Professional Documents

Culture Documents

Aerator Type ABS Venturi Jet: Applications

Uploaded by

rudiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aerator Type ABS Venturi Jet: Applications

Uploaded by

rudiCopyright:

Available Formats

Aerator Type ABS Venturi Jet

Jet aerator with single or twin diffuser pipes, for fixed or portable

installation, coupled to a Premium Efficiency pump from the XFP

range.

Applications

For the combined aeration and mixing of wastewater in small and

medium sized tanks. Also for the cleaning of storm water tanks

and for use in balancing tanks where a combination of aeration and

mixing reduces septicity and minimizes odours.

Features

• Stand-alone, self-aspirating system, with the option of fixed

installation with guide rail and pedestal, or portable installation with

stand. The portable option is especially suitable for emergency or

intermittent aeration tasks and allows for variable positioning in the

tank.

• Uses standard XFP pump featuring continuously rated Premium

Efficiency motor, temperature and seal monitoring, and double

mechanical seals.

• Blockage-free hydraulic design with Contrablock impeller.

• Lower noise levels and reduced spray compared to surface

systems.

• Maximum allowable temperature of the medium for continuous

operation is 40 °C. Motor

Premium Efficiency IE3, three-phase, squirrel-cage motor;

Venturi injection principle 460 V; 60 Hz; 4-pole (1750 r/min) and 6-pole (1180 r/min).

The venturi jet aerator is based on the injection principle that

Protection type: IP 68

produces an effective air-water mix which results in optimum

Stator insulation: Class H.

aeration and suspension of solids. The velocity of the primary flow

of liquid from the pump is accelerated when pumped through the Start-up: DOL (direct on line)

smaller nozzle inlet, lowering the internal pressure which draws in Cooling: 100C - 150E self-cooling,

the secondary flow of air through the air inlet pipe. The liquid and 150G & 201G version with closed cooling system.

air flows are then mixed in the turbulence of the diffuser pipe and Service factor: 1.3

ejected as a jet of fine air bubbles into the tank.

1

Notes

1. Stand and pedestal supplied as accessories.

2. Air inflow pipe and fittings, elbows, and flanges supplied by the

customer.

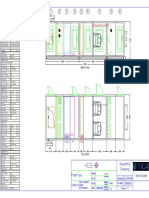

2 Materials

Description Material

5 4 3

Diffuser pipe Stainless steel 1.4301 (AISI 304)

Aerator

Venturi chamber housing Cast iron EN-GJL-200

8

6 7 Motor housing Cast iron EN-GJL-250

Motor shaft Stainless steel 1.4021 (AISI 420)

1. Air inflow 5. Mixed flow Impeller Cast iron EN-GJL-250

Pump

Volute Cast iron EN-GJL-250

2. XFP submersible pump 6. Venturi chamber housing

Bottom plate Cast iron EN-GJL-250

3. Mixing zone 7. Nozzle inlet Lifting hoop Stainless steel 1.4401 (AISI 316)

4. Diffuser pipe 8. Liquid inflow Fasteners Stainless steel 1.4401 (AISI 316)

Technical data

XFP Pump Aerator Nozzle Water Motor power * Rated Cable size Weight **

pump discharge inlet flow (kW) current (pump)

DN DN ø mm m3/h P1 P2 (A) kg

100C-CB1.2-PE20/6 100 100 55 50 2.4 2.0 4.2 SOOW 14/7 109

100C-CB1.1-PE20/6 100 100 55 70 2.4 2.0 4.2 SOOW 14/7 109

100C-CB1.4-PE35/4 100 100 55 100 3.9 3.5 6.2 SOOW 14/7 109

150E-CB1.7-PE45/4 150 150 80 140 5.0 4.5 8.2 SOOW 14/7 168

150E-CB1.6-PE75/4 150 150 80 190 8.2 7.5 13.8 SOOW 12/7 186

150E-CB1.4-PE105/4 150 150 80 240 11.4 10.5 17.7 SOOW 10/7 198

150G-CB1.7-PE185/4 150 150 80 315 19.8 18.5 32.3 AWM 8/4+16/3 445

201G-CB2.2-PE200/6 (1 200 150 80 500 21.5 20.0 32.7 AWM 8/4+16/3 475

(1

XFP 201G requires twin aerators. DN 150 T-piece, 2 x DN 150 elbows and DN 200 / DN 150 adaptor flange required for connection to pump discharge.

* P1 = power at mains. P2 = power at motor shaft.

** Aerator weight: DN 100 = 20 kg, DN 150 = 40 kg (does not include air inlet pipe or fittings). Portable stand: 100C = 9.5 kg, 100 & 150E = 10.5 kg,

150 & 201G = 17.5 kg.

Aerator selection / Tank dimensions (m)

XFP Wastewater tank Storm water tank

pump (sample size) (sample size)

Rectangular Rectangular Circular

Rectangular Square Circular

(outflow at one side) (central channel) (central outflow)

100C-CB1.2-PE20/6 6.0 X 4.0 4.9 ø 5.5 - - -

100C-CB1.1-PE20/6 7.2 X 4.8 5.9 ø 6.6 - - -

100C-CB1.4-PE35/4 8.0 X 5.3 6.5 ø 7.4 8.0 X 6.0 8.0 X 5.0 ø 5.5

150E-CB1.7-PE45/4 9.5 X 6.3 7.8 ø 8.8 12.0 X 8.0 10.0 X 6.5 ø 6.5

150E-CB1.6-PE75/4 12.0 X 8.0 9.8 ø 11.1 18.0 X 10.0 15.0 X 8.0 ø 8.0

150E-CB1.4-PE105/4 15.0 X 10.0 12.2 ø 13.8 22.0 X 12.0 20.0 X 10.0 ø 13.0

150G-CB1.7-PE185/4 17.5 X 11.5 14.2 ø 16.0 24.0 X 13.0 22.0 X 10.0 ø 14.0

201G-CB2.2-PE200/6 21.0 X 13.0 16.4 ø 18.0 27.0 X 14.0 24.0 X 10.0 -

Air flow performance Oxygen transfer performance

Air Oxygen

Nm3/h kg O2/h

600 20

60 Hz

201G-CB2.2-PE200/6

60 Hz

500

15

400 150G-CB1.7-PE185/4

300 10 201G-CB2.2-PE200/6

150E-CB1.4-PE105/4

150G-CB1.7-PE185/4

200

150E-CB1.6-PE75/4

5

150E-CB1.4-PE105/4

150E-CB1.7-PE45/4

100 150E-CB1.6-PE75/4

100C-CB1.4-PE35/4

100C-CB1.1-PE20/6 150E-CB1.7-PE45/4

100C-CB1.2-PE20/6 100C-CB1.4-PE35/4

100C-CB1.1-PE20/6

100C-CB1.2-PE20/6

1 2 3 4 5 6 1 2 3 4 5 6

Water depth (m) Water depth (m)

Oxygen transfer data measured as per “Measurement of Oxygen

Transfer in Clean Water” ASCE Standard 2-06, 2006.

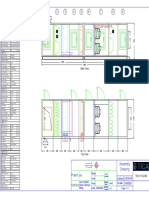

Dimensions (mm)

Transportable installation

100C 150E 150G 201G*

300

PE45/4 PE75/4 PE105/4

A 1596 2239 2239 2239 2319 2384*

A B 390 471 471 471 496 543*

C 686 749 749 819 1261 1348

B

D 193 198 198 198 300 320

E 105 105 105 105 200 200

C * Twin aerators as standard and only.

Required: DN 150 T-piece, 2 x DN 150 elbows and DN 200 / DN 150

adaptor flange for connecting to pump discharge (not included in

dimension; supplied by the customer).

D

E

Note: in some cases the support stand may need to be weighted to the tank

base to prevent lateral movement of the unit.

Installation with straight pedestal

100C 150E 150G 201G

PE45/4 PE75/4 PE105/4

A 1594+F 2251+F 2251+F 2251+F 2316+F 2505+F

B 442+F 531+F 531+F 531+F 556+F 995+F

300

C 716 783 783 853 1297 1348

D 289 286 286 286 286 286

A

B E 82 123 123 123 114 119

F G F ** ** ** ** ** **

G 318 372 372 372 397 546

H 200 250 250 250 250 240

** Variable dimension (supplied, and dimensions specified, by customer).

C

Required: DN 100 or DN 150 flange for XFP 100C - 150G, DN 150 T-piece,

2 x DN 150 elbows and DN 200 / DN 150 adaptor flange for

XFP 201G.

D H

E

Installation with 90º pedestal (duckfoot)

100C 150E 150G 201G

PE45/4 PE75/4 PE105/4

A 1816+F 2497+F 2497+F 2497+F 2562+F 2788+F

300 B 661+F 777+F 777+F 777+F 802+F 988+F

C 716 783 783 853 1297 1348

A D 289 286 286 286 286 286

B E 107 153 153 153 144 158

G

F ** ** ** ** ** **

F F1 F1 180 210 210 210 210 297

G 357 408 408 408 433 533

H 225 280 280 280 280 325

C

D I 262 397 397 397 397 524

J 371 463 463 463 463 550

J ** Variable dimension (supplied, and dimensions specified, by customer).

I H

E Required: DN 100 or DN 150 elbow for XFP 100C - 150G, DN 150 T-piece,

2 x DN 150 elbows and DN 200 / DN 150 adaptor elbow for

XFP 201G.

Note: further and more detailed dimension drawings for all installation types

are available on Sulzer.com or by request.

Accessories

Description Size XFP Part no.

Fixed installation - Pedestal (kit)* (cast iron EN-GJL-250) DN 100 100C & 100E 62320652

wet well with Sulzer 90º cast bend (single guide rail) - DIN flange DN 150 150E & 150G 62320655

Automatic Coupling connection DN 200 200G DPT91211A

System Pedestal (components)* DN 100 100C & 100E Gasket 14020018

cast iron EN-GJL-250 Base 32560611

straight (single guide rail) - DIN Bracket 41420520

flange connection Seal 43070518

Guide piece 31450510

DN 150 150E & 150G Gasket 14020020

Base 32560620

Bracket 31420535

Seal 43070519

Guide piece 31450510

DN 200 200G On request

Pedestal bracket fasteners 100C & 100E 62610633

single guide rail version 150E & 150G 62610635

(galvanised steel) 200G 62610883

single guide rail version 100C & 100E 62610637

(stainless steel) 150E & 150G 62610639

200G 62610862

Pedestal base anchor bolts 100C & 100E 62610775

single and twin guide rail 150E & 150G 62610784

(galvanised steel) 200G 62610785

Chain kit (stainless steel) 3m 100C - 200G 310101236013

including shackle 4m 310101236014

6m 310101236016

7m 310101236017

Transportable Ground support stand 100C 61355016

100E 61355018

150E 61355019

150G & 200G. 61355025

General Cathodic protection (zinc anodes) 100C - 200G 13905000

Leakage relay type ABS CA 461 110 - 230 VAC 100C - 200G 16907010

18 - 36 VDC, SELV 16907011

Temperature and leakage relay type ABS 110 - 230 VAC 100C - 200G 16907006

CA 462 18 - 36 VDC, SELV 16907007

* Guide rail not included.

www.sulzer.com

en (03.12.2019), Copyright © Sulzer Ltd 2019

This document does not provide a warranty or guarantee of any kind. Please contact us for a description of the warranties and guarantees offered with our products.

Directions for use and safety will be given separately. All information herein is subject to change without notice.

You might also like

- Aerator Type ABS Venturi Jet: ApplicationsDocument4 pagesAerator Type ABS Venturi Jet: ApplicationsRafael ZimmermannNo ratings yet

- Aerator Type ABS Venturi Jet: ApplicationsDocument4 pagesAerator Type ABS Venturi Jet: ApplicationsrudiNo ratings yet

- Abs Afp PDFDocument12 pagesAbs Afp PDFMehmet Akif GülNo ratings yet

- ABS Submersible Pump ABS pumpDocument3 pagesABS Submersible Pump ABS pumpDurrani SonsNo ratings yet

- Asco 8344 PDFDocument2 pagesAsco 8344 PDFOsman Lopez SalasNo ratings yet

- Brochure LPDA, 50 HZDocument6 pagesBrochure LPDA, 50 HZTAUFIQ ARIEF NUGRAHANo ratings yet

- Model 106-RPS-8700A UL / FM Pressure Relief Valve: Key FeaturesDocument3 pagesModel 106-RPS-8700A UL / FM Pressure Relief Valve: Key FeaturesCandela BarbisanNo ratings yet

- 2gpe Evm Espd - OptDocument4 pages2gpe Evm Espd - OptVu DangNo ratings yet

- Air Handling UnitsDocument28 pagesAir Handling Unitskgsatish1979No ratings yet

- EBARA 3GPE EVMSG Booster SetsDocument11 pagesEBARA 3GPE EVMSG Booster SetsVu DangNo ratings yet

- Asco Series 040 NC CatalogDocument4 pagesAsco Series 040 NC CatalogrtgeorgeNo ratings yet

- Data Sheet-FIREMIKS-FM-14000-GP-F-Aut 2016-02-23Document3 pagesData Sheet-FIREMIKS-FM-14000-GP-F-Aut 2016-02-23appril26No ratings yet

- Ecoline EST 150-300 FBDocument7 pagesEcoline EST 150-300 FBRicardo BarrosNo ratings yet

- Outline - AHU-1.03 (AHU Grade C-Corridor)Document1 pageOutline - AHU-1.03 (AHU Grade C-Corridor)23 M Gipaldi Putra AtamaNo ratings yet

- Data Sheet Firemiks FM 4000 GP F Aut 2016-11-14Document3 pagesData Sheet Firemiks FM 4000 GP F Aut 2016-11-14muthuvelaaNo ratings yet

- Jet Fans Se03 - Tunel - Jetfan - 2015enDocument4 pagesJet Fans Se03 - Tunel - Jetfan - 2015enRami goNo ratings yet

- Ref No. 050 PT. Tenggerraja Jaya Teknik (Revisi Spesifikasi Teknis Fan Dan Heater)Document2 pagesRef No. 050 PT. Tenggerraja Jaya Teknik (Revisi Spesifikasi Teknis Fan Dan Heater)black_geminiNo ratings yet

- Outline - AHU-1.04 (AHU Grade D-Production)Document1 pageOutline - AHU-1.04 (AHU Grade D-Production)23 M Gipaldi Putra AtamaNo ratings yet

- Grundfos - CR 5 3 A A A E HQQE PDFDocument15 pagesGrundfos - CR 5 3 A A A E HQQE PDFabhe prasetyaNo ratings yet

- Etaline Type SeriesDocument48 pagesEtaline Type SeriesChristopher Greg PermisonNo ratings yet

- 100G - 2100G ClavalDocument2 pages100G - 2100G Clavale1901bNo ratings yet

- Goodman Aruf060 00a 1aDocument4 pagesGoodman Aruf060 00a 1amartydavis123No ratings yet

- Fans PDFDocument1 pageFans PDFKhaled ELSaftawyNo ratings yet

- Avk Ball Float ValveDocument2 pagesAvk Ball Float ValveDota NgNo ratings yet

- Fluidchiller ManualDocument111 pagesFluidchiller Manualknizam1971No ratings yet

- Grundfos - TP 150 220 4 A F A BAQEDocument12 pagesGrundfos - TP 150 220 4 A F A BAQEYoesoef HasyimNo ratings yet

- Data Sheet-FIREMIKS-FM-3200-GP-F-Aut 2015-12-09Document3 pagesData Sheet-FIREMIKS-FM-3200-GP-F-Aut 2015-12-09appril26No ratings yet

- HIGH FLOW PULSE VALVESDocument4 pagesHIGH FLOW PULSE VALVESFelipe SalvatierraNo ratings yet

- TS 90 100 01Document4 pagesTS 90 100 01Lakee911No ratings yet

- Prochem Ball ValvesDocument5 pagesProchem Ball Valvesmd_taheriNo ratings yet

- Grundfos CR 5 13 A FGJ A e HqqeDocument15 pagesGrundfos CR 5 13 A FGJ A e HqqeRadu-Stefan MusatNo ratings yet

- Self-Priming Pumps: Type Series Booklet CTI-2100/0 2 (07-2016)Document32 pagesSelf-Priming Pumps: Type Series Booklet CTI-2100/0 2 (07-2016)mohsen aminiNo ratings yet

- Dust Collector Main Pulse Valves: FeaturesDocument4 pagesDust Collector Main Pulse Valves: FeaturesQuân TrịnhNo ratings yet

- G5 Medium Unit Cooler Ver 1.0Document10 pagesG5 Medium Unit Cooler Ver 1.0Wawan NuryanaNo ratings yet

- Grundfos - CR 10 4 A FJ A E HQQEDocument15 pagesGrundfos - CR 10 4 A FJ A E HQQErosneyNo ratings yet

- Nibco Wafer Style Twin Disc Ductile Iron Check ValveDocument1 pageNibco Wafer Style Twin Disc Ductile Iron Check ValveAlbeiro LeivaNo ratings yet

- Air Cooled Screw Chiller R134aDocument12 pagesAir Cooled Screw Chiller R134aalkaf08No ratings yet

- Side Pocket Mandral PDFDocument27 pagesSide Pocket Mandral PDFwajihhasnainNo ratings yet

- Main Oil PumpsDocument61 pagesMain Oil PumpsysabeleleuterioNo ratings yet

- CR1-33 A-FGJ-A-E-HQQE 3x400D 50HZ: Grundfos Pump 96513309Document15 pagesCR1-33 A-FGJ-A-E-HQQE 3x400D 50HZ: Grundfos Pump 96513309Muhammad GhufranNo ratings yet

- LPDA Technical DatabookDocument5 pagesLPDA Technical DatabookTAUFIQ ARIEF NUGRAHANo ratings yet

- Daikin FUW-FE Cabinet Fan Coil UnitDocument8 pagesDaikin FUW-FE Cabinet Fan Coil UnitPaul MendozaNo ratings yet

- EW - TECHNICAL CATALOGUE - Vol.21031 - 50HZ-R3Document41 pagesEW - TECHNICAL CATALOGUE - Vol.21031 - 50HZ-R3Linda MadlalaNo ratings yet

- Qty. Description CR 5-13: Note! Product Picture May Differ From Actual ProductDocument2 pagesQty. Description CR 5-13: Note! Product Picture May Differ From Actual ProductMáy bơm Công nghiệpNo ratings yet

- Pilot Operated Air and Water Solenoid ValvesDocument4 pagesPilot Operated Air and Water Solenoid ValvesDevinNo ratings yet

- ALLIGATOR - TECHNICAL CATALOGUE - Vol.21011 - 50SI-R4Document18 pagesALLIGATOR - TECHNICAL CATALOGUE - Vol.21011 - 50SI-R4Linda MadlalaNo ratings yet

- HVAC BOQDocument2 pagesHVAC BOQEx Why ZedNo ratings yet

- NH3 Compressor UnitDocument1 pageNH3 Compressor UnitdzungNo ratings yet

- AV2000_ThermostaticAirVentDocument1 pageAV2000_ThermostaticAirVentauxiliar.termicaNo ratings yet

- AHU specification data sheetDocument1 pageAHU specification data sheet23 M Gipaldi Putra AtamaNo ratings yet

- Sihi Aeh enDocument12 pagesSihi Aeh enIrvan NouriNo ratings yet

- Datasheet Vetec TY005.030Document16 pagesDatasheet Vetec TY005.030Ali Abdul MannanNo ratings yet

- Rotary Plug Valve Data SheetDocument12 pagesRotary Plug Valve Data SheetAnderson SiqueiraNo ratings yet

- Centrala de Tratare Aerului at Pico GBDocument28 pagesCentrala de Tratare Aerului at Pico GBportocala12No ratings yet

- Final Dwg-Sludge Pump-4178Document93 pagesFinal Dwg-Sludge Pump-4178erol100% (1)

- BAC FB Ball Valves Carbon Steel Stainless Steel Full Bore ANSI Class 150Document1 pageBAC FB Ball Valves Carbon Steel Stainless Steel Full Bore ANSI Class 150ChristianNo ratings yet

- Grundfos - CR 5 4 A A A E HQQE PDFDocument15 pagesGrundfos - CR 5 4 A A A E HQQE PDFabhe prasetyaNo ratings yet

- Jet 1Document20 pagesJet 1Karim El ShamashergyNo ratings yet

- SR - No. Valve Type Operation Size MM Qty. Rating Ex-Works Unit Price Ex-Works Total Price With ActuatorDocument8 pagesSR - No. Valve Type Operation Size MM Qty. Rating Ex-Works Unit Price Ex-Works Total Price With ActuatorSANDESHNo ratings yet

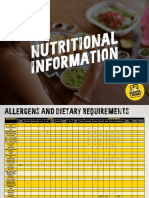

- Nutritional Guide Nov19 PDFDocument17 pagesNutritional Guide Nov19 PDFrudiNo ratings yet

- Breakfast PDFDocument4 pagesBreakfast PDFrudiNo ratings yet

- NSW Policy Initiative - Cannabis PDFDocument4 pagesNSW Policy Initiative - Cannabis PDFrudiNo ratings yet

- Removal 1Document6 pagesRemoval 1Amoghasakti AbinawaNo ratings yet

- Strategy 2020 4pp Flyer Updated3 PDFDocument2 pagesStrategy 2020 4pp Flyer Updated3 PDFrudiNo ratings yet

- In The Event of Moon DisasterDocument2 pagesIn The Event of Moon DisasterWordofgreenNo ratings yet

- Reduce Noise From Indoor VenuesDocument1 pageReduce Noise From Indoor VenuesrudiNo ratings yet

- Amplifier Devices: Be A Good Neighbour Ways You Can Reduce NoiseDocument1 pageAmplifier Devices: Be A Good Neighbour Ways You Can Reduce NoiserudiNo ratings yet

- Dulcotest Dt1B Photometer: Operating ManualDocument52 pagesDulcotest Dt1B Photometer: Operating ManualrudiNo ratings yet

- Fact Sheet HomeBuilder PDFDocument4 pagesFact Sheet HomeBuilder PDFWill NguyenNo ratings yet

- A Message From The TJX Companies Inc PDFDocument1 pageA Message From The TJX Companies Inc PDFrudiNo ratings yet

- NSW Policy Initiative - Cannabis PDFDocument4 pagesNSW Policy Initiative - Cannabis PDFrudiNo ratings yet

- Aerator Type ABS Venturi Jet: ApplicationsDocument4 pagesAerator Type ABS Venturi Jet: ApplicationsrudiNo ratings yet

- CAS Main Release PDFDocument6 pagesCAS Main Release PDFrudiNo ratings yet

- Yowie Rarity Chart A4 PDFDocument6 pagesYowie Rarity Chart A4 PDFrudiNo ratings yet

- BDW86S-F - 45cm Dishwasher UC 5.7.13 PDFDocument23 pagesBDW86S-F - 45cm Dishwasher UC 5.7.13 PDFrudiNo ratings yet

- COVID-19 & Flu Tests Now Bulk Billed Through MBSDocument1 pageCOVID-19 & Flu Tests Now Bulk Billed Through MBSrudiNo ratings yet

- Are You Hungry?: Want More?Document1 pageAre You Hungry?: Want More?rudiNo ratings yet

- BDW86S-F - 45cm Dishwasher UC 5.7.13 PDFDocument23 pagesBDW86S-F - 45cm Dishwasher UC 5.7.13 PDFrudiNo ratings yet

- Intentional Food Contamination PDFDocument12 pagesIntentional Food Contamination PDFrudiNo ratings yet

- Call. 07 3822 9199 0423 958 246: Saturday - Sunday 11.00 Am. - 2.00 PMDocument2 pagesCall. 07 3822 9199 0423 958 246: Saturday - Sunday 11.00 Am. - 2.00 PMrudiNo ratings yet

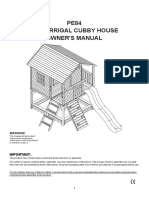

- PE84 Warrigal Cubby House 1.1 PDFDocument14 pagesPE84 Warrigal Cubby House 1.1 PDFrudiNo ratings yet

- BDW86S-F - 45cm Dishwasher UC 5.7.13 PDFDocument23 pagesBDW86S-F - 45cm Dishwasher UC 5.7.13 PDFrudiNo ratings yet

- Fact Sheet HomeBuilder PDFDocument4 pagesFact Sheet HomeBuilder PDFWill NguyenNo ratings yet

- STP Manual Final PDFDocument862 pagesSTP Manual Final PDFrudiNo ratings yet

- Yowie Rarity Chart A4 PDFDocument6 pagesYowie Rarity Chart A4 PDFrudiNo ratings yet

- Aerator Type ABS Venturi Jet: ApplicationsDocument4 pagesAerator Type ABS Venturi Jet: ApplicationsrudiNo ratings yet

- Intentional Food Contamination PDFDocument12 pagesIntentional Food Contamination PDFrudiNo ratings yet