Professional Documents

Culture Documents

Asme Sec Ix 2019 380

Uploaded by

Balkishan DyavanapellyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Asme Sec Ix 2019 380

Uploaded by

Balkishan DyavanapellyCopyright:

Available Formats

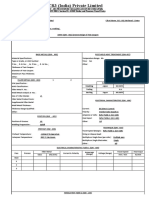

ASME BPVC.

IX-2019

FORM QW-483 SUGGESTED FORMAT FOR PROCEDURE QUALIFICATION RECORDS (PQR)

ð19Þ

(See QW-200.2, Section IX, ASME Boiler and Pressure Vessel Code)

Record Actual Variables Used to Weld Test Coupon

Organization Name

Procedure Qualification Record No. Date

WPS No.

Welding Process(es)

Types (Manual, Automatic, Semi-Automatic)

JOINTS (QW-402)

Groove Design of Test Coupon

(For combination qualifications, the deposited weld metal thickness shall be recorded for each filler metal and process used.)

BASE METALS (QW-403) POSTWELD HEAT TREATMENT (QW-407)

Material Spec. Temperature

Type or Grade, or UNS Number Time

P-No. Group No. to P-No. Group No. Other

Thickness of Test Coupon

Diameter of Test Coupon

Maximum Pass Thickness

Other

GAS (QW-408)

Percent Composition

Gas(es) (Mixture) Flow Rate

Shielding

FILLER METALS (QW-404) 1 2 Trailing

SFA Specification Backing

AWS Classification Other

Filler Metal F-No.

Weld Metal Analysis A-No. ELECTRICAL CHARACTERISTICS (QW-409)

Size of Filler Metal Current

Filler Metal Product Form Polarity

Supplemental Filler Metal Amps. Volts

Electrode Flux Classification Waveform Control

Flux Type Power or Energy

Flux Trade Name Arc Time

Weld Metal Thickness Weld Bead Length

Other Tungsten Electrode Size

Mode of Metal Transfer for GMAW (FCAW)

POSITION (QW-405) Heat Input

Position(s) Other

Weld Progression (Uphill, Downhill)

Other TECHNIQUE (QW-410)

Travel Speed

String or Weave Bead

PREHEAT (QW-406) Oscillation

Preheat Temperature Multipass or Single Pass (Per Side)

Interpass Temperature Single or Multiple Electrodes

Other Other

(07/17)

326

--`,``,``,,`,`,,````,`,``,,,`-`-`,,`,,`,`,,`---

Copyright ASME International (BPVC)

Provided by IHS under license with ASME Licensee=Khalda Petroleum/5986215001, User=Amer, Mohamed

No reproduction or networking permitted without license from IHS Not for Resale, 07/02/2019 13:22:09 MDT

You might also like

- Form Qw-483 Suggested Format For Procedure Qualification Records (PQR) (See QW-200.2, Section IX, ASME Boiler and Pressure Vessel Code) Record Actual Variables Used To Weld Test CouponDocument2 pagesForm Qw-483 Suggested Format For Procedure Qualification Records (PQR) (See QW-200.2, Section IX, ASME Boiler and Pressure Vessel Code) Record Actual Variables Used To Weld Test CouponMijanur Rahman100% (1)

- Suggested Format PQRDocument2 pagesSuggested Format PQRAngel RebolloNo ratings yet

- QW 483Document2 pagesQW 483delta lab sangliNo ratings yet

- Procedure Qualification RecordDocument2 pagesProcedure Qualification RecordDan ClarkeNo ratings yet

- WPS&PQR FormsDocument4 pagesWPS&PQR FormsArab WeldersNo ratings yet

- BPVC Ix qw-483 PDFDocument2 pagesBPVC Ix qw-483 PDFEmma DNo ratings yet

- BPVC Ix qw-483 PDFDocument2 pagesBPVC Ix qw-483 PDFDwi Agus YuliyantoNo ratings yet

- BPVC Ix qw-483 PDFDocument2 pagesBPVC Ix qw-483 PDFEmma DNo ratings yet

- PQR PROCEDURE QUALIFICATION RECORDDocument2 pagesPQR PROCEDURE QUALIFICATION RECORDEmma DNo ratings yet

- BPVC Ix qw-483 PDFDocument2 pagesBPVC Ix qw-483 PDFazizNo ratings yet

- BPVC Ix qw-483 PDFDocument2 pagesBPVC Ix qw-483 PDFedinson castrilloNo ratings yet

- QW-482 SUGGESTED FORMAT FOR WELDING PROCEDURE SPECIFICATIONSDocument2 pagesQW-482 SUGGESTED FORMAT FOR WELDING PROCEDURE SPECIFICATIONSVaibhav GuptaNo ratings yet

- Wps PQR FormDocument8 pagesWps PQR Formmayank0738No ratings yet

- Welding Procedure SpecificationDocument12 pagesWelding Procedure Specificationsanjay sharmaNo ratings yet

- FORM QW-482 WELDING PROCEDURE SPECIFICATIONDocument2 pagesFORM QW-482 WELDING PROCEDURE SPECIFICATIONsbmmlaNo ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)mohammadNo ratings yet

- SAMPLE FORMAT FOR PROCEDURE QUALIFICATION RECORDS (PQR) BPVC - Ix - qw-483Document2 pagesSAMPLE FORMAT FOR PROCEDURE QUALIFICATION RECORDS (PQR) BPVC - Ix - qw-483Lovedeep SinghNo ratings yet

- Fillet Inspection SheetDocument2 pagesFillet Inspection SheetShankey JAlanNo ratings yet

- FORM QW-482 WELDING PROCEDURE SPECIFICATION FORMATDocument6 pagesFORM QW-482 WELDING PROCEDURE SPECIFICATION FORMATStan HonNo ratings yet

- Wps FormatDocument2 pagesWps FormatMeghan GhoneNo ratings yet

- Formas Soldadura ASME IX 2017Document7 pagesFormas Soldadura ASME IX 2017Ulises GómezNo ratings yet

- Qw-483 Procedure Qualification Records (PQR) (See QW-200.2, Section IX, ASME Boiler and Pressure Vessel Code)Document3 pagesQw-483 Procedure Qualification Records (PQR) (See QW-200.2, Section IX, ASME Boiler and Pressure Vessel Code)Zam Zam NoorNo ratings yet

- QW-483 PQR PROCEDURE QUALIFICATION RECORDDocument6 pagesQW-483 PQR PROCEDURE QUALIFICATION RECORDZam Zam NoorNo ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)MALABAR TIMESNo ratings yet

- SC PTSS PQRDocument3 pagesSC PTSS PQRprayogaNo ratings yet

- 3 BodyPart Edcb3a5f Eede 445f A423 Ea2f5809c15eDocument6 pages3 BodyPart Edcb3a5f Eede 445f A423 Ea2f5809c15emayank0738No ratings yet

- PQR - 007 샘플Document2 pagesPQR - 007 샘플주용환No ratings yet

- PQR - 007 샘플Document2 pagesPQR - 007 샘플주용환No ratings yet

- WPS Format GuideDocument2 pagesWPS Format GuideKhaled bouhlelNo ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)pradeep4545No ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Muhammad MunadiNo ratings yet

- Procedure Qualification Record (PQR)Document3 pagesProcedure Qualification Record (PQR)surjithkocherilNo ratings yet

- WPS FormatDocument2 pagesWPS Formatakhilsyam21No ratings yet

- PT - SAE WPS PQR - MIGAS (PGDP) - Unlocked-2Document16 pagesPT - SAE WPS PQR - MIGAS (PGDP) - Unlocked-2Batara SinagaNo ratings yet

- PQR ASME SECTION IX WELD PROCEDUREDocument6 pagesPQR ASME SECTION IX WELD PROCEDUREZam Zam NoorNo ratings yet

- Smaw Manual See Permitted Figures (Right) or Per Constr. DWG Butt JointDocument3 pagesSmaw Manual See Permitted Figures (Right) or Per Constr. DWG Butt JointNirmala DeshaNo ratings yet

- JOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCDocument5 pagesJOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCmkhalil1148No ratings yet

- QW 483Document2 pagesQW 483Juan Manuel Fabregat MorenoNo ratings yet

- Suria Engineering: Procedure Qualification Record (PQR)Document2 pagesSuria Engineering: Procedure Qualification Record (PQR)suria qaqcNo ratings yet

- Welding Procedure Specification GuideDocument4 pagesWelding Procedure Specification GuideAndhira FarizkiNo ratings yet

- Tips Wps FormatDocument5 pagesTips Wps FormatWaqas WaqasNo ratings yet

- Wps PQR Welder Qualification Certification ConsultancyDocument2 pagesWps PQR Welder Qualification Certification ConsultancyEmam SayedNo ratings yet

- Ejemplo Prueba 991003Document2 pagesEjemplo Prueba 991003MARIO ALBANo ratings yet

- WPS-46 - Gtaw & Smaw Tig + SmawDocument8 pagesWPS-46 - Gtaw & Smaw Tig + SmawAvinash ShrivastavaNo ratings yet

- FORM QW-482 (Back) : ASME BPVC - IX-2019Document1 pageFORM QW-482 (Back) : ASME BPVC - IX-2019Balkishan DyavanapellyNo ratings yet

- METALS INSPECTION SERVICES WELDING PROCEDUREDocument6 pagesMETALS INSPECTION SERVICES WELDING PROCEDURELuis MuñozNo ratings yet

- Qw-483 Suggested Format For Welding Procedure Qualification Records (PQR)Document4 pagesQw-483 Suggested Format For Welding Procedure Qualification Records (PQR)aliNo ratings yet

- Qw-483 Procedure Qualification Records (PQR: Groove Design of Test Coupon Base Metals (Qw-403) Filler Metals (Qw-404)Document2 pagesQw-483 Procedure Qualification Records (PQR: Groove Design of Test Coupon Base Metals (Qw-403) Filler Metals (Qw-404)Parminder SinghNo ratings yet

- PQRDocument2 pagesPQRafqzfieNo ratings yet

- PQR (52a) ModelDocument1 pagePQR (52a) ModelSIDDHARTH BEHERAYNo ratings yet

- WPS Vessel 1Document4 pagesWPS Vessel 1Naqqash SajidNo ratings yet

- AMRITA ENGINEERING WORKS PQRDocument3 pagesAMRITA ENGINEERING WORKS PQRBalkishan DyavanapellyNo ratings yet

- Form QW-482 Welding Procedure Specification FormatDocument4 pagesForm QW-482 Welding Procedure Specification FormatJesus Silva HenaoNo ratings yet

- PQR Editable SampleDocument2 pagesPQR Editable SampleKoya ThangalNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Welding for Challenging Environments: Proceedings of the International Conference on Welding for Challenging Environments, Toronto, Ontario, Canada, 15–17 October 1985From EverandWelding for Challenging Environments: Proceedings of the International Conference on Welding for Challenging Environments, Toronto, Ontario, Canada, 15–17 October 1985No ratings yet

- Asme B31e-2008Document34 pagesAsme B31e-2008Balkishan DyavanapellyNo ratings yet

- STG GuidelinesDocument31 pagesSTG GuidelinesJoseph2309100% (2)

- 2 - Boiler HydrotestDocument22 pages2 - Boiler HydrotestMY NAME IS NEERAJ..:):)No ratings yet

- Best Practices in O&M of Thermal Power Stations: Tutorial Course OnDocument4 pagesBest Practices in O&M of Thermal Power Stations: Tutorial Course OnGaurav Singh0% (2)

- GHG Manual Thermal Power Plant PDFDocument45 pagesGHG Manual Thermal Power Plant PDFhonchoabhiNo ratings yet

- OPGC O & M WorksDocument233 pagesOPGC O & M WorksBalkishan DyavanapellyNo ratings yet

- RT Flash CardsDocument13 pagesRT Flash CardsBalkishan DyavanapellyNo ratings yet

- Asnt Standard - Cp189 - 2020Document4 pagesAsnt Standard - Cp189 - 2020Balkishan DyavanapellyNo ratings yet

- Id Fan Technical SpecDocument8 pagesId Fan Technical SpecBalkishan DyavanapellyNo ratings yet

- Asme B31e-2008Document34 pagesAsme B31e-2008Balkishan DyavanapellyNo ratings yet

- Iiw India Individual Membership Application Form Apr 2020Document3 pagesIiw India Individual Membership Application Form Apr 2020Balkishan DyavanapellyNo ratings yet

- Index B31Document2 pagesIndex B31Balkishan DyavanapellyNo ratings yet

- BQCP - 23 - Valves (Gate, Globe) Overhauling ProcedureDocument2 pagesBQCP - 23 - Valves (Gate, Globe) Overhauling ProcedureBalkishan DyavanapellyNo ratings yet

- Based Hardfacing Alloys: Cobalt & NickelDocument20 pagesBased Hardfacing Alloys: Cobalt & NickelsabrunoNo ratings yet

- BQCP - 24 - Insitu Repair Procedure For Primary Reheater Stub WeldsDocument2 pagesBQCP - 24 - Insitu Repair Procedure For Primary Reheater Stub WeldsBalkishan DyavanapellyNo ratings yet

- Radiography Test Acceptance Criteria: Type of Defects Asme Sec - Ix ASME B31.1 Asme Sec - I Asme Sec Viii Div-1 IBRDocument2 pagesRadiography Test Acceptance Criteria: Type of Defects Asme Sec - Ix ASME B31.1 Asme Sec - I Asme Sec Viii Div-1 IBRBalkishan DyavanapellyNo ratings yet

- Daily - Field Inspection Sheet (Date:-Xx - Xx.2018)Document7 pagesDaily - Field Inspection Sheet (Date:-Xx - Xx.2018)Balkishan DyavanapellyNo ratings yet

- Specification For Bare Electrodes and Rods For Surfacing: AWS A5.21:2001 An American National StandardDocument7 pagesSpecification For Bare Electrodes and Rods For Surfacing: AWS A5.21:2001 An American National StandardBalkishan DyavanapellyNo ratings yet

- Support Structure ProtocolDocument11 pagesSupport Structure ProtocolBalkishan DyavanapellyNo ratings yet

- RT Acceptance Criteria 10062019Document1 pageRT Acceptance Criteria 10062019Balkishan Dyavanapelly100% (2)

- NTPC Ge Power Services PVT LTD: Liquid Penetrant Examination ReportDocument2 pagesNTPC Ge Power Services PVT LTD: Liquid Penetrant Examination ReportBalkishan DyavanapellyNo ratings yet

- WPQ Format - SMAWDocument3 pagesWPQ Format - SMAWBalkishan DyavanapellyNo ratings yet

- System Punch List: CategoryDocument4 pagesSystem Punch List: CategoryBalkishan DyavanapellyNo ratings yet

- Welding Report FormattedDocument1 pageWelding Report FormattedBalkishan DyavanapellyNo ratings yet

- Daily - Field Inspection Sheet (Date:-Xx - Xx.2018)Document7 pagesDaily - Field Inspection Sheet (Date:-Xx - Xx.2018)Balkishan DyavanapellyNo ratings yet

- Consumable Receipt ReportDocument1 pageConsumable Receipt ReportBalkishan DyavanapellyNo ratings yet

- Record of Welder or Welding Operator Qualification TestsDocument1 pageRecord of Welder or Welding Operator Qualification TestsBalkishan DyavanapellyNo ratings yet

- WPQ Format - SMAWDocument3 pagesWPQ Format - SMAWBalkishan DyavanapellyNo ratings yet

- Welding Report FormattedDocument1 pageWelding Report FormattedBalkishan DyavanapellyNo ratings yet

- Consumable Receipt Report: Received Goods From:-C.R.R.No: - Delivery Challan No: - Delivery DateDocument1 pageConsumable Receipt Report: Received Goods From:-C.R.R.No: - Delivery Challan No: - Delivery DateBalkishan DyavanapellyNo ratings yet

- Grade 10 - Module 1Document3 pagesGrade 10 - Module 1Dypsy Pearl A. PantinopleNo ratings yet

- 342 Mechanical and Fluid Drive Maintenance Course DescriptionDocument2 pages342 Mechanical and Fluid Drive Maintenance Course Descriptionaa256850No ratings yet

- Study Plan VMware VSphere 6.5Document11 pagesStudy Plan VMware VSphere 6.5Milan PatelNo ratings yet

- San Diego Quick AssessmentDocument56 pagesSan Diego Quick AssessmentLizNo ratings yet

- GPSForex Robot V2 User GuideDocument40 pagesGPSForex Robot V2 User GuideMiguel Angel PerezNo ratings yet

- Lec # 10 Earthing and GroundingDocument68 pagesLec # 10 Earthing and GroundingSaddam jatt786No ratings yet

- Spraying TechniquesDocument12 pagesSpraying TechniquesX800XLNo ratings yet

- Centered Nursing Process Approach (9th Ed.) - St. Louis, MO: ElsevierDocument1 pageCentered Nursing Process Approach (9th Ed.) - St. Louis, MO: ElsevierfaizaNo ratings yet

- HypertensionDocument26 pagesHypertensionAbdalrhman Zaqqa100% (1)

- CancioneroDocument7 pagesCancioneroJocelyn Almaguer LariosNo ratings yet

- Sakha DictionaryDocument14 pagesSakha DictionarySojeong MinNo ratings yet

- Percent CompositionDocument4 pagesPercent CompositionTshiamo MotaungNo ratings yet

- VKS INFRA DPR Submission for NHAI Bihar ProjectDocument1 pageVKS INFRA DPR Submission for NHAI Bihar ProjectamirNo ratings yet

- Introduction To SQL Programming TechniquesDocument24 pagesIntroduction To SQL Programming Techniquesakashdeepime100% (2)

- Defying Danger RPGDocument9 pagesDefying Danger RPGmondytriggers2944No ratings yet

- Cilegon-Order Material Pt. Quantum Radja Perkasa-280823Document1 pageCilegon-Order Material Pt. Quantum Radja Perkasa-280823Ria Maretta DewiNo ratings yet

- Section 08500 - Windows: Whole Building Design Guide Federal Green Construction Guide For SpecifiersDocument7 pagesSection 08500 - Windows: Whole Building Design Guide Federal Green Construction Guide For SpecifiersAnonymous NMytbMiDNo ratings yet

- Quiz 10Document6 pagesQuiz 10Kath RiveraNo ratings yet

- Process Payments & ReceiptsDocument12 pagesProcess Payments & ReceiptsAnne FrondaNo ratings yet

- ENGG378 - 948 HydroPower-Lecture - 1 - 2019 PDFDocument34 pagesENGG378 - 948 HydroPower-Lecture - 1 - 2019 PDFJ CNo ratings yet

- The Teacher and Student Relationship of Haydn and BeethovenDocument10 pagesThe Teacher and Student Relationship of Haydn and BeethovenVinny MuscarellaNo ratings yet

- Ratio - Proportion - PercentDocument31 pagesRatio - Proportion - PercentRiyadh HaiderNo ratings yet

- ECT ModelDocument12 pagesECT Modelhii_bhartiNo ratings yet

- Crescent Moon InstructionsDocument7 pagesCrescent Moon InstructionsSARANo ratings yet

- Training ReportDocument56 pagesTraining ReportRavimini100% (2)

- Clarke 1973 Loss of InnocenceDocument13 pagesClarke 1973 Loss of InnocencePaula TralmaNo ratings yet

- Iranian Food Enquiries ReportDocument22 pagesIranian Food Enquiries Reportswapnilrane03100% (1)

- Insurance - Unit 3&4Document20 pagesInsurance - Unit 3&4Dhruv GandhiNo ratings yet

- Solar Bloc DatasheetDocument2 pagesSolar Bloc DatasheetandresNo ratings yet

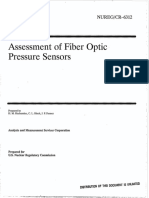

- Assessment of Fiber Optic Pressure Sensors: NUREG/CR-6312Document133 pagesAssessment of Fiber Optic Pressure Sensors: NUREG/CR-6312abhrajitsahaNo ratings yet