Professional Documents

Culture Documents

Offer Specifications: Bectochem

Uploaded by

anita shindeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Offer Specifications: Bectochem

Uploaded by

anita shindeCopyright:

Available Formats

BECTOCHEM

CONSULTANTS AND OFFER SPECIFICATIONS

ENGINEERS PVT. LTD. MULTIMILL

OFFER NO.: Q-11650 DATE: 13.07.2011

CLIENT: M/S. DAILY NEEDS LTD. A/C. ELOMATIC PHARMALAB PAGE 1 OF 3

STANDARD MODEL

DESCRIPTION SPECIFICATION

1. PROCESS & OPERATING DATA

General description. Multimill is a stand-alone unit for practice size

reduction through impact in air, on material by blades

moving at high speeds, inside a cylindrical hopper. The

particles of the desired size pass out through the

screen placed in side the hopper

Principle of working. Particles fall from the hopper into the blades of the mill

which are moving at a very high RPM. The impact of

the blades on the particles is the cause of the sizing.

The blade has sharp edge on one side and blunt on the

other. The direction can be reversed according to the

application.

Usage Milling of powders, granules, food products etc for

industrial and laboratory research

Type Standard Unit is mounted on platform cum Trolley

Capacity 25-300 Kg/hr, typically for a free flowing product,

through a 1mm sieve. However the capacity of the unit

will depend on the:

Nature of Product

Moisture content

Sieve size

Frequency of Motor input supply

Rate of feed

Quality of sieve

Input Used Client to specify

Output produced Sized product

2. DESIGN DATA

Overall dimensions 840 L x 880 B x 1700 H ( BELT MODEL)

770 L X 880 B X 1890 H ( BELT LESS MODEL)

Quality Assurance Design, manufacture, installation and

documentation in accordance with current Good

Manufacturing Practice.

Type Production model

Weight of machine 400 Kg

Finish Product contact parts internally finished to ≤0.5Ra.

Parts externally finished to ≤1.0 Ra.

C.S Parts painted.

Electrical rating Non Ex-rated, 415 V, 50 Hz, 3 phase

3. ROOM DETAILS

Overall Room Dimensions As per layout drawing

Available Room Height Client to specify

4. MAIN COMPONENTS

4.1 Drive Unit Motor 3.0 H.P / 1440 RPM / TEFC Non FLP

Prepared By: Gurpreet Checked By:Mayur

BECTOCHEM

CONSULTANTS AND OFFER SPECIFICATIONS

ENGINEERS PVT. LTD. MULTIMILL

OFFER NO.: Q-11650 DATE: 13.07.2011

CLIENT: M/S. DAILY NEEDS LTD. A/C. ELOMATIC PHARMALAB PAGE 2 OF 3

4.2 Blade Assembly Fitted on Rotor shaft consists of 12 Nos. Knife (Impact)

edge-swinging blades.

4.3 Charging Hopper Rectangular charge Hopper with Slide valve for

regulating the in feed of material.

4.4 Perforated Screens Fairly large aperture screens with sizes 3mm, 4mm,

6mm, 8mm, & 12mm are useful for wet material. For

dry materials the screen of 0.5mm, 1.0mm, 1.5mm or

2mm aperture can be used. (Client to choose

depending on the material).

4.5 Gaskets White Food Grade Neoprene Ensures powder tight

interface between the two hopper faces.

5 MATERIAL OF CONSTRUCTION

Product Contact Parts SS 316

Non Contact Parts SS 304

Motor Mounting Plate C.S.

Castor Wheel MOC Rubber Lockable with S.S.304 bracket.

Perforated Sieves S.S. 316

Pulley Aluminum

Sealing Bush Teflon.

6 ELECTRICAL CONTROLS Reversible switch

Starter

Speeds of the Beater Shaft 4 speeds with Step Cone Pulley 750/ 1440/ 2260 /

2880 RPM

7 SAFETY FEATURE

Noise Level The noise level will differ with the RPM, Material

Properties and way of charging the material.

Protection of Milling Area All moving parts are covered.

8 UTILITY REQUIRED Power Supply 3 ph / 415V / 50 Hz / AC

Total Load 2.2 KW

Cable Size 1.5 SQ. MM – COPPER

Free Space Required Minimum 1metres from all sides.

9 DOCUMENTATION Spares List

Material test certificate for contact parts

Surface Finish Test report

Installation & Maintenance Manual

Warranty Certificate of machine

Certificates & manuals of bought out items

Electrical Circuit Diagram

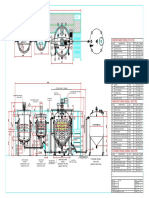

Schematic Diagram

GA diagram.

Prepared By: Gurpreet Checked By:Mayur

BECTOCHEM

CONSULTANTS AND OFFER SPECIFICATIONS

ENGINEERS PVT. LTD. MULTIMILL

OFFER NO.: Q-11650 DATE: 13.07.2011

CLIENT: M/S. DAILY NEEDS LTD. A/C. ELOMATIC PHARMALAB PAGE 3 OF 3

10 INSPECTION Client / Self / Bectochem

11 TRIAL No load Running Trial will be offered for ½ hr.

Load Trial can be offered. Material to be arranged by

client as a free issue of material.

Being a proprietary machine stage wise inspection will

not be offered.

Installation / trial at clients place will be at additional

cost.

12 PACKING Seaworthy packing

OPTIONS FOR CLIENT’S CONSIDERATION

1 Direct drive Instead of a pulley drive, the motor is directly coupled

to the beater shaft and the speed is varied through a

frequency inverter.

2 Beater shaft frequency inverter To vary the RPM of the beater.

3 Detailed Documentation at an Functional design Specifications FDS

extra cost Design Qualification DQ

Quality Assurance Plan QAP

Factory Acceptance Test FAT

IQ&OQ

4 Wheels PU coated caster wheels

Price for above mentioned standard equipment cGMP model along with Direct Drive, Variable

speed, NFLP unit & Detailed Documentation, On skid PU caster wheels , Seaworthy packing , 0.5

mm, 0.8 mm, 1.0 mm, 1.2 mm sieve included FOB Mumbai..................................................... USD. 5,450

Above unit along with flameproof system, FOB Mumbai……………………………………..…….... USD. 6,150

Glimpse:

Prepared By: Gurpreet Checked By:Mayur

You might also like

- 6head Syrup Filling Line Automatic PDFDocument18 pages6head Syrup Filling Line Automatic PDFSrinivas0% (1)

- Q-11650, Ancchor-Plm Type Paste Kettle 125 LDocument5 pagesQ-11650, Ancchor-Plm Type Paste Kettle 125 Lanita shindeNo ratings yet

- Q-11650, Vibrosifter 30 Inch PDFDocument6 pagesQ-11650, Vibrosifter 30 Inch PDFanita shinde0% (1)

- Concept Note PSD LAB - PHARMA API PLANTDocument17 pagesConcept Note PSD LAB - PHARMA API PLANTRishabh VermaNo ratings yet

- Per Bin BlenderDocument9 pagesPer Bin BlenderJonatan SallesNo ratings yet

- URS-oct BlenderDocument4 pagesURS-oct BlenderQANo ratings yet

- Tray Dryer and VibroshifterDocument8 pagesTray Dryer and Vibroshifterkalyane_gajananNo ratings yet

- URS Deviation ListDocument4 pagesURS Deviation ListjaiminNo ratings yet

- Q-11650, Cage Blender-600 LTRSDocument7 pagesQ-11650, Cage Blender-600 LTRSanita shindeNo ratings yet

- Homo Mixer, View Homo Mixer, Ding Xin Product Details From Wuhan Dingxin Mechanical & Electric Equipment Co., Ltd. On Alibaba PDFDocument5 pagesHomo Mixer, View Homo Mixer, Ding Xin Product Details From Wuhan Dingxin Mechanical & Electric Equipment Co., Ltd. On Alibaba PDFtahera aqeelNo ratings yet

- 01 Disintegration Test For Tablets and CapsulesDocument30 pages01 Disintegration Test For Tablets and CapsulesmefroNo ratings yet

- Tapasya Product Catalogue PDFDocument104 pagesTapasya Product Catalogue PDFMahesh Patil KahatulNo ratings yet

- Sunsai Pharma Equipments Pvt. ltd-2Document8 pagesSunsai Pharma Equipments Pvt. ltd-2Sunsai VasaiNo ratings yet

- Brexpiprazole - Chem RevDocument112 pagesBrexpiprazole - Chem RevSam SonNo ratings yet

- U R T For A Barrier Isolator and Hvac System: CL Tech. IncDocument33 pagesU R T For A Barrier Isolator and Hvac System: CL Tech. IncRND Biotis50% (2)

- Chamunda Pharma MachineryDocument10 pagesChamunda Pharma MachinerychamundapharmaNo ratings yet

- Handing OverDocument2 pagesHanding OverjackjbandaraNo ratings yet

- URs For V-BlenderDocument11 pagesURs For V-BlenderTanChantrea100% (1)

- Mixer and Agitators Operational and Maintenance ManualsDocument7 pagesMixer and Agitators Operational and Maintenance ManualsHenok TeshomeNo ratings yet

- Bin Washer-OqDocument11 pagesBin Washer-OqValeria Carlo BorroNo ratings yet

- Technical Specification For EtpDocument4 pagesTechnical Specification For EtpMadhavi TendleNo ratings yet

- Headspace Oxygen Measurement in Vials and AmpoulesDocument4 pagesHeadspace Oxygen Measurement in Vials and AmpoulesGhanta Ranjith KumarNo ratings yet

- Water Phase Vessel 275 LTRS: Control PanelDocument1 pageWater Phase Vessel 275 LTRS: Control Panelharshileng3992100% (1)

- HolvetDocument19 pagesHolvetSunil PrajapatiNo ratings yet

- Attachment 1 DocumentDocument4 pagesAttachment 1 DocumentBrian JacobsonNo ratings yet

- Arogyavardhini Flow Sheet - 25.08.07Document2 pagesArogyavardhini Flow Sheet - 25.08.07Vaishali SalunkeNo ratings yet

- New ProjectDocument4 pagesNew Projectjpmaurya77No ratings yet

- ELMACH Packages India Pvt. LTD - EDocument3 pagesELMACH Packages India Pvt. LTD - EYosses Sang NahkodaNo ratings yet

- Catalogue of Leak Test ApparatusDocument4 pagesCatalogue of Leak Test ApparatustixocNo ratings yet

- Ursfbd PG 16-06-16Document18 pagesUrsfbd PG 16-06-16Sudarshan Reddy Patil100% (1)

- VacuummixerDocument4 pagesVacuummixerKonigsNo ratings yet

- What Are The Key Benefits of Validation?Document6 pagesWhat Are The Key Benefits of Validation?siva sankarNo ratings yet

- Good Manufacturing PracticesDocument40 pagesGood Manufacturing Practicessandeep singh gaurNo ratings yet

- Auto Capsule Filling PDFDocument16 pagesAuto Capsule Filling PDFDuoc CongnghiepNo ratings yet

- Effect of Force Feeder On Tablet Strength During CompressionDocument9 pagesEffect of Force Feeder On Tablet Strength During CompressionJosé RojasNo ratings yet

- Smart Coater Technical Specification SheetDocument4 pagesSmart Coater Technical Specification SheetAbhilash Narayanan100% (2)

- Niin - Solid Dosage Line Turnkey Project SolutionDocument32 pagesNiin - Solid Dosage Line Turnkey Project SolutionbayoepoetroNo ratings yet

- Scope of Work Qualificatin & ValidationDocument8 pagesScope of Work Qualificatin & ValidationPerdana Mandiri TekindoNo ratings yet

- Incubator Shaker: MODEL NO. - ACM-22063-IDocument8 pagesIncubator Shaker: MODEL NO. - ACM-22063-Iwatson123No ratings yet

- ANDADocument12 pagesANDAManish NangaliaNo ratings yet

- User Requirement SpecificationDocument2 pagesUser Requirement SpecificationroopadharNo ratings yet

- Equipment and Their Model, Capacity-Ver1Document287 pagesEquipment and Their Model, Capacity-Ver1dhanu_lagwankarNo ratings yet

- Aseptic Processing Transfer SystemsDocument15 pagesAseptic Processing Transfer SystemsIvan PopovicNo ratings yet

- Wet GranulationDocument18 pagesWet GranulationRafeek Shaikh100% (1)

- Capsule Filling Machine, Automatic Capsule Filling Machine, Semi Automatic Capsule Filling MachineDocument10 pagesCapsule Filling Machine, Automatic Capsule Filling Machine, Semi Automatic Capsule Filling MachineDhananjay LodhaNo ratings yet

- Qualification Rest Risk Based Approach EvaluationDocument4 pagesQualification Rest Risk Based Approach EvaluationApoloTrevino100% (1)

- 0.2011 IMA Kilian R+D Concept PDFDocument37 pages0.2011 IMA Kilian R+D Concept PDFPaqui Miranda Gualda100% (1)

- Template - OQ - 0001 - 01 - Operational Qualification TemplateDocument9 pagesTemplate - OQ - 0001 - 01 - Operational Qualification TemplateSoon Kooi0% (1)

- Validation of Mixer Double Cone BlenderDocument6 pagesValidation of Mixer Double Cone BlenderSyed RizviNo ratings yet

- Non Destructive Container Closure Integrity Testing PDFDocument40 pagesNon Destructive Container Closure Integrity Testing PDFChang Woo JongNo ratings yet

- ProjectDocument62 pagesProjectprince_soni_9No ratings yet

- Department of Health and Human Services: AsepticallyDocument6 pagesDepartment of Health and Human Services: AsepticallyBrian WilliamsNo ratings yet

- SOP Gloves TesterDocument15 pagesSOP Gloves TesterDoan Chi ThienNo ratings yet

- Schedule M: Jijo Thomas M.Pharm Pharmaceutics College of Pharmaceutical Sciences TrivandrumDocument77 pagesSchedule M: Jijo Thomas M.Pharm Pharmaceutics College of Pharmaceutical Sciences TrivandrumVivek PanchabhaiNo ratings yet

- SVKM's Narsee Monjee Institute of Management Studies (NMIMS) ShirpurDocument23 pagesSVKM's Narsee Monjee Institute of Management Studies (NMIMS) ShirpurAnvi JainNo ratings yet

- Pantoprazole 40mg InjectionDocument36 pagesPantoprazole 40mg Injectiondaizhussain004No ratings yet

- Pilot Plant Scale-Up TechniquesDocument62 pagesPilot Plant Scale-Up TechniquesVaseline Robinson100% (2)

- Q-11650, Vibrosifter 30 InchDocument6 pagesQ-11650, Vibrosifter 30 Inchanita shindeNo ratings yet

- Q-11650, Ancchor-Plm Type Paste Kettle 125 L PDFDocument5 pagesQ-11650, Ancchor-Plm Type Paste Kettle 125 L PDFanita shindeNo ratings yet

- Lab Man EditedDocument50 pagesLab Man Editedguravshubham7777No ratings yet

- Google App Analysis Power BiDocument4 pagesGoogle App Analysis Power Bianita shindeNo ratings yet

- Landfill-Project-Verification-Protocol Capturing and Distroying Methane From LandfillsDocument9 pagesLandfill-Project-Verification-Protocol Capturing and Distroying Methane From Landfillsanita shindeNo ratings yet

- Valid Prcs S Gassy ST MsDocument6 pagesValid Prcs S Gassy ST MsqhpuongNo ratings yet

- Boiler Types Constr Aug08seminarDocument17 pagesBoiler Types Constr Aug08seminaranita shindeNo ratings yet

- Compatibility ChartDocument5 pagesCompatibility ChartpopohippoNo ratings yet

- Hydrogen System ValidationDocument4 pagesHydrogen System Validationanita shindeNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Part List HX2T-50NP/D, HX2T - 60NP/DDocument32 pagesPart List HX2T-50NP/D, HX2T - 60NP/Danita shinde100% (3)

- Guide To Selection of Sus Surface FinishDocument15 pagesGuide To Selection of Sus Surface FinishTun Chit FooNo ratings yet

- Surface Preparation Standards: National Association of Corrosion Engineers (NACE)Document4 pagesSurface Preparation Standards: National Association of Corrosion Engineers (NACE)ranjan_anishNo ratings yet

- Makeup Water Quality RequirementDocument2 pagesMakeup Water Quality Requirementanita shindeNo ratings yet

- Manual Recip Package Mar 09 PDFDocument29 pagesManual Recip Package Mar 09 PDFanita shindeNo ratings yet

- Rotary Evaporators RE300 SeriesDocument6 pagesRotary Evaporators RE300 Seriesanita shindeNo ratings yet

- Part List HX1T-20,25N1NPS/NPDSDocument32 pagesPart List HX1T-20,25N1NPS/NPDSanita shinde100% (1)

- Bectochem: Consultants & Engineers Pvt. LTDDocument28 pagesBectochem: Consultants & Engineers Pvt. LTDanita shindeNo ratings yet

- Q-11650, RMG 600 L With ConemillDocument22 pagesQ-11650, RMG 600 L With Conemillanita shinde100% (1)

- Q-11650, Ancchor-Plm Type Paste Kettle 125 L PDFDocument5 pagesQ-11650, Ancchor-Plm Type Paste Kettle 125 L PDFanita shindeNo ratings yet

- Bectochem: Consultants & Engineers Pvt. LTDDocument15 pagesBectochem: Consultants & Engineers Pvt. LTDanita shindeNo ratings yet

- Q-11650, Tablet Deduster PDFDocument1 pageQ-11650, Tablet Deduster PDFanita shindeNo ratings yet

- Q-11650, Fluid Bed Dryer - 250 KGS PDFDocument28 pagesQ-11650, Fluid Bed Dryer - 250 KGS PDFanita shindeNo ratings yet

- Q-11650, Tablet DedusterDocument1 pageQ-11650, Tablet Dedusteranita shindeNo ratings yet

- Q-11650, Vibrosifter 30 InchDocument6 pagesQ-11650, Vibrosifter 30 Inchanita shindeNo ratings yet

- Q-11650, Material Handling Device - Loader - For Vibrosifter, RMG & Paste KettleDocument5 pagesQ-11650, Material Handling Device - Loader - For Vibrosifter, RMG & Paste Kettleanita shindeNo ratings yet

- Q-11650, Material Handling Device - Loader - With y Chute For Compression MachineDocument6 pagesQ-11650, Material Handling Device - Loader - With y Chute For Compression Machineanita shindeNo ratings yet

- Q-11650, Cage Bin - 600 LTRSDocument4 pagesQ-11650, Cage Bin - 600 LTRSanita shindeNo ratings yet

- Q-11650, Cage Blender-600 LTRSDocument7 pagesQ-11650, Cage Blender-600 LTRSanita shindeNo ratings yet

- The Kite ShopDocument2 pagesThe Kite Shopanita shindeNo ratings yet

- 2 CSS Word FileDocument12 pages2 CSS Word Fileronak waghelaNo ratings yet

- Propulsive PowerDocument13 pagesPropulsive PowerWaleedNo ratings yet

- Assignment/ TugasanDocument12 pagesAssignment/ TugasanfletcherNo ratings yet

- Colin Campbell - Interview The Lady in WhiteDocument1 pageColin Campbell - Interview The Lady in WhiteMarcelo OlmedoNo ratings yet

- Raising CapitalDocument43 pagesRaising CapitalMuhammad AsifNo ratings yet

- Roman Empire Revived TheoryDocument173 pagesRoman Empire Revived TheoryBrenoliNo ratings yet

- Group BehaviourDocument13 pagesGroup Behaviourtasnim taherNo ratings yet

- Line Follower Robot Using ArduinoDocument5 pagesLine Follower Robot Using Arduinochockalingam athilingam100% (1)

- "Yfa - R : Keyboard Percussion RangesDocument2 pages"Yfa - R : Keyboard Percussion RangesmadroalNo ratings yet

- Ebook PDF Contracts in Context From Transaction To Litigation Aspen Casebook PDFDocument40 pagesEbook PDF Contracts in Context From Transaction To Litigation Aspen Casebook PDFflorence.padilla424100% (35)

- Analisa Getaran BerlebihDocument5 pagesAnalisa Getaran BerlebihMatsaid ReksonoNo ratings yet

- The List of the Korean Companies in the UAE: Company Name 이름 Off. Tel Off. Fax P.O.BoxDocument34 pagesThe List of the Korean Companies in the UAE: Company Name 이름 Off. Tel Off. Fax P.O.Boxnguyen phuong anh100% (1)

- Case Study: Political PartiesDocument26 pagesCase Study: Political PartiesChaii100% (1)

- Gesc 112Document10 pagesGesc 112Kalpavriksha1974No ratings yet

- Book 1Document30 pagesBook 1uday sonawaneNo ratings yet

- Arnold Böcklin Was Born in Basel, Switzerland inDocument6 pagesArnold Böcklin Was Born in Basel, Switzerland inDragos PlopNo ratings yet

- SAP Manufacturing Implementation Architecture-1Document17 pagesSAP Manufacturing Implementation Architecture-1andriesbuterNo ratings yet

- Sample Thesis of Medical Record SystemDocument8 pagesSample Thesis of Medical Record Systemfj9dbfw4100% (1)

- Manual BeefDocument82 pagesManual Beefcmukasauk100% (1)

- Supplementary Cause List - 16.10.2023Document7 pagesSupplementary Cause List - 16.10.2023Aamir BhatNo ratings yet

- Bahasa InggrisDocument11 pagesBahasa InggrisrivanidurratulhikmahNo ratings yet

- Keith Richards PDFDocument3 pagesKeith Richards PDFLugrinderNo ratings yet

- Growth and Instability of Cotton Crop in Major Cotton Growing States in IndiaDocument5 pagesGrowth and Instability of Cotton Crop in Major Cotton Growing States in IndiaMultidisciplinary JournalNo ratings yet

- Manual Murray OkDocument52 pagesManual Murray OkGIOVANNINo ratings yet

- Script For My AssignmentDocument2 pagesScript For My AssignmentKarylle Mish GellicaNo ratings yet

- Action Plan in Edukasyong Pantahanan at Pangkabuhayan School Year 2017-2018Document3 pagesAction Plan in Edukasyong Pantahanan at Pangkabuhayan School Year 2017-2018MERLINDA PACQUIAONo ratings yet

- Ball Lesson PlanDocument3 pagesBall Lesson Planapi-350245383No ratings yet

- 26th Sunday in Ordinary Time HNSDocument232 pages26th Sunday in Ordinary Time HNSJeanette FormenteraNo ratings yet

- ELT Catalog Secondary PDFDocument26 pagesELT Catalog Secondary PDFRafael Cruz IsidoroNo ratings yet

- WB TBA19 020vadvance PDFDocument266 pagesWB TBA19 020vadvance PDFTran Khang92% (12)