Professional Documents

Culture Documents

Repair of Fire-Damaged Reinforced Concrete Columns: Aci Structural Journal Technical Paper

Uploaded by

picottOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Repair of Fire-Damaged Reinforced Concrete Columns: Aci Structural Journal Technical Paper

Uploaded by

picottCopyright:

Available Formats

ACI STRUCTURAL JOURNAL TECHNICAL PAPER

Title no. 92-S38

Repair of Fire-Damaged Reinforced Concrete Columns

by Chien-Hung Lin, Shun-Tyan Chen, and Chen-An Yang

Both analytical and experimental methods were employed to investigate the

behavior of reinforced concrete columns repaired after fire. Eleven col-

umns were first exposed to various durations of fire and then repaired

based on results of thermal analyses using the finite element method. The

unheated and repaired columns were subjected to eccentric axial loads to

determine their stiffness and ultimate strengths. The results show that most

repaired columns could develop their original strength and stiffness or

even higher than those of unheated columns. Also, the analytical results

coincide with the experimental data.

Keywords: columns (supports); fires; reinforced concrete; repairs; stiff-

ness; strength.

If a reinforced concrete structure is exposed to a fire, the

question that arises is whether the structure is still adequate

to safely sustain the original design loads, since it is usually

more economical to repair the structure than rebuild it.

Research1-3 has been done to evaluate the strength and stiff-

ness of reinforced concrete columns after fires. This paper

Fig. 1—Test specimen.

presents an experimental study on repairing fire-damaged

concrete columns. Eleven columns with different cross

sections were exposed to various furnace-simulated levels of

needed data to those who may be engaged in rehabilitation of

fire environment to evaluate damage to the concrete columns

concrete columns after fire.

and subsequent repair procedures. The repair work involved

removing surface layers of calcined concrete and surface

SPECIMENS AND TEST PROCEDURES

cleaning and patching using specially designed concrete. A total of 11 square cross section test columns were made

The required strength of the repair concrete was determined for this study. The cross section dimensions were 400 mm

by means of thermal analyses based on finite element (15.7 in.), 300 mm (11.8 in.), and 200 mm (7.9 in.) square.

scheme. The analyses determined the temperature distribu- Details of the test columns are shown in Fig. 1 and Table 1.

tion in the column section during fire, computed the temper- Chromel-alumel K-type thermocouples that were 1.0 mm

ature effect on the residual strength of concrete, and varied were installed in each test column to monitor the temperature

the strength of repair concrete to find the required value to distribution through the cross sections during fire simula-

restore the original strength of the column cross sections. tions. The maximum temperature that can be measured by

After the columns were repaired, load tests were carried out. this type of thermocouple is 950 C (1742 F). It has been

The results of repaired columns were compared with those of shown that the temperature variation along the longitudinal

columns that were not exposed to fire (undamaged) to verify direction of the column is not significant;1 thermocouples

the adequacy of repair and the finite element analyses. were installed across one cross section at midheight of the

column. The locations of the thermocouples are shown in Fig. 2.

RESEARCH SIGNIFICANCE

Research on residual strengths of fire-damaged concrete ACI Structural Journal, V. 92, No. 4, July-August 1995.

columns has been reported. However, the literature survey Received November 3, 1994, and reviewed under Institute publication policies.

Copyright © 1995, American Concrete Institute. All rights reserved, including the

reveals that no data on repaired columns were conceivably making of copies unless permission is obtained from the copyright proprietors.

Pertinent discussion will be published in the May-June 1996 ACI Materials Journal if

available. The objective of this study is to generate the received by January 1, 1996.

406 ACI Structural Journal/July-August 1995

columns. The test setup is sketched in Fig. 3. The load was

ACI member Chien-Hung Lin is a professor of civil engineering at National Chung-

Hsing University, Taiwan, Republic of China. He received his MS and PhD degrees applied through displacement control so that the descending

from the University of Texas at Austin. His research interests include reinforced con- portion of the load-deformation curve could be obtained

crete structures and structural analysis. correctly. Readings from the dial gages were converted to the

Shun-Tyan Chen is a professor of construction engineering at National Taiwan Insti- column curvature at each load step.

tute of Technology, Taiwan, Republic of China. He received his PhD degree from the

University of Washington at Seattle. His research interests include finite element mod-

eling of reinforced concrete structures and construction engineering.

FINITE ELEMENT ANALYSES

A finite element computer program was developed5 to

Chen-An Yang is a former graduate student of construction engineering at National calculate the temperature distribution in the test columns

Taiwan Institute of Technology, and currently a PhD candidate in civil engineering at during fire. The results were used in conjunction with phys-

National Taiwan University.

ical properties of concrete exposed to fire to evaluate the

residual strength and stiffness of the column section. The

Ready-mixed concrete was used to cast the test columns. stress-strain curve for concrete after exposure to fire may be

After 28 days, the specimens were placed in a gas furnace, represented by the following:

which measured 4000 mm (157.5 in.) long, l500 mm (59.l for εc ≤ εo

in.) wide, and 1500 mm (59.1 in.) deep. The heat input was

controlled manually so that the average furnace temperature ε o – ε c⎞ 2

closely followed the BS476 temperature rise curve4 f c = f rc 1 – ⎛ ---------------

- (2)

⎝ ε ⎠

o

T = 345log(480t + 1) (1)

for εc > εo

where T is the temperature, C, and t is the time, hr. The test

columns were exposed to the simulated fire for the durations ε c – ε o⎞ 2

f c = f rc 1 – ⎛ ---------------

- (3)

specified in Table 1, cooled to ambient temperature, and ⎝ 3ε ⎠

o

taken out of the furnace. The damaged exterior concrete on

the heated columns was mechanically removed and repaired

with fresh cast-in-place concrete. The required design mix or in which

minimum compressive strength for the fresh concrete for

each damaged column was evaluated using finite element εo = 0.0025 + (6.0T + 0.04T 2) × 10–6 (4)

analyses. The strength of the new concrete had to be higher

than the original specified minimum to compensate for the frc = fco(1 – 0.001T) for T ≤ 500°C (5)

concrete strength loss in the column core. Before the new

concrete was cast, cement paste was placed on the roughened

surface of the concrete core to insure a good bond between

old and new concrete. The w/c of the cement paste was 0.5.

An expansive admixture was used in the new concrete mix

to reduce shrinkage.

After the repair concrete reached 28-day strength, the

columns were load-tested with a 600-ton MTS machine. The

axial load was applied eccentrically. To monitor the axial

deformation and curvature, six dial gages were installed

along the column. Swivel heads were employed to simulate

hinge-type connection at the top and bottom of the test Fig. 2—Locations of thermocouples.

Table 1—Specimen detail

Area of longitudinal Section size, Thickness of Eccentricity of Duration of fco of repair

Specimen no. steel, cm2 fy, MPa fco , MPa cm concrete cover, cm Tie spacing, cm axial load, cm fire, hr concrete, MPa

D1T0 23.2 391 18.6 40 x40 5.0 25.0 20.0 0 —

D1T1 23.2 391 18.6 40 x 40 5.0 25.0 20.0 1 30.9

DlT2 23.2 391 18.6 40 x 40 5.0 25.0 20.0 2 34.3

DlT3 23.2 391 18.6 40 x 40 5.0 25.0 20.0 3 33.2

D2T0 15.5 391 18.6 30 x 30 5.0 25.0 15.0 0 —

D2T1 15.5 391 18.6 30 x 30 5.0 25.0 15.0 1 30.3

D2T2 15.5 391 18.6 30 x 30 5.0 25.0 15.0 2 31.7

D3T0 7.6 435 18.6 20 x 20 6.0 20.0 10.0 0 —

D3T1 7.6 435 18.6 20 x 20 6.0 20.0 10.0 1 39.8

D3T2 7.6 435 18.6 20 x 20 6.0 20.0 10.0 2 39.8

D3T3 7.6 435 18.6 20 x 20 6.0 20.0 10.0 3 39.8

ACI Structural Journal/July-August 1995 407

Fig. 3—Test setup.

Fig. 5—Temperature distribution in column section, D1

specimens.

fc = fco k[1 – Zm(εc – εo)] for εc ≥ εo (9)

but

fc ≥ 0.2kfco

where

ρ s f y⎞

k = ⎛ 1 + --------

-

Fig. 4—Temperature rise curves. ⎝ f ⎠ co

frc = fco(1.375 – 0.00175T) for 500°C ≤ T ≤ 700°C (6) εco = 0.002k

frc = 0 for T > 700°C (7)

0.5

Z m = -------------------------------------

-

where ε 50u + ε 50h – ε o

fco = cylinder strength of concrete not exposed to fire, at

28 days ε50u = strain of unconfined concrete corresponding to 0.5fco

frc = residual strength of concrete after fire ε50u + ε50h = strain of confined concrete corresponding to 0.5fco

fc = concrete stress ρs = volumetric ratio of transverse reinforcement.

εc = concrete strain The reinforcing steel will recover almost all its original

εo = concrete strain corresponding to frc strength after cooling to ambient temperature.1,8 Thus, the

T = highest temperature attained by concrete stress-strain relations for steel before and after fire employed

The preceding stress-strain relations for concrete after fire in this study may be expressed by

were obtained by combining the stress-strain curve for

concrete under fire,6 and relations between residual strength fs = Es εs for εs ≤ εy (10)

and temperature of concrete.1

The stress-strain curve for concrete not exposed to fire can fs = fy for εs > εy (11)

be represented by7

where

2ε ε

f c = f co k -------c- – ⎛ ----c-⎞ for 0 ≤ εc ≤ εo (8) fs = steel stress

εo ⎝ ε o⎠ εs = steel strain

408 ACI Structural Journal/July-August 1995

Table 2—Thermocouple readings, C, versus time, min

D1T3 D2T2 D3T3

Fire dura-

tion, min S1 S2 S3 Ml M2 M3 M4 L1 L2 L3 L4 L5

10 20.2 25.8 45.2 19.6 19.6 34.7 104.7 17.8 17.8 19.0 31.3 74.6

20 39.2 61.2 109.5 30.9 29.6 90.8 169.9 17.9 18.4 30.8 68.4 118.4

30 105.4 119.9 136.3 55.9 59.2 120.5 259.0 18.9 20.5 49.7 109.9 165.7

40 126.5 130.2 153.7 92.9 88.6 119.8 324.2 22.4 30.2 97.1 116.1 229.2

50 111.6 118.5 195.0 105.8 105.2 134.1 378.7 52.6 104.2 114.8 126.8 289.9

60 111.8 134.6 242.6 109.1 110.2 164.9 426.2 95.6 115.8 116.7 158.2 340.1

70 113.9 172.9 295.6 106.3 107.5 196.3 469.1 104.9 114.5 115.1 190.3 383.5

80 138.3 219.0 346.7 104.8 105.8 227.2 511.3 107.6 112.6 113.4 222.0 422.4

90 190.0 267.8 395.7 104.1 106.3 258.5 549.5 108.2 110.6 123.1 252.0 458.6

100 245.9 316.9 442.9 104.6 115.7 289.5 586.3 107.8 109.0 140.7 279.7 493.5

110 297.5 364.6 489.0 114.7 128.2 320.1 621.8 106.7 107.3 156.4 307.0 526.7

120 343.8 410.6 532.4 130.1 148.0 349.7 642.2 105.7 106.0 180.2 333.7 559.3

130 388.3 454.4 574.6 — — — — 104.7 105.0 200.4 360.4 592.1

140 430.2 494.4 617.8 — — — — 103.7 104.0 221.1 386.6 622.9

150 471.1 530.9 659.1 — — — — 103.5 103.6 242.6 412.6 653.0

160 507.9 561.9 699.9 — — — — 102.8 103.0 263.5 437.6 682.3

170 532.5 600.0 739.0 -— — — — 102.0 101.9 282.2 460.4 709.3

180 546.4 640.0 776.2 — — — — 102.0 109.3 303.2 485.4 733.3

Fig. 6—Test results of Specimen D1T1. Fig. 7—Test results of Specimen D1T2.

εy = yield strain of steel ical results. Curve 1 represents the analytical load-curvature

Es = modulus of elasticity of steel relations of the fire-exposed but unrepaired column, Curve 2

The residual strength and stiffness of the test columns with represents the analytical load-curvature relations of the fire-

eccentric axial loading can then be derived from load-curva- exposed and repaired column, Curve 3 represents the exper-

ture analysis. imental load-curvature relations of the fire-exposed and

repaired column, and Curve 4 represents the experimental

RESULTS AND DISCUSSION load-curvature relations of the undamaged column not

The measured furnace temperature followed by Eq. (1) is

exposed to fire. In Fig. 6 and 7, the repaired columns

shown in Fig. 4. The measured temperature distribution in

regained about the same strength and stiffness as the undam-

the column sections coincide with the analytical temperature

distribution as shown in Fig. 5. Temperature readings from aged column not exposed to fire. But in Fig. 8, because weak

thermocouples versus time are shown in Table 2. repair concrete cover spalled early in the load test, the

During load tests, the readings from dial gages were repaired column showed a much lower strength. Fig. 9 and

converted to curvature. The load-curvature curves for all the 10 show good comparisons. The repaired 30 x 30-cm test

test columns are plotted in Fig. 6 through 13. In each of these columns regained about the same strength as the undamaged

figures, comparisons can be made between unrepaired column. In Fig. 11 and 12, owing to mix proportions, which

columns and repaired columns, and experimental and analyt- yielded excessive compressive strength of the new concrete,

ACI Structural Journal/July-August 1995 409

Fig. 8—Test results of Specimen D1T3.

Fig. 11—Test results of Specimen D3T1.

Fig. 9—Test results of Specimen D2T1.

Fig. 12—Test results of Specimen D3T2.

Fig. 10—Test results of Specimen D2T2.

Fig. 13—Test results of Specimen D3T3.

the repaired columns showed higher strength and stiffness

than the undamaged columns. In Fig. 13, the experimental

and analytical results are again close enough. columns that were damaged by fire can be repaired to retain

In the preceding comparisons, the analytical results coin- their original strength and stiffness, if the repair work is

cide with the experimental results. Also, the concrete properly done.

410 ACI Structural Journal/July-August 1995

CONCLUSIONS t = fire duration, hr

Both analytical and experimental methods were employed T = highest temperature attained by concrete, C

to investigate the strength and stiffness of reinforced εc = strain in concrete

εo = concrete strain corresponding to maximum stress

concrete columns repaired after fire damage. The results εs = strain in reinforcement

showed that the analytical approach is a useful tool and that εy = yield strain of steel

damaged columns are, in general, repairable. They also indi- ρs = volumetric ratio of transverse reinforcement

cated that the stress-strain curve for concrete after fire repre-

sented by Eq. (2) and (3) is reasonable, as shown in the REFERENCES

1. Lie, T. T.; Rowe, T. J.; and Lin, T. D., “Residual Strength of Fire

comparisons of analytical and experimental results. Exposed RC Columns,” Evaluation and Repair of Fire Damage to Con-

crete, SP-92, American Concrete Institute, Detroit, 1986, pp. 153-174.

ACKNOWLEDGMENTS 2. Lin, C. H.; Chen, S. T.; and Hwang, T. L., “Residual Strength of RC

The study described in this paper was sponsored through Grant No. NSC78- Columns Exposed to Fire,” Journal, Chinese Institute of Engineers (Tai-

0410-E011-13 by the National Science Council, Taiwan, R.O.C. The authors wan), V. 12, No. 5, 1989, pp. 557-565.

gratefully acknowledge the support. Thanks are also extended to National 3. Lin, C. H., and Tsay, C. S., “Deterioration of Strength and Stiffness of

Taiwan Institute of Technology for providing the needed test facilities. RC Columns after Fire,” Journal, Chinese Institute of Engineers (Taiwan),

V. 13, No. 3, 1990, pp. 273-283.

4. British Standards Institution, “Fire Tests on Building Materials and

CONVERSION FACTORS Structures, Part 8: Test Methods and Criteria for the Fire Resistance of Ele-

2.54 cm = l in.

1 MPa = 145 psi ments of Building Construction,” BS 476, London, 1972.

1 cm = 10 mm 5. Shieh, T. H., “Behavior of RC Members after Fire Analyzed by Finite

1 kN = 224.8 lb Element Method,” MS thesis, Department of Construction Engineering,

National Taiwan Institute of Technology, Taipei, 1989.

NOTATION 6. Lie, T. T.; Lin, T. D.; Allen, D. E.; and Abrams, M. S., “Fire Resis-

b = width of column section tance of Reinforced Concrete Columns,” National Research Council Can-

Es = modulus of elasticity of reinforcement ada, Division of Building Research, DBR Paper 1167, NRCC 23065,

fc = stress in concrete Ottawa, 1984.

fco = cylinder strength of concrete without being exposed to fire 7. Scott, B. D.; Park, R.; and Priestley, M. J. N., “Stress-Strain Behavior

frc = residual strength of concrete after exposed to temperature, T of Concrete Confined by Overlapping Hoops at Low and High Strain

fs = stress in reinforcement Rate,” ACI JOURNAL, Proceedings V. 79, No. 1, 1982, pp. 13-27.

fy = yield stress of reinforcement 8. Malhotra, H. L., Design of Fire-Resisting Structures, Chapman &

h = depth of column section Hall, New York, 1982, 226 pp.

ACI Structural Journal/July-August 1995 411

You might also like

- Strength Evaluation of Shotcrete Repaired Beams: Aci Structural Journal Technical PaperDocument5 pagesStrength Evaluation of Shotcrete Repaired Beams: Aci Structural Journal Technical PaperpicottNo ratings yet

- Shear Resistance of Connections Between Reinforced Concrete Linear Precast ElementsDocument34 pagesShear Resistance of Connections Between Reinforced Concrete Linear Precast ElementspicottNo ratings yet

- Strength of Reinforced Concrete Corbles With Fibers: Aci Structural Journal Technical PaperDocument8 pagesStrength of Reinforced Concrete Corbles With Fibers: Aci Structural Journal Technical PaperpicottNo ratings yet

- Modeling of Concrete Damage: Aci Structural Journal Technical PaperDocument12 pagesModeling of Concrete Damage: Aci Structural Journal Technical PaperpicottNo ratings yet

- Lateral Displacement Ductility of Reinforced Concrete Flat PlatesDocument9 pagesLateral Displacement Ductility of Reinforced Concrete Flat PlatespicottNo ratings yet

- Creep Model For Reinforced Concrete Columns: Aci Structural Journal Technical PaperDocument5 pagesCreep Model For Reinforced Concrete Columns: Aci Structural Journal Technical PaperpicottNo ratings yet

- Membrane Analysis of Flat Plate Slabs: Aci Structural Journal Technical PaperDocument10 pagesMembrane Analysis of Flat Plate Slabs: Aci Structural Journal Technical PaperpicottNo ratings yet

- Torsional Response of Reinforced Fibrous Concrete Beams: Aci Structural Journal Technical PaperDocument9 pagesTorsional Response of Reinforced Fibrous Concrete Beams: Aci Structural Journal Technical PaperpicottNo ratings yet

- Response of Reinforced Concrete Columns To Simulated Seismic LoadingDocument10 pagesResponse of Reinforced Concrete Columns To Simulated Seismic LoadingpicottNo ratings yet

- Torsion in Concrete Deep Beams With An Opening: Aci Structural Journal Technical PaperDocument6 pagesTorsion in Concrete Deep Beams With An Opening: Aci Structural Journal Technical PaperpicottNo ratings yet

- Softened Truss Model Theory For Shear and Torsion: Aci Structural Journal Technical PaperDocument12 pagesSoftened Truss Model Theory For Shear and Torsion: Aci Structural Journal Technical PaperpicottNo ratings yet

- Interaction of Concrete and Curved Reinforcement As Applied To Construction PracticeDocument29 pagesInteraction of Concrete and Curved Reinforcement As Applied To Construction PracticepicottNo ratings yet

- Strength of Concrete On An Extremely Small Bearing Area: Aci Structural Journal Technical PaperDocument9 pagesStrength of Concrete On An Extremely Small Bearing Area: Aci Structural Journal Technical PaperpicottNo ratings yet

- Angetal Circolari PDFDocument15 pagesAngetal Circolari PDFCiro AscioneNo ratings yet

- Cracking Load For A Wind-Loaded Reinforced Concrete Cooling TowerDocument8 pagesCracking Load For A Wind-Loaded Reinforced Concrete Cooling TowerpicottNo ratings yet

- Nonlinear Finite Element Analysis of Reinforced Concrete MembranesDocument10 pagesNonlinear Finite Element Analysis of Reinforced Concrete MembranespicottNo ratings yet

- Air Entrainment in The Presence of Superplasticizers: Aci Journal Technical PaperDocument6 pagesAir Entrainment in The Presence of Superplasticizers: Aci Journal Technical PaperpicottNo ratings yet

- Computer-Aided Concrete Mix Proportioning: Aci Journal Technical PaperDocument6 pagesComputer-Aided Concrete Mix Proportioning: Aci Journal Technical PaperpicottNo ratings yet

- Serviceability Behavior and Failure Mechanisms of Concrete Inverted T-Beam Bridge BentcapsDocument11 pagesServiceability Behavior and Failure Mechanisms of Concrete Inverted T-Beam Bridge BentcapspicottNo ratings yet

- High-Strength Concrete Deep Beams With Effective Span and Shear Span VariationsDocument9 pagesHigh-Strength Concrete Deep Beams With Effective Span and Shear Span VariationspicottNo ratings yet

- Durability of Some Glass Fiber Reinforced Cement CompositesDocument7 pagesDurability of Some Glass Fiber Reinforced Cement CompositespicottNo ratings yet

- Performance of High-Strength Concrete Corbels: Aci Structural Journal Technical PaperDocument9 pagesPerformance of High-Strength Concrete Corbels: Aci Structural Journal Technical PaperpicottNo ratings yet

- The Performance of Epoxy-Coated Shear Reinforcement: Aci Structural Journal Technical PaperDocument7 pagesThe Performance of Epoxy-Coated Shear Reinforcement: Aci Structural Journal Technical PaperpicottNo ratings yet

- Flexural Strength of Reinforced Polymer Concrete Made With Recycled Plastic WasteDocument7 pagesFlexural Strength of Reinforced Polymer Concrete Made With Recycled Plastic WastepicottNo ratings yet

- Modeling Nonlinear Bond-Slip Behavior For Finite Element Analyses of Reinforced Concrete StructuresDocument6 pagesModeling Nonlinear Bond-Slip Behavior For Finite Element Analyses of Reinforced Concrete StructurespicottNo ratings yet

- Flexural Strength of Externally Prestressed Concrete BridgesDocument11 pagesFlexural Strength of Externally Prestressed Concrete BridgespicottNo ratings yet

- Effect of High-Strength Concrete Columns On The Behavior of Slab-Column ConnectionsDocument8 pagesEffect of High-Strength Concrete Columns On The Behavior of Slab-Column ConnectionspicottNo ratings yet

- Bond Stress-Slip Response of Reinforcing Bars Embedded in FRC Matrices Under Monotonic and Cyclic LoadingDocument12 pagesBond Stress-Slip Response of Reinforcing Bars Embedded in FRC Matrices Under Monotonic and Cyclic LoadingpicottNo ratings yet

- Seismic Assessment of The Santa Monica Viaduct Bent Details: Aci Structural Journal Technical PaperDocument12 pagesSeismic Assessment of The Santa Monica Viaduct Bent Details: Aci Structural Journal Technical PaperpicottNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidraulica 6.125Document19 pagesHidraulica 6.125Mario MedinaNo ratings yet

- Design of Evaporator Cooling Coil For Cooling Load Abhijeet Samal1 Mechanical Engineering B.M.S College of Engineering, BengaluruDocument4 pagesDesign of Evaporator Cooling Coil For Cooling Load Abhijeet Samal1 Mechanical Engineering B.M.S College of Engineering, BengaluruPT VeritasNo ratings yet

- The Principles of Air Flow, Air Pressure, and Air FiltrationDocument12 pagesThe Principles of Air Flow, Air Pressure, and Air FiltrationONAFUWA AyodeleNo ratings yet

- Quiz Bee - QuestionsDocument14 pagesQuiz Bee - QuestionsLaurence Blaire IonNo ratings yet

- Belt, Rope and Chain DrivesDocument60 pagesBelt, Rope and Chain DrivesJason Dequin VillarosaNo ratings yet

- NWJ s2 Yousra ZghoundiDocument10 pagesNWJ s2 Yousra ZghoundioussamaNo ratings yet

- What Is Free Energy Generator - Flywheel Working - Advantages & Disadvantages of Free Energy GeneratorDocument14 pagesWhat Is Free Energy Generator - Flywheel Working - Advantages & Disadvantages of Free Energy GeneratorPieter SteenkampNo ratings yet

- Phase Difference & Phase RelationshipsDocument24 pagesPhase Difference & Phase RelationshipsGabriel Carl AlpuertoNo ratings yet

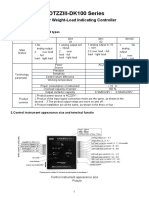

- PESA CARGA DTZZIII-DK100系列说明书英文Document6 pagesPESA CARGA DTZZIII-DK100系列说明书英文NelsonEnrriqueInfante100% (2)

- Zincform G300 G300SDocument2 pagesZincform G300 G300SBaziNo ratings yet

- JO003-10-LB - MDD-IDM-001-3 P&ID Steam and Bypass SystemDocument9 pagesJO003-10-LB - MDD-IDM-001-3 P&ID Steam and Bypass SystemHasan MustafaNo ratings yet

- Siemens Electric Motor 15hp 1500rpmDocument17 pagesSiemens Electric Motor 15hp 1500rpmShamsul HaqueNo ratings yet

- Local Manufacture of Cast Resin Transformers: Transmission and DistributionDocument2 pagesLocal Manufacture of Cast Resin Transformers: Transmission and DistributionSharafat AliNo ratings yet

- Laplace Transformation of Periodic FunctionsDocument15 pagesLaplace Transformation of Periodic FunctionsOlin D'souzaNo ratings yet

- Dynamics of Rigid Bodies MotionDocument12 pagesDynamics of Rigid Bodies MotionIusty ĨustyNo ratings yet

- Gr12 Physical Sciences Term 3 Resource PackDocument146 pagesGr12 Physical Sciences Term 3 Resource PackKevin SmithNo ratings yet

- Distinguish TestDocument1 pageDistinguish TestAnsia MeenazNo ratings yet

- Struc 2Document14 pagesStruc 2keeno manzanoNo ratings yet

- Abb Manual On MV Switch GearDocument60 pagesAbb Manual On MV Switch GearUrooj RizviNo ratings yet

- 7 HPLC Ay2223s2Document31 pages7 HPLC Ay2223s2Matty JakeNo ratings yet

- Andersen 2009Document23 pagesAndersen 2009Lucas MartinsNo ratings yet

- Dokumen - Pub Renewable Energy Systems 1536104418 9781536104417Document282 pagesDokumen - Pub Renewable Energy Systems 1536104418 9781536104417Tacko KanouteNo ratings yet

- Electrostatic ToysDocument7 pagesElectrostatic ToysBrandon McCormickNo ratings yet

- Curriculum Vitae: Hamad MushtaqDocument3 pagesCurriculum Vitae: Hamad MushtaqUzair IjazNo ratings yet

- Data Sheet 3VM1340-4EE32-0AA0: ModelDocument4 pagesData Sheet 3VM1340-4EE32-0AA0: ModelVicthor TrautmannNo ratings yet

- Comparative Tracking Index of Electrical Insulating MaterialsDocument6 pagesComparative Tracking Index of Electrical Insulating MaterialsAbu Anas M.SalaheldinNo ratings yet

- Flight Planning Speed SelectionDocument21 pagesFlight Planning Speed Selectionoswaldo venegas100% (1)

- Aircraft Maintenance Manual: TASK 12 13 21 610 801 Servicing of The Oil Level of The ACMDocument10 pagesAircraft Maintenance Manual: TASK 12 13 21 610 801 Servicing of The Oil Level of The ACMCHIMONo ratings yet

- EHP EngDocument8 pagesEHP EngalastairNo ratings yet

- Lighting SystemsDocument67 pagesLighting SystemsSuzette BinongcalNo ratings yet