Professional Documents

Culture Documents

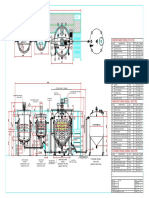

Q-11650, Vibrosifter 30 Inch PDF

Uploaded by

anita shindeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Q-11650, Vibrosifter 30 Inch PDF

Uploaded by

anita shindeCopyright:

Available Formats

BECTOCHEM

CONSULTANTS AND OFFER SPECIFICATIONS

ENGINEERS PVT. LTD. VIBROSIFTER 30”

OFFER NO.: Q-11650 DATE:16.07.2011

CLIENT : M/S. DAILY NEEDS LTD. A/C. ELOMATIC PHARMALAB PAGE 1 OF 6

STANDARD MODEL

DESCRIPTION SPECIFICATION

1. PROCESS & OPERATIONAL DATA

Purpose Sieving of powders or granules.

Construction Stand alone, floor-supported unit. The whole unit along

with the motor, sieves, hopper etc are covered by a SS skirt.

Principle of operation Optimally tensioned sieves are made to vibrate using a

vibratory motor which rotates eccentric weights. As they

vibrate, the material gets sieved and the oversized particles

get retained while undersized particles fall from the

discharge through gravity.

Working capacity Maximum : 300 Kg/hour & Minimum : 40 Kg/hour

depending on the :

Nature of Product

Moisture content

Sieve size

Amplitude of vibration

Weight position on the motor

Frequency of Motor input supply

Rate of feed

Number of decks

Anti blinding options present or not

Quality of sieve

Charging Inputs The Powder is loaded manually

2. DESIGN DATA

Overall Dimensions a) Overall 1200 mm L x 750 mm W x 1270 mm H

b) Base 520 ID x 520 Height (for Standard 750 discharge)

c) Upper deck 710 ID x 1.6mm thick x 150 H

d) Central Shell 710 mm ID x 150mm H x 1.6 mm Thick

Quality assurance Built as per Good Engineering Practice and GMP model &

cGMP compliant

Electrical Rating Non – Ex rated,415V, 50 Hz, 3 phase

3. MAIN COMPONENTS

3.1 DRIVE ASSEMBLY

Type Vibratory,

Motor Make Good Earth.

Motor Specifications 0.5 H.P./ 1440 RPM

Motor Mounting Flange mounted.

Mounting Drive assembly mounted on a tubular framework, with help

of motor mounting plate.

MOC Frame Work & Guards SS 304

Mounting Plates CS

Prepared By: Jagandeep kaur Checked By: Mr. Mayur

BECTOCHEM

CONSULTANTS AND OFFER SPECIFICATIONS

ENGINEERS PVT. LTD. VIBROSIFTER 30”

OFFER NO.: Q-11650 DATE:16.07.2011

CLIENT : M/S. DAILY NEEDS LTD. A/C. ELOMATIC PHARMALAB PAGE 2 OF 6

3.2 BASE Cylindrical with welded flange face at the top and bottom.

Base with inspection / access window on hinges for

approach to the motor.

Made of SS 304 Flanges. Inspection window 200 X 300.

Base with lockable castors with SS bracket & rubber

wheels.

3.3 LOWER HOPPER Cylindrical, with lip faces at both ends. Provided with an

internal cone to channelize the flow of materials towards

the external perimeter. Cone is fully welded to the inner

diameter.

Type Central cylindrical shell with welded conical frustums at

both ends. Cones having included angle between 30-50O.

Discharge port Discharge Port is rectangular to circular, with an effective

radial opening of 500 approx. x 100 dia at the outlet

3.4 UPPER DECK

Construction Cylindrical with lip faces at both ends.

3.5 MOTOR MOUNTING 12 mm thick C S plate, with tapered edges to suit clamp

. PLATE profile. Plate houses the motor, bolted at the center, and

retains the hopper assembly on the top. Transmission

springs couple the plate to the base of the unit.

3.6 TRANSMISSION 8 nos. springs are fixed on the upper girth flange of the

SPRINGS base. Upper end of the springs are fixed to the bottom of the

motor mounting plate.

3.7 SKIRT FOR SPRINGS SS 304 Cylindrical girth ring skirt to protect the springs

from exposure and achieve greater cGMP compliance. Skirt

is fixed to the bottom of the motor mounting plate.

3.8 CLAMPS ‘C’ section clamps in two halves with hinging arrangement.

Closure with toggle action between the two halves. Locking

lever has screw adjustment to compensate for tension

required. The bottom hopper is secured to the motor

mounting plate by a clamp. Similarly each sieve is

sandwiched between the hopper faces with the clamp

securing the lips of the upper and the lower hopper.

3.9 GASKET White food Grade Neoprene ‘C’ section gasket. Ensures

powder tight interface between the two hopper faces and

the sieve.

4 STARTER DOL Starter

5 FINISH SS 316 Contact Parts internally 240 grit mirror.

SS 304 cladded/covered Parts externally 180 grit Matt.

C.S Parts to be painted with enamel paint.

6 UTILITIES Electrical Consumption 0.37KW @415 V, 50 Hz.

Prepared By: Jagandeep kaur Checked By: Mr. Mayur

BECTOCHEM

CONSULTANTS AND OFFER SPECIFICATIONS

ENGINEERS PVT. LTD. VIBROSIFTER 30”

OFFER NO.: Q-11650 DATE:16.07.2011

CLIENT : M/S. DAILY NEEDS LTD. A/C. ELOMATIC PHARMALAB PAGE 3 OF 6

7. DOCUMENTATIONS Scope of Standard Documentation

Material test certificate for contact parts.

Installation & Maintenance Manual

Spare Part List.

Warranty Certificate of machine

Certificates, Manual for Brought out items.

Electrical Circuit Diagram

Schematic Diagram of machine.

GA Diagram.

Instrument List with manufacturer’s calibration Certificate.

8. INSPECTION Client / consultant / Bectochem

9. TRIAL No load Running Trial will be offered for ½ hr.

10. PACKING Wrapped in Plastic

OPTIONS FOR CLIENT’S CONSIDERATION

1. MOTORS Italvibras, non FLP.

To confirm

2. Dust Hood With Conical profile, with locating lugs and flat face at the seat to

Charging Port the hopper deck. Charging Port at center of hood 200 dia

with welded square girth ring. The vent could be connected

Selected to the Local Exhaust Ventilating Unit for effective dust

control.

NOTE: the sieve should not have any rigid interfaces with

connecting devices/machines. This will affect the

throughput of the unit greatly.

3. Vent nozzle 1 ½” with T C connection.

Selected

4. Vent Filter Hydrophobic filter at the vent port on the Lid, 0.2 Micron or

rating to suit the individual application.

Selected

5. Double decks To Confirm

6. Documentation at extra Functional design Specifications – FDS

cost Design Qualification Protocol – DQ

Formats for IQ and OQ

Selected Factory Acceptance Test – FAT

Surface Finish Test report.

Prepared By: Jagandeep kaur Checked By: Mr. Mayur

BECTOCHEM

CONSULTANTS AND OFFER SPECIFICATIONS

ENGINEERS PVT. LTD. VIBROSIFTER 30”

OFFER NO.: Q-11650 DATE:16.07.2011

CLIENT : M/S. DAILY NEEDS LTD. A/C. ELOMATIC PHARMALAB PAGE 4 OF 6

COMMERICIAL SECTION:

PRICE SCHEDULE

VIBROSIFTER 30”

SR. 30"

MODEL

NO.

Price (FOB, Mumbai

Specification

Particulars port)

(in USD)

Single Deck vibrosifter

SS 316 Contact Parts

01 2950

cGMP Model

Non FLP Construction

One screen included

Starter Included

PU wheels

No hood

OPTIONS

SS 316, with Clamp and

02 Addition Deck with Screen 375

Gasket

Addition for Dust Hood with SS 316, with Clamp and

03 415

Charging Port with Clamp Gasket

04 Vent nozzle with hydrophobic filter Ss 316 nozzle on TC 175

05 Italian Vibro motor Non FLP type 825

06 Flameproof System 595

Additional for PU coated castor 4" x 1.1/4" with SS 304

07 Included

wheels bracket, lockable

08 Detailed Documentation 215

Prepared By: Jagandeep kaur Checked By: Mr. Mayur

BECTOCHEM

CONSULTANTS AND OFFER SPECIFICATIONS

ENGINEERS PVT. LTD. VIBROSIFTER 30”

OFFER NO.: Q-11650 DATE:16.07.2011

CLIENT : M/S. DAILY NEEDS LTD. A/C. ELOMATIC PHARMALAB PAGE 5 OF 6

Glimpse:

Single deck Vibrosifter

Lab Vibrosifter

Prepared By: Jagandeep kaur Checked By: Mr. Mayur

BECTOCHEM

CONSULTANTS AND OFFER SPECIFICATIONS

ENGINEERS PVT. LTD. VIBROSIFTER 30”

OFFER NO.: Q-11650 DATE:16.07.2011

CLIENT : M/S. DAILY NEEDS LTD. A/C. ELOMATIC PHARMALAB PAGE 6 OF 6

Vacuum Vibrosifter

Vacuum Vibrosifter in Operation

Prepared By: Jagandeep kaur Checked By: Mr. Mayur

You might also like

- Offer Specifications: BectochemDocument3 pagesOffer Specifications: Bectochemanita shindeNo ratings yet

- Pharma Engineering Equipment CatalogDocument8 pagesPharma Engineering Equipment Catalogkalyane_gajananNo ratings yet

- Concept Note PSD LAB - PHARMA API PLANTDocument17 pagesConcept Note PSD LAB - PHARMA API PLANTRishabh VermaNo ratings yet

- Q-11650, Ancchor-Plm Type Paste Kettle 125 L PDFDocument5 pagesQ-11650, Ancchor-Plm Type Paste Kettle 125 L PDFanita shindeNo ratings yet

- Q-11650, Cage Blender-600 LTRSDocument7 pagesQ-11650, Cage Blender-600 LTRSanita shindeNo ratings yet

- Water Phase Vessel 275 LTRS: Control PanelDocument1 pageWater Phase Vessel 275 LTRS: Control Panelharshileng3992100% (1)

- URS-oct BlenderDocument4 pagesURS-oct BlenderQANo ratings yet

- Sunsai Pharma Equipments Pvt. ltd-2Document8 pagesSunsai Pharma Equipments Pvt. ltd-2Sunsai VasaiNo ratings yet

- Qualifying Pharmaceutical EquipmentDocument8 pagesQualifying Pharmaceutical EquipmentMahdi HajizadehNo ratings yet

- Vibratory Bowl FeederDocument21 pagesVibratory Bowl Feederdavid mierNo ratings yet

- Template For Installation Qualification Protocol - Pharmaceutical GuidanceDocument6 pagesTemplate For Installation Qualification Protocol - Pharmaceutical GuidanceMSL IndiaNo ratings yet

- Per Bin BlenderDocument9 pagesPer Bin BlenderJonatan SallesNo ratings yet

- IQ-OQ Report for Dryer and FiltersDocument8 pagesIQ-OQ Report for Dryer and FiltersArwin PradanaNo ratings yet

- Highest Quality IBCs for Pharma & Food HandlingDocument4 pagesHighest Quality IBCs for Pharma & Food HandlingJonatan SallesNo ratings yet

- Liquid Filling Section MachineryDocument18 pagesLiquid Filling Section MachinerySANJAY100% (1)

- U R T For A Barrier Isolator and Hvac System: CL Tech. IncDocument33 pagesU R T For A Barrier Isolator and Hvac System: CL Tech. IncRND Biotis50% (2)

- 6head Syrup Filling Line Automatic PDFDocument18 pages6head Syrup Filling Line Automatic PDFSrinivas0% (1)

- Cleaning Validation in Non-Sterile Solid Dosage ProductionDocument36 pagesCleaning Validation in Non-Sterile Solid Dosage ProductionTa100% (1)

- Ointment Manufacturing PlantDocument15 pagesOintment Manufacturing PlantPooja Chavande-SuradkarNo ratings yet

- Homo Mixer, View Homo Mixer, Ding Xin Product Details From Wuhan Dingxin Mechanical & Electric Equipment Co., Ltd. On Alibaba PDFDocument5 pagesHomo Mixer, View Homo Mixer, Ding Xin Product Details From Wuhan Dingxin Mechanical & Electric Equipment Co., Ltd. On Alibaba PDFtahera aqeelNo ratings yet

- Blister Machine Surface Area CalculationDocument4 pagesBlister Machine Surface Area CalculationDarlenis RodriguezNo ratings yet

- Sunsai Catalogue - Final 2019 (New)Document24 pagesSunsai Catalogue - Final 2019 (New)abdou dacardNo ratings yet

- URs For V-BlenderDocument11 pagesURs For V-BlenderTanChantrea100% (1)

- Florfenicol Oral Solution RecipeDocument7 pagesFlorfenicol Oral Solution RecipeBejoy KarimNo ratings yet

- Maintaining Vibratory FeedersDocument37 pagesMaintaining Vibratory FeedersLê Thanh SangNo ratings yet

- Technical Specification for ETPDocument4 pagesTechnical Specification for ETPMadhavi TendleNo ratings yet

- Good Manufacturing PracticesDocument40 pagesGood Manufacturing Practicessandeep singh gaurNo ratings yet

- Angela Brevetti Blow Fill Seal CatalogDocument22 pagesAngela Brevetti Blow Fill Seal CatalogipatoffNo ratings yet

- Content of PSUR Medical DeviceDocument1 pageContent of PSUR Medical DeviceKabomed QANo ratings yet

- Clinical Evluation GiudenceDocument20 pagesClinical Evluation GiudenceabcNo ratings yet

- Accelerated Testing SystemsDocument4 pagesAccelerated Testing SystemsAvinash AgrawalNo ratings yet

- IQ and OQ Protocol MET ONE 3413 CountersDocument112 pagesIQ and OQ Protocol MET ONE 3413 Counterslau50% (2)

- Design Qualification: Cip Skid & Distribution Piping (Veg Blender Flavours Powder)Document12 pagesDesign Qualification: Cip Skid & Distribution Piping (Veg Blender Flavours Powder)Chay Nag100% (1)

- Chamunda Pharma MachineryDocument10 pagesChamunda Pharma MachinerychamundapharmaNo ratings yet

- Capsule Filling Machine, Automatic Capsule Filling Machine, Semi Automatic Capsule Filling MachineDocument10 pagesCapsule Filling Machine, Automatic Capsule Filling Machine, Semi Automatic Capsule Filling MachineDhananjay LodhaNo ratings yet

- Design and Analysis of Powder Mixing Ribbon Blender - A ReviewDocument5 pagesDesign and Analysis of Powder Mixing Ribbon Blender - A ReviewjohnsonregoNo ratings yet

- Smart Coater Technical Specification SheetDocument4 pagesSmart Coater Technical Specification SheetAbhilash Narayanan100% (2)

- VacuummixerDocument4 pagesVacuummixerKonigsNo ratings yet

- Automatic Fillling Liquid 4nozzle PistonDocument5 pagesAutomatic Fillling Liquid 4nozzle Pistonagung tunasNo ratings yet

- Water For Injection Production - (MED) Multiple Effect DistillationDocument6 pagesWater For Injection Production - (MED) Multiple Effect DistillationQuang Hiếu NgôNo ratings yet

- NGVF 2017 Sterile Masterclass 03 Process MFG Technologies 2017-07-10Document61 pagesNGVF 2017 Sterile Masterclass 03 Process MFG Technologies 2017-07-10Tuan NguyenNo ratings yet

- 6 Heads Automatic Filling MachineDocument10 pages6 Heads Automatic Filling MachineCITRO GREENNo ratings yet

- Method To Determine Test Profile in Accelerated RDTDocument7 pagesMethod To Determine Test Profile in Accelerated RDTilan BenNo ratings yet

- OQ System TestDocument9 pagesOQ System TestSoon Kooi0% (1)

- SCP Series Technical DataDocument8 pagesSCP Series Technical DataJaldhij PatelNo ratings yet

- Types of Agitators, Agitator's Design and Significance - Pharma EngineeringDocument58 pagesTypes of Agitators, Agitator's Design and Significance - Pharma Engineeringmyself_riteshNo ratings yet

- CVC Inline Filling PresentationDocument26 pagesCVC Inline Filling PresentationFithrul Mubarok100% (1)

- Riddhi Pharma Machinery LTDDocument4 pagesRiddhi Pharma Machinery LTDNeeraj MishraNo ratings yet

- Aftermarket Products For Encapsulation Machines PDFDocument53 pagesAftermarket Products For Encapsulation Machines PDFAni AndrianiNo ratings yet

- Price Book PDFDocument193 pagesPrice Book PDFaasma100% (1)

- GEA Niro Pharma SDDocument16 pagesGEA Niro Pharma SDchien_yu_leeNo ratings yet

- 17 Questions PDFDocument19 pages17 Questions PDFmuzammil21_adNo ratings yet

- Universita degli Studi di Milano Freeze Drying LectureDocument120 pagesUniversita degli Studi di Milano Freeze Drying Lectureఝాన్సీ పుత్ర సతీష్No ratings yet

- PQ-Sample FOURDocument9 pagesPQ-Sample FOURcpkakopeNo ratings yet

- Vibro SifterDocument3 pagesVibro SifterRaj K SharmaNo ratings yet

- MDCG 2020-8 Guidance On PMCF Evaluation Report TemplateDocument10 pagesMDCG 2020-8 Guidance On PMCF Evaluation Report TemplateNuno TeixeiraNo ratings yet

- Biological Indicators TOC PDFDocument20 pagesBiological Indicators TOC PDFnsk79in0% (1)

- Installation / Operational Qualification Protocol Insert Incubator Name & I.DDocument32 pagesInstallation / Operational Qualification Protocol Insert Incubator Name & I.DMuhammad AzeemNo ratings yet

- Q-11650, Vibrosifter 30 InchDocument6 pagesQ-11650, Vibrosifter 30 Inchanita shindeNo ratings yet

- Hydrogen System ValidationDocument4 pagesHydrogen System Validationanita shindeNo ratings yet

- Chemical Compatibility Matrix ChartDocument5 pagesChemical Compatibility Matrix ChartpopohippoNo ratings yet

- Boiler Types Constr Aug08seminarDocument17 pagesBoiler Types Constr Aug08seminaranita shindeNo ratings yet

- Google App Analysis Power BiDocument4 pagesGoogle App Analysis Power Bianita shindeNo ratings yet

- Landfill-Project-Verification-Protocol Capturing and Distroying Methane From LandfillsDocument9 pagesLandfill-Project-Verification-Protocol Capturing and Distroying Methane From Landfillsanita shindeNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Makeup Water Quality RequirementDocument2 pagesMakeup Water Quality Requirementanita shindeNo ratings yet

- Rotary Evaporator GuideDocument6 pagesRotary Evaporator Guideanita shindeNo ratings yet

- Valid Prcs S Gassy ST MsDocument6 pagesValid Prcs S Gassy ST MsqhpuongNo ratings yet

- Surface Preparation Standards: National Association of Corrosion Engineers (NACE)Document4 pagesSurface Preparation Standards: National Association of Corrosion Engineers (NACE)ranjan_anishNo ratings yet

- Manual Recip Package Mar 09 PDFDocument29 pagesManual Recip Package Mar 09 PDFanita shindeNo ratings yet

- Guide To Selection of Sus Surface FinishDocument15 pagesGuide To Selection of Sus Surface FinishTun Chit FooNo ratings yet

- Bectochem Proposes TIPPER for Daily NeedsDocument15 pagesBectochem Proposes TIPPER for Daily Needsanita shindeNo ratings yet

- Part List HX2T-50NP/D, HX2T - 60NP/DDocument32 pagesPart List HX2T-50NP/D, HX2T - 60NP/Danita shinde100% (3)

- Bectochem: Consultants & Engineers Pvt. LTDDocument28 pagesBectochem: Consultants & Engineers Pvt. LTDanita shindeNo ratings yet

- Q-11650, Tablet Deduster PDFDocument1 pageQ-11650, Tablet Deduster PDFanita shindeNo ratings yet

- Q-11650, Material Handling Device - Loader - For Vibrosifter, RMG & Paste KettleDocument5 pagesQ-11650, Material Handling Device - Loader - For Vibrosifter, RMG & Paste Kettleanita shindeNo ratings yet

- Part List HX1T-20,25N1NPS/NPDSDocument32 pagesPart List HX1T-20,25N1NPS/NPDSanita shinde100% (1)

- Q-11650, Fluid Bed Dryer - 250 KGS PDFDocument28 pagesQ-11650, Fluid Bed Dryer - 250 KGS PDFanita shindeNo ratings yet

- Q-11650, Material Handling Device - Loader - With y Chute For Compression MachineDocument6 pagesQ-11650, Material Handling Device - Loader - With y Chute For Compression Machineanita shindeNo ratings yet

- Q-11650, RMG 600 L With ConemillDocument22 pagesQ-11650, RMG 600 L With Conemillanita shinde100% (1)

- Q-11650, Vibrosifter 30 InchDocument6 pagesQ-11650, Vibrosifter 30 Inchanita shindeNo ratings yet

- Q-11650, Tablet DedusterDocument1 pageQ-11650, Tablet Dedusteranita shindeNo ratings yet

- Specifications for 125L planetary mixerDocument5 pagesSpecifications for 125L planetary mixeranita shindeNo ratings yet

- Q-11650, Cage Bin - 600 LTRSDocument4 pagesQ-11650, Cage Bin - 600 LTRSanita shindeNo ratings yet

- The Kite ShopDocument2 pagesThe Kite Shopanita shindeNo ratings yet

- Dwnload Full Physical Science 11th Edition Tillery Test Bank PDFDocument35 pagesDwnload Full Physical Science 11th Edition Tillery Test Bank PDFzugiraafim100% (12)

- Ramsey Mercury Free Tilt Sensor 8054.0514 CODocument4 pagesRamsey Mercury Free Tilt Sensor 8054.0514 COlf123No ratings yet

- Whats Map ProjectionDocument19 pagesWhats Map Projectionmahmoud abdelrahmanNo ratings yet

- Strand7 - Buckling Analysis - Linear Vs NonlinearDocument5 pagesStrand7 - Buckling Analysis - Linear Vs Nonlinearaktc100% (1)

- A Demonstration Lesson Plan Solutions and ColloidsDocument9 pagesA Demonstration Lesson Plan Solutions and ColloidsJenny Lynn dela Rosa100% (1)

- Fire Protection Systems Engineering GuideDocument18 pagesFire Protection Systems Engineering GuideAli MehrpourNo ratings yet

- Si924x - Class D Audio Driver With Precision Dead-Time GeneratorDocument1 pageSi924x - Class D Audio Driver With Precision Dead-Time GeneratorBen M'rad SkanderNo ratings yet

- Final CodingDocument6 pagesFinal CodingSasikala RajendranNo ratings yet

- How To Draw Manga - Vegeta (Dragon Ball Z)Document7 pagesHow To Draw Manga - Vegeta (Dragon Ball Z)Constantino Paucar Vega100% (1)

- Lightweight Universal Formwork For Walls, Slabs, Columns and FoundationsDocument52 pagesLightweight Universal Formwork For Walls, Slabs, Columns and FoundationsKrishiv ChanglaniNo ratings yet

- NanomagnetismDocument32 pagesNanomagnetismMohammad RameezNo ratings yet

- 2019 A Review On Resistance Spot Welding of Steel MaterialDocument13 pages2019 A Review On Resistance Spot Welding of Steel Materialguravshubham7777No ratings yet

- HeatDocument31 pagesHeatnicky1213a100% (1)

- Ansi B36.19Document13 pagesAnsi B36.19BimaNo ratings yet

- SQL Cheat Sheet For Data Scientists by Tomi Mester 2019 PDFDocument12 pagesSQL Cheat Sheet For Data Scientists by Tomi Mester 2019 PDFVishal Shah100% (1)

- Shs Genmath Module 8 Core Revised DuenasDocument42 pagesShs Genmath Module 8 Core Revised DuenasAPRIL JOY ARREOLANo ratings yet

- Line and Plan in 3DDocument31 pagesLine and Plan in 3DMing Fong LiawNo ratings yet

- Marine Engine-6170 Series: General SpecificationsDocument3 pagesMarine Engine-6170 Series: General SpecificationsTrần Hoài VinhNo ratings yet

- Determine Best Model for Manufacturer Based on Probability and PayoffDocument6 pagesDetermine Best Model for Manufacturer Based on Probability and PayoffNallapati KaavyaNo ratings yet

- Water Pressure Grid TutorialDocument17 pagesWater Pressure Grid Tutorialrrj44No ratings yet

- Wireless Prepaid Energy Metering Using RF and Arduino TechnologyDocument4 pagesWireless Prepaid Energy Metering Using RF and Arduino TechnologyMabrouk HamzaNo ratings yet

- Summed Area TablesDocument29 pagesSummed Area TablesDhillonvNo ratings yet

- Chapter-14 Final Aerobic-DigestionDocument18 pagesChapter-14 Final Aerobic-DigestionIrvin joseNo ratings yet

- s7-1500 in A Nutshell PDFDocument44 pagess7-1500 in A Nutshell PDFSivaNo ratings yet

- Acceleration LabDocument6 pagesAcceleration LabBlesvill BaroroNo ratings yet

- Evaluación 1T1 HLDocument3 pagesEvaluación 1T1 HLIllojuanNo ratings yet

- Thermodynamic and transport properties of saturated steam and waterDocument26 pagesThermodynamic and transport properties of saturated steam and waterMuhammad Reza FahleviNo ratings yet

- Agile Testing Methods Guide: Scrum, Crystal, DSDM, FDD, Lean, XP & MoreDocument19 pagesAgile Testing Methods Guide: Scrum, Crystal, DSDM, FDD, Lean, XP & Moreangelica campuedNo ratings yet

- Multi-Hole Orifice CalculationDocument10 pagesMulti-Hole Orifice Calculationadrianrrcc100% (1)

- Interacting With Generative MusicDocument14 pagesInteracting With Generative Musicdavidoggit100% (1)