Professional Documents

Culture Documents

Questions: 2.1.1 ECDIS (Electronic Chart Display and Information Systems)

Uploaded by

Kaleb Z king webOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Questions: 2.1.1 ECDIS (Electronic Chart Display and Information Systems)

Uploaded by

Kaleb Z king webCopyright:

Available Formats

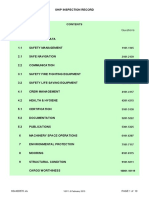

SHIP INSPECTION RECORD

CONTENTS

SECTION Questions

cover INSPECTION DATA

1.1 SAFETY MANAGEMENT 1101-1145

2.1 SAFE NAVIGATION 2101-2138

2.1.1 ECDIS (Electronic Chart Display and Information Systems) 2139-2153

2.2 COMMUNICATIONS 2201-2209

3.1 SAFETY FIRE FIGHTING EQUIPMENT 3101-3122

3.2 SAFETY LIFE SAVING APPLIANCES 3201-3228

4.1 CREW MANAGEMENT 1401-4117

4.2 HEALTH & HYGIENE 4201-4215

5.1 CERTIFICATION 5101-5139

5.2 DOCUMENTATION 5201-5222

5.3 PUBLICATIONS 5301-5325

6 MACHINERY SPACE OPERATIONS 6101-6207

7 ENVIRONMENTAL PROTECTION 7101-7117

8 MOORING 8101-8115

9 STRUCTURAL CONDITION 9101-9211

13 CARGO WORTHINESS 13001-13050

505545094.xls Ver 1.0 February 2015 PAGE 1 of 12

SHIP INSPECTION RECORD

BILBROUGH REFERENCE

Ship's Name:

IMO No:

Place/Date of build.

Flag.

Official Number.

Class Society.

Inspection Company.

Inspector's Reference.

Inspector's Name.

Date of inspection.

Place of Inspection.

Activity during inspection.

Date & place last dry-docking.

Date & place of last PSC.

Date of last SMC audit.

Date of last ISPS Audit.

Date of last Internal Audit.

Date of last Special Survey

Place of last Special Survey

Date of last tech. inspection.

Trading Area.

Name of DPA.

e-mail / tel number of DPA.

Vessel in OCIMF SIRE scheme

Vessel in CDI-m or CDI-mpc

Vessel in RIGHTSHIP

Condition Assessment Programme Rating: (if entered in a programme)

ISM Manager Details

505545094.xls Ver 1.0 February 2015 PAGE 2 of 12

SHIP INSPECTION RECORD

SAFETY MANAGEMENT

NA NI F X

1101 Are SMS Manuals and documents written in a language understood by the crew?

1102 Are the name, function and contact details of the DPA well known?

1103 Does the master understand his overriding authority?

1104 Are crew familiar with the company's safety and environmental policy?

1105 Are any Non Conformities properly cleared, verified and closed out?

1106 Are PSC inspections recorded and defects dealt with?

1107 Are accidents incidents and near misses recorded and reported to the company?

1108 Are accidents incidents and near misses investigated systematically onboard?

1109 Is there objective evidence of company follow up of accidents/incidents, near misses?

1110 Does the Master review the SMS?

1111 Does the company respond to the Master's review of the SMS?

1112 Has an officer been designated as shipboard Safety Officer?

1113 Are safety committee meetings held regularly and records kept?

1114 Are they reported to the company?

1115 Does the company respond to safety committee meetings?

1116 Are safety bulletins and/or circulars onboard and available to the crew?

1117 Is Risk Assessment undertaken onboard?

1118 Are enclosed spaces entry permits used?

1119 Are hot work permits used?

1120 Are there generalised procedures for work permits other than those above?

1121 Is sufficient PPE provided and in use onboard?

1122 Are fire control plans posted throughout the ship & available externally?

1123 Is the handling use and storage of hazardous Chemicals controlled?

1124 Are MSDS for these chemicals available?

1125 Is there a plan for emergency drills and training?

1126 Is the plan being followed, the drills conducted and recorded as required?

1127 Are there Emergency Contingency Plans onboard?

1128 Are these drills exercised?

1129 Is an Emergency Command Structure in place?

1130 Is a Planned Maintenance System available, which is sufficient in scope?

1131 Is the Planned Maintenance System ship specific?

1132 Is the Planned Maintenance System properly observed?

1133 Are access control and security measures in place?

1134 Are bilge and tank soundings taken regularly and recorded?

1135 Are bilge alarms tested and recorded?

1136 Is stability calculated on a regular basis, especially during critical periods?

1137 Are gangways and accommodation ladders in satisfactory condition?

1138 Are pilot boarding arrangements satisfactory?

1139 Are loose gear and spare parts, especially heavy items, properly secured?

1140 Are Emergency exits unobstructed?

1141 Do

If theofficers

vesseland crewto

is likely display

transitsafety awareness

the area where the(are

risksafety procedures

of attack followed)

by Somali ?

based pirates

1142 isIsconsidered

the ship's ETB

to be(Emergency Towing

high, is a copy Booklet)

of the available

latest version of -BMP

SOLAS Chapter

onboard II-1/3-4

along with NP

1143 Q6099 "Anti-Piracy Planning Chart"?"

1144 Does the SMS address the subject of Maritime Cyber Risk Management in accordance

with Resolution MSC.428(98)?

505545094.xls Ver 1.0 February 2015 PAGE 3 of 12

SHIP INSPECTION RECORD

SAFE NAVIGATION

NA NI F X

2101 Are Company Bridge Procedures available?

2102 Are Company Standing Orders available?

2103 Are Master's Standing Orders available?

2104 Are the Master's Night Orders available and in regular use?

2105 Are all above countersigned as understood by all bridge officers?

2106 Are bridge watch conditions defined (leaving port, restricted visibility etc.)?

2107 Are watch handover procedures defined?

2108 Are the occasions on when the Master is to be called specified?

2109 Has an officer been designated as "Navigator"?

2110 Is there Objective Evidence that Passage Planning is carried out? Berth to berth?

2111 Does Passage Planning conform to industry guidelines?

2112 Are Position fixing intervals clearly defined on the passage plan?

2113 Is there Objective Evidence that more than one position fixing system is being used?

2114 Are times when steering gear is to be doubled up shown on the plan? (SOLASV 25)

2115 Is SQUAT understood?

2116 Is UKC understood, calculated for the voyage, and shown on the plan?

2117 Are radio navigation warnings filed and used (includes Navtex and EGC messages)?

2118 Are Temporary and Preliminary Notices properly, retrievable and used?

2119 Does the SMS document procedures for chart/publication correction/maintenance and

does this system function effectively?

2120 Does the company provide Notices to Mariners at regular intervals?

2121 Have charts and publications been corrected for latest NtM onboard?

2122 Is system in place for the removal of cancelled charts?

2123 Does the chart outfit provide adequate geographical coverage?

2124 Is a copy of the deviation card available on the bridge?

2125 Are compass errors frequently taken at sea and recorded?

2126 Has the ship been swung to confirm deviations at least annually?

2127 Are navigation lights in a satisfactory condition?

2128 Do navigation light alarms work?

2129 Are navigation shapes available?

2130 Navigation Equipment is checked prior departure/arrival each port & recorded?

2131 Astern propulsion tested prior entry into port?

2132 Regular steering and emergency steering tests conducted SOLAS V, 26?

2133 Is the navigational equipment listed in Form E fully operational and serviced as

2134 required?

VDR (examined and tested by approved service facility and copy of CoC onboard)?

2135 Master knows how & when to save data and to download from VDR?

2136 Manoeuvring information is posted? SOLAS II-1 Reg 28.3

2137 Are auto to manual and Emergency Steering changeover procedures displayed?

2138 Are procedures to vacate anchorage due to impending bad weather available?

ECDIS (Electronic Chart Display and Information System)

NA NI F X

Section to be completed only on ships carrying ECDIS as "primary means of navigation" otherwise mark "N/A"

2139 Does the company SMS provide instructions on the use/management of ECDIS?

2140 Are all users suitably certificated and type specific training provided?

2141 Is audible alarm connected/demonstrated satisfactorily?

2142 Are all mandatory sensors operable and connected?

2143 Can users demonstrate manual position fixing methods (visual/radar)?

2144 Are voyage charts adequately checked by Master prior to commencement of voyages?

2145 Is ECDIS Safety Depth/Safety Contour/Deep Contour/Shallow Contour usage managed by SMS?

2146 Are ECDIS #1 and #2 well sited in the wheelhouse?

2147 Is CCRP (Consistent Common Reference Point) set correctly and locked by password?

2148 Is ECDIS a documented element of 'watch handover procedure' and prescribed under the SMS?

2149 Are required UPS/battery back-up/Emergency Power systems fitted?

2150 Are UPS/battery back-up/Emergency Power systems is good condition/maintained under ship's PMS?

2151 Do officers show a good understanding of the voyage alarm check facility?

2152 Is the alarm log for the previous voyage reasonable?

2153 Do all users demonstrate confidence/understanding of the full use of the ECDIS system?

COMMUNICATIONS

505545094.xls Ver 1.0 February 2015 PAGE 4 of 12

SHIP INSPECTION RECORD

NA NI F X

2201 Are navigating officers familiar with radio equipment and procedures?

2202 Is all radio equipment fully functional and regularly tested?

2203 Are statutory radio publications the latest editions and fully corrected?

2204 Are GMDSS hand held VHFs available and emergency batteries within date?

2205 Is EPIRB in place, tested as required by shore technician and hydro release in date?

2206 Are SARTs in place and batteries within date?

2207 Daily reports sent to company as per SOLAS, V, Regulation 28 para 2?

2208 Safety net messages available and filed?

2209 Are GMDSS instructions posted?

505545094.xls Ver 1.0 February 2015 PAGE 5 of 12

SHIP INSPECTION RECORD

SAFETY - FIRE FIGHTING EQUIPMENT

NA NI F X

3101 Are fire fighting equipment and inspections covered by PMS?

3102 Is the fire detection system operational?

3103 Are fire pumps operational?

3104 Fire stations in condition of readiness?

3105 Self contained breathing apparatus in good condition and cylinders charged?

3106 Inventory available in fire stations?

3107 EEBDs provided and ready for use?

3108 Fire extinguishers in satisfactory condition?

3109 Have portable fire extinguishers been serviced as required?

3110 Are fire hoses, nozzles and hydrants in satisfactory condition?

3111 Fixed fire extinguishing system in satisfactory condition, instructions posted?

3112 Fixed fire extinguishing system guarded against unauthorised use?

3113 Fixed fire fighting system for E.R. in operable condition?

3114 Crew familiar in its operation?

3115 Foam analysed at required intervals?

3116 Has the FF system been inspected/tested annually and serviced every 2 years?

3117 Are fire doors functioning correctly?

3118 Are fire dampers in operable condition?

3119 Are fire mains and isolating valves well maintained and in good condition?

3120 Is an International shore Connection available?

3121 Have weekly, monthly and quarterly tests of FFE been carried out and recorded?

3122 Are manuals available for the onboard maintenance of FFE?

SAFETY - LIFESAVING APPLIANCES & EQUIPMENT

NA NI F X

3201 Are weekly, monthly, quarterly & annual inspections & tests conducted & recorded?

3202 Are portable oxygen and gas analysers provided and regularly calibrated?

3203 Is adequate lighting provided throughout the vessel?

3204 Are portable safety guards such as rails, lines and wires provided and in use?

3205 Are lifeboat davits including MOB boat(s) in good condition?

3206 Has an approved service company surveyed the davit/winch systems?

3207 Are life rafts and hydrostatic releases properly secured/fitted and in good condition?

3208 Are lifebuoys of approved type properly stowed and sufficient ?

3209 Are life jackets of approved type properly stowed and sufficient in numbers?

3210 Are IMO symbols marking the location of safety equipment in place?

3211 Are safety instructions written in the working language in place?

3212 Are photoluminescent emergency escape route markings in place?

3213 Are lifeboats swung out at required intervals?

3214 Are lifeboats lowered to the water and exercised?

3215 Has the Emergency generator been tested and found to function efficiently?

3216 Is the Emergency Switchboard in satisfactory condition?

3217 Are pyrotechnics complete, in good order and within date?

3218 Are immersion suits in good order and fitted with the prescribed lights?

3219 Is the emergency lighting system fully functional?

CREW MANAGEMENT

NA NI F X

4101 Is the ship manned according to the Flag State Minimum Safe Manning Certificate?

4102 Is the ship sufficiently manned for its current trade?

4103 Are officers in possession of National Licences and Flag State endorsements?

4104 Do at least 2 officers hold GMDSS General Operator Certificates?

4105 Are crew in possession of valid medical examination certificates?

4106 Have crew received familiarisation training and are records kept?

4107 Are records of hours of rest and work according STCW maintained?

4108 Are working hours and watch schedules posted up?

505545094.xls Ver 1.0 February 2015 PAGE 6 of 12

SHIP INSPECTION RECORD

4109 Has a Working Language been established?…………..SOLAS V. Reg 14.3?

4110 Are all records maintained in the working language of the vessel?

4111 Can (at least bridge) officers communicate in English?

4112 Are officers familiar with this type and size of ship?

4113 Are "first trip" in consecutive ranks avoided?

4114 Is there a Drug and Alcohol policy in place?

4115 Is onboard testing and sampling equipment available. (USCG)?

4116 Is there objective evidence of ongoing crew training?

HEALTH & HYGIENE

NA NI F X

4201 Is the accommodation well lit, clean and habitable?

4202 Is ventilation, heating and air conditioning adequate?

4203 Are sanitary facilities adequate (sinks, toilets and showers clean etc.)?

4204 Are food storage facilities in good condition and adequate?

4205 Are provision rooms maintained at the correct temperature?

4206 Do cold store alarms work and can doors be opened from inside?

4207 Are the galley and food preparation areas clean, tidy and free from vermin?

4208 Are galley extractors and grease traps clean?

4210 Is the hospital and bathroom clean and tidy?

4211 Is the medical locker well stocked against a Flag State or WHO standard?

4212 Is a valid medical chest certificate provided?

4213 Is medical oxygen provided?

4214 Are first aid kits available at key locations?

4215 Is a system in place to ensure that potable water is maintained in a safe condition?

CERTIFICATION

NA NI F X

PLEASE SELECT 3 OF THE FOLLOWING ITEMS FOR RANDOM CHECK: Are the

selected Class/Statutory Certificates valid at the time of inspection:

5101 Is a Class Survey Status Report available; is the ship free from CoCs / significant

recommendations?

5102 Is a register of all LSA / FFA equipment test certificates maintained and all valid?

5103 Certificate of Registry

5104 Maritime Labour Certificate & Declaration of Maritime Labour Compliance (MLC)

5105 Cargo Ship Safety Equipment Certificate + Form E

5106 Cargo Ship Safety Radio Certificate

5107 Cargo Ship Safety Construction Certificate

5108 International Safety Management Certificate

5109 Exemption Certificate

5110 Document of Compliance (ISM) copy

5111 International Ship Security Certificate

5112 Continuous Synopsis Record

5113 International Tonnage Certificate

5114 International Load line Certificate

5115 International Oil Pollution Prevention Certificate

5116 International Air Pollution Prevention Certificate

5117 International Sewage Pollution Prevention Certificate

5118 International Pollution Prevention Certificate NLS (bulk)

5119 International Anti-Fouling System Certificate

5120 International Certificate of Fitness for the Carriage of Dangerous Chemicals in Bulk

5121 International Certificate of Fitness for the Carriage of Liquefied Gases in Bulk

5122 Document of Compliance for the Carriage of Dangerous Goods

5123 Document of Authorisation for the carriage of grain

5124 Document of Compliance for the Carriage of Solid Bulk Cargoes.

5125 Civil Liability Convention Certificate

5126 Minimum Safe Manning Certificate

5127 Class (Hull)

505545094.xls Ver 1.0 February 2015 PAGE 7 of 12

SHIP INSPECTION RECORD

5128 Class (Machinery)

5129 Class (refrigeration)

5130 International Ship Sanitation Certificate

DOCUMENTATION

NA NI F X

PLEASE SELECT 5 OF THE FOLLOWING ITEMS FOR RANDOM CHECK: Are the

following onboard, approved and properly maintained:

5202 SOPEP

5203 SMPEP

5204 Oil Record Book part I

5205 Oil Record Book part II

5206 Record of oil discharge monitoring and control system for the last ballast voyage

5207 Garbage Management Plan

5208 Garbage Record Book

5209 Intact Stability Booklet

5210 Damage Control Booklet (plans)

5211 Bulk Carrier Booklet (or equivalent) - Please refer to SOLAS, Chapter 6 Reg. 7.2

5212 Ballast Water Management Plan

5213 Cargo Securing Manual

5214 Lifting Equipment Register

5215 Dangerous Goods manifest

5216 Enhanced Survey report File

5217 SOLAS Training manual and FSS Code (in language crew can understand)

5218 Safety Management manuals

5219 Official Log Book

5220 Deck Log Book

5221 Engine Room Log Book

5222 GMDSS Log Book

5223 Medical Log

PUBLICATIONS

NA NI F X

PLEASE SELECT 5 OF THE FOLLOWING ITEMS FOR RANDOM CHECK: Are the

following onboard, approved and in the current edition:

5301 Bridge Procedures Guide (ICS/IMO)

5302 Are relevant IMO publications onboard (SOLAS, MARPOL, STCW, etc)

5303 SOLAS & Amendments

5304 MARPOL

5305 STCW

5306 IMDG Code

5307 Code of safe Practice for ships carrying Timber cargoes (IMO)

5308 International Maritime Solid Bulk Cargo Code (IMSBC Code)

5309 IMO Grain Rules

5310 International Bulk Chemicals Code

5311 International Regulations for the Prevention of Collisions at Sea.

5312 International Safety Management Code

5313 Loadline Regulations

5314 IAMSAR Manual Vol III

5315 Clean Seas Guide for Oil Tankers (ICS/OCIMF)

5316 ISGOTT

5317 ICS Tanker safety Guide (Chemicals)

5318 ICS Tanker safety Guide (Liquefied Gas)

5319 Medical Guide (repeated in 5223)

5320 Code of Safe Working Practices

5321 Ship to Ship transfer Guide

5322 Standard Marine Communication Phrases

5323 Standard Marine Communication Phrases

5324 IMO Code of Safe Practice for Cargo Stowage and Securing

MACHINERY SPACE OPERATIONS

NA NI F X

6101 Is the status of the PMS up to date for the machinery spaces?

6102 Are the Chief Engineer's Standing Orders available?

6103 Are the Company Standing Orders available?

6104 Are machinery spaces well lit, clean, tidy and free from combustible material?

6105 Is the main engine free from oil and water leaks?

505545094.xls Ver 1.0 February 2015 PAGE 8 of 12

SHIP INSPECTION RECORD

6106 Are machinery exhaust gas manifold and trunking in satisfactory condition?

505545094.xls Ver 1.0 February 2015 PAGE 9 of 12

SHIP INSPECTION RECORD

6107 Are necessary machinery spare parts available?

6108 Are machinery spare parts properly stowed, secured and protected?

6109 Are machinery HP pipes double walled ?

6110 Are machinery monitoring and control systems fully operational and tested?

6111 Is the main engine operating satisfactorily?

6112 Are boilers, exhaust gas economisers and associated equipment in good condition?

6113 Are boilers, piping and valves free from leakage?

6114 Are boiler safety devices in satisfactory operable condition?

6115 Are the auxiliary engines free from oil and water leaks?

6116 Are auxiliary engines operating satisfactorily?

6117 Self closing devices on E.R. sounding pipes operational?

6118 Are bilge and ballast pumps in operable condition?

6119 Are bilge and ballast pumps free from leakages and patches?

6120 Are F.O., L.O. pipes and flanges adequately shielded?

6121 Are F.O., L.O., purifiers, heaters and coolers in good condition?

6122 Are E.R. floor plates secured in place and clean?

6123 Are the bilges clean?

6124 Are bilge high level alarms operable?

6125 Is machinery guarded where appropriate (including coupling guards)?

6126 Are oxygen and acetylene bottles correctly stored in designated locations?

6127 Are E.R. pipe systems free from leaks, patches and temporary repairs?

6128 Are sea suction + overboard valves free from leaks, temp repairs & cement boxes?

6129 Self closing devices of sight glasses on all oil tanks fully operational?

6130 Is Main switchboard earth fault monitoring equipment operational -satisfactory status?

6131 Is deck insulation provided to the front and rear of switchboards (220v and above)?

6132 Is lifting gear (ER crane etc) tested and in good condition?

6133 Are ladders and guard rails in satisfactory condition?

6134 Are machinery guards in place in the workshop and PPE available?

6135 Have emergency remote stops and fuel oil shut-offs been tested?

STEERING GEAR SYSTEM

NA NI F X

6201 Has the steering gear been tested and found to comply with SOLAS requirements?

6202 Is the steering linkage satisfactory?

6203 Is the hydraulic system free from any leaks?

6204 Does the communication system with the navigation bridge work?

6205 Are emergency change-over procedures posted?

6206 Are officers familiar with change over procedures?

6207 Is heading information displayed at the emergency steering position? (>1992)

ENVIRONMENTAL PROTECTION

NA NI F X

7101 Have all sources of pollution been identified?

7102 Are measures in place to control these sources?

7103 Are savealls in satisfactory condition?

7104 Are deck scupper plugs available?

7105 Is Oil Spill Equipment available and an inventory maintained?

7106 Are bunkering and oil transfer procedures available?

7107 Are bunkering and oil transfer procedures adhered to?

7108 Is the bunkering gauging system operational?

7109 Is the Oily Water separator functioning and 15ppm monitor calibrated?

7110 Is the overboard discharge valve secured in the closed position?

7111 Is the custody and location of the key for the overboard discharge valve locking device

7112 controlled?

Confirm no sign of any illegal piping (e.g. to bypass Oily Water Separator)

7113 Are Bunker Lines in a satisfactory condition?

7114 Does the ship have an operational incinerator?

505545094.xls Ver 1.0 February 2015 PAGE 10 of 12

SHIP INSPECTION RECORD

7115 Are garbage posters and placards displayed throughout the ship?

7116 Is Garbage separated and stowed properly?

7117 Are receipts obtained for garbage landed ashore?

MOORING

NA NI F X

8101 Are windlasses and winches in satisfactory condition?

8102 Are brake linings, drums and pins in satisfactory condition?

8103 If hydraulically powered, is the system free from leaks?

8104 Are rollers, fairleads and bollards in satisfactory condition?

8105 Are mooring ropes sufficient in number?

8106 Are mooring lines in satisfactory condition?

8107 Are ropes turned up / stored on barrels correctly?

8108 If tails are fitted to wires, do they have proper connecting links?

8109 Is there an inspection procedure for mooring equipment?

8110 Are the visible portions of anchor cables in satisfactory condition?

8111 Are moorings satisfactorily deployed and tended?

8112 Are crew aware of 'snap back zones'?

8113 Has non-slip paint been used in way of winches and bollards?

8114 Are safely constructed heaving lines employed?

8115 Is effective hazard marking employed (use of highlighting paint/contrasting colours)?

STRUCTURAL CONDITION - HULL & DECK

NA NI F X

9101 Is the visible condition of shell plating and coatings satisfactory?

9102 Is the visible condition of the deck plating and coatings satisfactory?

9103 Are bow and stern doors plus any alarms in satisfactory condition?

9104 Are side shell doors in satisfactory condition?

9105 Are guardrails and bulwarks in good condition?

9106 Are hull markings legible (IMO # load line, draft marks, bulbous bow & thrusters)?

9107 Are vents and air pipes on deck in satisfactory condition?

9108 Are closing devices efficient on vents and air pipes?

9109 Are sounding pipes in satisfactory condition?

9110 Are above in 9108 & 9109 clearly marked with the spaces they service?

9111 Are weather tight doors and stores hatches fully operational and provide effective seal?

9112 Are walkways, stairways, catwalks, ladders and platforms in satisfactory condition?

9113 Are voids, cofferdams and pipe tunnels closed down correctly?

STRUCTURAL COND. - BALLAST TANKS & VOID SPACES

NA NI F X

9201 Are these tanks and spaces included in the Planned Maintenance System?

9202 Does the safety management system require these to be inspected?

9203 Are records of onboard inspections of tanks and void spaces maintained?

9204 Are any tanks inspected free from mud and debris?

9205 Are tanks and void spaces inspected free from significant wastage, pitting and scale?

9206 Is the corrosion protection (coatings/anodes) in satisfactory condition?

9207 Is the inspected structure free from buckling, fracture, doublers & temporary repairs?

9208 Are manhole covers in satisfactory condition?

9209 Are tanks free from any sign of oil contamination?

9210 Is pipe work passing through tanks and void spaces in satisfactory condition?

9211 Are internal ladders in good condition?

9203 Are records of onboard inspections of tanks and void spaces maintained?

9204 Are any tanks inspected free from mud and debris?

9205

Are tanks and void spaces inspected free from significant wastage, pitting and scale?

9206 Is the corrosion protection (coatings/anodes) in satisfactory condition?

9207 Is the inspected structure free from buckling, fracture, doublers & temporary repairs?

505545094.xls Ver 1.0 February 2015 PAGE 11 of 12

SHIP INSPECTION RECORD

9208 Are manhole covers in satisfactory condition?

9209 Are tanks free from any sign of oil contamination?

9210 Is pipe work passing through tanks and void spaces in satisfactory condition?

9211 Are internal ladders in good condition?

CARGO WORTHINESS, TANKER

NA NI F X

13001 Are safe cargo operation policy statements, guidance and procedures available?

13002 Are maximum loading rates and ventilation capacities available?

13003 Are up to date cargo pipeline, inert gas and vent system diagrams available?

13004 Are written procedures available for the handling of heavy weather ballast?

13005 Is a class approved loading computer available?

13006 Are there records to show the loading computer is tested regularly?

13007 Are stability and stress calculations carried out at various stages during loading?

13008 Are procedures available for restoring stability in case of emergency?

13009 Are officers aware of the dangers of free surface effect?

13010 Are officers familiar with the cargo system?

13011 Has a cargo plan been prepared including a sequence of cargo/ballast transfer?

13012 Has the plan been signed by officers?

13013 Are cargo operations recorded in a log book?

13014 Are MSDS available for the products handled?

13015 Are officers aware of the emergency procedures to deal with a spillage or fire?

13016 Are Ship/Shore Safety Checklists completed and recorded?

13017 Are cargo, ballast and stripping pumps, eductors and instruments in good condition?

13018 Cargo, ballast pump bearing, casing and shaft gland temperature monitoring?

13019 Are cargo, crude oil washing, vapour and inert gas lines in good condition?

13020 Are cargo pump emergency shut down systems in good condition?

13021 Are cargo and ballast system valves in good condition?

13022 Are cargo system ullage gauges, vapour locks and UTI tapes in good condition?

13023

Are remote and local temperature and pressure sensors and gauges in good condition?

13024 Are cargo tank high level alarms in good condition?

13025 Are deck fittings in apparent satisfactory condition?

13026 Are cargo pipelines pressure tested annually?

13027 Where fitted, is the cargo tank heating system tested regularly?

13028 Are ullaging, sampling and closed operations equipment and procedures satisfactory?

13029 Is the cargo venting system including P/Vs in a satisfactory condition?

13030 Is the venting system being used correctly?

13031 Are SOLAS secondary venting requirements being complied with?

13032 Are stop v/vs fitted which permit isolation of indiv tanks from common vent system?

13033 Are these v\vs provided with positive locking arrangements?

13034 Is the IG system well maintained?

13035 Are IG alarms and monitoring systems tested regularly?

13036 If fitted, is the COW system and procedures satisfactory?

13037 Are static electricity precautions in place and being observed?

13038 Are manifold arrangements in good condition?

13039

Are pump rooms entry procedures, rescue appliances and coms to CCR satisfactory?

13040 Are cargo hoses in good condition?

13041 Are all cargo lifting appliances properly marked, tested and in good condition?

13042 Are foam monitors operable and in good condition?

13043 Can you confirm that purging records are free of any indications of cargo / hydraulic oil leaks?

13044 Where fitted are deep well hydraulic pumps free of indications of oil leaks?

Can you confirm that Class survey records are free of any significant deficiencies in

13045

cargo/ballast structures/coatings?

13046 Are shipboard checks of cargo tank structures carried out periodically?

13047 Is the ODMS in use and records preserved?

13048 Is the pump room high level alarm tested regularly

13049 Is the pump room atmospheric monitoring system functional?

13050 Is the pump room generally well maintained and clean?

505545094.xls Ver 1.0 February 2015 PAGE 12 of 12

You might also like

- BoardingPass PDFDocument7 pagesBoardingPass PDFNecko VejzaNo ratings yet

- DG AutomationDocument39 pagesDG AutomationdskribdNo ratings yet

- Oil Tanker Vessel Particulars QuestionnaireDocument29 pagesOil Tanker Vessel Particulars Questionnairesumedhb21No ratings yet

- Breathing Oxygen Mox-40 Filling SpecsDocument2 pagesBreathing Oxygen Mox-40 Filling SpecsLe Ngoc AnhNo ratings yet

- Determining Critical Wind Velocity For Dragging AnchorDocument2 pagesDetermining Critical Wind Velocity For Dragging AnchorOctavianNo ratings yet

- Tekomar Performance Evaluation SWDocument17 pagesTekomar Performance Evaluation SWmaronnamNo ratings yet

- ATLAS CYLINDER LUBRICATOR MANUALDocument36 pagesATLAS CYLINDER LUBRICATOR MANUALKaleb Z king webNo ratings yet

- Renault K-Type EngineDocument24 pagesRenault K-Type EngineTaimoor AhmedNo ratings yet

- CVT Comet 780Document1 pageCVT Comet 780Wagner Oliveira100% (1)

- QAP WD-71-BD-15 Compliance To STRDocument19 pagesQAP WD-71-BD-15 Compliance To STRAnonymous kQUFSJuW4uNo ratings yet

- Ship Certificates Anniversary Date ListDocument3 pagesShip Certificates Anniversary Date ListConstantine Ktzmn100% (1)

- Incinerator Training OverviewDocument22 pagesIncinerator Training OverviewNicanor AliagaNo ratings yet

- SEEMPDocument19 pagesSEEMPswapneel_kulkarniNo ratings yet

- NSRP Ship Vetting PolicyDocument11 pagesNSRP Ship Vetting PolicyNgôThếLạcNo ratings yet

- Inventory List Sparepart Me YutakaDocument4 pagesInventory List Sparepart Me Yutakarandy warouwNo ratings yet

- Biro Klasifikasi Indonesia: Application For ClassificationDocument7 pagesBiro Klasifikasi Indonesia: Application For ClassificationJoy Arief JanuarNo ratings yet

- Compass Deviation Card: M/V "Bay Ranger"Document3 pagesCompass Deviation Card: M/V "Bay Ranger"михаилNo ratings yet

- List of Ship's Certificates for Tanker ClearanceDocument3 pagesList of Ship's Certificates for Tanker ClearanceBrian PhamNo ratings yet

- Data Steering GearDocument32 pagesData Steering GearBaris AkgülNo ratings yet

- Uae Tasneef GCC CodeDocument147 pagesUae Tasneef GCC Codekoib789No ratings yet

- Samsung Shipbuilding Quality StandardsDocument74 pagesSamsung Shipbuilding Quality StandardsThanos NiotisNo ratings yet

- E16 Starbulk S.A. Diesel Generator Performance Report: M/V For Engine No: 1Document3 pagesE16 Starbulk S.A. Diesel Generator Performance Report: M/V For Engine No: 1joreyvilNo ratings yet

- ABS Matrix of Regulation - Updated May 2019Document37 pagesABS Matrix of Regulation - Updated May 2019Claudio SantellanesNo ratings yet

- 资料Document12 pages资料zxy320dNo ratings yet

- Putri Iona - Survey StatusDocument28 pagesPutri Iona - Survey StatusDiana Triswasti KumariNo ratings yet

- Pub174bk Sailing Directions MalaccaDocument196 pagesPub174bk Sailing Directions MalaccaFernando Igor AlvarezNo ratings yet

- 18 Ships Particular For Risk AssessmentDocument33 pages18 Ships Particular For Risk AssessmentKunal SinghNo ratings yet

- MV Toronto TraderDocument3 pagesMV Toronto TraderPapitas FritasNo ratings yet

- Holding Power CalculationDocument2 pagesHolding Power CalculationImroz AhmedNo ratings yet

- Preloading Plan FO GuayaquilDocument1 pagePreloading Plan FO GuayaquilGanesh AnandNo ratings yet

- Maritime Signs 08Document40 pagesMaritime Signs 08Lenin ValerioNo ratings yet

- Voyage Plan from Singapore to ZhanjiangDocument1 pageVoyage Plan from Singapore to Zhanjiangb0b027No ratings yet

- 07 Radiotelex Sailor 6300-User ManualDocument60 pages07 Radiotelex Sailor 6300-User ManualRayfly66No ratings yet

- 890080057-001 - HDU 2x27-108 GP-E2PTXYDocument222 pages890080057-001 - HDU 2x27-108 GP-E2PTXYRobsNo ratings yet

- Omd 24 eDocument30 pagesOmd 24 eabuzer1981No ratings yet

- An Estimate of Operating Costs For Bulk, Ro-Ro and Container ShipsDocument50 pagesAn Estimate of Operating Costs For Bulk, Ro-Ro and Container ShipsJoseoNo ratings yet

- Ship Energy Efficiency Management Plan GuideDocument3 pagesShip Energy Efficiency Management Plan GuideLagon AinNo ratings yet

- FS5070 1570 2570 Operator's Manual D 7-10-09 PDFDocument219 pagesFS5070 1570 2570 Operator's Manual D 7-10-09 PDFSignal Tecnica100% (1)

- FreeboardDocument10 pagesFreeboardpothirajkalyanNo ratings yet

- Ship Hull Calculation - Calculations - Paint Inspector Com PDFDocument3 pagesShip Hull Calculation - Calculations - Paint Inspector Com PDFНиколай СтешенкоNo ratings yet

- DS Test and Calibration EquipmentDocument7 pagesDS Test and Calibration Equipmentjirafabg123No ratings yet

- Speed R/min Mep Bar KW KW 12V32/40 14V32/40 16V32/40 18V32/40 Specific Fuel Oil Consumption (SFOC) To ISO Conditions MCR V32/40 V32/40 FPPDocument1 pageSpeed R/min Mep Bar KW KW 12V32/40 14V32/40 16V32/40 18V32/40 Specific Fuel Oil Consumption (SFOC) To ISO Conditions MCR V32/40 V32/40 FPPghostt123No ratings yet

- Ship Info MRV and Seemp and Basic Vessel Info.1Document4 pagesShip Info MRV and Seemp and Basic Vessel Info.1Sachin SikkaNo ratings yet

- OCIMFDocument36 pagesOCIMFgeorgeNo ratings yet

- Tonnage Calculations for M/V OTTAWA IVDocument6 pagesTonnage Calculations for M/V OTTAWA IVtahtoh25No ratings yet

- Company Profile - Trenggana 01.2018 PDFDocument17 pagesCompany Profile - Trenggana 01.2018 PDFSunardi AstrominNo ratings yet

- Ballast Water Management Plan - CSO Deep BlueDocument36 pagesBallast Water Management Plan - CSO Deep BlueCosmin IulianNo ratings yet

- Nittochi Contact DetailsDocument34 pagesNittochi Contact DetailsAfrizal SetiawanNo ratings yet

- A (A D) (A D 2) (I) : Midship Section Area and Modulus CalculationDocument1 pageA (A D) (A D 2) (I) : Midship Section Area and Modulus Calculationdilip_deepblueNo ratings yet

- Port berthing details for multiple tankersDocument5 pagesPort berthing details for multiple tankersjohn salazarNo ratings yet

- Bridge structure components and stress analysisDocument4 pagesBridge structure components and stress analysisyan9naing9shinNo ratings yet

- Yokohama FENDER PRODUCT LITERATURE PDFDocument8 pagesYokohama FENDER PRODUCT LITERATURE PDFitaaliyenNo ratings yet

- Free Crew Internet Allowance Policy PDFDocument5 pagesFree Crew Internet Allowance Policy PDFLourene Jauod- GuanzonNo ratings yet

- Code On Alerts and Indicators 2009Document61 pagesCode On Alerts and Indicators 2009Hasancan YavaşNo ratings yet

- Rev Ag - Smart Bilge ManualDocument36 pagesRev Ag - Smart Bilge ManualAly ElkadyNo ratings yet

- NAV04 Pilot Card SummaryDocument9 pagesNAV04 Pilot Card SummaryirakliNo ratings yet

- T1000 MinervaDocument18 pagesT1000 MinervaFaizulNo ratings yet

- Osd 570 - MSDSDocument4 pagesOsd 570 - MSDSRizki Try AtmantiNo ratings yet

- How NBDP Works and How to Use it in GMDSS CommunicationsDocument14 pagesHow NBDP Works and How to Use it in GMDSS CommunicationsKunal SinghNo ratings yet

- GX 8000 Tips and CautionsDocument11 pagesGX 8000 Tips and CautionsalexanderNo ratings yet

- Propeller performance data comparison for various vesselsDocument6 pagesPropeller performance data comparison for various vesselsZaw Moe MyintNo ratings yet

- Bulk Carrier Inpsection EngDocument10 pagesBulk Carrier Inpsection EngAji ArnowoNo ratings yet

- Pandi - Sir FP General 2019 CheklistDocument11 pagesPandi - Sir FP General 2019 Cheklistreka ShippingNo ratings yet

- Questions: 654490878.xls PAGE 1 of 10Document10 pagesQuestions: 654490878.xls PAGE 1 of 10ahlan zulfakhriNo ratings yet

- Dropped Objects Prevention SchemeDocument17 pagesDropped Objects Prevention SchemekhurramNo ratings yet

- Qhse 06 2023Document10 pagesQhse 06 2023Kaleb Z king webNo ratings yet

- (E-49) Simplified Manual For Marine Radar EquipmentDocument24 pages(E-49) Simplified Manual For Marine Radar EquipmentKaleb Z king webNo ratings yet

- 13.omd VN87Document58 pages13.omd VN87Kaleb Z king webNo ratings yet

- CER-20 Level Switch Technical ManualDocument10 pagesCER-20 Level Switch Technical ManualKaleb Z king webNo ratings yet

- (E-01) Final ListDocument10 pages(E-01) Final ListKaleb Z king webNo ratings yet

- PSC Checklist: On Board Maintenance Check ListDocument15 pagesPSC Checklist: On Board Maintenance Check ListAbebè TeferiNo ratings yet

- CER-20 Level Switch Technical ManualDocument10 pagesCER-20 Level Switch Technical ManualKaleb Z king webNo ratings yet

- Checklist - ILO 178 Seafarers' Working and Living ConditionsDocument11 pagesChecklist - ILO 178 Seafarers' Working and Living ConditionsKaleb Z king webNo ratings yet

- Rboat Davit MAINTENANCE MANUAL PDFDocument14 pagesRboat Davit MAINTENANCE MANUAL PDFAnoop AnupNo ratings yet

- FFD - 4 - Maintenance Manual PDFDocument15 pagesFFD - 4 - Maintenance Manual PDFKaleb Z king webNo ratings yet

- Railway Intelligent Transportation System ArchitectureDocument14 pagesRailway Intelligent Transportation System ArchitectureAdiKalem0% (1)

- AMSOIL Synthetic Motor Oils For OE Oil Change Interval. 3000 Mile Oil ChangeDocument2 pagesAMSOIL Synthetic Motor Oils For OE Oil Change Interval. 3000 Mile Oil ChangeBruce WappmanNo ratings yet

- English For The Real World (En+ru) - 42pDocument42 pagesEnglish For The Real World (En+ru) - 42pGiselle MattosNo ratings yet

- Gateshead Annual Parking Report 2009-10Document21 pagesGateshead Annual Parking Report 2009-10parkingeconomicsNo ratings yet

- JCE-61-2009-03-05 - Ždrelac - Građevinar PDFDocument9 pagesJCE-61-2009-03-05 - Ždrelac - Građevinar PDFMilena KatičinNo ratings yet

- Straight Line Diagram Along Poblacion - Balud - Coroconog SectionDocument10 pagesStraight Line Diagram Along Poblacion - Balud - Coroconog SectionSamuel ObayanNo ratings yet

- BlueManta EquipmentDocument33 pagesBlueManta Equipmentcasda73No ratings yet

- Air Canada v. CIR - Taxation Law - DebtDocument3 pagesAir Canada v. CIR - Taxation Law - DebtMichael VillalonNo ratings yet

- Blizzard of Glass Book Report 1Document3 pagesBlizzard of Glass Book Report 1api-269004789No ratings yet

- CSR Activities of Tata MotorsDocument26 pagesCSR Activities of Tata MotorsNeha PaigudeNo ratings yet

- PM Clinic GD655-5Document9 pagesPM Clinic GD655-5Naughty VongNo ratings yet

- European Grocery Supplier Shows How CPFR Really Works PDFDocument5 pagesEuropean Grocery Supplier Shows How CPFR Really Works PDFNikhilNo ratings yet

- EOR Decision Making ProgramDocument264 pagesEOR Decision Making Programএকেএম এহসানুল হকNo ratings yet

- BPCL Jacketed GasketsDocument15 pagesBPCL Jacketed GasketsPinak VadherNo ratings yet

- KanpurDocument24 pagesKanpuravinash.co.in3100No ratings yet

- Import Policy Order 22020Document132 pagesImport Policy Order 22020futurehorizonssNo ratings yet

- Pneumatic tire loading capacities at different pressuresDocument8 pagesPneumatic tire loading capacities at different pressuresdionisio emilio reyes jimenezNo ratings yet

- Version - 2.0 Page - 1 - of - 14 Weights - and - Capacities - in - Metric - Tonnes, - Dimensions - in - Meters. - For - Reference - Only.Document14 pagesVersion - 2.0 Page - 1 - of - 14 Weights - and - Capacities - in - Metric - Tonnes, - Dimensions - in - Meters. - For - Reference - Only.Anonymous 1qAH6CKCNo ratings yet

- Transportation of Water From Kimberley To Perth AquatankersDocument11 pagesTransportation of Water From Kimberley To Perth AquatankersareffarookNo ratings yet

- Motoroids2 April 2010Document66 pagesMotoroids2 April 2010Amit ChhanganiNo ratings yet

- Military Fire Suppression SystemsDocument17 pagesMilitary Fire Suppression Systemselianacelestepereira100% (1)

- Star Trek RPG - CODA - Expanded Rules PDFDocument22 pagesStar Trek RPG - CODA - Expanded Rules PDFTess Mercer100% (1)

- Ibadan, Nigeria: by Laurent FourchardDocument27 pagesIbadan, Nigeria: by Laurent Fourchardcharles100% (2)

- D4B805CB339-Manual For Troubleshooting and Diagnosing NoisesDocument25 pagesD4B805CB339-Manual For Troubleshooting and Diagnosing NoisesAnonymous W7u3qzaO0PNo ratings yet

- Ship Construction SystemDocument2 pagesShip Construction SystemNabil AyyasyNo ratings yet

- Srs Ticket PDFDocument1 pageSrs Ticket PDFTapan Chandratre0% (1)