Professional Documents

Culture Documents

ASME 831.4-an2 allowable stress table

Uploaded by

lechepinitoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASME 831.4-an2 allowable stress table

Uploaded by

lechepinitoCopyright:

Available Formats

ASME 831.

4-an2

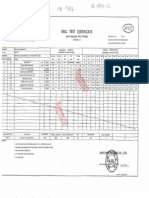

TABLE 402.3.Lh)

TABULATION OF EXAMPLES OF ALLOWABLE STRESSES

FOR REFERENCE USE IN PIPING

SYSTEMS WITHIN THE SCOPE OF THIS CODE

Specified Min. Allowable Stress Value S,

Yield Strength,

Specification -20oF to 250'F (-30'C to 120'C),

Grade psi (MPa) Weld Joint Factor E psi(MPa')

Seamless

API 5L 425 25,O0O lt72) 1.00 18,000 (124)

API sL, ASTM A 53, ASTM A 106 A 30,000 (207) 1.00 21/600 (149)

API sL, ASTM A 53, ASTM A 106 B 35,000 (241) 1.00 25,200 <t74)

API 5L x42 (289)

42,O0O 1.00

API 5L 3O¡25O QUe)

x4ó 46,000 (317) 1.00 33,t00 Q28)

API 5L xs2 52,000 (358) I.00 37,450 (23A)

API 5L x56 56,000 (386) 1.00 40,300 Q7A)

API 5L x60 60,000 (413) 1.00 43,200 Q98)

API 5L X65 65,000 (448) 1.00 461800 (3231

API 5L x70 70,000 (482) 1..00 50,4OO e47)

API 5L x80 80,000 (551) 1.00 57,600 (397)

ASTM A 106 40,000 (278) 1.00 28,800 (199)

ASTM A 333 6 35,000 (241) 1.00 25,000 (.J74)

ASTM A,524 I 35,0OO Q4L) 1.00 25,200 (174')

ASTM A 524 H 30,000 (207) 1.00 2L,600 |J49)

Furnace Butt Welded, Continuous Welded

ASTM A 53

25,OOO (L72) 0.60 10,800 i74)

API 5L Ctasses I and II ir 25,000 (t72) 0.60 10,800 (74)

Electric Resiitance Welded and Electric Flash

Welded

API 5L 425 (I72,

25,000 1.00 18,000 (l-24)

API sL, ASTM A s3, ASTM A 135 A 3O,0OO QO7) I.00

API 51, ASTM A s3, ASTM A 135 2r,60q (149)

B 3s,000 (241) 1.00 25,200 (r74)

API 5L x42 42,O0O (289) 1.00 302so (¿la,

API 5L x46 (3t7)

46,000 r.00 33tL0O (228)

AFI 5L xs2 52,000 (358) 1.00 37,450 (.¿58'

APT 5L

x56 56,000 (386) 1.00

API 5L 4o,3oo Q79)

x60 60,000 (413) 1.00 43,200 Q97)

API 5L x65 ó5,000 (448) 1.00 46,800 G23)

API 5L x70 70,000 (482) 1.00 s0A00 e47)

API 5L x80 80,00fl (55t) 1.ü0 57,600 {397)

ASTM A 333

is,o00 Q4t) l-oo 2s,000 (L74)

Gontinued)

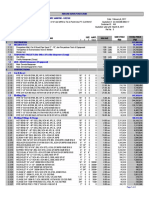

You might also like

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Grade F: Tabulation Allowable Within TheDocument1 pageGrade F: Tabulation Allowable Within ThelechepinitoNo ratings yet

- Asme B31.4 - Allowable StressDocument2 pagesAsme B31.4 - Allowable Stressjoaquin torrano veraNo ratings yet

- Allowable Stress in PipingDocument6 pagesAllowable Stress in PipingpelotoNo ratings yet

- ASME Material SpectDocument46 pagesASME Material SpectPankajDhobleNo ratings yet

- Table 4-1 Maximum Allowable Shell Stresses: (Not For Use For Reconstructed Tanks, See Note 6)Document1 pageTable 4-1 Maximum Allowable Shell Stresses: (Not For Use For Reconstructed Tanks, See Note 6)muhd.qasimNo ratings yet

- Grade Yield Strength Tensile Strength: Api 5LDocument1 pageGrade Yield Strength Tensile Strength: Api 5LArifinNo ratings yet

- 3 70a e Pa 140 Pa206 Pa436 Linear Pneumatic ActuatorsDocument6 pages3 70a e Pa 140 Pa206 Pa436 Linear Pneumatic Actuatorsryando fernandaNo ratings yet

- Tabela Acos Carbono PDFDocument1 pageTabela Acos Carbono PDFRafael PaivaNo ratings yet

- Everything You Need to Know About Corten Steel Grades and SpecificationsDocument8 pagesEverything You Need to Know About Corten Steel Grades and SpecificationsadihindNo ratings yet

- Mandatory Appendix D Specified Minimum Yield Strength For Steel Pipe Commonly Used in Piping SystemsDocument2 pagesMandatory Appendix D Specified Minimum Yield Strength For Steel Pipe Commonly Used in Piping SystemsAmr HeshamNo ratings yet

- Water Tank SizeDocument1 pageWater Tank SizeTerence LeongNo ratings yet

- Tabel 8.1Document1 pageTabel 8.1topan hidayatNo ratings yet

- Ductile Iron Casting Specifications SummaryDocument15 pagesDuctile Iron Casting Specifications SummarySiriusNo ratings yet

- Low Hydrogen Low Alloy Electrodes for High Strength Steel WeldsDocument2 pagesLow Hydrogen Low Alloy Electrodes for High Strength Steel WeldsFranklin Aranda ChacónNo ratings yet

- SF-71 en EngDocument2 pagesSF-71 en EngbvbarcNo ratings yet

- OKFlux 1062Document1 pageOKFlux 1062jpvtvNo ratings yet

- MS-264Document15 pagesMS-264Felipe De la cruzNo ratings yet

- Lehr Piping Equipment List 2016.5.13 @Document8 pagesLehr Piping Equipment List 2016.5.13 @hagia sophiaNo ratings yet

- Pipe Grade Pipe Body of Seamless and Welded Pipes: A t0,5 A M FDocument2 pagesPipe Grade Pipe Body of Seamless and Welded Pipes: A t0,5 A M FMauricio RinconNo ratings yet

- Blind Flange TCDocument1 pageBlind Flange TCDEEPAKNo ratings yet

- 00) 60236 ODshrc BOM REV00 Paltes&profilesDocument2 pages00) 60236 ODshrc BOM REV00 Paltes&profilesAshkan AsefiNo ratings yet

- Calculating Gas Pipe SizingDocument4 pagesCalculating Gas Pipe SizingGonzalo vargasNo ratings yet

- Catalogue Hitachi-01-05-2016 PDFDocument8 pagesCatalogue Hitachi-01-05-2016 PDFBach HuynhNo ratings yet

- Price List-IDocument1 pagePrice List-Imohan_27109150No ratings yet

- Comparacion Tierras DiatomeasDocument2 pagesComparacion Tierras DiatomeasjosemendozaoNo ratings yet

- Caracteristicas API 2HGr50 PDFDocument3 pagesCaracteristicas API 2HGr50 PDFFernandoBarreraDominguezNo ratings yet

- ATOM ARC LOW HYDROGEN ELECTRODESDocument2 pagesATOM ARC LOW HYDROGEN ELECTRODESanupmenon menonNo ratings yet

- American Society For Testing and Materials Specification: Astm - AMS - Aerospace MaterialDocument10 pagesAmerican Society For Testing and Materials Specification: Astm - AMS - Aerospace MaterialjleonosNo ratings yet

- XEL Siemens Price ListDocument5 pagesXEL Siemens Price Listমোঃ মোমিনুল ইসলাম শোভনNo ratings yet

- BoQ - Structure Steel Request CostingDocument12 pagesBoQ - Structure Steel Request CostingRanu JanuarNo ratings yet

- Technical Specification EM13KDocument1 pageTechnical Specification EM13KVåïbhäv ÇhåühåñNo ratings yet

- API 650 Annular Plate Annex MDocument1 pageAPI 650 Annular Plate Annex Mhector cano moraNo ratings yet

- AcerinoxDocument1 pageAcerinoxOmkar PrindavankarNo ratings yet

- Comp of Flanges KochiDocument1 pageComp of Flanges KochiRabindra SutradharNo ratings yet

- Land Cruiser technical specificationsDocument2 pagesLand Cruiser technical specificationsALEJONo ratings yet

- Performance Sliding Vane Z SeriesDocument6 pagesPerformance Sliding Vane Z Seriescarlos sotoNo ratings yet

- Astm B85 B85M 18Document6 pagesAstm B85 B85M 18BinitNo ratings yet

- JAPANESE INDUSTRIAL STANDARD FOR PRESTRESSED CONCRETE PILESDocument15 pagesJAPANESE INDUSTRIAL STANDARD FOR PRESTRESSED CONCRETE PILESVõ Quang Kiệt100% (2)

- Preparation and Characterization of Supported Nickel Catalysts.Document12 pagesPreparation and Characterization of Supported Nickel Catalysts.Hugo SolìsNo ratings yet

- Lampiran: Rencana Kebutuhan Material Dan Anggaran Biaya Pembuatan Lapangan FutsalDocument2 pagesLampiran: Rencana Kebutuhan Material Dan Anggaran Biaya Pembuatan Lapangan FutsalsyaifulRizal12345678No ratings yet

- List Acceptance Criteria For Mechanical Test (03032017)Document7 pagesList Acceptance Criteria For Mechanical Test (03032017)Alfian Imaduddin100% (1)

- Aerospace Material SpecificationDocument6 pagesAerospace Material SpecificationAnonymous T6GllLl0No ratings yet

- Canada Culvert Non Woven Geotextile Spec Sheet 1Document1 pageCanada Culvert Non Woven Geotextile Spec Sheet 1VindireNo ratings yet

- s30 SMetallic Data SheetDocument5 pagess30 SMetallic Data Sheetluis miguel velarde manriqueNo ratings yet

- B56. 6775-4_BRIDA WN (1)Document1 pageB56. 6775-4_BRIDA WN (1)danielsalcedomringenierosNo ratings yet

- Check Valves 50 Series (MS-01-98) R4Document2 pagesCheck Valves 50 Series (MS-01-98) R4herysyam1980No ratings yet

- BEAM DESIGN - RSLT - Member - Detail - 1 - 1 - 348Document22 pagesBEAM DESIGN - RSLT - Member - Detail - 1 - 1 - 348CSEC Uganda Ltd.No ratings yet

- WG263-7 Valvula Gate 10 SCH 150Document1 pageWG263-7 Valvula Gate 10 SCH 150ksi meritosNo ratings yet

- 2MM 3.15MM HRDocument1 page2MM 3.15MM HRMarshallNo ratings yet

- Breakdown Attachment Geodipa - TenderDocument1 pageBreakdown Attachment Geodipa - TenderHarryNo ratings yet

- E9018 M Specifications PDFDocument2 pagesE9018 M Specifications PDFMohamed MostafaNo ratings yet

- Tubular Plate Open Battery (Opzs) : CharacteristicsDocument1 pageTubular Plate Open Battery (Opzs) : CharacteristicsFlavio Cesar contreras chuquitarquiNo ratings yet

- Product Data Sheet Pipeweld 70S-6: G 'Gas-Shielded Metal-Arc Welding'Document2 pagesProduct Data Sheet Pipeweld 70S-6: G 'Gas-Shielded Metal-Arc Welding'RobertoNo ratings yet

- Hobart Hachene-590Document1 pageHobart Hachene-590Felipe montanaNo ratings yet

- ปริมาณท่อเหล็กDocument1 pageปริมาณท่อเหล็กPichai ChaibamrungNo ratings yet

- Datasheet Sandvik 2rk65 en v2019!06!19 14 - 54 Version 1Document13 pagesDatasheet Sandvik 2rk65 en v2019!06!19 14 - 54 Version 1mauferesNo ratings yet

- 1.1 Welder Test 86,350,000: PackageDocument2 pages1.1 Welder Test 86,350,000: PackageAhmad Dzulfiqar RahmanNo ratings yet

- Base Slab - BBS TramaniDocument16 pagesBase Slab - BBS TramaniDevesh GuptaNo ratings yet

- SUPERDUPLEXDocument7 pagesSUPERDUPLEXM RNo ratings yet

- .D/D Thernal 400 500 600 800: CH.,/RTS Tables c-2. Expansion, Ca¡bon and - (IloyDocument1 page.D/D Thernal 400 500 600 800: CH.,/RTS Tables c-2. Expansion, Ca¡bon and - (IloylechepinitoNo ratings yet

- 36 Normas FabricacionDocument1 page36 Normas FabricacionlechepinitoNo ratings yet

- 31 Astm A-53Document1 page31 Astm A-53lechepinitoNo ratings yet

- 33 Astm A-53Document1 page33 Astm A-53lechepinitoNo ratings yet

- 35 Astm A-53Document1 page35 Astm A-53lechepinitoNo ratings yet

- Selecting and specifying valves for new plantsDocument1 pageSelecting and specifying valves for new plantslechepinitoNo ratings yet

- 58 Válvula Doble Sello ExpDocument1 page58 Válvula Doble Sello ExplechepinitoNo ratings yet

- 27 Astm A-53Document1 page27 Astm A-53lechepinitoNo ratings yet

- 30 Astm A-53Document1 page30 Astm A-53lechepinitoNo ratings yet

- 34 Astm A-53Document1 page34 Astm A-53lechepinitoNo ratings yet

- Pipe component diagramDocument1 pagePipe component diagramlechepinitoNo ratings yet

- 32 Astm A-53Document1 page32 Astm A-53lechepinitoNo ratings yet

- 29 Astm A-53Document1 page29 Astm A-53lechepinitoNo ratings yet

- 28 Astm A-53Document1 page28 Astm A-53lechepinitoNo ratings yet

- Resistencias de codos, tees y curvas: tablas de referenciaDocument1 pageResistencias de codos, tees y curvas: tablas de referencialechepinitoNo ratings yet

- VRF inverter multi-system overview and benefitsDocument132 pagesVRF inverter multi-system overview and benefitslechepinitoNo ratings yet

- Voyager 27.5 - 5o Ton Product DataDocument140 pagesVoyager 27.5 - 5o Ton Product DatalechepinitoNo ratings yet

- DELTA CP AC-evo Inglese Compatto Pinza A BeccoDocument43 pagesDELTA CP AC-evo Inglese Compatto Pinza A BeccolechepinitoNo ratings yet

- Smacna - Duct.1995 BookDocument308 pagesSmacna - Duct.1995 BookJason RogersNo ratings yet

- 04 Coef Friccion KDocument1 page04 Coef Friccion KlechepinitoNo ratings yet

- VRF inverter multi-system overview and benefitsDocument132 pagesVRF inverter multi-system overview and benefitslechepinitoNo ratings yet

- Catalogo General HailinDocument68 pagesCatalogo General HailinlechepinitoNo ratings yet

- Croker PDF Catalog 2009Document153 pagesCroker PDF Catalog 2009lechepinitoNo ratings yet

- VWDocument27 pagesVWlechepinitoNo ratings yet

- GMR1838-2CK: Battery Level and Low Battery AlertDocument2 pagesGMR1838-2CK: Battery Level and Low Battery AlertlechepinitoNo ratings yet

- Articulo Cientifico LCOE y PPADocument10 pagesArticulo Cientifico LCOE y PPAlechepinitoNo ratings yet

- Manual Del Termostato PDFDocument81 pagesManual Del Termostato PDFlechepinitoNo ratings yet

- Condensing Unit & Evaporador PC: GTF SeriesDocument2 pagesCondensing Unit & Evaporador PC: GTF Serieslechepinito100% (1)

- Good Hygiene On The JobDocument2 pagesGood Hygiene On The JobTeodoro EsquilloNo ratings yet

- Project Details: Synthetic Organic Chemicals 5 (F) For Terms of Reference (Tor) New ProjectDocument14 pagesProject Details: Synthetic Organic Chemicals 5 (F) For Terms of Reference (Tor) New Projectrajesh kothariNo ratings yet

- Mangan Reagent Set - 1457799Document10 pagesMangan Reagent Set - 1457799Ajib Sari PutraNo ratings yet

- Cells to OrganismsDocument15 pagesCells to OrganismsElleNo ratings yet

- Conceptual Diagram of Ways To Increase SalesDocument1 pageConceptual Diagram of Ways To Increase SalesO6U Pharmacy RecordingsNo ratings yet

- Chemistry For Allied Health Professionals (Lab)Document3 pagesChemistry For Allied Health Professionals (Lab)Corinne Bautista RenivaNo ratings yet

- Diesel SDS V2Document14 pagesDiesel SDS V2francisNo ratings yet

- NCH INDIA MT - Commercial BuildingsDocument34 pagesNCH INDIA MT - Commercial Buildingsr vasudevNo ratings yet

- Chemistry HL - Study Guide - Tim Van Puffelen - Second Edition - IB Academy 2020 (Ib - Academy)Document143 pagesChemistry HL - Study Guide - Tim Van Puffelen - Second Edition - IB Academy 2020 (Ib - Academy)Saket GudimellaNo ratings yet

- Processes: Available Technologies and Materials For Waste Cooking Oil RecyclingDocument13 pagesProcesses: Available Technologies and Materials For Waste Cooking Oil RecyclingIlham fathaNo ratings yet

- 02 Latent PrintDocument94 pages02 Latent PrintMoussa ToudjaniNo ratings yet

- Practice Exam 1 - Chem 2400Document8 pagesPractice Exam 1 - Chem 2400Mareline MendietaNo ratings yet

- PDFDocument35 pagesPDFUmar FarouqNo ratings yet

- Single Replacement Reactions LabDocument2 pagesSingle Replacement Reactions Labapi-239477691No ratings yet

- Introduction To Fuels: OilDocument7 pagesIntroduction To Fuels: Oilkcp1986No ratings yet

- 6 F 2Document4 pages6 F 2Jon Lewis-CooperNo ratings yet

- Powder Metallurgy (PM) Titanium and Titanium Alloy Structural ComponentsDocument4 pagesPowder Metallurgy (PM) Titanium and Titanium Alloy Structural ComponentsVijay KumarNo ratings yet

- Astm c110 Cal PDFDocument23 pagesAstm c110 Cal PDFJosé A. Moscol Vizconde100% (2)

- Paper 10 - J. SaravananDocument4 pagesPaper 10 - J. SaravananSaravanan JayabalanNo ratings yet

- Colloids and Surfaces B: Biointerfaces: SciencedirectDocument9 pagesColloids and Surfaces B: Biointerfaces: SciencedirectFrederik RareNo ratings yet

- From PCP To MXE A Comprehensive Review of The Non Medical Use of Dissociative DrugsDocument20 pagesFrom PCP To MXE A Comprehensive Review of The Non Medical Use of Dissociative DrugsMatthewNo ratings yet

- 1 Romania Catalog 2023 _compressedDocument141 pages1 Romania Catalog 2023 _compressedbazarulonline.roNo ratings yet

- Name: Tati Elfrida Samosir NIM: 1951170 Class: Pharmacy 1-A Chemistry Number Symbol Name NotesDocument2 pagesName: Tati Elfrida Samosir NIM: 1951170 Class: Pharmacy 1-A Chemistry Number Symbol Name NotesTaty Ai Elfrida SamosirNo ratings yet

- Sindh University 2014Document9 pagesSindh University 2014Raees BachaNo ratings yet

- Laboratory Report CHM 213 (Physical Chemistry) : 1. Muhammad Mirza Hizami Bin RajieiDocument6 pagesLaboratory Report CHM 213 (Physical Chemistry) : 1. Muhammad Mirza Hizami Bin RajieiMuhd Mirza Hizami100% (2)

- BEDD TITLEDocument21 pagesBEDD TITLESubrata DasNo ratings yet

- Additives For High Solids and Water-Borne CoatingsDocument12 pagesAdditives For High Solids and Water-Borne CoatingsWIlliam CheungNo ratings yet

- WEEK 10 Aromatic HydrocarbonDocument26 pagesWEEK 10 Aromatic HydrocarbonChris Angelo De GuzmanNo ratings yet

- Battery: Vijayanandh RDocument24 pagesBattery: Vijayanandh RVijayanandh RNo ratings yet

- Microsoft Word - Transposition of Directive 414 - 1991Document418 pagesMicrosoft Word - Transposition of Directive 414 - 1991Alfredo MéndezNo ratings yet