Professional Documents

Culture Documents

1 PDF

1 PDF

Uploaded by

Rohit Shrestha0 ratings0% found this document useful (0 votes)

14 views2 pagesOriginal Title

1 (55).pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views2 pages1 PDF

1 PDF

Uploaded by

Rohit ShresthaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Air Conditioning Systems 57

refrigerant will enter the expansion stage’s pressure reducing

device (metering device) at approximately 90°F. The liquid was

subcooled 30°F. Only liquids can be subcooled and only vapors

can be superheated or desuperheated. When the liquid refrigerant

goes through the metering device the pressure on the refrigerant

is reduced to 70 psig. This reduction in pressure (from 260 psig to

70 psig) reduces the boiling point of the liquid refrigerant to 40°F.

However, the temperature of the liquid refrigerant at 90°F is

above the new boiling point (40°F). Because the liquid refrigerant

is hotter than its boiling point a part of the liquid refrigerant

begins to boil off. This boiling off of the liquid refrigerant is called

flashing. The liquid refrigerant which is boiled off or flashed,

changes state to a vapor or gas. This vapor is called “flash gas.”

When a part of the liquid refrigerant is flashed, it removes heat

from the remaining liquid. This flashing continues until the re-

maining liquid refrigerant is cooled down to the boiling point

which corresponds to the pressure on the liquid (40°F @ 70 psig).

About 18% of the liquid is flashed off to a vapor and is not avail-

able to pick up heat (i.e., latent heat of vaporization) but can pick

up sensible heat in the evaporator stage. The vapor and the re-

maining liquid (82%) enters the evaporation stage and the cycle

starts over. The AHU has taken 1200 cfm of mixed air at 78°F and

cooled it down to 55°F supply air.

AIRFLOW

The supply air moves through the ductwork because of a

difference in pressures. Just as heat moves from a higher level to

a lower level, so do fluids. Fluids move from a higher pressure to

a lower pressure. Air is a vapor and as such is a compressible

fluid.

Remember, we said that the refrigerant vapor moved

through the system because the pressure on one side of the com-

pressor was higher than on the other side. The same is true for the

air. The fan produces a pressure at the discharge of the fan that is

58 HVAC Fundamentals

higher than the pressure in the conditioned space. For example,

the pressure in the conditioned space is atmospheric pressure

while the pressure at the fan discharge is greater than atmo-

spheric pressure.

To continue, the air moves through the ductwork until it

reaches the supply air outlets in the conditioned space. As the

55°F supply air is discharged it mixes with the warmer room air.

Also as the supply air comes in contact with the greater mass of

room air the velocity of the air slows down. After circulating

through the room the air exits the room by way of the return air

inlet. This amount of air, the 1200 cfm of supply air continuously

flowing through the room, will result in about 7.5 complete air

changes per hour. Once again, the air flows through the ductwork

because of a difference in pressures. In this case, the room air is

at atmospheric pressure, or slightly above, because of room pres-

surization and the inlet to the fan is less than atmospheric pres-

sure so the air flows towards the fan. The return air carrying the

heat removed from the conditioned space mixes with the outside

air, which also contains some heat. This mixture goes through the

filter section and into the cooling coil and our cooling cycle starts

over again.

FOUR TYPES OF

AIR CONDITIONING COOLING SYSTEMS

Water to Water

Air to Air

Air to Water

Water to Air

AC COOLING SYSTEM #1

Heat Rejection Side Heat Pickup Side

Water to Water

You might also like

- Air Conditioning Systems 55Document2 pagesAir Conditioning Systems 55rohitNo ratings yet

- Aircon NotesDocument5 pagesAircon Notesprado01No ratings yet

- Evaporator: Fan SpeedsDocument2 pagesEvaporator: Fan SpeedsPradeep SukumaranNo ratings yet

- Thumb RuleDocument4 pagesThumb RulenishadNo ratings yet

- The Importance of A Clean CondenserDocument5 pagesThe Importance of A Clean CondenserD HarNo ratings yet

- Condenser: Lesson 3 Lesson Title: Learning Outcomes: at The End of The Lesson, Students of BTLE Will Be Able ToDocument37 pagesCondenser: Lesson 3 Lesson Title: Learning Outcomes: at The End of The Lesson, Students of BTLE Will Be Able ToAliceNo ratings yet

- Refrigeration Cycle DiagramDocument7 pagesRefrigeration Cycle DiagramsrybsantosNo ratings yet

- What Is The Basic Principle of Refrigeration and What Do You Understand by Refrigeration Cycle?Document3 pagesWhat Is The Basic Principle of Refrigeration and What Do You Understand by Refrigeration Cycle?a4104165No ratings yet

- Facility Maintenance 1Document163 pagesFacility Maintenance 1Ashok AmnarNo ratings yet

- Water Chillers 85Document2 pagesWater Chillers 85Rohit ShresthaNo ratings yet

- Vapor Compression CycleDocument10 pagesVapor Compression Cyclevinit joryNo ratings yet

- Refrigeration CycleDocument5 pagesRefrigeration CycleMa Zaira ObilloNo ratings yet

- Knowledge Troubleshooting AC SystemDocument13 pagesKnowledge Troubleshooting AC SystemRupak KumarNo ratings yet

- Refrigeration and Air Conditioning (7.2.22)Document148 pagesRefrigeration and Air Conditioning (7.2.22)Edwin Abregú Leandro100% (1)

- Refrigeration Unit Lab ReportDocument28 pagesRefrigeration Unit Lab ReportShinigdho Synthia79% (14)

- Air Conditioning Theory PDFDocument13 pagesAir Conditioning Theory PDFJan AmoresNo ratings yet

- Basic Refrigeration CycleDocument14 pagesBasic Refrigeration Cyclehussein alnasryNo ratings yet

- How It WorksDocument6 pagesHow It WorksFaizal IsmailNo ratings yet

- Group 5 Melab3Document14 pagesGroup 5 Melab3Gigi SalesNo ratings yet

- 5 200 PDFDocument12 pages5 200 PDFDee RajaNo ratings yet

- RefrigerationDocument65 pagesRefrigerationyassinNo ratings yet

- Heat Pump TrainerDocument6 pagesHeat Pump TrainerAfzaal FiazNo ratings yet

- Reerigeation System Basics, Week 2 Part 1Document17 pagesReerigeation System Basics, Week 2 Part 1Musfirah AdeelNo ratings yet

- Refrigeration Unit Lab Report FKKDocument28 pagesRefrigeration Unit Lab Report FKKKicauan KataNo ratings yet

- Vapor Compression Refrigeration CycleDocument21 pagesVapor Compression Refrigeration CycleUSHA PAWARNo ratings yet

- Refrigeration Systems: Home License Page Engineer Exam Questions Deck Exam QuestionsDocument20 pagesRefrigeration Systems: Home License Page Engineer Exam Questions Deck Exam QuestionsDennis ErminoNo ratings yet

- Parts of A Refrigeration SystemDocument8 pagesParts of A Refrigeration SystemRay RavelNo ratings yet

- The Pressure - Enthalpy ChartDocument12 pagesThe Pressure - Enthalpy ChartJohnMerrNo ratings yet

- Philippine Society of Mechanical EngineersDocument45 pagesPhilippine Society of Mechanical EngineersbabadapbadapNo ratings yet

- Refrigeration Cycle, HVAC System Basics and Refrigerant Charging PDFDocument13 pagesRefrigeration Cycle, HVAC System Basics and Refrigerant Charging PDFMurillo MendesNo ratings yet

- Part 3 Phase Change of The Refrigerant in The CycleDocument7 pagesPart 3 Phase Change of The Refrigerant in The CycleKenneth JameroNo ratings yet

- Expansion Valves - Working PrincipleDocument3 pagesExpansion Valves - Working PrinciplePradeep Sukumaran100% (1)

- Rules of Thumb For TroubleshootingDocument2 pagesRules of Thumb For TroubleshootingkktayNo ratings yet

- Air Conditioning Theory (Automotive)Document21 pagesAir Conditioning Theory (Automotive)ingenierosunidosNo ratings yet

- Part 3 Phase Change of The Refrigerant in The CycleDocument7 pagesPart 3 Phase Change of The Refrigerant in The CycleKenneth JameroNo ratings yet

- Super Heat and Sub CoolingDocument2 pagesSuper Heat and Sub CoolingMuhammad BilalNo ratings yet

- Physics 2Document5 pagesPhysics 2SOLAIMANNo ratings yet

- CondenserDocument42 pagesCondenserpavan1211No ratings yet

- Air Conditioner Pump System PressuresDocument11 pagesAir Conditioner Pump System PressuresingenierosunidosNo ratings yet

- Refrig Terms GoodDocument6 pagesRefrig Terms GoodAbhilashNo ratings yet

- Performance and Efficiency Test of Refrigeration PlantDocument26 pagesPerformance and Efficiency Test of Refrigeration PlantGigi Sales100% (2)

- Hvac Lab Report: Name: Ali Raza Roll No: 18-MCE-18 Submitted To: Sir Murawat Abbas Semester 6Document11 pagesHvac Lab Report: Name: Ali Raza Roll No: 18-MCE-18 Submitted To: Sir Murawat Abbas Semester 6AliNo ratings yet

- Mechanical-Compression Refrigeration SystemsDocument4 pagesMechanical-Compression Refrigeration Systemsaruna MoonNo ratings yet

- Unit VDocument12 pagesUnit VYuvaperiyasamy MayilsamyNo ratings yet

- RAC FundamentalsDocument8 pagesRAC FundamentalsGalvez ChaChaNo ratings yet

- FridgeDocument6 pagesFridgeshashlearnNo ratings yet

- 18-Tugas 1-Prak. Perawatan Mesin Konversi Energi 1Document5 pages18-Tugas 1-Prak. Perawatan Mesin Konversi Energi 1Oh WiwinNo ratings yet

- Refrigerant DistributionDocument4 pagesRefrigerant DistributionjorgedvfNo ratings yet

- Section 1: Theory of Heat Unit 3: Refrigeration and RefrigerantsDocument43 pagesSection 1: Theory of Heat Unit 3: Refrigeration and Refrigerantslemuel ramirezNo ratings yet

- Refrigeration Technology: Types of Refrigeration Systems AND Principles of OperationDocument3 pagesRefrigeration Technology: Types of Refrigeration Systems AND Principles of OperationJoseph Francis GalleraNo ratings yet

- Air Conditioning Circuit and CycleDocument5 pagesAir Conditioning Circuit and CyclePintoo MainNo ratings yet

- Vapor Compression Refrigeration SystemDocument6 pagesVapor Compression Refrigeration SystemGerson Paul BangoyNo ratings yet

- Comfort Air ConditioningDocument85 pagesComfort Air Conditioningshrikant100% (6)

- 4 Performance and Efficiency Test of A Refrigeration PlantDocument52 pages4 Performance and Efficiency Test of A Refrigeration PlantIvy Joy UbinaNo ratings yet

- Refrigeration CircuitDocument32 pagesRefrigeration CircuitHassan Iftekhar Ahmed100% (1)

- Basic On CycleDocument12 pagesBasic On CycleSantosh JaiswalNo ratings yet

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- Oral and Practical Review: Reflections on the Part 147 CourseFrom EverandOral and Practical Review: Reflections on the Part 147 CourseNo ratings yet

- 1 PDFDocument2 pages1 PDFrohitNo ratings yet

- Heating and Ventilating Systems 25Document2 pagesHeating and Ventilating Systems 25rohitNo ratings yet

- Figure 3-3. Btu Change in One Pound of Ice To Water To Steam To Superheated SteamDocument2 pagesFigure 3-3. Btu Change in One Pound of Ice To Water To Steam To Superheated SteamrohitNo ratings yet

- Heating and Ventilating Systems 33Document2 pagesHeating and Ventilating Systems 33rohitNo ratings yet

- Heating and Ventilating Systems 35Document2 pagesHeating and Ventilating Systems 35rohitNo ratings yet

- Btuh GPM ×: Heat Flow 23Document2 pagesBtuh GPM ×: Heat Flow 23rohitNo ratings yet

- Heating and Ventilating Systems 29: Figure 3-2. Steam BoilerDocument2 pagesHeating and Ventilating Systems 29: Figure 3-2. Steam BoilerrohitNo ratings yet

- Heating and Ventilating Systems 37: Figure 3-6. Combustion Chamber and Fire Tubes. Two-Pass BoilerDocument2 pagesHeating and Ventilating Systems 37: Figure 3-6. Combustion Chamber and Fire Tubes. Two-Pass BoilerrohitNo ratings yet

- Heating and Ventilating Systems 27Document2 pagesHeating and Ventilating Systems 27rohitNo ratings yet

- Air Conditioning Systems 63: Evaporators (Heat Picked Up From The Conditioned Space)Document2 pagesAir Conditioning Systems 63: Evaporators (Heat Picked Up From The Conditioned Space)rohitNo ratings yet

- Air Conditioning Systems 59: Figure 4-3. Water-to-Water AC SystemDocument2 pagesAir Conditioning Systems 59: Figure 4-3. Water-to-Water AC SystemrohitNo ratings yet

- Figure 4-.2 Air Conditioning System ExampleDocument2 pagesFigure 4-.2 Air Conditioning System ExamplerohitNo ratings yet

- Figure 4-4. Air-to-Water AC SystemDocument2 pagesFigure 4-4. Air-to-Water AC SystemrohitNo ratings yet

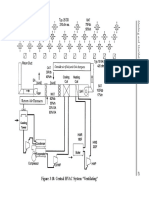

- Figure 4-1. Central HVAC System "Air Conditioning"Document2 pagesFigure 4-1. Central HVAC System "Air Conditioning"rohitNo ratings yet

- Air Conditioning Systems 47Document2 pagesAir Conditioning Systems 47rohitNo ratings yet

- Air Conditioning Systems 51Document2 pagesAir Conditioning Systems 51rohitNo ratings yet

- Figure 3-10. Central HVAC System "Ventilating"Document2 pagesFigure 3-10. Central HVAC System "Ventilating"rohitNo ratings yet

- Latent HeatDocument2 pagesLatent HeatrohitNo ratings yet

- Heating and Ventilating Systems 43: MAT (%OA ×Document2 pagesHeating and Ventilating Systems 43: MAT (%OA ×rohitNo ratings yet

- Heating and Ventilating Systems 41: Figure 3-8. Oil BurnerDocument2 pagesHeating and Ventilating Systems 41: Figure 3-8. Oil BurnerrohitNo ratings yet

- This Page Intentionally Left BlankDocument2 pagesThis Page Intentionally Left BlankrohitNo ratings yet

- HVAC Systems 1Document2 pagesHVAC Systems 1rohitNo ratings yet

- Heat Flow 19Document2 pagesHeat Flow 19rohitNo ratings yet

- Heat Flow 17: ConductionDocument2 pagesHeat Flow 17: ConductionrohitNo ratings yet

- This Page Intentionally Left BlankDocument2 pagesThis Page Intentionally Left BlankrohitNo ratings yet

- Heat Flow 15Document2 pagesHeat Flow 15rohitNo ratings yet

- HVAC Systems 13: VentilatingDocument2 pagesHVAC Systems 13: VentilatingrohitNo ratings yet

- Air Volume: HVAC Systems 11Document2 pagesAir Volume: HVAC Systems 11rohitNo ratings yet

- HVAC Systems 9Document2 pagesHVAC Systems 9rohitNo ratings yet

- CHAPTER 3 FINAL PAPER AirconDocument8 pagesCHAPTER 3 FINAL PAPER Airconjohanna faith israelNo ratings yet

- r717 PT Chart PDFDocument2 pagesr717 PT Chart PDFTechnos GuruNo ratings yet

- Weather Monitor Records: HSE Department LOG SheetDocument3 pagesWeather Monitor Records: HSE Department LOG SheetFarooq MohammadNo ratings yet

- WL 320 Wet Cooling Tower: Direct-Contact Heat ExchangersDocument1 pageWL 320 Wet Cooling Tower: Direct-Contact Heat ExchangersatheerNo ratings yet

- HVAC Testing-Adjusting-Balancing For Small SystemsDocument17 pagesHVAC Testing-Adjusting-Balancing For Small SystemsgabrielNo ratings yet

- CV Engr. Md. HasmotuzzamanDocument7 pagesCV Engr. Md. HasmotuzzamanEngr SwapanNo ratings yet

- Candy Cdi1012/1 Service ManualDocument28 pagesCandy Cdi1012/1 Service ManualPavel KellerNo ratings yet

- Vam Principle of OperationDocument7 pagesVam Principle of OperationAnubhav Kumar JainNo ratings yet

- Introduction To HVACSystems (General)Document94 pagesIntroduction To HVACSystems (General)Francis Boey100% (1)

- Hvac Design Manual: First EditionDocument124 pagesHvac Design Manual: First EditionNathan Tom100% (7)

- Week 3 Lecture: Thermal Loads in BuildingsDocument24 pagesWeek 3 Lecture: Thermal Loads in Buildingsgagandhawan31No ratings yet

- 6 MeteorologyDocument168 pages6 MeteorologyShann Xad100% (1)

- VENTUS - Catalogue - 2013 PDFDocument98 pagesVENTUS - Catalogue - 2013 PDFatisz333No ratings yet

- Assignment # 2: Thermo LabDocument4 pagesAssignment # 2: Thermo LabmjunaidNo ratings yet

- Air Conditioning System On ShipsDocument18 pagesAir Conditioning System On ShipsAzym Azizi100% (3)

- Energy Curve POGILDocument5 pagesEnergy Curve POGILCody Palmer100% (1)

- Fuji-Electric Fujitsu Rsa07lgc Rsa09lgc Rsa12lgcDocument22 pagesFuji-Electric Fujitsu Rsa07lgc Rsa09lgc Rsa12lgcjuliNo ratings yet

- Mdrsjrns v20n4p901 FaDocument13 pagesMdrsjrns v20n4p901 FaBehi GhNo ratings yet

- Despiece DXW51Document8 pagesDespiece DXW51Carmen Adriana Garcia MendozaNo ratings yet

- Refrigeration Lab (HVAC Load Calculations)Document9 pagesRefrigeration Lab (HVAC Load Calculations)Jahan Raaz KhanNo ratings yet

- Physics Lab Heat and HumidityDocument3 pagesPhysics Lab Heat and HumidityLAUREN YAPNo ratings yet

- Introduction To World EnergyDocument47 pagesIntroduction To World Energyjylee@No ratings yet

- YANGFAN Primary Air HandlerDocument9 pagesYANGFAN Primary Air Handlerferdie107No ratings yet

- Mitsubishi Electric CPD Guide To VentilationDocument12 pagesMitsubishi Electric CPD Guide To VentilationMoriyasuNguyenNo ratings yet

- TDP InfoDocument7 pagesTDP InfoEN LeedNo ratings yet

- Density, Thermal Expansivity, and Compressibility of Liquid Water From 0° To 150°CDocument9 pagesDensity, Thermal Expansivity, and Compressibility of Liquid Water From 0° To 150°CJuan Daniel Vallejo BernalNo ratings yet

- Cooling Tower UtilitasDocument32 pagesCooling Tower UtilitasVlany DorisNo ratings yet

- VDI2089 MedenceDocument3 pagesVDI2089 MedenceIstvan MadacsyNo ratings yet

- Refrigeration and Air ConditioningDocument7 pagesRefrigeration and Air ConditioningManjunatha EikilaNo ratings yet

- Karakteristika Razmenjivača Toplote I Njen Uticaj Na Izbor Regulacionih Ventila Characteristic of Heat Exchanger and Its Influence On Selection of Control ValveDocument10 pagesKarakteristika Razmenjivača Toplote I Njen Uticaj Na Izbor Regulacionih Ventila Characteristic of Heat Exchanger and Its Influence On Selection of Control Valvemjaric81No ratings yet