Professional Documents

Culture Documents

Sep Ijmte - CW

Uploaded by

SaravanakumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sep Ijmte - CW

Uploaded by

SaravanakumarCopyright:

Available Formats

International Journal of Management, Technology And Engineering ISSN NO : 2249-7455

DESIGN AND ANALYSIS OF RETAINING WALL

D.R. Dhamdhere1, Dr. V. R. Rathi2, Dr. P. K. Kolase3

Department of Civil engineering, PREC, Loni, University of Pune, Maharashtra, India

1

Post Graduate Student, Pravara College of Engineering, Loni, Maharashtra, 2 Professor and Head, Civil

Engineering Department, Pravara College of Engineering, Loni, Maharashtra India.

3

Professor, Civil Engineering Department, Pravara College of Engineering, Loni, Maharashtra

Abstract

This paper consist of analysis and design of cantilever and relieving platform retaining wall with

varying height from 3m to 10m and SBC 160KN/m2. It also shows comparative study such as cost,

economy, bending moment, stability against overturning &sliding between both the retaining wall. The

comparative study is carried out along with the cost and optimum or least cost estimate is chosen as the

best option. In this paper it is also shown that the relieving platform retaining wall is economical, more

stable than cantilever retaining wall and it also relives the bending moment of heel portion.

Keywords- Retaining wall, cantilever retaining wall, relieving platform retaining wall, design and

analysis.

I.INTRODUCTION

A retaining wall is a structure designed to sustain the earth behind it. It retains a steep faced slope of an

earth mass against rupture of slopes faced slopes in cuts and fills and against sliding down. The retained material

exerts a push on structures and this tends to overturn and slide it.

Besides the self-weight, the main predominant force for analysis and design of the retaining wall is lateral

earth pressure. The lateral earth pressure behind the wall depends on the angle of internal friction and the cohesive

strength of the retained material, as well as the direction and magnitude of movement of the stems. Its distribution is

typically triangular, least at the top of the wall and increasing towards the bottom. The earth pressure could push the

wall forward or overturn it if not properly addressed. Retaining walls are encountered and constructed in various

fields of engineering such as roads, harbors, dams, subways, railroads, tunnels, mines and military fortifications.

This research is generally focusing on the the following types of retaining walls,

1.1 Cantilever retaining wall:

The wall consists of a relatively thin stem and base slab. The base is also divided into two parts, the heel and the

toe. The heel is the part of base under the backfill. The toe is the other part of base.

Volume 8, Issue IX, SEPTEMBER/2018 Page No:1246

International Journal of Management, Technology And Engineering ISSN NO : 2249-7455

Use much less concrete than monolithic gravity walls, but requires more design and careful

construction.

Generally economical up to 8m to 9m in height

Can be precast in a factory or formed on site

1.2 Counterfort Retaining walls:

Counter fort retaining walls are similar to cantilever walls except they have thin vertical concrete webs at

regular intervals along the backside of the wall. These webs are known as counterforts.

The counterfort tie the slab and base together, and the purpose of them is to reduce the shear force and

bending moments imposed on the wall by the soil.

Can be precast or formed on site

Counterfort retaining walls are more economical than cantilever walls for heights 8m.

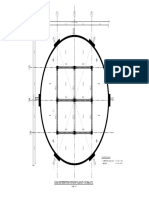

Fig. 1 Types Of Retaining Wall

1.3Relieving platform retaining wall:

This type of wall is modified form of cantilever retaining wall with added relieving platform. The platform is

provided at stem. The one can provide one or more platform as design demands. This platforms changes entire

pressure distribution diagram. This platform gives economical design as well as less bending moments.

Can be precast or formed on site

Economical than cantilever retaining wall

Can be used for any height.(more than 8m and less than 8m)

Retaining wall with relieving platform or relief shelves can also be considered as a special type of retaining

walls. Some researchers have stated that using reinforced walls is the most economical method for constructing high

walls with relieve platforms in their reports. The relive platform have the advantages of deceasing the acting lateral

earth pressure and increasing the overall stability of the retaining wall.

Volume 8, Issue IX, SEPTEMBER/2018 Page No:1247

International Journal of Management, Technology And Engineering ISSN NO : 2249-7455

1.4 Change in pressure due to presence of shelf:

When the relieving platform is provided to the retaining wall, the setback of the wall increases and the

sliding wedge is reduced. This reduction lowers the pressure on the retaining wall.

The most important consideration in proper design and installation of retaining wall is recognize and

counteract the tendency of the retained to move down slope due to gravity. This creates lateral earth pressure behind

the wall which depends on the angle of internal friction and the cohesive strength of the retained material, as well as

the direction and magnitude of movements the retaining structure undergoes.

Lateral earth pressure are zero at the top of the wall and in homogeneous ground increase proportionally to

a maximum value at the lower depth. Earth pressure will push the all forward or overturn it if not properly designed.

Also, any groundwater behind the wall causes hydrostatic pressure.

Fig. 2. Pressure distribution diagram for cantilever wall and the wall with relieving platform

II. LITERATURE REVIEW:

Donkadaet. al[1], found that at developing an understanding of optimal design solutions for three types of reinforced

concrete retaining walls, namely, cantilever retaining walls, counterfort retaining walls and retaining walls with

relieving platforms. Using genetic algorithms, parametric studies were carried out to establish heuristic rules for

proportioning the wall dimensions corresponding to the minimum cost points. Optimal cost-estimates of the

retaining walls types were compared to establish the best design alternative for a given height. Also, the advantages

of retaining walls with relieving platforms, which are relatively new in India, are discussed.

Patilet. al[2], found that a retaining wall is one of the most important types of retaining structures. It is extensively

used in variety of situations such as highway engineering, railways engineering, bridge engineering and irrigation

engineering. Reinforced concrete retaining walls have a vertical or inclined stem cast with base slab. These are

considered suitable upto a height of 6m. it resist lateral earth pressure by cantilever action of stem, toe slab and heel

slab. The tendency of wall to slide forward due to lateral earth pressure should be investigated and the factor of

safety of 1.5 shall be provided against sliding. Cantilever retaining walls are found best up to a height of 6m. for

greater heights earth pressure due to retained fill will be higher due to lever arm effect, higher moments are

Volume 8, Issue IX, SEPTEMBER/2018 Page No:1248

International Journal of Management, Technology And Engineering ISSN NO : 2249-7455

produced at base, which leads to higher section for stability design as well as structural design. This proves to be an

uneconomical design. As an alternative to this, one may go for counter for retaining wall, which demands greater

base area as well as steel. As a solution to this difficulty, a new approach that is to minimize effect of foeces coming

from retained fill, short reinforced concerete balance the locally appearing forces and will result into lesser moment

and shear forces along the stem. Also it will reduce the bending action that is pressure below the base.

Patilet. al[3], have found that a retaining wall is a structure designed and constructed to resist the lateral pressure of

soil when there is a desired change in ground elevation that exceeds the angle of repose of the soil. The most

important consideration in proper design and installation of retaining walls is to recognize and counteract the

tendency of the retained material to move down slope due to gravity. This creates lateral earth pressure behind the

wall which depends on the angle of internal friction (ø) and the cohesive strength (c) of the retained material, as well

as the direction and magnitude of movement the retaining structure undergoes. In many cases we have to come

across the retaining wall of 7m, 8m, 9m height. So we will consider these heights for noncohesive soil conditions for

different spacing of counter-forts. We studied, by changing the spacing of counter-forts what will be the change in

thickness of stem as well as heel slab, what is the optimum spacing of the counter-forts, what is the effect of

changing spacing of counter-forts on bending moments, and plotted a graph of optimum spacing of counter-forts vs

height of wall. The data presented here in following sections clearly indicates that changing spacing of counter-forts

for retaining wall results in, reduction of spacing of counter forts will result in reduction in bending moments in heel

slab and stem wall, reduction of spacing of counter forts will result in reduction in thickness of heel slab and stem

wall. It is also observed that for 1m, 1.5m, 2m, 3m, 3.5m, 4m spacing of counter-forts the concrete and steel

quantities per meter length of retaining wall is more than at 2.5m spacing. So optimum spacing of counter-forts for

7m, 8m, 9m height retaining wall is observed to be 2.5m.

TamadherAboodet. al[4], has found that retaining structures hold back soil or other loose material where an abrupt

change in ground elevation occurs. The retained material or backfill exerts a push on the structure and thus tends to

overturn or slide it, or both. The cantilever is the most common type of retaining wall and is used for walls in the

range of 3to 6m in height. This study presents analyses and design of cantilever retaining wall which is made from

an internal stem of steel-reinforced, cast-in-place concrete (often in the shape of an inverted T). In this work a

detailed analyses and design for this type of walls which include estimation of primary dimensions of the wall, then

these dimensions were checked.The factor of safety against sliding, overturning and bearing were calculated.the

shear resistance for the base, the tension stresses in the stem and the tension stresses for the base were checked.

Calculation of reinforcement for each part of the wall were done. All analysis and design are based on the ACI code

Inder Kumar et al[5], found that the analysis for the behaviour & optimal design of counter fort retaining wall and

gravity wall in concrete dam. Cost analysis against each design of wall is evaluated by using volume of concrete and

amount of steel. A comparative study is carried out & alternative with the least cost estimate is chosen as the best

design solution.

Prof. SaritaSingla et al[6], has discovered that during development of land, one often comes across with the

challenge of creating a difference in terrain elevation over an arbitrary horizontal distance. This can often be done by

creating slopes or by constructing retaining walls. Retaining walls are structures that are constructed to retail soil or

Volume 8, Issue IX, SEPTEMBER/2018 Page No:1249

International Journal of Management, Technology And Engineering ISSN NO : 2249-7455

any such materials which are unable to stand vertically by themselves. In this paper the study of the behaviour and

optimal design of three types of reinforced concrete walls of varying heights namely cantilever retaining wall,

counterfort retaining wall and retaining wall with relieving platforms is done. Cost against each optimal design of

wall for particular height is calculated by using the volume of concrete and the amount of steel. Amidst the cost

estimates of all the three optimal designs for particular height, a comparative study is carried out and the alternative

with the least cost estimate is chosen as the best design solution.

YashChaliawala et al[7], has found that the behavior and optimal design of two types of reinforced concrete walls of

varying heights namely cantilever retaining wall, counter fort retaining wall. Cost against each optimal design of

wall foe particular height is calculated using the volume of concrete and the amount of steel. Amidst the cost

estimate is chosen as the best design solution.

III METHODOLOGY:

3.1Design of retaining wall:

Technically while designing, all the necessary parameters and requirements are considered and all the

possible solutions are generated. Then a thorough analysis and calculations are carried out considering all the

parameters especially cost involved and the risk and uncertainties involved. Then the solution with the optimal cost

is chosen as the best solution. Thus, it is overall a rigorous decision making process.

The design of retaining will includes the following steps:

Fixation of the base width and the other dimensions of retaining wall

Performing stability checks and computation of maximum and minimum bearing pressure.

Design of various parts like stem, toe slab, heel slab, relieving platform.

For the analysis purpose three reinforced concrete retaining walls namely cantilever retaining wall,

counterfort retaining wall and retaining wall with relieving platforms with height ranging from 3m to 10m with

interval of 0.5m are considered. Safe bearing capacity is ranging from 100KN/m3 to 200 KN/m3 with interval of

10 KN/m3. Length of relieving platform is kept equal to length of heel slab for analysis purpose.

3.2. Design parameters:

Length of relieving platform: It is kept equal to the length of heel slab for easy analysis purpose.

Thickness of relieving platform: It is considered as a one fourth of the thickness of base slab.

Location of relieving platform: It is considered at the mid height of the retaining wall.

Angle of friction(ϕ) : 35º

Coefficient of active earth pressure(Ka): = 0.27

Coefficient of passive earth pressure(Kp) : = 3.69

Volume 8, Issue IX, SEPTEMBER/2018 Page No:1250

International Journal of Management, Technology And Engineering ISSN NO : 2249-7455

Depth of foundation: Height or depth of foundation ranging from 3m to 10m with interval of 0.5m is

considered.

Soil bearing capacity: SBC is ranging from 100KN/m3 to 200 KN/m3 with interval of 10 KN/m3

Unit weight of soil (ϒs): 18 KN/m3

Unit weight of concrete: 25 KN/m3

Grade of concrete: M25

Grade of steel: Fe500

3.3 Stability Checks:

The following stability checks are used in the design of retaining wall

Eccentricity of the resultant reaction force should lie between 0 and the base width/6

Factor of safety against sliding is taken greater than 1.5

Factor of safety against overturning is also taken greater than 1.5

The maximum and minimum bearing pressure is taken greater than 0 and less than soil bearing capacity

Maximum and minimum reinforcement percentage and reinforcement spacing is taken as per IS456:2000

code.

Restrictions on maximum shear stress in different parts are based on concrete grade as per IS456:2000 code

3.4. Total Cost of construction:

As mentioned in the above, the design with the optimal cost is taken as a best solution, the formula

involved in calculation is as follows,

Total cost: = cost for steel + cost for concrete

Volume 8, Issue IX, SEPTEMBER/2018 Page No:1251

International Journal of Management, Technology And Engineering ISSN NO : 2249-7455

IV RESULTS AND DISCUSSION

4.1 Variation of bending moments:

Table 1: bending moment variation

height of retaining wall Cantilever retaining wall retaining wall with relieving platform

bending moment(KN-m) bending moment(KN-m)

steam heel toe steam heel toe relieving platform

3 30.52 26.8 12.73 20.2 5.85 7.18 15.71

3.5 44.85 39.99 18.42 29.68 8.26 10.46 20.19

4 63.07 56.93 25.61 41.75 11.24 14.61 25.24

4.5 85.67 78.08 34.45 56.71 14.85 19.72 30.85

5 113.11 103.91 45.14 74.87 19.15 25.90 37.02

5.5 145.85 134.9 57.83 96.54 24.19 33.24 43.76

6 184.38 171.51 72.71 122.04 30.03 41.85 51.06

6.5 229.16 214.21 89.95 151.68 36.74 51.82 58.92

7 280.65 263.47 109.71 185.76 44.38 63.26 67.34

7.5 339.33 319.76 132.19 224.61 52.99 76.26 76.33

8 405.67 383.54 157.54 268.52 62.64 90.93 85.88

8.5 480.14 455.28 185.94 317.81 73.39 107.36 95.99

9 563.20 535.47 217.56 372.79 85.3 125.65 106.66

9.5 655.33 624.55 252.59 433.77 98.43 145.92 117.90

10 757.00 723 291.19 501.06 112.83 168.24 129.69

As we can see the bending moment for heel and toe is less in retaining wall with the relieving platform as

relieving wall is relieving some BM. From above table values we can plot the graphs and can see the variation of

bending moment.

Volume 8, Issue IX, SEPTEMBER/2018 Page No:1252

International Journal of Management, Technology And Engineering ISSN NO : 2249-7455

Figure 3: BM vs. height of wall for cantilever retaining wall

Figure 4: BM vs. height of wall for retaining wall with relieving platform

Volume 8, Issue IX, SEPTEMBER/2018 Page No:1253

International Journal of Management, Technology And Engineering ISSN NO : 2249-7455

From graph 1 and 2 we can see that as height of wall is increases, the bending moment of stem, toe and

heel is also increases in both the cases. But bending moment of heel and toe decreases in retaining wall with

relieving platform than cantilever retaining wall.

From graph, the equation for bending moment of different part of retaining wall is as follows,

For cantilever retaining wall:

Stem BM: y = 3.3593x2 - 3.0778x + 38.785

Heel BM: y = 3.2762x2 - 3.9969x + 35.912

Toe BM: y = 1.2652x2 - 0.8141x + 15.411

For retaining wall with relieving platform:

Stem BM: y = 2.2235x2 - 2.0372x + 25.672

Heel BM: y = 1.1908x2 - 1.6134x + 19.89

Toe BM: y = 1.1656x2 - 0.7622x + 14.083

Relieving platform: y = 0.3562x2 + 4.6133x + 14.925

Where x = height of wall

4.2 Variation of Area of steel:

Table 2: area of steel variation

Cantilever retaining wall retaining wall relieving platform

height of Area of steel (mm2) height of area of steel (mm2)

retaining wall steam heel toe retaining wall steam heel toe relieving

platform

3 436.28 425.69 377.14 3 323.63 377.14 377.14 321.17

3.5 588.99 545.78 419.05 3.5 439.27 419.05 419.05 412.90

4 766.12 681.06 471.43 4 574.01 452.57 471.43 516.13

4.5 967.85 831.51 565.71 4.5 728.04 514.29 565.71 630.86

5 1194.34 997.14 595.49 5 901.53 670.48 595.49 757.10

5.5 1445.67 1177.93 670.48 5.5 1094.58 670.48 670.48 894.84

6 1721.93 1373.88 693.60 6 1307.28 670.48 693.60 1044.08

6.5 2023.17 1584.98 744.97 6.5 1539.7 804.57 744.97 1204.82

7 2349.45 1811.25 773.63 7 1791.89 804.57 773.63 1377.07

7.5 2700.81 2052.67 838.10 7.5 2063.91 914.29 838.10 1560.81

8 3077.27 2309.24 874.53 8 2355.79 942.86 874.53 1756.06

8.5 3478.87 2580.97 957.82 8.5 2667.56 1028.57 957.82 1962.82

9 3905.62 2867.85 1005.71 9 2999.24 1131.43 1005.71 2181.07

Volume 8, Issue IX, SEPTEMBER/2018 Page No:1254

International Journal of Management, Technology And Engineering ISSN NO : 2249-7455

9.5 4357.54 3169.88 1117.46 9.5 3350.86 1257.14 1117.46 2410.83

10 4834.65 3487.07 1183.19 10 3722.43 1340.95 1183.19 2652.09

As we can see the area of steel for heel and toe is less in retaining wall with the relieving platform. But the

total area of steel for both cases is almost equal. From above table values we can plot the graphs and can see the

variation of area of steel.

Figure 5: Ast vs. height of wall for cantilever retaining wall

Volume 8, Issue IX, SEPTEMBER/2018 Page No:1255

International Journal of Management, Technology And Engineering ISSN NO : 2249-7455

Figure 6: Ast vs. height of wall for retaining wall with relieving platform

For cantilever retaining wall:

Stem Ast: y = 12.497x2 + 114.08x + 310.86

Heel Ast: y = 7.5794x2 + 97.097x + 318.71

Toe Ast: y = 2.8109x2 + 40.885x + 158

For retaining wall with relieving platform:

Stem Ast: y = 9.8651x2 + 84.77x + 230.3

Heel Ast: y = 7.2849x2 + 94.335x + 305.19

Toe Ast: y = 4.0678x2 + 92.977x + 164.67

Relieving platform Ast: y = 3.4906x2 + 17.743x + 244.73

Where x = height of wall

Volume 8, Issue IX, SEPTEMBER/2018 Page No:1256

International Journal of Management, Technology And Engineering ISSN NO : 2249-7455

4.2 Cost comparison:

Table 3 cost comparison

height Cantilever retaining wall Retaining wall with relieving platform

steel cost concrete cost total cost steel cost concrete cost total cost

3 2915 7274 10189.96 3428.14 6302 9729.93

3.5 3558 9166 12723.45 3995.33 7911 11905.92

4 4631 11272 15903.74 4818.09 9699 14517.17

4.5 5415 13595 19009.75 5776.68 11667 17443.94

5 6377 16133 22509.56 6697.40 13815 20512.52

5.5 6826 18887 25712.95 6173.16 16143 22315.84

6 8185 21856 30040.81 6781.53 18650 25431.45

6.5 9795 25041 34835.85 7339.28 21337 28676.13

7 10678 28442 39119.15 8281.68 24203 32485.15

7.5 12692 32058 44749.69 8969.05 27250 36218.83

8 14542 35890 50431.54 9385.63 30476 39861.40

8.5 14918 39937 54855.29 10488.32 33881 44369.77

9 16992 44200 61191.87 11584.58 37467 49051.40

9.5 18372 48679 67050.81 12352.61 41232 53584.48

10 20537 53373 73910.51 12994.94 45177 58171.55

As we can see the cost for steel in both the cases are almost same. But the cost for concrete is less for retaining wall

with relieving platform than cantilever retaining wall. This is happened because when we provide platforms to the

retaining wall the thickness of the base and the steam is reduces, and the volume of concrete is also reduces.

Volume 8, Issue IX, SEPTEMBER/2018 Page No:1257

International Journal of Management, Technology And Engineering ISSN NO : 2249-7455

Figure 7: Steel Cost vs. height

Figure 8: Concrete Cost vs. height of wall

Volume 8, Issue IX, SEPTEMBER/2018 Page No:1258

International Journal of Management, Technology And Engineering ISSN NO : 2249-7455

Figure 9: Cost comparison

From Graph 8, we can see than the as height increases the cost for construction is also increases. But the

cost for retaining wall with relieving platform is more than the cantilever retaining wall up to height 5.5-6m and

after that it is starting decreases.

For cantilever retaining wall:

Steel cost: y = 41.134x2 + 594.63x + 2271.4

Concrete cost: y = 114.1x2 + 2035x + 9550.9

Total cost: y = 114.1x2 + 2035x + 9550.9

For retaining wall with relieving platform:

Steel cost: y = 99.219x2 + 1612.5x + 6223

Concrete cost: y = 107.81x2 + 1565.9x + 5587.1

Total cost: y = 148.95x2 + 2160.5x + 7858.5

Where x = height of wall

4.4 Percentage cost:

Volume 8, Issue IX, SEPTEMBER/2018 Page No:1259

International Journal of Management, Technology And Engineering ISSN NO : 2249-7455

Table 4. Percentage profit

height total cost for total cost for retaining percentage

cantilever retaining wall with relieving cost

wall platform

3 10189.96 9729.928 4.73

3.5 12723.45 11905.92 6.87

4 15903.74 14517.17 9.55

4.5 19009.75 17443.94 8.98

5 22509.56 20512.52 9.74

5.5 25712.95 22315.84 15.22

6 30040.81 25431.45 18.12

6.5 34835.85 28676.13 21.48

7 39119.15 32485.15 20.42

7.5 44749.69 36218.83 23.55

8 50431.54 39861.4 26.52

8.5 54855.29 44369.77 23.63

9 61191.87 49051.4 24.75

9.5 67050.81 53584.48 25.13

10 73910.51 58171.55 27.06

From table 4, we can say that the retaining wall with the relieving platform retaining wall is slightly costlier

than cantilever retaining wall up to height 5.5m but after 5.5m its economical than cantilever retaining wall.

Volume 8, Issue IX, SEPTEMBER/2018 Page No:1260

International Journal of Management, Technology And Engineering ISSN NO : 2249-7455

4.5 Stability Consideration:

Table 5: Stability checks

height of Cantilever retaining wall Retaining wall with relieving platform

retaining wall FOS against FOS against FOS against FOS against

overturning>1.5 sliding>1.5 overturning>1.5 sliding>1.5

3 3.42 1.97 3.87 3.37

3.5 3.40 1.95 3.84 3.33

4 3.38 1.94 3.81 3.29

4.5 3.37 1.92 3.79 3.27

5 3.35 1.91 3.77 3.24

5.5 3.34 1.90 3.76 3.23

6 3.33 1.90 3.74 3.21

6.5 3.33 1.89 3.73 3.20

7 3.32 1.89 3.72 3.18

7.5 3.31 1.88 3.71 3.17

8 3.31 1.88 3.71 3.16

8.5 3.30 1.87 3.70 3.16

9 3.30 1.87 3.69 3.15

9.5 3.30 1.87 3.69 3.14

10 3.29 1.86 3.68 3.14

From above table we can evident that FOS against overturning and sliding for both the wall decreases as

the height of wall increases. But for the same height, both the safety factors are almost 2 times greater in relieving

tform retaining wall as compared to the cantilever retaining wall. So we can conclude that the relieving platform

retaining wall is more stable and safe as compared to cantilever one.

V CONCLUSION

A retaining wall is one of the most important types of retaining structures. It is extensively used in variety

of situations such as highway engineering, railway engineering, bridge engineering and irrigation engineering. This

research aims at developing an relationship between various parameter of retaining wall and showing their

comparative study.

The bending moment in toe and heel is less for retaining wall with relieving platform than

cantilever retaining wall.

Volume 8, Issue IX, SEPTEMBER/2018 Page No:1261

International Journal of Management, Technology And Engineering ISSN NO : 2249-7455

The area of steel for toe and heel is less for retaining wall with relieving platform than cantilever

retaining wall.

The construction cost for the retaining wall with relieving platform is more than cantilever

retaining wall up to height 5.5m and less after that.

The retaining wall with relieving platform is economical after 5.5m

By providing platform, the stability against sliding in increases much more. And the FOS against

sliding and overturning is almost double in retaining wall with relieving platform than cantilever

retaining wall.

The retaining wall with relieving platform is much more safer against overturning and sliding than

cantilever retaining wall.

And we also get inter-relationship between height of wall and various parameters of retaining wall

like dimensions, area of main steel, bending moments for different part of retaining wall and cost

of construction.

Parameter component Cantilever retaining wall Retaining wall with relieving platform

Dimension Height of wall x x

Total height H H

Base width 0.6H 0.6H

Base depth H/12 H/12

Steam top width 200mm 200mm

Steam bottom width H/10 H/12

Toe width 0.2H 0.2H

2

BM Stem y = 3.3593x - 3.0778x + 38.785 y = 2.2235x2 - 2.0372x + 25.672

Heel y = 3.2762x2 - 3.9969x + 35.912 y = 1.1908x2 - 1.6134x + 19.89

Toe y = 1.2652x2 - 0.8141x + 15.411 y = 1.1656x2 - 0.7622x + 14.083

Relieving platform y = 0.3562x2 + 4.6133x + 14.925

Ast main Stem y = 12.497x2 + 114.08x + 310.86 y = 9.8651x2 + 84.77x + 230.3

Heel y = 7.5794x2 + 97.097x + 318.71 y = 7.2849x2 + 94.335x + 305.19

Toe y = 2.8109x2 + 40.885x + 158 Toe Ast: y = 4.0678x2 + 92.977x + 164.67

Relieving platform Ast: y = 3.4906x2 + 17.743x + 244.73

Cost Steel y = 41.134x2 + 594.63x + 2271.4 y = 99.219x2 + 1612.5x + 6223

Concrete y = 114.1x2 + 2035x + 9550.9 y = 107.81x2 + 1565.9x + 5587.1

Total cost y = 114.1x2 + 2035x + 9550.9 y = 148.95x2 + 2160.5x + 7858.5

Volume 8, Issue IX, SEPTEMBER/2018 Page No:1262

International Journal of Management, Technology And Engineering ISSN NO : 2249-7455

REFERENCES

1. Shravya Donkada and Devdas Menon, “Optimal design of reinforced concrete retaining walls”, The

Indian concrete journal. April 2012, page 9-18

2. S. S.Patil and A. A. R. Babgan, “analysis and design of reinforced concrete stepped cantilever

retaining wall”, IJRET, vol. 04, Feb-2015, page 46-67

3. Rupa B. Patil, G. R. Patil, “Design and detailing of counter fort retaining walls for construction site”,

International journal of informative & fururistic research, Vol. 3, September 2015, page 61-71

4. Tamadher abood, Haten E. Younis Eldawi, Faeza R. Elnaji Abdulrahim, “Design of Cantilever

retaining wall with 4m height ”, Imternational journal of civil and structural engineering research, vol.

3, April 2015, pp 318-326

5. Inder kummar Lilani, Dr. Rakesh Patel, “Analysis of counterfort retaining wall in non over flow

section of gravity dam” , IJSRD, Vol. 5, May 2017, pp. 920-924

6. Sarita Singla and Er. Sakshi Gupta, “Optimisation of reinforced concrete walls of varing heights using

relieving platform”, IJERT, Vol. 4, June 2015, pp 1071-1077

7. Yash Chaliawala, Gunvant Solanki, Anuj K. Chandiwala, “Comparative study of cantilever and

counter fort retaining wall”, International journal of advanced engineering and research development,

Vol. 2, Dec. 2015, pp. 221-224

8. S. Tatahari, R. Sheikoleslami, M. Shadfaran and M. Pourbaba, “Optimum Design of gravity retaining

walls using charged system search algorithm”, Hindawi Publishing corporation, sep. 2012,

9. Su Yang, Amin Chegnizadeh and Hamid Nikraz, “Review of studies on retaining walls behavior on

dynamic/ seismic condition”, vol. 3, Nov 2013, pp. 1012-1021

10. Swati Nagare, Rutuja Shinde, Sushma Ladkat and Komal Mahisare, “Case study of retaining wall”,

April 2017

11. IS 14458 (1998): Guidelines for retaining wall for hill area, part-1: selection of type of wall

12. IS 14458 (1998): Guidelines for retaining wall for hill area, part-2: Design of retaining/ breast walls

13. IS 14458 (1998): Guidelines for retaining wall for hill area, part-3: Construction of Dry stone walls

Volume 8, Issue IX, SEPTEMBER/2018 Page No:1263

You might also like

- Tall Buildings: The Proceedings of a Symposium on Tall Buildings with Particular Reference to Shear Wall Structures, Held in the Department of Civil Engineering, University of Southampton, April 1966From EverandTall Buildings: The Proceedings of a Symposium on Tall Buildings with Particular Reference to Shear Wall Structures, Held in the Department of Civil Engineering, University of Southampton, April 1966A. CoullRating: 5 out of 5 stars5/5 (1)

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- 147.Sepijmte CwDocument19 pages147.Sepijmte CwvediannanjaganNo ratings yet

- Paper BW and RWDocument18 pagesPaper BW and RWPriya GautamNo ratings yet

- Optimal Reinforced Concrete Wall DesignDocument7 pagesOptimal Reinforced Concrete Wall DesignPrsNo ratings yet

- Design of Retaining Wall: A Mini Project Report ONDocument40 pagesDesign of Retaining Wall: A Mini Project Report ONMohnika SamineniNo ratings yet

- Analysis and Design of RCC Retaining Wall To Overcome LandslideDocument9 pagesAnalysis and Design of RCC Retaining Wall To Overcome LandslideIJRASETPublicationsNo ratings yet

- Effective - Use - of - Shelves - in - Cantilever - جدار استنادي ذو الرفوفDocument5 pagesEffective - Use - of - Shelves - in - Cantilever - جدار استنادي ذو الرفوفقيس عبدالرحمن قيسNo ratings yet

- Analysis and Design of Stepped Cantilever Retaining Wall IJERTV4IS020033Document13 pagesAnalysis and Design of Stepped Cantilever Retaining Wall IJERTV4IS020033Mahesh MamidiNo ratings yet

- V4i2 Ijertv4is020033Document14 pagesV4i2 Ijertv4is020033vishnuNo ratings yet

- Comparative Study of Cantilever and Counter Fort Retaining Wall-46768Document4 pagesComparative Study of Cantilever and Counter Fort Retaining Wall-46768Editor IJAERDNo ratings yet

- Shear WallDocument17 pagesShear WallIjaz100% (1)

- Jagan'S College of Engineering and Technology: Choutapalem (V), Nellore (D)Document26 pagesJagan'S College of Engineering and Technology: Choutapalem (V), Nellore (D)Sandeep HøñeyNo ratings yet

- Learning Outcome 4 Retaining WallsDocument9 pagesLearning Outcome 4 Retaining WallsChris FindlayNo ratings yet

- Comparing The Effect of Earthquake On High Rise Buildings With & Without Shear Wall and Flanged Concrete Column Using STAAD ProDocument4 pagesComparing The Effect of Earthquake On High Rise Buildings With & Without Shear Wall and Flanged Concrete Column Using STAAD ProLim TiNo ratings yet

- Shear Wall Analysis and DesignDocument35 pagesShear Wall Analysis and DesignSai Muthiki100% (1)

- 1.INTRODUCTION - Retaining Walls Are Constructed To Hold Back Ground Which Would Otherwise Move Downwards.Document5 pages1.INTRODUCTION - Retaining Walls Are Constructed To Hold Back Ground Which Would Otherwise Move Downwards.Shubham MareNo ratings yet

- Stages For Construction: Retaining WallDocument37 pagesStages For Construction: Retaining WallIkhwan HasiffNo ratings yet

- Review Paper Ijrt Retaining WallDocument5 pagesReview Paper Ijrt Retaining WallSharad KumarNo ratings yet

- Report Project Mom Section 10 Group 1Document24 pagesReport Project Mom Section 10 Group 1Muhammad Hazim Bin Abdul HishamNo ratings yet

- Seismic Analysis of Multi-Storied Building With Shear Walls Using ETABS-2013Document11 pagesSeismic Analysis of Multi-Storied Building With Shear Walls Using ETABS-20138790922772No ratings yet

- Design of brick fin walls for tall wide-span buildingsDocument5 pagesDesign of brick fin walls for tall wide-span buildingschoriya007No ratings yet

- A Review On Shear Wall in High Rise Buildings: Sonali Pandey, DR - Krishna Murari, Ashish Pathak, Chandan KumarDocument3 pagesA Review On Shear Wall in High Rise Buildings: Sonali Pandey, DR - Krishna Murari, Ashish Pathak, Chandan KumarSann MyintmgNo ratings yet

- Research Paper On Shear WallDocument7 pagesResearch Paper On Shear Wallp0lolilowyb3100% (1)

- ITJEGAN'S OptionDocument14 pagesITJEGAN'S OptionMohan0% (1)

- Shear Wall SeminarDocument12 pagesShear Wall SeminarJithu SukumaranNo ratings yet

- Masonry IV PDFDocument40 pagesMasonry IV PDFBaraka GotoraNo ratings yet

- Loadbearing Precast Concrete Wall Panels for Architectural DesignDocument24 pagesLoadbearing Precast Concrete Wall Panels for Architectural DesignErnest NavarroNo ratings yet

- CFRP strengthening improves load capacity of brick and concrete block bearing wallsDocument7 pagesCFRP strengthening improves load capacity of brick and concrete block bearing wallsHussain AbbasNo ratings yet

- Shear Walls - An OverviewDocument6 pagesShear Walls - An OverviewTabish IslamNo ratings yet

- 2022 V13i373Document10 pages2022 V13i373muzamilillahi7No ratings yet

- BACDISDocument16 pagesBACDISJorge EspinoNo ratings yet

- Earthquake Resistant Design of A Building Using Shear WallDocument7 pagesEarthquake Resistant Design of A Building Using Shear Wallnithya kjNo ratings yet

- 8.CE 483 Retaining Walls CH 17 3rd 1444 - 2Document95 pages8.CE 483 Retaining Walls CH 17 3rd 1444 - 2Saad MohammedNo ratings yet

- Shear WallDocument22 pagesShear WallWanda Beasley100% (1)

- Seismic Analysis of Shear Wall at Different Location On Multi-Storey RCC BuildingDocument22 pagesSeismic Analysis of Shear Wall at Different Location On Multi-Storey RCC BuildingSrinivas Taniganti100% (1)

- Classification of Shear WallDocument23 pagesClassification of Shear WallShivkamal50% (2)

- Shear Wall Design and FunctionsDocument20 pagesShear Wall Design and FunctionsKeyur VasavaNo ratings yet

- Cavity Walls PDFDocument23 pagesCavity Walls PDFAsghar Hussain Shah100% (1)

- Seismic Analysis of Multi-Storied Building With Shear Walls Using EtabsDocument6 pagesSeismic Analysis of Multi-Storied Building With Shear Walls Using EtabsIsmailNo ratings yet

- Unit 5 - Construction Technology - WWW - Rgpvnotes.inDocument6 pagesUnit 5 - Construction Technology - WWW - Rgpvnotes.inRitesh Agarwal OYOwalaNo ratings yet

- Chapter-5-Analysis and Design of Retaining WallsDocument21 pagesChapter-5-Analysis and Design of Retaining WallsephNo ratings yet

- Design of Retaining WallDocument8 pagesDesign of Retaining WallMarkos KochitoNo ratings yet

- Tek 14-16BDocument9 pagesTek 14-16Bmiguel fuentesNo ratings yet

- Earthquake Engineering Design for Multi-Storey Composite StructuresDocument21 pagesEarthquake Engineering Design for Multi-Storey Composite StructuresLibre Joel IanNo ratings yet

- Effect of Shear Wall On Response of Multi-Storied Building FrameDocument5 pagesEffect of Shear Wall On Response of Multi-Storied Building Framestructure123No ratings yet

- IJSDR1803015Document8 pagesIJSDR1803015Afaq AhmedNo ratings yet

- Analysis and Design of Shear WallsDocument24 pagesAnalysis and Design of Shear WallsRkkodi100% (3)

- Shear Wall: Guided by Roll No:21 S7 Civil SngistDocument20 pagesShear Wall: Guided by Roll No:21 S7 Civil SngistAnonymous POUAc3zNo ratings yet

- Hybrid Masonry Design 2.13.01 - 12.29.09Document6 pagesHybrid Masonry Design 2.13.01 - 12.29.09Sovich82No ratings yet

- Retaining Wall DesignDocument11 pagesRetaining Wall DesignMustefa Mohammed AdemNo ratings yet

- Analysis of Reinforced Retaining Wall Failure Based On Reinforcement LengthDocument14 pagesAnalysis of Reinforced Retaining Wall Failure Based On Reinforcement LengthPrabhu Nath SinghNo ratings yet

- Design of Earth Retaining and Supporting Structures ReportDocument38 pagesDesign of Earth Retaining and Supporting Structures Reportsaurav kumar singhNo ratings yet

- Shear Wall MainDocument37 pagesShear Wall MainMr420• NeffexNo ratings yet

- Analysis of Shear Wall Thicknesses and Opening EffectsDocument7 pagesAnalysis of Shear Wall Thicknesses and Opening EffectsBadr AmmarNo ratings yet

- ANALYSIS AND DESIGN OF REINFORCED CONCRETE RECTANGULAR SHEAR WALLDocument3 pagesANALYSIS AND DESIGN OF REINFORCED CONCRETE RECTANGULAR SHEAR WALLAnonymous g1LSaANo ratings yet

- Applsci 07 00629Document19 pagesApplsci 07 00629Venkataraju BadanapuriNo ratings yet

- Role of Shear To High Rise BuildingsDocument18 pagesRole of Shear To High Rise BuildingsAxmed ShirwacNo ratings yet

- Erbil Polytechnic University Retaining WallsDocument12 pagesErbil Polytechnic University Retaining WallsHelan AdnanNo ratings yet

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionFrom EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionNo ratings yet

- Load Distribution DrawingDocument1 pageLoad Distribution DrawingSaravanakumarNo ratings yet

- Filling The Gaps With The VerbsDocument1 pageFilling The Gaps With The VerbsPavelNo ratings yet

- Finite Element Modeling For Piled Raft Foundation in SandDocument8 pagesFinite Element Modeling For Piled Raft Foundation in SandtangkokhongNo ratings yet

- 1323 IjirseDocument7 pages1323 IjirseKarthikeyan PanchatcharamNo ratings yet

- Behaviour of rigid retaining walls with relief shelvesDocument8 pagesBehaviour of rigid retaining walls with relief shelvesSaravanakumarNo ratings yet

- Surcharge Induced Earth Pressure Reduction On Non-Yielding Rigid Retaining Wall Using Relief ShelfDocument5 pagesSurcharge Induced Earth Pressure Reduction On Non-Yielding Rigid Retaining Wall Using Relief ShelfSaravanakumarNo ratings yet

- Staad Pro - Mat FoundationDocument16 pagesStaad Pro - Mat FoundationV.m. Rajan100% (1)

- 0772 PDFDocument8 pages0772 PDFSaravanakumarNo ratings yet

- Assessment of Crude Oil Blends PDFDocument6 pagesAssessment of Crude Oil Blends PDFDanivian HigginsNo ratings yet

- Properties and Reactions of Acids and BasesDocument46 pagesProperties and Reactions of Acids and Basesaliefyan4769No ratings yet

- Élan VitalDocument3 pagesÉlan Vitalleclub IntelligenteNo ratings yet

- LGU Performance Monitoring FrameworkDocument3 pagesLGU Performance Monitoring FrameworkMichelle GozonNo ratings yet

- Architect's Professional Practice 2Document48 pagesArchitect's Professional Practice 2Joshua CorpuzNo ratings yet

- Procurement of Land in Indonesia: Challenges and Solutions in the Legal Sociological PerspectiveDocument12 pagesProcurement of Land in Indonesia: Challenges and Solutions in the Legal Sociological PerspectiveFrans OleyNo ratings yet

- English 1000 Most Repeated MCQs by Learning With Rizwan - 083731Document145 pagesEnglish 1000 Most Repeated MCQs by Learning With Rizwan - 083731Athleteboy7No ratings yet

- Enthalpy, Spontaneity, EntropyDocument16 pagesEnthalpy, Spontaneity, EntropyJeremy MacalaladNo ratings yet

- Interpreting SNT TC 1A PDF 2Document1 pageInterpreting SNT TC 1A PDF 2Jagannath SahuNo ratings yet

- Spe 193796 MsDocument22 pagesSpe 193796 MsMurtibaahshe HDNo ratings yet

- Questions of Reliability Centered MaintenanceDocument15 pagesQuestions of Reliability Centered Maintenancemariana100% (1)

- FAO Fisheries & Aquaculture - Cultured Aquatic Species Information Programme - Penaeus Vannamei (Boone, 1931)Document14 pagesFAO Fisheries & Aquaculture - Cultured Aquatic Species Information Programme - Penaeus Vannamei (Boone, 1931)Dalis FaNo ratings yet

- Фонетика Тест 1-4Document1 pageФонетика Тест 1-4Карина КамаловаNo ratings yet

- Pavement Design in The USA: Andrey KorochkinDocument8 pagesPavement Design in The USA: Andrey KorochkinJobaer Al-MahmudNo ratings yet

- Flushing and Passivation SystemDocument2 pagesFlushing and Passivation Systemmyo myint aungNo ratings yet

- Marking Scheme BI Penulisan PPT 5MDocument7 pagesMarking Scheme BI Penulisan PPT 5MTAN KOH SIANG MoeNo ratings yet

- Probability TheoryDocument9 pagesProbability TheoryAlamin AhmadNo ratings yet

- Read ChromaticDocument20 pagesRead ChromaticGURNOORNo ratings yet

- Work, Power & Energy Module JB (MS)Document17 pagesWork, Power & Energy Module JB (MS)Danil Mohd AzmaniNo ratings yet

- Bai Giang - CT361 - Chuong 4 (PDF - Io)Document18 pagesBai Giang - CT361 - Chuong 4 (PDF - Io)Nghiệp Nguyễn ThànhNo ratings yet

- (Reuters Institute For The Study of Journalism) James Painter - Climate Change in The Media - Reporting Risk and Uncertainty-I. B. Tauris (2013)Document192 pages(Reuters Institute For The Study of Journalism) James Painter - Climate Change in The Media - Reporting Risk and Uncertainty-I. B. Tauris (2013)Thomas Ravelly Batista dos SantosNo ratings yet

- Disputed Paternity and DNA Testing in IndiaDocument14 pagesDisputed Paternity and DNA Testing in IndiaAtulya Singh ChauhanNo ratings yet

- NRG Systems SRM Station VerificationDocument5 pagesNRG Systems SRM Station VerificationLuis PulidoNo ratings yet

- Fy2023 CBLD-9 RevisedDocument11 pagesFy2023 CBLD-9 Revisedbengalyadama15No ratings yet

- UROP Proceedings 2015-16Document95 pagesUROP Proceedings 2015-16alex61937No ratings yet

- WorkbookDocument7 pagesWorkbookᜃᜋᜒᜎ᜔ ᜀᜂᜇᜒᜈᜓ ᜋᜓᜆ᜔ᜑNo ratings yet

- Quadratics Unit Quiz #1Document3 pagesQuadratics Unit Quiz #1hix8073No ratings yet

- Listado 13Document436 pagesListado 13Abel Hernandez SoteloNo ratings yet

- MTH002 Core MathematicsDocument11 pagesMTH002 Core MathematicsRicardo HoustonNo ratings yet

- SAT Practice Test 1 Combined PDFDocument122 pagesSAT Practice Test 1 Combined PDFRay728No ratings yet