Guide Jotafloor TopcoatDocument1 pageQuality Assurance: Application Guide Jotafloor TopcoatTamerTamerNo ratings yet

- Hardtop Alfa: Technical Data SheetDocument1 pageHardtop Alfa: Technical Data SheetTamerTamerNo ratings yet

- Drying and Curing Time: Technical Data Sheet Jotafloor TopcoatDocument1 pageDrying and Curing Time: Technical Data Sheet Jotafloor TopcoatTamerTamerNo ratings yet

- Jotafloor Topcoat: Technical Data Sheet Application GuideDocument1 pageJotafloor Topcoat: Technical Data Sheet Application GuideTamerTamerNo ratings yet

- Drying and Curing Time: Application Guide Jotafloor TopcoatDocument1 pageDrying and Curing Time: Application Guide Jotafloor TopcoatTamerTamerNo ratings yet

- Storage: Technical Data Sheet Jotafloor TopcoatDocument1 pageStorage: Technical Data Sheet Jotafloor TopcoatTamerTamerNo ratings yet

- Jotafloor Topcoat Application GuideDocument1 pageJotafloor Topcoat Application GuideTamerTamerNo ratings yet

- Jotafloor Topcoat: Technical Data Sheet Application GuideDocument1 pageJotafloor Topcoat: Technical Data Sheet Application GuideTamerTamerNo ratings yet

- Film Thickness Per Coat: Application Guide Jotafloor TopcoatDocument1 pageFilm Thickness Per Coat: Application Guide Jotafloor TopcoatTamerTamerNo ratings yet

- Jotafloor Topcoat Application GuideDocument1 pageJotafloor Topcoat Application GuideTamerTamerNo ratings yet

- Drying and Curing Time: Application Guide Jotafloor TopcoatDocument1 pageDrying and Curing Time: Application Guide Jotafloor TopcoatTamerTamerNo ratings yet

- Quality Assurance: Application Guide Jotafloor TopcoatDocument1 pageQuality Assurance: Application Guide Jotafloor TopcoatTamerTamerNo ratings yet

- Symbols and Abbreviations: Application Guide Jotafloor PU TopcoatDocument1 pageSymbols and Abbreviations: Application Guide Jotafloor PU TopcoatTamerTamerNo ratings yet

- Jotafloor Coating - Part4Document1 pageJotafloor Coating - Part4TamerTamerNo ratings yet

- Film Thickness Per Coat: Application Guide Jotafloor TopcoatDocument1 pageFilm Thickness Per Coat: Application Guide Jotafloor TopcoatTamerTamerNo ratings yet

- Disclaimer: Application Guide Jotafloor TopcoatDocument1 pageDisclaimer: Application Guide Jotafloor TopcoatTamerTamerNo ratings yet

- Jotafloor Coating - Part1Document1 pageJotafloor Coating - Part1TamerTamerNo ratings yet

- Jotafloor Coating - Part3Document1 pageJotafloor Coating - Part3TamerTamerNo ratings yet

- Drying and Curing Time: Application Guide Jotafloor PU TopcoatDocument1 pageDrying and Curing Time: Application Guide Jotafloor PU TopcoatTamerTamerNo ratings yet

- Surface Preparation: Application Guide Jotafloor PU TopcoatDocument1 pageSurface Preparation: Application Guide Jotafloor PU TopcoatTamerTamerNo ratings yet

- Condition During Application: Other SurfacesDocument1 pageCondition During Application: Other SurfacesTamerTamerNo ratings yet

- Jotafloor PU Topcoat Application GuideDocument1 pageJotafloor PU Topcoat Application GuideTamerTamerNo ratings yet

- Tugas Bahasa Inggris Analytical Exposition Text: Disusun Oleh: Nama:Hansel Hendrawan Effendy Kelas:XI IPA 1Document4 pagesTugas Bahasa Inggris Analytical Exposition Text: Disusun Oleh: Nama:Hansel Hendrawan Effendy Kelas:XI IPA 1Hansel HendrawanNo ratings yet

- Grab E-Receipt for 15,000 RP Ride on March 30Document1 pageGrab E-Receipt for 15,000 RP Ride on March 30WellyNo ratings yet

- Andromeda Council About The 4th DimensionDocument11 pagesAndromeda Council About The 4th DimensionWonderlust100% (1)

- Tiresocks CatalogDocument19 pagesTiresocks CatalogAshBossNo ratings yet

- MNCs-consider-career-development-policyDocument2 pagesMNCs-consider-career-development-policySubhro MukherjeeNo ratings yet

- Unit 2 - Chapter 04 - Working With FormsDocument24 pagesUnit 2 - Chapter 04 - Working With FormsSnr Berel ShepherdNo ratings yet

- Nigeria Emergency Plan NemanigeriaDocument47 pagesNigeria Emergency Plan NemanigeriaJasmine Daisy100% (1)

- Computer ViruesDocument19 pagesComputer ViruesMuhammad Adeel AnsariNo ratings yet

- Chapter 25 (10) Capital Investment Analysis: ObjectivesDocument40 pagesChapter 25 (10) Capital Investment Analysis: ObjectivesJames BarzoNo ratings yet

- Community HelpersDocument3 pagesCommunity Helpersapi-252790280100% (1)

- All Creatures Great and SmallDocument4 pagesAll Creatures Great and SmallsaanviranjanNo ratings yet

- B.Ed Syllabus NEW 2015-16 PDFDocument170 pagesB.Ed Syllabus NEW 2015-16 PDFVikas KuthadiNo ratings yet

- Definition and Scope of Public FinanceDocument2 pagesDefinition and Scope of Public FinanceArfiya MubeenNo ratings yet

- SolidWorks2018 PDFDocument1 pageSolidWorks2018 PDFAwan D'almightyNo ratings yet

- 01 A Brief Introduction To Cloud ComputingDocument25 pages01 A Brief Introduction To Cloud ComputingfirasibraheemNo ratings yet

- Technology Class ResumeDocument4 pagesTechnology Class Resumeapi-259588430No ratings yet

- Shooting ScriptDocument12 pagesShooting Scriptapi-544851273No ratings yet

- FIL M 216 2nd Yer Panitikan NG PilipinasDocument10 pagesFIL M 216 2nd Yer Panitikan NG PilipinasJunas LopezNo ratings yet

- F FS1 Activity 3 EditedDocument15 pagesF FS1 Activity 3 EditedRayshane Estrada100% (1)

- Huang V Tesla State of Calif 20190430Document20 pagesHuang V Tesla State of Calif 20190430jonathan_skillings100% (1)

- 02 1 Cohen Sutherland PDFDocument3 pages02 1 Cohen Sutherland PDFSarra AnitaNo ratings yet

- The Mysteries of Plato: Lunar NotebookDocument2 pagesThe Mysteries of Plato: Lunar NotebookDavor BatesNo ratings yet

- Quantification Skills in The Construction IndustryDocument34 pagesQuantification Skills in The Construction IndustryBRGRNo ratings yet

- 24.ratios, Rates and Proportions PDFDocument9 pages24.ratios, Rates and Proportions PDFMilsonNo ratings yet

- Chemical ReactionDocument13 pagesChemical ReactionSujit LawareNo ratings yet

- Unit Rates and Cost Per ItemDocument213 pagesUnit Rates and Cost Per ItemDesiree Vera GrauelNo ratings yet

- Lost Jar Action: WCP Slickline Europe Learning Centre SchlumbergerDocument19 pagesLost Jar Action: WCP Slickline Europe Learning Centre SchlumbergerMohsin PvNo ratings yet

- Forecast Time Series-NotesDocument138 pagesForecast Time Series-NotesflorinNo ratings yet

- Unit 2 Water Treatment Ce3303Document18 pagesUnit 2 Water Treatment Ce3303shivaNo ratings yet

- If Sentences Type 1 First Type Conditionals Grammar Drills - 119169Document2 pagesIf Sentences Type 1 First Type Conditionals Grammar Drills - 119169Ivanciu DanNo ratings yet