Professional Documents

Culture Documents

Review Questions 5

Uploaded by

Mary Jane PabroaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Review Questions 5

Uploaded by

Mary Jane PabroaCopyright:

Available Formats

Requirement II. Answer Briefly.

1. Describe the steps of the product design and development process.

The steps in product design and development process involves idea

generation, preliminary concept, product/process development, full-scale production,

market introduction and market evaluation. Idea generation is the development of

concept that incorporates customer needs and expectations. Preliminary concept

means to study new ideas for feasibility. In this phase, questions related to the

satisfaction of customer requirements as well as the product’s economic value and

quality are addressed. In product/process development, design alternatives are

evaluated engineering specifications such as test prototypes, development, test, and

standardized processes are determined. Full-scale production is the release of

product to manufacturing or service delivery teams once the design is approved and

the production processes has been set up. Market introduction means to distribute

the product to the customers and market evaluation means evaluating the market

and gather customer feedback to initiate continuous improvements.

2. What is Design for Six Sigma? Explain the four basic elements of DFSS and the

various tools and methodologies that comprise this body of knowledge.

Design for Six Sigma is a powerful approach for designing new products or

process development that uses a set of tools and methodologies in the product

development process to make sure that goods and services will meet customer

needs and achieve performance objectives, and that the processes used to make and

deliver them achieve high level of quality.

Concept development, design development, design optimization and design

verification comprise the DFSS. In concept development, product functionality is

determined based upon customer requirements, technological capabilities, and

economic realities. Design development focuses on product and process performance

issues necessary to fulfill the product and service requirements in manufacturing or

delivery. Design optimization seeks to minimize the impact of variation in production

and use, creating a “robust” design and design verification ensures that the

capability of the production system meets the appropriate sigma level.

3. Explain the concept development and innovation. Describe the importance of

innovation and creativity in concept development.

Concept development is the process of applying scientific, engineering, and

business knowledge to produce a basic functional design that meets both customer

needs and manufacturing or service delivery requirements. Innovation involves the

adoption of an idea, process, technology, product, or business model that is either

new or new to its proposed application. Its outcome is a breakthrough change and

results in new and unique goods and services that delight customers which create

competitive advantage.

The main goal of concept development is to meet both customer and

manufacturing or service delivery requirements and innovation so with creativity play

an integral part in achieving this. Innovation and creativity unlock the uniqueness of

the product or service concept to reach its full potential to not just limit on the mere

satisfaction of the customers but to exceed it.

4. How can a product design affect manufacturability? Explain the concept and

importance of design for manufacturability.

Before manufacturing, defining, and developing a product design must be

done first. Sans product design, effective manufacturability is not possible.

Manufacturers cannot manufacture a product without a product design. Therefore,

quality is also impossible to achieve. In concurrence with that, design for

manufacturability is the process of designing a product so that it can be produced

efficiently at the highest level of quality. Design for manufacturability is important

because it improves quality, increase productivity, reduce lead time, and maintain

flexibility to adapt to future market conditions.

You might also like

- Basic French ConversationDocument7 pagesBasic French Conversationeszti kozmaNo ratings yet

- HOPE 3A MODULE 1 Introduction To DanceDocument13 pagesHOPE 3A MODULE 1 Introduction To DanceLeo PatrickNo ratings yet

- The Open Banking StandardDocument148 pagesThe Open Banking StandardOpen Data Institute95% (21)

- Aci 306.1Document5 pagesAci 306.1safak kahramanNo ratings yet

- Chapter 3 Income TaxationDocument7 pagesChapter 3 Income TaxationMary Jane PabroaNo ratings yet

- Chapter 3 Income TaxationDocument7 pagesChapter 3 Income TaxationMary Jane PabroaNo ratings yet

- Phases in Product Design and DevelopmentDocument10 pagesPhases in Product Design and DevelopmentJia_Amin89% (9)

- VRF, MPLS and MP-BGP FundamentalsDocument55 pagesVRF, MPLS and MP-BGP FundamentalsIVAN TANEV100% (2)

- Chapter 10 Compensation IncomeDocument6 pagesChapter 10 Compensation IncomeMary Jane Pabroa100% (2)

- Abdominal Exam Guide: Palpation, Inspection & Surface MarkingsDocument4 pagesAbdominal Exam Guide: Palpation, Inspection & Surface MarkingsPhysician AssociateNo ratings yet

- Q:-Discuss The Stages in Product Design Process: 1. Idea GenerationDocument7 pagesQ:-Discuss The Stages in Product Design Process: 1. Idea GenerationSuraj KumarNo ratings yet

- Product Design PresentationDocument64 pagesProduct Design PresentationAnthony Royupa0% (1)

- Design For Quality & Product ExcellenceDocument104 pagesDesign For Quality & Product ExcellenceAbhishek Srivastava100% (1)

- New Product Design ProcessDocument4 pagesNew Product Design Processsonam katiyarNo ratings yet

- PRODUCT Design and DevelopmentDocument6 pagesPRODUCT Design and DevelopmentJames IshakuNo ratings yet

- Product and service design processDocument36 pagesProduct and service design processramjanmsinghNo ratings yet

- Product and Service DesignDocument46 pagesProduct and Service DesignKim TaengoossNo ratings yet

- Cot 1 Detailed Lesson Plan in Science 10Document3 pagesCot 1 Detailed Lesson Plan in Science 10Arlen FuentebellaNo ratings yet

- Acoustic EmissionDocument11 pagesAcoustic Emissionuyenowen@yahoo.comNo ratings yet

- Preferential TaxationDocument8 pagesPreferential TaxationMary Jane PabroaNo ratings yet

- Product Management: 7-Step Guide from Zero to Hero: Product ManagementFrom EverandProduct Management: 7-Step Guide from Zero to Hero: Product ManagementNo ratings yet

- New Product Development Essentials: Hands-on Help for Small Manufacturers and Smart Technical People: No Nonsence Manuals, #2From EverandNew Product Development Essentials: Hands-on Help for Small Manufacturers and Smart Technical People: No Nonsence Manuals, #2Rating: 4 out of 5 stars4/5 (1)

- #7 Design For Quality and Product ExcellenceDocument8 pages#7 Design For Quality and Product ExcellenceNeyka YinNo ratings yet

- Sop 4Document2 pagesSop 4Leon Hong83% (6)

- Design for Quality and Product Excellence Chapter SummaryDocument13 pagesDesign for Quality and Product Excellence Chapter Summarygiovanni roaNo ratings yet

- Product and Service DesignDocument18 pagesProduct and Service DesignMary Elaine DiasantaNo ratings yet

- PRODUCT DESIGN PROCESSDocument24 pagesPRODUCT DESIGN PROCESSYatharth GargNo ratings yet

- 4000 Word's AssignmentDocument13 pages4000 Word's AssignmentAbdurrhmanNo ratings yet

- OM CHAPTER THREEE Student Handout-1Document34 pagesOM CHAPTER THREEE Student Handout-1kassahungedefaye312No ratings yet

- Product Design Development GuideDocument35 pagesProduct Design Development Guidefareesa hussainNo ratings yet

- POM Unit IIDocument13 pagesPOM Unit IIShiVâ SãiNo ratings yet

- OM 2022 (MG) Module2Document139 pagesOM 2022 (MG) Module2Ananda KrishnanNo ratings yet

- Product Design and Development Consists of Six StepsDocument2 pagesProduct Design and Development Consists of Six Stepsrustom chavezNo ratings yet

- CH 5 Product DesignDocument18 pagesCH 5 Product DesignMahi VirmaniNo ratings yet

- Production & Operations ManagementDocument0 pagesProduction & Operations ManagementAbdul AzisNo ratings yet

- Chapter3 Product DesignDocument43 pagesChapter3 Product DesignGeni AshuraNo ratings yet

- Product Design & Development: The Generic Process For Developing New ProductsDocument7 pagesProduct Design & Development: The Generic Process For Developing New ProductsRandeep DevNo ratings yet

- DT Notes Unit 1,2,3Document83 pagesDT Notes Unit 1,2,3Akriti JaiswalNo ratings yet

- Week 2 EM (Autosaved)Document35 pagesWeek 2 EM (Autosaved)JOHN ISIDRO ANTICNo ratings yet

- EM PresentationDocument36 pagesEM PresentationJohn Isidro Jacob AnticNo ratings yet

- PD620 - Revision Questions 2022-2023 - 1Document30 pagesPD620 - Revision Questions 2022-2023 - 1Geofrey L PaulNo ratings yet

- OMF551 Unit 1 & 2Document77 pagesOMF551 Unit 1 & 2Bharath JbNo ratings yet

- ChaPter V_20231208_155040_0000Document24 pagesChaPter V_20231208_155040_0000Kurt BongolNo ratings yet

- Product Design & Development: Unit 1Document36 pagesProduct Design & Development: Unit 1Tushar SrivastavaNo ratings yet

- Chapter Two Design of The Operations/production Systems 2.1. Product-Service Design and DevelopmentDocument42 pagesChapter Two Design of The Operations/production Systems 2.1. Product-Service Design and DevelopmentYared TeshomeNo ratings yet

- Quality & Product ExcellenceDocument104 pagesQuality & Product ExcellenceAbhishek SrivastavaNo ratings yet

- 2 Product Design ProcessDocument3 pages2 Product Design Process6abdul1ghani9No ratings yet

- Product Design and DevelopmentDocument13 pagesProduct Design and Developmentkarnavatiuniversity2No ratings yet

- #2. C2-Product DesignDocument14 pages#2. C2-Product DesignHashane PereraNo ratings yet

- Ingeniero de ProductoDocument27 pagesIngeniero de ProductoJuan Diego Arroyave SernaNo ratings yet

- Unit 3 - Design of The Operation System Part One.Document32 pagesUnit 3 - Design of The Operation System Part One.Birhanu AdmasuNo ratings yet

- Chapter 7Document3 pagesChapter 7Cathy MamigoNo ratings yet

- Innovation Management How Ensure Business Competitiveness SustainabilityDocument25 pagesInnovation Management How Ensure Business Competitiveness SustainabilityRached LazregNo ratings yet

- Unit 1 POMDocument4 pagesUnit 1 POMAnmolpreet KaurNo ratings yet

- Quality by Design TechniquesDocument4 pagesQuality by Design TechniquesJay GeeNo ratings yet

- Cookery Module 1Document74 pagesCookery Module 1FLORDELIZ CANJANo ratings yet

- Sum POMDocument8 pagesSum POMTidene BaynoNo ratings yet

- Edited Unit 3 OMDocument17 pagesEdited Unit 3 OMermiasnasirtaleginNo ratings yet

- Som Assignment-2Document17 pagesSom Assignment-2Saurav RanaNo ratings yet

- Apparel Quality Management: National Institute of Fashion TechnologyDocument13 pagesApparel Quality Management: National Institute of Fashion TechnologyBhaswati PandaNo ratings yet

- Product and Service DesignDocument4 pagesProduct and Service Designjth55936zwohocomNo ratings yet

- Product Design & Development PDFDocument6 pagesProduct Design & Development PDFAnonymous 26tZJAYNo ratings yet

- Unit 3 OMDocument7 pagesUnit 3 OMAsegid gezehagnNo ratings yet

- DT - Unit 1Document18 pagesDT - Unit 1YoNo ratings yet

- Linking These Phases Provides A Mechanism To Deploy The Customer Voice Through To Control of Process OperationsDocument10 pagesLinking These Phases Provides A Mechanism To Deploy The Customer Voice Through To Control of Process OperationsSiddharth KalsiNo ratings yet

- MODULE 6 StudentsDocument12 pagesMODULE 6 Studentspetertadifa2231No ratings yet

- Discovering New Product Development StrategyDocument7 pagesDiscovering New Product Development StrategyLi An BautistaNo ratings yet

- Topic 7 Design For Quality Product and Product Excellence StudentsDocument7 pagesTopic 7 Design For Quality Product and Product Excellence StudentsMonica Pablo SabadoNo ratings yet

- New Product Development and Managing Innovation - Sem 4Document10 pagesNew Product Development and Managing Innovation - Sem 4Yash GuptaNo ratings yet

- Unit I IntroductionDocument98 pagesUnit I IntroductionGowthamanNo ratings yet

- Product and Service Design GuidelinesDocument84 pagesProduct and Service Design GuidelinesShafayet JamilNo ratings yet

- Agile Product Management: Streamlining Product Development with Agile PrinciplesFrom EverandAgile Product Management: Streamlining Product Development with Agile PrinciplesNo ratings yet

- OutlineNotes OBLICONDocument22 pagesOutlineNotes OBLICONMary Jane PabroaNo ratings yet

- REGULAR INCOME TAXATION OVERVIEWDocument4 pagesREGULAR INCOME TAXATION OVERVIEWMary Jane Pabroa100% (1)

- Chapter 15 Regular Income Taxation CorporationsDocument9 pagesChapter 15 Regular Income Taxation CorporationsMary Jane PabroaNo ratings yet

- Case AnalysisDocument2 pagesCase AnalysisMary Jane PabroaNo ratings yet

- REGULAR INCOME TAXATION OVERVIEWDocument4 pagesREGULAR INCOME TAXATION OVERVIEWMary Jane Pabroa100% (1)

- Chapter 8 Exclusions From Gross IncomeDocument4 pagesChapter 8 Exclusions From Gross IncomeMary Jane PabroaNo ratings yet

- Chapter 8 Exclusions From Gross IncomeDocument4 pagesChapter 8 Exclusions From Gross IncomeMary Jane PabroaNo ratings yet

- MGS 4301 Decision Making Sample ExerciseDocument1 pageMGS 4301 Decision Making Sample ExerciseMarielle AllouNo ratings yet

- English AssignmentDocument79 pagesEnglish AssignmentAnime TubeNo ratings yet

- (已压缩)721 260 PBDocument879 pages(已压缩)721 260 PBflorexxi19No ratings yet

- Unit 2 GEC 106Document132 pagesUnit 2 GEC 106fernando.gl559No ratings yet

- Final MTech ProjectDocument30 pagesFinal MTech ProjectArunSharmaNo ratings yet

- Ayushi HR DCXDocument40 pagesAyushi HR DCX1048 Adarsh SinghNo ratings yet

- Frame Fit Specifications 2019 MTB Components Rev CDocument167 pagesFrame Fit Specifications 2019 MTB Components Rev Cpicko 86No ratings yet

- Guided Reading Activity: The Reach of ImperialismDocument2 pagesGuided Reading Activity: The Reach of ImperialismevertNo ratings yet

- Robert Frost BiographyDocument3 pagesRobert Frost Biographypkali18No ratings yet

- Montageanleitung sf25 35 enDocument20 pagesMontageanleitung sf25 35 enPaulo santosNo ratings yet

- Idebenone Increases Chance of StabilizationrecoverDocument5 pagesIdebenone Increases Chance of StabilizationrecoverRaluca PascalauNo ratings yet

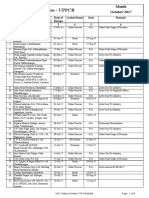

- NOC Status for UPPCB in October 2017Document6 pagesNOC Status for UPPCB in October 2017Jeevan jyoti vnsNo ratings yet

- IED670 - A Major Leap in Grid ReliabilityDocument2 pagesIED670 - A Major Leap in Grid ReliabilityunorulezNo ratings yet

- Latin Fathers On Spirit PDFDocument20 pagesLatin Fathers On Spirit PDFZakka LabibNo ratings yet

- Excel Case Study 1 - DA - Questions With Key AnswersDocument56 pagesExcel Case Study 1 - DA - Questions With Key AnswersVipin AntilNo ratings yet

- D820-93 (2009) Standard Test Methods For ChemicalDocument10 pagesD820-93 (2009) Standard Test Methods For Chemicalobis8053No ratings yet

- Robbins OB15GE Inppt16Document31 pagesRobbins OB15GE Inppt16Nida IsrarNo ratings yet

- The Philosophy of Composition (1846)Document20 pagesThe Philosophy of Composition (1846)Denise CoronelNo ratings yet

- Miscellanea: Arab-Sasanian Copper P Esents Varie Ypo OgyDocument24 pagesMiscellanea: Arab-Sasanian Copper P Esents Varie Ypo Ogy12chainsNo ratings yet

- Xist PDFDocument2 pagesXist PDFAgustin Gago LopezNo ratings yet

- Scalable Machine-Learning Algorithms For Big Data Analytics: A Comprehensive ReviewDocument21 pagesScalable Machine-Learning Algorithms For Big Data Analytics: A Comprehensive ReviewvikasbhowateNo ratings yet