Professional Documents

Culture Documents

Machine Walk Around & Safety Inspection: Wheel Loaders

Machine Walk Around & Safety Inspection: Wheel Loaders

Uploaded by

Alzaki Abdullah0 ratings0% found this document useful (0 votes)

16 views1 pageInspection

Original Title

machine walk around

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentInspection

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

16 views1 pageMachine Walk Around & Safety Inspection: Wheel Loaders

Machine Walk Around & Safety Inspection: Wheel Loaders

Uploaded by

Alzaki AbdullahInspection

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Machine Walk

Around & Safety

Inspection: Wheel

Loaders

Walk Around Inspections should be performed at the beginning of every

Operator:

shift prior to starting the machine. It can help prevent machine damage

and ensure your safety. Always consult your OMM for more information. Shift: _________

Walk Around Tips for Wheel Loaders

Begin Your Walk Around… Comments:

– Check transmission fluid level

– Look for wear in driveline area

– Inspect all hoses for wear and leaks

________________________________

– Check for loose lug nuts and general wheel condition

– Look at tires for imbedded stones, foreign material, cuts, overall tread condition, ________________________________

and sidewall condition

– Check tire pressure and verify correctness before beginning work ________________________________

Move To the Lift Arms…

– Inspect pin areas for wear

________________________________

– Look for loose or broken greasing tubes

– Look for loose or leaking lines, fittings or hose clamps ________________________________

– Check coupler for wear (if equipped)

Move To the Bucket... ________________________________

– Inspect the cutting edge

– If cutting edge isn’t square with the ground you may have an under inflated tire

________________________________

– Inspect the edge for loose, broken or missing parts

– Look for unusual wear patterns and cracked welds around the bucket ________________________________

– Examine the cylinder rod

– Make sure the tilt cylinder rod isn’t scratched or dented

Move To the Next Wheel…

– Inspect tire as you did on the other side

– Check the center articulation area

– Look at he cab area, check for broken glass or mirrors

– Move to the next wheel and inspect as you did on the other side

Move To the Engine Compartment…

– Check for and remove any dirt or debris

– Checks for any leaks

– Check the engine dipstick using a white towel

– If there is any fuel in the oil it will separate from the oil first leaving a “bulls eye”

look on the white towel

– Check fan housing for damage

– Inspect the radiator

– Close the engine compartment and move to the last tire for inspection

– Check under the machine one last time to make sure there isn’t any leaks or

problems you may have overlooked

Move To the Operators Station…

– Be sure to maintain three points of contact as you enter the cab face first

– Clean, adjust, and inspect external mirrors (if equipped)

– Check the window glass, mirrors, floor and interior and clean as needed

– Inspect seat and seatbelt condition, including the mountings

– Test all indicator lights for proper operation

– Check the fuel level

SAFETY.CAT.COM™

http://safety.cat.com/toolbox V0810.1

CAT, CATERPILLAR, their respective logos, “Caterpillar Yellow” and the POWER EDGE trade dress, as well as corporate and product identity used herein, are

trademarks of Caterpillar and may not be used without permission. © 2009 Caterpillar All Rights Reserved

You might also like

- Anne Murray - Best of - BookDocument55 pagesAnne Murray - Best of - Bookjoakil95% (20)

- Jerry Gray - Jazz Czerny - PianoDocument32 pagesJerry Gray - Jazz Czerny - Pianovnnw100% (43)

- Excavator Student ManualDocument25 pagesExcavator Student ManualSamuel Woldemichael Yohannes83% (6)

- Excavator Instructors NotesDocument31 pagesExcavator Instructors Notescandracute33% (3)

- Mathematics Extension 1 Notes (UPDATED)Document12 pagesMathematics Extension 1 Notes (UPDATED)Andrew LeeNo ratings yet

- Baby Go To Leggings PatternDocument12 pagesBaby Go To Leggings Patterncamby1No ratings yet

- VW Eos Maintenance PDFDocument75 pagesVW Eos Maintenance PDFNick P100% (1)

- Forklift Inspection ChecklistDocument1 pageForklift Inspection ChecklistVikas Singh100% (1)

- Cat 631g 637g NpiDocument39 pagesCat 631g 637g NpiMahmmod Al-Qawasmeh100% (1)

- Cat Cb434c 534c 634c ST MatDocument43 pagesCat Cb434c 534c 634c ST MatMahmmod Al-Qawasmeh100% (2)

- OTIS LIFT PM ChecklistDocument2 pagesOTIS LIFT PM ChecklistMVSEETARAMAN70% (10)

- Heavy Equipment: Workforce Safety & InsuranceDocument7 pagesHeavy Equipment: Workforce Safety & InsuranceShams TabrezNo ratings yet

- Truck Test Field Test Version1 Changes5Document33 pagesTruck Test Field Test Version1 Changes5moscraiun22No ratings yet

- Krazy Kragnars Alchemical Surplus ShopDocument9 pagesKrazy Kragnars Alchemical Surplus ShopJavi MorenoNo ratings yet

- How To Inspect A Gearbox PDFDocument5 pagesHow To Inspect A Gearbox PDFsurawutwijarn100% (2)

- Electrohydraulics Basic LevelDocument202 pagesElectrohydraulics Basic LevelSavio Fernandes100% (9)

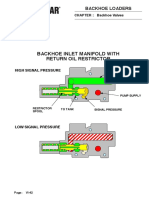

- Backhoe Loaders: Service Training MalagaDocument7 pagesBackhoe Loaders: Service Training MalagaMahmmod Al-QawasmehNo ratings yet

- Dump Truck PPT 1Document18 pagesDump Truck PPT 1Omosigho Osaro100% (1)

- Bosch Rexroth Training PDFDocument19 pagesBosch Rexroth Training PDFMahmmod Al-Qawasmeh100% (1)

- Cat 621G 623G 627G NpiDocument51 pagesCat 621G 623G 627G NpiMahmmod Al-QawasmehNo ratings yet

- (Yr 12) Extension 2 Extra Q'sDocument294 pages(Yr 12) Extension 2 Extra Q'sSreeya DasNo ratings yet

- BizplanbDocument390 pagesBizplanbMuhands JoNo ratings yet

- Forklift Truck ChecklistDocument1 pageForklift Truck ChecklistdnmuleNo ratings yet

- Lifts and Hoists Maintenance TasksDocument19 pagesLifts and Hoists Maintenance TasksMachineryengNo ratings yet

- ePAVE ManualDocument14 pagesePAVE ManualSajin Bs100% (1)

- 05 CB534D Machine Systems Tech InstDocument23 pages05 CB534D Machine Systems Tech InstMahmmod Al-QawasmehNo ratings yet

- Cat D Series Aws BHL - SLDDocument10 pagesCat D Series Aws BHL - SLDMahmmod Al-QawasmehNo ratings yet

- Quality ControlDocument27 pagesQuality ControlDe DeNo ratings yet

- Excavator Instructors NotesDocument31 pagesExcavator Instructors NotesWALTER EMMANUEL FLORES COSCONo ratings yet

- 926M Wheel Loader TrainingDocument49 pages926M Wheel Loader Trainingotak04No ratings yet

- Loader Checklist PDFDocument2 pagesLoader Checklist PDFMahmmod Al-Qawasmeh100% (1)

- 03 CAT CB534D Vibratory System Tech InstDocument20 pages03 CAT CB534D Vibratory System Tech InstMahmmod Al-QawasmehNo ratings yet

- Holt Algebra 1 - Chapter 3 TestDocument15 pagesHolt Algebra 1 - Chapter 3 TestStanleyNo ratings yet

- Determination of A Machine's TIER LevelDocument8 pagesDetermination of A Machine's TIER LevelMahmmod Al-QawasmehNo ratings yet

- ESC - 240 - V2-2 (1) BallastDocument11 pagesESC - 240 - V2-2 (1) BallastWisit BestNo ratings yet

- Starting A Bookstore BusinessDocument11 pagesStarting A Bookstore BusinessBunkun15No ratings yet

- Astm-C 240 PDFDocument4 pagesAstm-C 240 PDFIvan AlanizNo ratings yet

- 09 Cat BHL B&C Hydsys3Document15 pages09 Cat BHL B&C Hydsys3Mahmmod Al-QawasmehNo ratings yet

- BACKHOE LOADER Pre-Operations ChecklistDocument3 pagesBACKHOE LOADER Pre-Operations Checklistmanny daleonNo ratings yet

- De Praestigiis DaemonumDocument763 pagesDe Praestigiis DaemonumHector Lorenzo100% (4)

- Forklift Pre Start ChecklistDocument1 pageForklift Pre Start ChecklistConnie Rodriguez100% (1)

- 13bme0513 Vehicle ReportDocument23 pages13bme0513 Vehicle ReportManas PandeyNo ratings yet

- 01 CAT CB534D Propulsion System Tech InstDocument19 pages01 CAT CB534D Propulsion System Tech InstMahmmod Al-Qawasmeh100% (1)

- LHD Operator Guide BookDocument17 pagesLHD Operator Guide BookJose CarmonaNo ratings yet

- Forklift Empilhadeira PDFDocument94 pagesForklift Empilhadeira PDFLuis BomfimNo ratings yet

- Machine Walk Around and InspectionDocument3 pagesMachine Walk Around and Inspectionjt4fdsNo ratings yet

- Driving Commercial Vehicles Manual Class 4 Unrestricted Pre-Trip InspectionDocument7 pagesDriving Commercial Vehicles Manual Class 4 Unrestricted Pre-Trip InspectionjwNo ratings yet

- Pre-Departure Checking (Training)Document48 pagesPre-Departure Checking (Training)raymond paul adelantarNo ratings yet

- PSV PulloutDocument1 pagePSV PulloutKeenanCoachesNo ratings yet

- Class4 Pre Trip InspectionDocument3 pagesClass4 Pre Trip Inspection法璋No ratings yet

- Before Operation: Operation and Maintenance Manual ExcerptDocument4 pagesBefore Operation: Operation and Maintenance Manual ExcerptFabian Ariza ArizaNo ratings yet

- Automatic Gearbox CheckDocument10 pagesAutomatic Gearbox CheckJohnnoNo ratings yet

- Practical Report (Brake System Inspection and Diagnosis)Document6 pagesPractical Report (Brake System Inspection and Diagnosis)Rohan BhanotNo ratings yet

- 204-00 - Suspension System - General InformationDocument17 pages204-00 - Suspension System - General InformationSofia AltuzarraNo ratings yet

- Steel Erection Crane InspectionDocument3 pagesSteel Erection Crane InspectionSyaiful BahriNo ratings yet

- A Guide To Successful Baja SAE Technical Inspection 9-5-17Document24 pagesA Guide To Successful Baja SAE Technical Inspection 9-5-17Vidarr RodríguezNo ratings yet

- Abrasive (Grinding) Wheels: A Health and Safety Guideline For Your WorkplaceDocument8 pagesAbrasive (Grinding) Wheels: A Health and Safety Guideline For Your WorkplaceAkhtar QuddusNo ratings yet

- MaintenanceDocument40 pagesMaintenanceWisnu NugrohoNo ratings yet

- MERCURY Tehnicheskoe Ustroystvo ReduktoraDocument139 pagesMERCURY Tehnicheskoe Ustroystvo Reduktorafabbromauricioyahoo.com.arNo ratings yet

- Crankcase Inspection Safety & Procedure MMD Favourite QuestionsDocument1 pageCrankcase Inspection Safety & Procedure MMD Favourite QuestionsAnkit ChatterjeeNo ratings yet

- Antes Da Operação 777F Ing.Document10 pagesAntes Da Operação 777F Ing.Jardel Fernandes de MoraesNo ratings yet

- Overhead Crane: Maintenance ProgramDocument3 pagesOverhead Crane: Maintenance ProgramMuhammad RafiNo ratings yet

- 10 Maintenance - MT2200 - enDocument28 pages10 Maintenance - MT2200 - enjackNo ratings yet

- What Inspectors Are Looking ForDocument1 pageWhat Inspectors Are Looking Forapi-276220347No ratings yet

- Kia-Carnival 2008 en Manual de Mantenimiento C6b3ec5b7aDocument48 pagesKia-Carnival 2008 en Manual de Mantenimiento C6b3ec5b7aAmelia Sofía Sanhueza GrandónNo ratings yet

- 13bme0513 Vehicle ReportDocument22 pages13bme0513 Vehicle ReportManas PandeyNo ratings yet

- Acetrack AR EAM AME AR EAR AKE Odel Olor Uthorized EAM EP ELL AT RackDocument2 pagesAcetrack AR EAM AME AR EAR AKE Odel Olor Uthorized EAM EP ELL AT RackPablo FernándezNo ratings yet

- Wheels and Tires PresentationDocument42 pagesWheels and Tires Presentationeder contrerasNo ratings yet

- International Roadcheck Checklist For Drivers: Buckle UplDocument2 pagesInternational Roadcheck Checklist For Drivers: Buckle UplMohammed ImtiyazNo ratings yet

- Crane and Hoist Safety ProgramDocument1 pageCrane and Hoist Safety ProgramAARON QA QCNo ratings yet

- Prepare For Pre-DeliveryDocument2 pagesPrepare For Pre-DeliveryHazel CompendioNo ratings yet

- Wheel Loss Sensor WHeely SafeDocument4 pagesWheel Loss Sensor WHeely SafevijayNo ratings yet

- Inside Vehicle: General MaintenanceDocument2 pagesInside Vehicle: General Maintenancejeremih alhegnNo ratings yet

- 204-04A - Wheels and TiresDocument21 pages204-04A - Wheels and TiresSofia AltuzarraNo ratings yet

- Before Operation: Operation and Maintenance Manual ExcerptDocument5 pagesBefore Operation: Operation and Maintenance Manual Excerptalice_dickson523No ratings yet

- CS76 Before OperationDocument4 pagesCS76 Before OperationJosé Carlos CarvalhoNo ratings yet

- Ex400-5, Ex400lc-5, Ex450lc-5 WMDocument598 pagesEx400-5, Ex400lc-5, Ex450lc-5 WMAnonymous vxpVVAcjJ8No ratings yet

- Pre-Trip Vehicle ChecklistDocument5 pagesPre-Trip Vehicle ChecklistDominador SANTOS JR.No ratings yet

- Safety Topics 238 Backhoe Safety PDFDocument2 pagesSafety Topics 238 Backhoe Safety PDFVepxvia NadiradzeNo ratings yet

- Mine Canadian Royalties: Excavator TrainingDocument72 pagesMine Canadian Royalties: Excavator Trainingotak04No ratings yet

- PDI ChecklistDocument6 pagesPDI ChecklistchhotelalpalmkpNo ratings yet

- 1M210 11 - MaintenanceDocument43 pages1M210 11 - Maintenanceasri novhandiNo ratings yet

- Accu-211 - Formatoalumnotrabajofinal 2Document8 pagesAccu-211 - Formatoalumnotrabajofinal 2Dilmer Silvano AscayoNo ratings yet

- Chariot PM Checklist SCRUBBERDocument2 pagesChariot PM Checklist SCRUBBERherik0% (1)

- Luxury Air CurtainDocument2 pagesLuxury Air CurtainMahmmod Al-QawasmehNo ratings yet

- Cost Types of Facility Management1Document8 pagesCost Types of Facility Management1Mahmmod Al-QawasmehNo ratings yet

- CAT Machine Care 02Document14 pagesCAT Machine Care 02Mahmmod Al-QawasmehNo ratings yet

- 9 PDFDocument2 pages9 PDFMahmmod Al-QawasmehNo ratings yet

- 0315CWLDocument2 pages0315CWLMahmmod Al-Qawasmeh100% (1)

- Important Safety InformationDocument3 pagesImportant Safety InformationMahmmod Al-QawasmehNo ratings yet

- Row Crop Challenger SpecsDocument88 pagesRow Crop Challenger SpecsMahmmod Al-Qawasmeh100% (1)

- Difinition of Load SensingDocument16 pagesDifinition of Load SensingMahmmod Al-QawasmehNo ratings yet

- 10 Cat BHL B&C Appendix IIDocument4 pages10 Cat BHL B&C Appendix IIMahmmod Al-QawasmehNo ratings yet

- CAT BHL B&C Answers PDFDocument14 pagesCAT BHL B&C Answers PDFMahmmod Al-QawasmehNo ratings yet

- Cat D Series Aws BHLDocument21 pagesCat D Series Aws BHLMahmmod Al-QawasmehNo ratings yet

- Caterpillar "Auto Patrol": Some HistoryDocument2 pagesCaterpillar "Auto Patrol": Some HistoryMahmmod Al-QawasmehNo ratings yet

- Filter Information: 216B3 Skid Steer Loader PWK00001-UP (MACHINE) POWERED BY C2.2 EngineDocument2 pagesFilter Information: 216B3 Skid Steer Loader PWK00001-UP (MACHINE) POWERED BY C2.2 EngineMahmmod Al-QawasmehNo ratings yet

- Caterpillar Engine Fundaident Als: Course OverviewDocument1 pageCaterpillar Engine Fundaident Als: Course OverviewMahmmod Al-QawasmehNo ratings yet

- Filter Information: 216B3 Skid Steer Loader PWK00001-UP (MACHINE) POWERED BY C2.2 EngineDocument2 pagesFilter Information: 216B3 Skid Steer Loader PWK00001-UP (MACHINE) POWERED BY C2.2 EngineMahmmod Al-QawasmehNo ratings yet

- Shantui Motor Grader Sg16 3 Parts Book EnchDocument22 pagesShantui Motor Grader Sg16 3 Parts Book Enchcalaw1876No ratings yet

- 35 U.S.C. 100 (pre-AIA) DefinitionsDocument3 pages35 U.S.C. 100 (pre-AIA) DefinitionsJenna AliaNo ratings yet

- Open Source AssingmentDocument9 pagesOpen Source Assingmenthidayat-has-3683No ratings yet

- Material Transfer Agreement: Klinikum Rechts Der Isar Der Technischen Universität MünchenDocument9 pagesMaterial Transfer Agreement: Klinikum Rechts Der Isar Der Technischen Universität MünchenchristinaNo ratings yet

- MotionBuilder 2012 Features and Benefits EnglishDocument2 pagesMotionBuilder 2012 Features and Benefits EnglishBrian MillerNo ratings yet

- Catalogue 2010Document34 pagesCatalogue 2010sales4016No ratings yet

- Grade 1 Odd One Out: Choose Correct Answer(s) From The Given ChoicesDocument4 pagesGrade 1 Odd One Out: Choose Correct Answer(s) From The Given ChoicesKhaing PhyuNo ratings yet

- Inteplast Group v. Primex PlasticsDocument6 pagesInteplast Group v. Primex PlasticsPriorSmartNo ratings yet

- Truly Helpless A Nature of Desire Series Novel Joey W Hill Ebook Full ChapterDocument51 pagesTruly Helpless A Nature of Desire Series Novel Joey W Hill Ebook Full Chapterjohn.beisch240100% (5)

- Marc 2010 DocumentationDocument904 pagesMarc 2010 DocumentationNieczesanyNo ratings yet

- KonsultaMD AF With Terms and ConditionsDocument2 pagesKonsultaMD AF With Terms and ConditionsAlbasir Tiang Sedik REENo ratings yet

- Стандартам: Asme, Din, Nf, Uni, En, Jis:Document19 pagesСтандартам: Asme, Din, Nf, Uni, En, Jis:Roberto ServinNo ratings yet

- Intra Web ManDocument109 pagesIntra Web ManTheodor-Florin LefterNo ratings yet

- CLX-4195FW PC v00Document30 pagesCLX-4195FW PC v00mestrefellipeNo ratings yet

- 21 103Document29 pages21 103Pen ValkyrieNo ratings yet

- EN - ISO - 10423 (2004) - (E) CodifiedDocument7 pagesEN - ISO - 10423 (2004) - (E) CodifiedjczezarNo ratings yet

- Front MatterDocument2 pagesFront MatterLaranjinhaLimaNo ratings yet