Professional Documents

Culture Documents

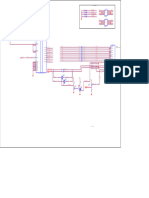

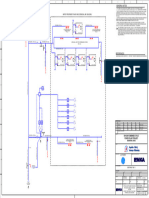

Instrument Hookup 11

Uploaded by

Wael ZakariaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Instrument Hookup 11

Uploaded by

Wael ZakariaCopyright:

Available Formats

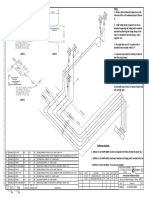

INSTRUCTIONS:

13 12

1. Instrument sensing lines shall have a continous slope. The slope shall be a minimum of 20mm or

PGESCo Confidential © PGESCo 2017. Contains confidential and/or proprietary information to PGESCo which shall not be used, disclosed, or reproduced in any non-PGESCo. party without PGESCo’s prior written permission. All rights reserved.

more per 1m.

11 2. Fixed 3D support shall be put on the first fixed support point on the tubing after the process piping

14 and at the ends of each run for every change of direction (X,Y,Z)

3. Anchor support shall restrain pipe in all directions (3-D support). This support is to be directly

8 attached to the tubing (not to the insulation jacket).

4.Guide support shall restrain pipe in the vertical and lateral directions but shall be free in the axial

9 1 direction (2-D support). This support to be attached to the tubing (not to the insulation jacket).

INSTRUMENT TAG EXPANSION LOOP TYPE

MLC

MLC

13 12 9 1AABFIT001A LOOP E

2D- support

10 1AABFIT001B LOOP E (Loose clamp)

11 1BABFIT001A LOOP B

14 2

1BABFIT001B LOOP B 2D- support

(Loose clamp)

8 1CABFIT001A LOOP B

3D support

(Tight clamp)

4

1CABFIT001B LOOP B

3

1DABFIT001A LOOP E

2

1DABFIT001B LOOP E

1 2AABFIT001A LOOP E

2AABFIT001B LOOP E

EXPANSION LOOP 2BABFIT001A LOOP B

2BABFIT001B LOOP B

SYMBOLS LEGEND:

2CABFIT001A LOOP B

2

2CABFIT001B LOOP B

3D support

DP Instrument 2DABFIT001A LOOP E (Tight clamp)

+

2DABFIT001B LOOP E

5-valve manifold

14 MLC MLC 4 EA PROVIDED BY I&C NIPPLE, NPS 3/4 ,ASTM A335 GR. P91, Schedule XS, Plain Both Ends, Per ASTM A733, Seamless, 3 inch

13 MLC MLC 2 EA PROVIDED BY I&C NIPPLE, NPS 3/4 ,ASTM A335 GR. P91, Schedule XS, Plain End X Male National Pipe Thread End, Per ASTM A733, Seamless, 3 inch

12 MLC MLC 2 EA PROVIDED BY I&C CAP, NPS 3/4 , ASTM A182, GR. F91, Class 3000,FNPT, Per ASME B16.11, Marked per MSS SP 25.

Valve - Ball,NPS 3/4 , Forged Steel Per ASTM A182 Grade F91 body, ASME Class 2500, Lever Operated, Non Lubricated Ball Valve, One Piece Body Design, Blow Out Proof Stem Design, Socket weld Ends; Designed

11 MLC MLC 4 EA PROVIDED BY I&C as per ASME B16.34, Inconel 718 ball and seat rings with hardfaced coating (ball and seat shall be chrome carbide spray and fused coating); ASTM A638, Grade 660 Stem; live-loaded Precompressed Graphite Packing

Rings w/Graphite Anti Extrusion Rings; Bolts/Nuts Per A193-B16/A194-3. Marked per MSS SP 25. The Valve shall be a Velan Power Ball Valve or approved equivalent.

10 MLC MLC 2 EA PROVIDED BY I&C Elbow - 90,NPS 3/4 , ASTM A182 Grade F91, Class 3000, Socketweld End, ASME B16.11, Marked per MSS SP 25

9 MLC MLC 4 EA PROVIDED BY I&C NIPPLE,NPS 3/4 , ASTM A335 GR. P91, SEAMLESS ,SCH. XS,Seamless, PLAIN BOTH ENDS, LENGTH AS REQUIRED,Per ASTM B36.10.

8 MLC MLC 2 EA PROVIDED BY I&C SEAL POT,3" Sch. XS X 8" length ,ASTM A335 P91, 2 X NPS 3/4 Socket weld PROCESS CONNECTIONS AND NPS 3/4 Socket weld VENT CONNECTION

4 * * 2 EA PROVIDED BY I&C DOUBLE FERRULE FITTING, 316 SST, CONNECTOR, MALE, TUBE x MALE NPT, 3/8 in x 1/2 in

3 * * A/R EA PROVIDED BY I&C DOUBLE FERRULE FITTING, 316 SST, UNION, TUBE, 3/8 in

2 * * A/R M PROVIDED BY I&C ANNLD SMLSS TUBING, 316 SS-ASTM A213, 90RB MAX, .065inWT, 3/8 in

1 * * 2 EA PROVIDED BY I&C DOUBLE FERRULE FITTING, 316 SST, CONNECTOR, TUBE x MALE PIPE WELD, 3/8 in x 3/4 in

ITEM

MFR MODEL QTY UNIT NOTES DESCRIPTION

NO.

NOTES NEW ASSIUT COMBINED

CYCLE ADD-ON POWER

REV DATE REVISION BY CHK SUPV APPR PLANT

1. Asterisk(*) = Vendor Supplied.

2. For the MLC items, refer to the P&ID to identify the main piping class & material. 0 4/19/17 ISSUED FOR USE SY HM HS SH Instrument Installation Detail

3. This detail is NOT to be used for seismic or blowdown installations. 1 6/1/17 REISSUED FOR USE HM HS HS SH D/P Flow Transmitter - Below Taps Steam And Double

4. The 5-valve manifold is supplied with the DP flow transmitter.

Root Valve

JOB NO. DRAWING NO. REV.

10083A 09-J8-000G-F0131 1

You might also like

- Instrument Hookup 8Document1 pageInstrument Hookup 8Wael ZakariaNo ratings yet

- 8-Schematic DiagramDocument5 pages8-Schematic DiagramblolchekNo ratings yet

- Instrument Hookup 10Document1 pageInstrument Hookup 10Wael ZakariaNo ratings yet

- Diagrama Electrónico Adv8105Document30 pagesDiagrama Electrónico Adv8105Fast ServiceNo ratings yet

- SM-J105H Esquematico Completo Anibal Garcia IrepairDocument6 pagesSM-J105H Esquematico Completo Anibal Garcia Irepairjhosseph contrerasNo ratings yet

- 1.1.1 PID For DEMINERALIZED WATER TREATMENT SYSTEMDocument12 pages1.1.1 PID For DEMINERALIZED WATER TREATMENT SYSTEMShilu GhoshNo ratings yet

- MCB Toilet ElevationspdfDocument1 pageMCB Toilet Elevationspdfjuy rose cunananNo ratings yet

- From IRAC7200 Circuit DiagrammeDocument1 pageFrom IRAC7200 Circuit DiagrammeAndi PrengaNo ratings yet

- Ghial LNT D PTB e 72 4302Document4 pagesGhial LNT D PTB e 72 4302Anthony Robert XNo ratings yet

- Polar 37CTV3160 54CTV3160 U21AXTDocument1 pagePolar 37CTV3160 54CTV3160 U21AXTalexmaster073No ratings yet

- A11-00h - Ground Level - Part HDocument1 pageA11-00h - Ground Level - Part Hconsultnadeem70No ratings yet

- Sentron: Technological Leader Amongst The Circuit-Breakers: SENTRON CommunicationDocument186 pagesSentron: Technological Leader Amongst The Circuit-Breakers: SENTRON Communicationsatelite54No ratings yet

- TV Beko 12.7Document1 pageTV Beko 12.7João Pedro AlmeidaNo ratings yet

- Beko12.7 CTV Chassis (Esquema) PDFDocument1 pageBeko12.7 CTV Chassis (Esquema) PDFSekoNo ratings yet

- 8-1. Schematic Diagram (Main)Document2 pages8-1. Schematic Diagram (Main)CADiLONo ratings yet

- DPB - Auxn DPB - Auxp DPB - Dongle - Det: Part 9 of 15Document21 pagesDPB - Auxn DPB - Auxp DPB - Dongle - Det: Part 9 of 15Toàn ĐỗNo ratings yet

- I WI I 5: GR AT NG Plat Form DTH NSI DER ADI US NDocument1 pageI WI I 5: GR AT NG Plat Form DTH NSI DER ADI US NAbid AyubNo ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- Downtown Dubai Opera District: Typical Services Reservation Cross Section For Corridor Width of 30.50MDocument1 pageDowntown Dubai Opera District: Typical Services Reservation Cross Section For Corridor Width of 30.50Mabdullah sahibNo ratings yet

- FLR A9sn Ep 3810 PD Is 5605 08Document1 pageFLR A9sn Ep 3810 PD Is 5605 08Brandon C LoyolaNo ratings yet

- Sobha Hartland Greens - Phase 02: InvestmentsDocument1 pageSobha Hartland Greens - Phase 02: InvestmentsrajatNo ratings yet

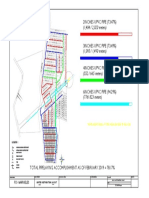

- 2INCHES UPVC PIPE (73.47%) : (1,484 / 2,020 Meters)Document1 page2INCHES UPVC PIPE (73.47%) : (1,484 / 2,020 Meters)Jhn Cbllr BqngNo ratings yet

- WSA20-MPX-04000-ME-DRG-21600002 (00) - Riser Details - Sheet 2 - SWDocument1 pageWSA20-MPX-04000-ME-DRG-21600002 (00) - Riser Details - Sheet 2 - SWAnh Khoa LeNo ratings yet

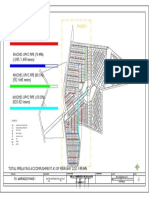

- (2,020 / 2,020 Meters) : 2INCHES UPVC PIPE (100.00%)Document1 page(2,020 / 2,020 Meters) : 2INCHES UPVC PIPE (100.00%)VWSSI Technical TeamNo ratings yet

- Downtown Dubai Opera District: Typical Services Reservation Cross Section For Corridor Width of 30.50MDocument1 pageDowntown Dubai Opera District: Typical Services Reservation Cross Section For Corridor Width of 30.50Mabdullah sahibNo ratings yet

- External Switching Charger: D2 S1 D1 D1 D2Document1 pageExternal Switching Charger: D2 S1 D1 D1 D2Suhas PatilNo ratings yet

- Demin Water SystemDocument1 pageDemin Water Systemmohamed abourayaNo ratings yet

- Renr1242 02Document2 pagesRenr1242 02AJCMANDEMAQNo ratings yet

- Strategic Directions 7TM504-2018-2019Document10 pagesStrategic Directions 7TM504-2018-2019Panos AnonioumNo ratings yet

- ASF 607-02 - AD-518 (Rev - A)Document1 pageASF 607-02 - AD-518 (Rev - A)Haseeb RazviNo ratings yet

- Road "B" Road "B": Thai Oil Public Company LimitedDocument1 pageRoad "B" Road "B": Thai Oil Public Company LimitedRachane NuanyaiNo ratings yet

- Away From The Rain: Rubato ( 120)Document7 pagesAway From The Rain: Rubato ( 120)AlFisherGaiusCoronadoNo ratings yet

- En Skydeck Wall ChartDocument3 pagesEn Skydeck Wall ChartPaplu PaulNo ratings yet

- Ejercicio 1 de StacattoDocument1 pageEjercicio 1 de StacattoLuis Alonzo JacoboNo ratings yet

- Reference Drawing Bill of Material For This Drawing General Notes Topographic Symbols Pipeline Symbols Soil SymbolsDocument26 pagesReference Drawing Bill of Material For This Drawing General Notes Topographic Symbols Pipeline Symbols Soil SymbolssubudhiprasannaNo ratings yet

- PID Turbcompr Desc1raEtapaDocument1 pagePID Turbcompr Desc1raEtapaJholman SanchezNo ratings yet

- Geo 3eroDocument62 pagesGeo 3eroHumberto MinayaNo ratings yet

- Chalana Chitra Nirmaata TeluguDocument12 pagesChalana Chitra Nirmaata TeluguMurali GurajalaNo ratings yet

- Romeu and JulietDocument3 pagesRomeu and JulietNanci HennichNo ratings yet

- BleachedDocument2 pagesBleachedcrystalNo ratings yet

- 98 140656 A01 Installation Guide Sailor 6588 Dgnss ReceiverDocument2 pages98 140656 A01 Installation Guide Sailor 6588 Dgnss ReceiverAnonymous XnufDzrpoNo ratings yet

- P&id Demineralized Water DistributionDocument1 pageP&id Demineralized Water DistributionAjeng OctaviaNo ratings yet

- Instrument Hookup 9Document1 pageInstrument Hookup 9Wael ZakariaNo ratings yet

- A6V10906627 enDocument2 pagesA6V10906627 enFabrizio TruglioNo ratings yet

- Waves of The Danube: Ion Ivanovici Trans. Carolina Puruncajas. 120Document1 pageWaves of The Danube: Ion Ivanovici Trans. Carolina Puruncajas. 120Kro PuruncajasNo ratings yet

- Ocf - Pipe Rack 4 - Sheet-6Document1 pageOcf - Pipe Rack 4 - Sheet-6Suresh KannanNo ratings yet

- Sobha Hartland Greens - Phase 02: InvestmentsDocument1 pageSobha Hartland Greens - Phase 02: InvestmentsrajatNo ratings yet

- A01-W-23 (As Built-For Approval)Document1 pageA01-W-23 (As Built-For Approval)HasmukhNo ratings yet

- Tu 8BK80Document1 pageTu 8BK80Kenn NguyenNo ratings yet

- From 2003 Hindi Film 'Kal Ho Naa Ho'Document5 pagesFrom 2003 Hindi Film 'Kal Ho Naa Ho'Hassan ShehadiNo ratings yet

- Deltarune TabsDocument3 pagesDeltarune TabscalemextremeNo ratings yet

- SadfghjklDocument1 pageSadfghjklLê Đức Bảo MinhNo ratings yet

- Unit 330Document22 pagesUnit 330mohamed ghorabNo ratings yet

- Plan at El.2268 MM Tos: WBCD Support at El.45100, Buckstay Guide at El.50000Document1 pagePlan at El.2268 MM Tos: WBCD Support at El.45100, Buckstay Guide at El.50000shisNo ratings yet

- Column LayoutDocument1 pageColumn LayoutAugustine yigaNo ratings yet

- PVI 6000 TL OUTD W Quick Installation Guide en RevADocument2 pagesPVI 6000 TL OUTD W Quick Installation Guide en RevA王伯恩No ratings yet

- DA05Document1 pageDA05Johann Nick Flores AparicioNo ratings yet

- DN 40 - 1200 PN10/16: Large Tolerance Multimaterials Coupling Flanged AdaptorDocument4 pagesDN 40 - 1200 PN10/16: Large Tolerance Multimaterials Coupling Flanged Adaptorpablo gerardo gil cocaNo ratings yet

- Extremoduro - Dulce Introducción Al Caos: Cover by Rocamora PianoDocument10 pagesExtremoduro - Dulce Introducción Al Caos: Cover by Rocamora PianoLaura100% (1)

- Instrument Hookup 6Document1 pageInstrument Hookup 6Wael ZakariaNo ratings yet

- Instrument Hookup 9Document1 pageInstrument Hookup 9Wael ZakariaNo ratings yet

- Instruments Hookup 5Document1 pageInstruments Hookup 5Wael ZakariaNo ratings yet

- Notes:: 3D Anchor Support (Tight Clamp) 2D Directional Support (Loose Clamp) Allow Tubing Axial Movement 2 7Document1 pageNotes:: 3D Anchor Support (Tight Clamp) 2D Directional Support (Loose Clamp) Allow Tubing Axial Movement 2 7Wael ZakariaNo ratings yet

- Notes:: 3D Anchor Support (Tight Clamp) 2D Directional Support (Loose Clamp) Allow Tubing Axial Movement 2 7Document1 pageNotes:: 3D Anchor Support (Tight Clamp) 2D Directional Support (Loose Clamp) Allow Tubing Axial Movement 2 7Wael ZakariaNo ratings yet

- General Catalogue: Piping SystemsDocument132 pagesGeneral Catalogue: Piping SystemsOmar GuillenNo ratings yet

- Williamstown Hazard Mitigation Grant ApplicationDocument72 pagesWilliamstown Hazard Mitigation Grant ApplicationiBerkshires.comNo ratings yet

- Assigment 3Document8 pagesAssigment 3Zoheb ShaikhNo ratings yet

- Franklin Home Power Quick Installation GuideDocument35 pagesFranklin Home Power Quick Installation GuideIEEPRO SASNo ratings yet

- Artificial Lift Systems Power Point PresentationDocument20 pagesArtificial Lift Systems Power Point PresentationIlmiNo ratings yet

- KULIAH3 EC3 UNRESTRAINED BEAM-kl PDFDocument66 pagesKULIAH3 EC3 UNRESTRAINED BEAM-kl PDFZazliana Izatti100% (1)

- Valvula de Succion CK-2Document4 pagesValvula de Succion CK-2Ramon BriceñoNo ratings yet

- Material Selection Using Ashby MethodDocument6 pagesMaterial Selection Using Ashby MethodRaúl AnelNo ratings yet

- ShoringDocument8 pagesShoringJeo LawrenceNo ratings yet

- Astm A556 PDFDocument2 pagesAstm A556 PDFgaminNo ratings yet

- Saudi Aramco Inspection Checklist: Post-Application Inspection of Fireclay Brick Installation SAIC-N-2041 15-Dec-09 MechDocument5 pagesSaudi Aramco Inspection Checklist: Post-Application Inspection of Fireclay Brick Installation SAIC-N-2041 15-Dec-09 MechaamirapiNo ratings yet

- 09 Cast IronDocument34 pages09 Cast IronyogeshmangulkarNo ratings yet

- Protech Peb BrochureDocument8 pagesProtech Peb BrochureAzhar IqbalNo ratings yet

- Product Catalog: High-Precision Ball BearingsDocument52 pagesProduct Catalog: High-Precision Ball BearingsMD HussainNo ratings yet

- Machine DesignDocument34 pagesMachine DesignMohammed Yunus33% (3)

- Analysis of Section BeamDocument26 pagesAnalysis of Section BeamNur Azrin AzlanNo ratings yet

- ASME - ANSI B16.5 - Flanges and Bolt Dimensions Class 150 To 2500Document11 pagesASME - ANSI B16.5 - Flanges and Bolt Dimensions Class 150 To 2500Isaac IglesiasNo ratings yet

- GYPROC LEEDv4 GenericBrochureDocument40 pagesGYPROC LEEDv4 GenericBrochureKoala Tube88No ratings yet

- Industrial Sliding DoorsDocument40 pagesIndustrial Sliding DoorsAnonymous CPEha1db7UNo ratings yet

- Product CAT IXSU - DatasheetDocument10 pagesProduct CAT IXSU - DatasheetRicardo Gomez GuevaraNo ratings yet

- Fire Risk Assessment FormDocument16 pagesFire Risk Assessment Formmukamat safiiNo ratings yet

- ARTICULO 2 Parte 2Document26 pagesARTICULO 2 Parte 2DEINA GERAUDY BARON ATUESTANo ratings yet

- Scopus Preview - Scopus - SourcesDocument6 pagesScopus Preview - Scopus - SourcesJose CarrascoNo ratings yet

- (XPERTZ) Preboard Exam 1ST HGE Nov 2022Document9 pages(XPERTZ) Preboard Exam 1ST HGE Nov 2022Fely Joy RelatoresNo ratings yet

- Solo 451 Spare ItemsDocument12 pagesSolo 451 Spare Itemsshohimi harunNo ratings yet

- Crosby Catalogo.Document12 pagesCrosby Catalogo.rony adonay sandovalNo ratings yet

- DK Ching (House)Document8 pagesDK Ching (House)Jerzy Mae GloriosoNo ratings yet

- Tables Design Tables and EquationsDocument23 pagesTables Design Tables and Equationsامين الزريقيNo ratings yet

- Bogibeel Bridge - Wikipedia PDFDocument14 pagesBogibeel Bridge - Wikipedia PDFZiarul Islam KhanNo ratings yet