Professional Documents

Culture Documents

R&D Intake Manifolds: Pressure

Uploaded by

Васил СавовскиOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

R&D Intake Manifolds: Pressure

Uploaded by

Васил СавовскиCopyright:

Available Formats

Page 3 to DVS 2207-11

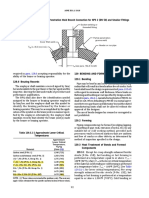

pressure possible, with a linear rise. The times necessary for this purpose

are shown in Table 2, Column 5. The joining pressure is

joining pressure 0.10 ± 0.01 N/mm².

alignment pressure

R&D INTAKE MANIFOLDS

A mechanical load on the joint is permissible, at the earliest, after

the end of the cooling process. For this purpose, the full joining

heating-up pressure must be maintained during the cooling time at the

pressure ambient temperature (see Table 2, Column 5).

time Subject to the following prerequisites, it is permitted to shorten

changeover time

heating-up the cooling time by as much as 50%, i. e. joining pressure relief

time cooling time and removal of the welded part from the welding machine:

alignment joining pressure build-up time – the joint is manufactured in workshop conditions,

time

total joining time

– the removal from the welding machine and the temporary

total welding time storage cause only a slight load on the joint and

– the joining parts have wall thicknesses ≥ 15 mm.

Figure 2. Process steps in heated tool butt welding. Further processing with a full mechanical load on the joint may

only take place after complete cooling according to Table 2,

Alignment Column 5.

In this respect, the joining faces to be welded are pressed on to

A uniform double bead must exist after the joining. The bead

the heated tool until the entire faces are in contact with the

formation provides orientation with regard to the uniformity of the

heated tool with parallel faces. This can be recognised by the

welds with each other. Different bead formations may be caused

formation of the beads. The alignment is finished when the bead

by the various types of flow behaviour of the joined materials.

heights around the entire pipe circumference or on the entire top

The weldability may be assumed from the experience with the

side of the plate have reached the values specified in Table 2,

commercially available semi-finished PP products in the specified

Column 2. The bead heights are regarded as an indicator that the

MFR range, even if this may lead to asymmetric welding beads.

whole area of the joining faces is in contact with the heated tool.

K must always be > 0 (see Figure 3).

The alignment pressure of 0.10 N/mm² is effective throughout the

alignment operation.

Heating-up

For the heating-up, the faces must be in contact with the heated

tool at a low pressure. To this end, the pressure is reduced to

nearly zero (≤ 0.01 N/mm²). During the heating-up, the heat

penetrates into the faces to be welded and heats these up to the

welding temperature. The heating-up times are shown in Table 2,

Column 3.

Changeover

After the heating-up, the joining faces must be detached from the

heated tool which must be taken out without damaging or soiling

the heated joining faces. The joining faces must then be moved

together quickly until they almost touch. The changeover time

should be kept as short as possible (see Table 2, Column 4)

since the plastified faces would otherwise cool down. This would

exert a detrimental influence on the weld quality. Figure 3. Bead formation in the case of heated tool butt welding

(principle using the example of a pipe).

Joining

The faces to be welded should come into contact at a speed of For a short version of the processing instructions, see the

nearly zero. The required joining pressure is applied, if at all appendix.

Table 2. Guide values for the heated tool butt welding of pipes, fittings and panels made of PP at an outdoor temperature of approx. 20°C with

moderate air movement (intermediate values must be interpolated).

1 2 3 4 5

Alignment Heating-up Changeover Joining

Heated tool temperature 210 ± 10°C

Nominal wall Changeover Joining Cooling time under

Bead height at the heated tool time pressure joining pressure

thickness s

at the end of the alignment time (Heating-up (maximum build-up (minimum values)

(minimum values) p = ≤ 0.01 N/mm2) time) time p = 0.10 ± 0.01 N/mm²

(alignment p = 0.10 N/mm2)

mm mm s s s min

Up to 4.5 0.5 up to 135 5 6 6

4.5 ... 7 0.5 135 ... 175 5 ... 6 6 .. 7 6 ...12

7 ... 12 1.0 175 ... 245 6 ... 7 7 .. 11 12 ... 20

12 ... 19 1.0 245 ... 330 7 ... 9 11 ... 17 20 ... 30

19 ... 26 1.5 330 ... 400 9 ... 11 17 ... 22 30 ... 40

26 ... 37 2.0 400 ... 485 11 ... 14 22 ... 32 40 ... 55

37 ... 50 2.5 485 ... 560 14 ... 17 32 ... 43 55 ... 70

407

You might also like

- Butt WeldingDocument4 pagesButt WeldingNavin Ullas100% (1)

- HDPE Jointing Methods: Butt-Weld ProcessDocument1 pageHDPE Jointing Methods: Butt-Weld ProcessBoraNo ratings yet

- Heated Tool WeldingDocument14 pagesHeated Tool WeldingВасил СавовскиNo ratings yet

- Simultaneous Cold and Hot Forging in A Single ...Document4 pagesSimultaneous Cold and Hot Forging in A Single ...Mustafa Mert SAMLINo ratings yet

- Hot Plate and Hot Gas WeldingDocument14 pagesHot Plate and Hot Gas WeldingВасил СавовскиNo ratings yet

- CSWIP 2017) - Compressed-483-492Document10 pagesCSWIP 2017) - Compressed-483-492Tahar DabbarNo ratings yet

- F 2620 Fig. 3: 4. Significance and UseDocument1 pageF 2620 Fig. 3: 4. Significance and UseArnold Ochochoque ArcosNo ratings yet

- R&D Intake Manifolds: Sleeve Welding With An Incorporated Electric Heating Element (Principle)Document1 pageR&D Intake Manifolds: Sleeve Welding With An Incorporated Electric Heating Element (Principle)Васил СавовскиNo ratings yet

- Cutting Temperatures and Their Effects On The Machining Behaviour in Drilling Reinforced Plastic CompositesDocument6 pagesCutting Temperatures and Their Effects On The Machining Behaviour in Drilling Reinforced Plastic CompositesmathsantosNo ratings yet

- Butt Fusion Welding of HDPE Pipes: Work ProcedureDocument9 pagesButt Fusion Welding of HDPE Pipes: Work ProcedureVignesh BharathiNo ratings yet

- A319 - A321 - LAA - and - LUS - A321NX - (A321 Structural Repair Manual) - (51-77-11-911-023)Document6 pagesA319 - A321 - LAA - and - LUS - A321NX - (A321 Structural Repair Manual) - (51-77-11-911-023)Juan MartelNo ratings yet

- Heat Treatment Procedure.Document15 pagesHeat Treatment Procedure.Vijay ShamNo ratings yet

- To Heat Treatment of Welded Structures and Technical Data: CooperheatDocument11 pagesTo Heat Treatment of Welded Structures and Technical Data: Cooperheatsnipertomb100% (9)

- R&D Intake Manifolds: PreparationDocument1 pageR&D Intake Manifolds: PreparationВасил СавовскиNo ratings yet

- Document 2 OHlj 03052016 PDFDocument5 pagesDocument 2 OHlj 03052016 PDFEgi SlankersbimaNo ratings yet

- Gear Temperature MeassureDocument9 pagesGear Temperature MeassurejizuNo ratings yet

- Butt WeldingDocument4 pagesButt Weldinghatman1929No ratings yet

- RereDocument1 pageRereCITRIXNo ratings yet

- Understanding Process Sensitivities in Press Quenching An IntegratedDocument19 pagesUnderstanding Process Sensitivities in Press Quenching An Integratedmanashree02No ratings yet

- Qpedia Jul08 HS-Attachment-OptionsDocument6 pagesQpedia Jul08 HS-Attachment-OptionsAshish ShuklaNo ratings yet

- Low-Distortion Heat Treatment of Transmission ComponentsDocument8 pagesLow-Distortion Heat Treatment of Transmission Componentsmanashree02No ratings yet

- PROCEDUREDocument9 pagesPROCEDUREAîda hajriNo ratings yet

- Manufacture of Components: 1 GeneralDocument37 pagesManufacture of Components: 1 GeneralPaolita Auza BalderramaNo ratings yet

- tb334 Guidelines For Soldering Surface MountDocument2 pagestb334 Guidelines For Soldering Surface MountLuis ArévaloNo ratings yet

- Advances in Friction Welding Process A ReviewDocument26 pagesAdvances in Friction Welding Process A ReviewDr.K.BALAMURUGANNo ratings yet

- Resistance Spot Welding (RSW) : Period Produced Application WorkpieceDocument7 pagesResistance Spot Welding (RSW) : Period Produced Application WorkpieceRohanNo ratings yet

- Wave Heigh ImprovementDocument7 pagesWave Heigh Improvementquang huuNo ratings yet

- Hot Box Design PDFDocument8 pagesHot Box Design PDFAbu Anas M.SalaheldinNo ratings yet

- About Welding Process 42Document1 pageAbout Welding Process 42XerexNo ratings yet

- Friction Coe Cient in Hot Compression of Cylindrical Sample: Yunping Li, Emi Onodera and Akihiko ChibaDocument6 pagesFriction Coe Cient in Hot Compression of Cylindrical Sample: Yunping Li, Emi Onodera and Akihiko ChibaKaren OrtegaNo ratings yet

- PWHT Recommendation TemperatureDocument3 pagesPWHT Recommendation TemperaturekapsarcNo ratings yet

- Sample Heat Treatment ProcedureDocument13 pagesSample Heat Treatment ProcedureAnonymous uXdS9Y7100% (1)

- Design of Forming Processes Bulk Forming PDFDocument23 pagesDesign of Forming Processes Bulk Forming PDFAsia Ct0% (1)

- Heidenhain - Machining Accuracy For Machine ToolsDocument6 pagesHeidenhain - Machining Accuracy For Machine ToolsAnonymous gnbh26No ratings yet

- Leak Tightness Analysis of Bolted Body Flange of Heat Exchanger Near Pass Partition PlateDocument6 pagesLeak Tightness Analysis of Bolted Body Flange of Heat Exchanger Near Pass Partition PlateAcacio VieiraNo ratings yet

- Pressure Temperature Ratings Asme b16.5Document2 pagesPressure Temperature Ratings Asme b16.5edisjdavNo ratings yet

- Vibration Welding 2009Document11 pagesVibration Welding 2009Rodrigo ToasaNo ratings yet

- 331 Heat Treatment: ASME B31.3-2012Document4 pages331 Heat Treatment: ASME B31.3-2012Stephen RajNo ratings yet

- DIY - Soldering P36 & 37Document2 pagesDIY - Soldering P36 & 37RamavallabhanNo ratings yet

- 1im142-Asig 3-Ao, El, RS, RMDocument4 pages1im142-Asig 3-Ao, El, RS, RMEnrique LauNo ratings yet

- Analysis of Friction Stir Welds. Part I: Transient Thermal Simulation Using Moving Heat SourceDocument10 pagesAnalysis of Friction Stir Welds. Part I: Transient Thermal Simulation Using Moving Heat SourceZahi AekNo ratings yet

- Review of Resistance Spot Welding of SteelDocument31 pagesReview of Resistance Spot Welding of SteelLívia RodriguesNo ratings yet

- Irc 6 Ammendment ShowimgDocument12 pagesIrc 6 Ammendment ShowimgHardik TrivediNo ratings yet

- Effect of Surface Roughness On Heat Transfer: Mahendrakumar MaisuriaDocument4 pagesEffect of Surface Roughness On Heat Transfer: Mahendrakumar MaisuriaMohammed Naim UddinNo ratings yet

- 05350G SampleDocument10 pages05350G SampleSaurabh BhorNo ratings yet

- AN0-42 - Practical Considerations For Attaching Surface-Mount ComponentsDocument7 pagesAN0-42 - Practical Considerations For Attaching Surface-Mount Componentsketab_doostNo ratings yet

- 1992 - Heat Transfer Enhancement in The Direct Contact Melting Process - SaitoDocument11 pages1992 - Heat Transfer Enhancement in The Direct Contact Melting Process - SaitohakeemniyasNo ratings yet

- Finite Element Analysis of Welded Structures: Conference PaperDocument8 pagesFinite Element Analysis of Welded Structures: Conference PaperMihaela NastaseNo ratings yet

- Ablation CastingDocument3 pagesAblation CastingSoumyadeep PradhanNo ratings yet

- A Review On Band Heaters For Heating Performance EnhancementDocument7 pagesA Review On Band Heaters For Heating Performance EnhancementFITIWINo ratings yet

- Service RSVP Post Weld Heat TreatDocument2 pagesService RSVP Post Weld Heat Treat1339979No ratings yet

- Hot Gas WeldingDocument9 pagesHot Gas WeldingВасил СавовскиNo ratings yet

- Computer Simulation of Pipe-Bending Processes With Small Bending Radius Using Local Induction HeatingDocument5 pagesComputer Simulation of Pipe-Bending Processes With Small Bending Radius Using Local Induction Heatingsatheeshsep24No ratings yet

- 1 s2.0 S1270963821005927 MainDocument17 pages1 s2.0 S1270963821005927 Mainmr.fanjiazhengNo ratings yet

- Integrated Modelling of DeformationsDocument16 pagesIntegrated Modelling of DeformationsericNo ratings yet

- Butt Fusion ParametersDocument9 pagesButt Fusion ParametersarkadjyothiprakashNo ratings yet

- Heat TreatmentDocument15 pagesHeat TreatmentSebastian JoyNo ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- R&D Intake Manifolds: Welding of ThermoplasticsDocument1 pageR&D Intake Manifolds: Welding of ThermoplasticsВасил СавовскиNo ratings yet

- R&D Intake Manifolds: Sleeve Welding With An Incorporated Electric Heating Element (Principle)Document1 pageR&D Intake Manifolds: Sleeve Welding With An Incorporated Electric Heating Element (Principle)Васил СавовскиNo ratings yet

- R&D Intake Manifolds: PreparationDocument1 pageR&D Intake Manifolds: PreparationВасил СавовскиNo ratings yet

- Buttweld SpecsDocument14 pagesButtweld SpecsВасил СавовскиNo ratings yet

- Hot Gas WeldingDocument9 pagesHot Gas WeldingВасил СавовскиNo ratings yet

- Supplier GPO Q TM 0001 02 SPDCR TemplateDocument6 pagesSupplier GPO Q TM 0001 02 SPDCR TemplateMahe RonaldoNo ratings yet

- ProceedingsDocument656 pagesProceedingsgkgjNo ratings yet

- Piping Handbook - Hydrocarbon Processing - 1968Document140 pagesPiping Handbook - Hydrocarbon Processing - 1968VS271294% (16)

- Lecture10 Combined FootingsDocument31 pagesLecture10 Combined FootingsGopalram Sudhirkumar100% (3)

- Gordon NovelDocument50 pagesGordon NovelNic Hotep100% (2)

- TDS Sadechaf UVACRYL 2151 - v9Document5 pagesTDS Sadechaf UVACRYL 2151 - v9Alex MacabuNo ratings yet

- Sec VlanaclsDocument10 pagesSec VlanaclsTry FajarmanNo ratings yet

- Component Modeling - HDocument5 pagesComponent Modeling - HVasu IyerNo ratings yet

- Biodegradability of SurfactantsDocument1 pageBiodegradability of SurfactantsTinnysumardiNo ratings yet

- Ism CodeDocument9 pagesIsm CodePraneel KurhadeNo ratings yet

- GMP Male BearingDocument3 pagesGMP Male BearingMahdi HajizadehNo ratings yet

- Prospects For Alkaline Zero Gap Water Electrolysers For Hydrogen ProductionDocument16 pagesProspects For Alkaline Zero Gap Water Electrolysers For Hydrogen Productionkhan47pkNo ratings yet

- Psychrometric Chart - Us and Si UnitsDocument1 pagePsychrometric Chart - Us and Si UnitsRaden_Rici_Abi_1914No ratings yet

- Internship Report May 2016Document11 pagesInternship Report May 2016Rupini RagaviahNo ratings yet

- PNR90 PNR510 PNR91 PNR515 PNR92 PNR520: Manual of - Installation - Operating - Maintenance Heavy Oil Burners TypeDocument28 pagesPNR90 PNR510 PNR91 PNR515 PNR92 PNR520: Manual of - Installation - Operating - Maintenance Heavy Oil Burners Typec_lucian2004No ratings yet

- Tube Well Design Project SolutionDocument5 pagesTube Well Design Project SolutionEng Ahmed abdilahi IsmailNo ratings yet

- RT 8090 TDocument40 pagesRT 8090 TManuel100% (1)

- Wiring Color and Pin-Out Schematic Electronic Vessel Control EVC - C, D4/D6-DPH/DPRDocument2 pagesWiring Color and Pin-Out Schematic Electronic Vessel Control EVC - C, D4/D6-DPH/DPRSivan Raj50% (2)

- PACSystemsRX3i CS GFA559G (2010)Document4 pagesPACSystemsRX3i CS GFA559G (2010)Omar Alfredo Del CastilloNo ratings yet

- AHRLACDocument18 pagesAHRLACVictor Pileggi100% (1)

- VB Script ReferenceDocument27 pagesVB Script ReferenceRajkumarNo ratings yet

- Electro Magnetic Induction PDFDocument28 pagesElectro Magnetic Induction PDFPuran BistaNo ratings yet

- 1998-10 The Computer Paper - Ontario EditionDocument156 pages1998-10 The Computer Paper - Ontario Editionthecomputerpaper100% (1)

- Vibro SifterDocument7 pagesVibro SifterDIpesh SahooNo ratings yet

- SQ Presentation 2021-r2Document43 pagesSQ Presentation 2021-r2nadeem4ahmed-805026No ratings yet

- UMTS AircomDocument20 pagesUMTS AircomDũng PhạmNo ratings yet

- E 7016 Product-SheetDocument1 pageE 7016 Product-SheetAlireza TakrimiNo ratings yet

- Rational Suite ToolsDocument47 pagesRational Suite ToolsZatin GuptaNo ratings yet

- JNTUA B Tech 2018 1 2 May R15 ECE 15A54201 Mathematics IIDocument2 pagesJNTUA B Tech 2018 1 2 May R15 ECE 15A54201 Mathematics IIMRUDULA KULAKARNINo ratings yet