Professional Documents

Culture Documents

MPT Fire Pump Controller Alarm Guide

Uploaded by

Andres CortesOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MPT Fire Pump Controller Alarm Guide

Uploaded by

Andres CortesCopyright:

Available Formats

MPT Electric Fire Pump Controller

Alarm Messages and Troubleshooting Guide

This manual provides alarm descriptions, troubleshooting steps, and alarm set

point configuration information for Metron MPT Fire Pump Controllers and

MPT Electric Fire Pump Controllers with Metron Transfer Switch (MTS).

Section Page

Introduction 3

Pressure Alarms 4

Normal Source Power Alarms 6

Emergency Source Power Alarms 10

Motor Alarms 14

Hardware Alarms 18

Troubleshooting 21

Replacement Parts & Technical Support 22

Publication 246.2C-EN – September 2017

2 MPT Alarm Messages and Troubleshooting Guide

History of Changes

Rev. No. Date Descritpion of Changes

A May 2016 Initial Release

B November 2016 Update text so manual can be used with non-

MTS controllers.

C September 2017 Updated Eledyne contact info

Publication 246.2C-EN – September 2017

MPT Alarm Messages and Troubleshooing Guide 3

Introduction

This manual provides alarm descriptions, troubleshooting steps, and alarm set

point configuration information for all alarm conditions for the controller.

For instructions for navigating the Operator Interface Device (OID) and for

configuration set points, please refer to Publication 245, MPT Electric Fire

Pump Controller with MTS Setup and Operating Instructions.

NOTICE Read these instructions thoroughly before

troubleshooting the controller. If there are still

questions, contact your Metron factory

representative for assistance.

Precautions

CAUTION To avoid risk of SERIOUS INJURY or DEATH, and to

avoid damage to the controller, READ THIS SECTION

CAREFULLY. If questions or concerns still exist,

contact the Metron factory for further

clarification.

ARC FLASH

Do not operate controls or open covers without

appropriate personal protection equipment.

Failure to comply may result in SERIOUS INJURY

or DEATH! Refer to NFPA70E for PPE requirements.

HAZARD

If work must be carried out on the motor or controller, ensure the controller is

ISOLATED AND LOCKED OFF from the AC mains supply before work

commences. Lockout/Tag out procedures should be followed in accordance

with NFPA standard and any local standards that may apply.

On application of power, to prevent automatic starting of the motor press and

hold the S T O P key. The system will be in a configuration mode and will not start

the motor. Configuration mode will last for five (5) minutes, unless the on-

screen "Exit Config Mode" button is pressed.

Publication 246.2C-EN – September 2017

4 MPT Alarm Messages and Troubleshooting Guide

Pressure Alarms

Low Pressure

Description

System pressure is at or below the configured low pressure level. The alarm

is configured per the user’s discretion and may be disabled.

Troubleshooting

If typical system pressure is causing the alarm, lower the Low Pressure

Level set point. If a valid low pressure condition occurs routinely, but

quickly returns to the typical system pressure level (i.e., the Jockey

pump boosts pressure), increase the Low Pressure Alarm Delay set

point to prevent nuisance alarms and motor starts.

Verify pressure readings on display are correct.

Calibrate pressure readings

Replace the transducer

Related Set Points

Pressure Settings: Low Pressure Alarm Option

Pressure Settings: Low Pressure Level

Pressure Settings: Low Pressure Alarm Delay

High Pressure

Description

System Pressure is at or above the configured high pressure level. The

alarm is configured per the user’s discretion and may be disabled.

Troubleshooting

If typical system pressure is causing the alarm, increase the High

Pressure Level set point. If a valid high pressure condition occurs

routinely, but quickly returns to the typical system pressure level,

increase the High Pressure Alarm Delay set point to prevent nuisance

alarms.

Verify pressure readings on display are correct.

Calibrate pressure readings

Publication 246.2C-EN – September 2017

MPT Alarm Messages and Troubleshooing Guide 5

Replace the transducer.

Related Set Points

Pressure Settings: High Pressure Alarm Option

Pressure Settings: High Pressure Level

Pressure Settings: High Pressure Alarm Delay

Pressure Transducer Fault

Description

This critical alarm occurs because there is a problem with the pressure

transducer or its wiring.

Troubleshooting

Check transducer cable.

Related Set Points

None

Low Intake

Description

The low intake contact at Input 54/55 on the 12 Channel I/O board is not in

its normal position. This alarm will only occur while the motor is running.

Troubleshooting

If a low intake condition has occurred, the issue is external to the MPT

controller. If a false alarm occurred, verify that the Low Intake Contact

Type set point is configured properly.

If the system is not equipped with low intake monitoring equipment, set

the Low Intake Contact Type set point to “N/O” and do not connect any

wires to Input 54/55 on the 12-Channel I/O board. Input 54/55 cannot

be reused for any other purpose.

Check the wiring connected to the 12 Ch IO board TB2 input 54/55.

Related Set Points

Stop Settings: Low Intake Shutdown

Stop Settings: Low Intake Alarm Delay

Stop Settings: Low Intake Auto Reset

Stop Settings: Low Intake Contact Type

Publication 246.2C-EN – September 2017

6 MPT Alarm Messages and Troubleshooting Guide

Normal Source Power Alarms

CAUTION To avoid risk of SERIOUS INJURY or DEATH, and to

avoid damage to the controller, READ THIS SECTION

CAREFULLY. If questions or concerns still exist,

contact the Metron factory for further

clarification.

Normal Source Phase Reversal

Description

This alarm occurs when a phase reversal is detected on the normal source.

Troubleshooting

Insure that both the normal source and the emergency source have the same

phase rotation. If the phase rotation is different between the two sources,

correct one of the sources.

Once both sources have the same phase rotation, if the phase reversal alarm

is still exists, toggle the settings for the Phase Order set point.

Next, verify that the motor spins in the correct direction. If the motor spins

in the opposite direction, the motor power wires must be corrected.

Related Set Points

Normal Power Parameters: Phase Order

Phase Failure on AB/BC/AC

Description

The voltage on the specified phase is at or below 85% of the nominal

system voltage.

Troubleshooting

Verify incoming voltage is correct across all three phases.

Is the alarm interemittent?

This alarm indicates a problem with the normal source power supply.

To avoid nuisance alarms caused by momentary dips in voltage, the

Phase Loss Alarm Delay set point may be adjusted.

Publication 246.2C-EN – September 2017

MPT Alarm Messages and Troubleshooing Guide 7

Related Set Points

Normal Power Parameters: Phase Loss Alarm Delay

Loss of Normal Power

Description

This alarm indicates that normal source voltage has dropped below 120V on

all phases.

Troubleshooting

Verify incoming voltage is correct.

If line side voltage for the normal source is available:

Verify that the normal source circuit breaker has not tripped by

turning the normal source power isolation switch to the off position

and then back to the on position.

Related Set Points

None

Normal Source Low Voltage

Description

This alarm indicates that normal source voltage on at least one phase is at or

below the configured Low Voltage Percentage set point.

Troubleshooting

Verify incoming voltage is correct across all three phases.

If typical normal source voltage is causing the alarm, lower the Low

Voltage Percentage set point (default is 90% of nominal). If a valid

under voltage alarm occurs routinely, but quickly returns to the typical

normal source voltage, increase the Low Voltage Alarm Delay set point

to prevent nuisance alarms.

This alarm is configurable per the user’s discretion and may be disabled

by configuring the Low Voltage Percentage set point to its lowest

value.

Related Set Points

Normal Power Parameters: Low Voltage Percentage

Normal Power Parameters: Low Voltage Alarm Delay

Publication 246.2C-EN – September 2017

8 MPT Alarm Messages and Troubleshooting Guide

Normal Source High Voltage

Description

Normal source voltage on at least one phase is at or above the configured

High Voltage Percentage set point.

Troubleshooting

Verify incoming voltage is correct across all three phases.

If typical normal source voltage is causing the alarm, increase the High

Voltage Percentage set point (default is 115% of nominal). If a valid

over voltage condition occurs routinely, but quickely returns to the

typical normal source voltage, increase the High Voltage Alarm Delay

set point to prevent nuisance alarms.

Related Set Points

High Voltage Percentage

High Voltage Alarm Delay

Normal Source Under Frequency

Description

Normal source frequency on at least one phase is at or below the configured

Under Frequency % of Nominal set point.

Troubleshooting

If typical normal source frequency is causing the alarm, lower the Under

Frequency % of Nominal set point. If a valid under frequency alarm occurs

routinely, but quickly returns to the typical normal source voltage, increase

the Under Frequency Alarm Delay set point to prevent nuisance alarms.

Related Set Points

Normal Power Parameters: Under Frequency % of Nominal

Normal Power Parameters: Under Frequency Alarm Delay

Normal Source Over Frequency

Description

Normal source frequency on at least one phase is at or above the configured

Over Frequency % of Nominal set point.

Troubleshooting

If typical normal source frequency is causing the alarm, lower the Over

Frequency % of Nominal set point. If a valid under frequency alarm occurs

Publication 246.2C-EN – September 2017

MPT Alarm Messages and Troubleshooing Guide 9

routinely, but quickly returns to the typical normal source voltage, increase

the Over Frequency Alarm Delay set point to prevent nuisance alarms.

Related Set Points

Normal Power Parameters: Over Frequency % of Nominal

Normal Power Parameters: Over Frequency Alarm Delay

Supervisory Power Failure

Description

This alarm indicates a loss of supervisory power, which is external to the

MPT controller. The input for the alarm is normally closed and is located at

Input 56/57 on the 12-Channel I/O board.

Troubleshooting

Check for Supervisor Power 120VAC on terminals 207/211.

If a supervisory power 120VAC is available, check the wiring from the

12-Channel I/O board to teminals 207/211. See field connection

schematic page 1 on door of the enclosure.

NOTE: this alarm relates to a factory-installed option and is not

available on all controllers.

Related Set Points

Start Settings: Supervisory Power Failure Start

Start Settings: Supervisory Power Failure Start Delay

Publication 246.2C-EN – September 2017

10 MPT Alarm Messages and Troubleshooting Guide

Emergency Source Power Alarms

This section only applies to controllers equipped with MTS.

CAUTION To avoid risk of SERIOUS INJURY or DEATH, and to

avoid damage to the controller, READ THIS SECTION

CAREFULLY. If questions or concerns still exist,

contact the Metron factory for further

clarification.

Emergency Source Isolation Switch Open

Description

The emergency power source isolation switch is in the off position.

Troubleshooting

Turn the emergency power source isolation switch to the on position.

Verify that the circuit breaker has not tripped by turning the emergency

power source isolation switch to the off position, and then back to the

on position.

Check the wiring per the system schematic on the enclosure door.

Related Set Points

None

Emergency Source Phase Reversal

Description

This alarm occurs when a phase reversal is detected on the emergency

source.

Troubleshooting

Insure that both the normal source and the emergency source have the same

phase rotation. If the phase rotation is different between the two sources,

correct one of the sources.

Once both sources have the same phase rotation, if the phase reversal alarm

still exists, toggle the settings for the Phase Order set point.

Next, verify that the motor spins in the correct direction. If the motor spins

in the opposite direction, the motor power wires must be corrected.

Publication 246.2C-EN – September 2017

MPT Alarm Messages and Troubleshooing Guide 11

Related Set Points

Normal Power Parameters: Phase Order

Emergency Phase Failure on AB/BC/AC

Description

The voltage on the specified phase is at or below 85% of the nominal

system voltage.

Troubleshooting

Verify incoming voltage is correct.

This alarm indicates a problem with the emergency source power

supply. To avoid nuisance alarms caused by momentary dips in

voltage, the Phase Loss Alarm Delay set point may be adjusted.

Related Set Points

Emergency Power Parameters: Phase Loss Alarm Delay

Loss of Emergency Power

Description

This alarm indicates that emergency source voltage has dropped below

120V on all phases. This alarm only occurs if the Emergency Source Type

set point is configured as Utility.

Troubleshooting

Verify side voltage for the emergency source is available:

Verify that the emergency source circuit breaker has not tripped by

turning the emergency source power isolation switch to the off position

and then back to the on position.

Related Set Points

Transfer Switch Settings: Emergency Source Type

Genset Fail to Start

Description

This alarm indicates that emergency source voltage was not detected after

the genset start relay was energized. This alarm only occurs if the

Emergency Source Type set point is configured as Genset.

Publication 246.2C-EN – September 2017

12 MPT Alarm Messages and Troubleshooting Guide

Troubleshooting

Verify the Emergency Source Isolation Switch is not open.

Verify the Engine Start contact closed.

Related Set Points

Transfer Switch Settings: Emergency Source Type

Emergency Source Low Voltage

Description

This alarm indicates that emergency source voltage on at least one phase is

at or below the configured Low Voltage Percentage set point.

Troubleshooting

Verify incoming voltage is correct across all three phases.

If typical emergency source voltage is causing the alarm, lower the Low

Voltage Percentage set point (default is 90% of nominal). If a valid

under voltage alarm occurs routinely, but quickly returns to the typical

emergency source voltage, increase the Low Voltage Alarm Delay set

point to prevent nuisance alarms.

This alarm is configurable per the user’s discretion and may be disabled

by configuring the Low Voltage Percentage set point to its lowest

value.

Related Set Points

Emergency Power Parameters: Low Voltage Percentage

Emergency Power Parameters: Low Voltage Alarm Delay

Emergency Source High Voltage

Description

Emergency source voltage on at least one phase is at or above the

configured High Voltage Percentage set point.

Troubleshooting

Verify incoming voltage is correct across all three phases.

If typical emergency source voltage is causing the alarm, increase the

High Voltage Percentage set point (default is 115% of nominal). If a

valid over voltage condition occurs routinely, but quickely returns to

Publication 246.2C-EN – September 2017

MPT Alarm Messages and Troubleshooing Guide 13

the typical emergency source voltage, increase the High Voltage Alarm

Delay set point to prevent nuisance alarms.

Related Set Points

High Voltage Percentage

High Voltage Alarm Delay

Emergency Source Under Frequency

Description

Emergency source frequency on at least one phase is at or below the

configured Under Frequency % of Nominal set point.

Troubleshooting

If the emergency source is a Genset verify operation.

If typical normal source frequency is causing the alarm, lower the

Under Frequency % of Nominal set point. If a valid under frequency

alarm occurs routinely, but quickly returns to the typical normal source

voltage, increase the Under Frequency Alarm Delay set point to

prevent nuisance alarms.

Related Set Points

Emergency Power Parameters: Under Frequency % of Nominal

Emergency Power Parameters: Under Frequency Alarm Delay

Emergency Source Over Frequency

Description

Emergency source frequency on at least one phase is at or above the

configured Over Frequency % of Nominal set point.

Troubleshooting

If the emergency source is a Genset verify operation.

If typical emergency source frequency is causing the alarm, lower the

Over Frequency % of Nominal set point. If a valid under frequency

alarm occurs routinely, but quickly returns to the typical normal source

voltage, increase the Over Frequency Alarm Delay set point to prevent

nuisance alarms.

Related Set Points

Emergency Power Parameters: Over Frequency % of Nominal

Emergency Power Parameters: Over Frequency Alarm Delay

Publication 246.2C-EN – September 2017

14 MPT Alarm Messages and Troubleshooting Guide

Motor Alarms

Fail to Start

Description

This alarm indicates that the controller attempted to energize the Run

Contact, but no motor current was detected and the Run Contact feedback

was not detected.

Troubleshooting

Verfiy current on each of the phases.

The run contactor/aux contacts did not close.

Check wiring to the run contactor’s coil.

Check the run contactor’s coil.

Check run contactor operation.

Related Set Points

Motor Parameters: No Load/Fail to Start Time Delay

No Load

Description

This alarm indicates that the controller energized the Run Contact and the

Run Contact feedback was detected, but the motor current did not exceed

the configured No Load Amps % of FLA set point level.

Troubleshooting

Verify current on each of the phases.

Check the wiring from the run contactor to the motor.

Check the motor continuity.

Related Set Points

Motor Parameters: No Load/Fail to Start Time Delay

Motor Parameters: No Load Amps % of FLA

Publication 246.2C-EN – September 2017

MPT Alarm Messages and Troubleshooing Guide 15

Run Contact Fault

Description

This alarm indicates that the controller energized the Run Contact and the

motor started, but the Run Contact feedback was not detected.

Troubleshooting

Check wiring to 12 Ch IO board HC90775 Input 2-42/43. Check operation

of run contactor Aux contact.

Related Set Points

None

Motor Overload

Description

This alarm indicates that the motor current exceeded the configured

Overload Alarm % of FLA set point level (default is 300%).

Troubleshooting

Verify motor FLA with controller nameplate raings.

Is the alarm intermittent?

If the motor overload alarm occurs momentarily, but then clears,

increase the Overload Alarm Time Delay set point value.

Verify that the configured Overload Alarm % of FLA set point value is

not within the acceptable level for the motor.

Check the motor.

Related Set Points

Motor Parameters: Overload Alarm % of FLA

Motor Parameters: Overload Alarm Time Delay

Motor Parameters: Overload Shunt Trip Time

Locked Rotor

Description

This alarm indicates that the motor current exceeded the configured Locked

Rotor Alarm % of FLA set point value for at least three (3) seconds (default

of 600% ).

Publication 246.2C-EN – September 2017

16 MPT Alarm Messages and Troubleshooting Guide

Troubleshooting

Is the alarm intermittent?

Check motor operation

Related Set Points

Motor Parameters: Locked Rotor Alarm % of FLA

Motor Parameters: Locked Rotor Alarm Delay

Start Contact Fault

Description

This alarm indicates that the when starting the motor, the Start Contact

feedback was not detected.

This alarm only occurs for models MPT420, MPT430, and MPT435.

Troubleshooting

Check wiring going to the start contactor per the system schematic on

the enclosure door.

Check start contactor coil.

Related Set Points

None

Soft Start Fault

Description

This alarm indicates that a soft start fault has occurred.

This alarm only occurs for model MPT700.

Troubleshooting

Verify the soft starter operation.

Check soft starter wiring per the system schematic on the enclosure

door.

Related Set Points

None

Publication 246.2C-EN – September 2017

MPT Alarm Messages and Troubleshooing Guide 17

Transfer Switch Fault (MTS Only)

Description

This alarm indicates that the transfer switch position indicator has a fault.

Troubleshooting

Check position of transfer switch.

Verify transfer switch operation.

Related Set Points

None

Low Zone Fail to Start

Description

This alarm indicates that the low zone run signal was not detected at Input

60/61 on the 12-Channel I/O board.

Troubleshooting

Verify low zone controller is operational.

Check wiring to the 12-Channel I/O board TB2-Input 60/61.

Related Set Points

High Zone Settings: High Zone Option

High Zone Settings: Low Zone Start Delay

High Zone Settings: Always Start

Low Zone Quit

Description

This alarm indicates that the low zone run signal at Input 60/61 on the 12-

Channel I/O board was lost.

Troubleshooting

Verify low zone controller is operational.

Check wiring to the 12-Channel I/O board TB2-Input 60/61.

Related Set Points

High Zone Settings: High Zone Option

High Zone Settings: Low Zone Start Delay

High Zone Settings: Always Start

Publication 246.2C-EN – September 2017

18 MPT Alarm Messages and Troubleshooting Guide

Hardware Alarms

Low/Missing Clock Battery

Description

The clock backup battery has low voltage, is faulty, or is missing.

Troubleshooting

Replace coin battery on HC90772002 board with the exact part number.

Related Set Points

None

Problem with Power Comms PCB Hub

Description

This alarm indicates that I/O communication with the Power Comms Hub

board is not working as expected.

Troubleshooting

Verify cables are securily connected to the board.

Verify that the 12-Channel I/O board/Power Monitor board is not

causing the problem:

1. With power turned off, disconnect the 12-Channel I/O board and

the Power Monitor board from the Power Comms board.

2. Reapply power.

3. If the “Problem with Power Comms PCB” alarm reoccurs, replace

the Power Comms Hub board (P/N HC90773).

4. If the “Problem with Power Comms PCB” alarm does not occur,

the issue may be with the 12-Channel I/O board or Power Monitor

board. Refer to the Troubleshooting steps for those boards.

Problem with 12-Channel I/O PCB

Description

This alarm indicates that I/O communication with the 12-Channel I/O board

is not working as expected.

Troubleshooting

Verify cables are securely connected to the board.

Publication 246.2C-EN – September 2017

MPT Alarm Messages and Troubleshooing Guide 19

Verify that the issue is not with the Power Comms Hub board:

1. With power turned off, disconnect the 12-Channel I/O board from

the Power Comms board PC1 connector, and reconnect to the PC 4

connector.

2. Reapply power.

3. If the “Problem with 12-Channel I/O PCB” alarm reoccurs, replace

the 12-Channel I/O board (P/N HC90775).

4. If the “Problem with 12-Channel I/O PCB” alarm does not occur,

the issue may be with the PC1 connector on the Power Comms

Hub board. Replace the Power Comms Hub board (P/N HC90773).

Problem with Power Monitor PCB

Description

This alarm indicates that I/O communication with the Power Monitor board

is not working as expected.

Troubleshooting

Verify cables are securely connected to the board.

Verify the the issue is not with the Transfer Switch Interface board:

o With power turned off, disconnect the Transfer Switch Interface

board from the Power Monitor board, and then reapply power.

o If the “Problem with Power Monitor PCB” alarm does not reoccur,

replace the Transfer Switch board (P/N HC90764).

Verify that the issue is not with the Power Comms Hub board:

o With power turned off, disconnect the Power Monitor board from

the Power Comms board PC2 connector, and reconnect to the PC 4

connector.

o Reapply power.

o If the “Problem with Power Monitor PCB” alarm reoccurs, replace

the Power Monitor board (P/N HC90764).

o If the “Problem with Power Monitor PCB” alarm does not occur,

the issue may be with the PC2 connector on the Power Comms

Hub board. Replace the Power Comms Hub board (P/N HC90773).

Publication 246.2C-EN – September 2017

20 MPT Alarm Messages and Troubleshooting Guide

Problem with Transfer Sw. PCB

Description

This alarm indicates that I/O communications with the Transfer Switch

board is not working as expected.

Troubleshooting

Verify cables are securely connected to the board.

Replace the Transfer Switch Interface board (P/N HC90764).

Publication 246.2C-EN – September 2017

MPT Alarm Messages and Troubleshooing Guide 21

Troubleshooting

1. The displayed voltage does not match my calibrated voltmeter

readings.

Calibrate the voltage.

Replace the Power Monitor board HC90763

2. This displayed motor current does not match my calibrated ammeter

readings.

Calibrate the currentReplace the Power Monitor board HC90763.

3. This displayed system pressure does not match my calibrated pressure

guage.

Calibrate the pressure readings.

Replace the transducer.

Publication 246.2C-EN – September 2017

22 MPT Electric Fire Pump Controller with MTS Modbus Setup Instructions

Replacement Parts

For replacement parts, contact your local Metron sales office or the Metron

factory at:

United States Telephone: +1 (336) 434-2800 ext. 202

FAX: +1 (336) 434-2809

Email: salesmail@metroninc.com

Europe Telephone: +44 (0) 7730 050 100

Email: jmcivor@hubbell-icd.com

Technical Support

United States For 24-hour technical support:

Telephone: +1 (336) 434-2800 ext. 183

Email: fpctechsupport@metroninc.com

Europe Service & Commissioning

Telephone: +44 (0) 1283 493 215

Email: djones@gai-tronics.co.uk

Emergency Contact:

Telephone: +44 (0) 7730 050100

www.metroninc.com www.metroneledyne.com.uk

Hubbell Industrial Controls, Inc.

Metron Fire Pump Controls Division

4301 Cheyenne Drive, Archdale NC 27263 USA, Tel: (336) 434-2800, Fax: (336) 434-2809

Hubbell Limited incorporating Metron Eledyne,

Stretton Busioness Park, Brunel Drive, Burton-on-Trent Staffordshire, DE13 0BZ, United Kingdom

Tel: +44 (0) 1283 500 500, Fax: +44 (0) 1283 500 400

Publication 246.2C-EN – September 2017 Printed in USA

You might also like

- Control Smart Alternators CAN ParametersDocument4 pagesControl Smart Alternators CAN Parameterslitieuduy100% (1)

- 3 Phase Auto Change Over SwitchDocument23 pages3 Phase Auto Change Over Switchajaykeshav100% (3)

- Automatic Transfer Switch Panel Operation GuideDocument23 pagesAutomatic Transfer Switch Panel Operation Guideyorgo7002100% (2)

- Поиск 1Document6 pagesПоиск 1suriantoNo ratings yet

- Sensor Signal (Analog, Active) - Test: TroubleshootingDocument5 pagesSensor Signal (Analog, Active) - Test: TroubleshootingcristianNo ratings yet

- Mounting Instructions / Manual MV1171Document21 pagesMounting Instructions / Manual MV1171leonardseniorNo ratings yet

- Dkg-207 Amf and Remote Start Unit Installation and Operating InstructionsDocument4 pagesDkg-207 Amf and Remote Start Unit Installation and Operating InstructionsBambang Ardiansyah SetiadyNo ratings yet

- 555 Audio Alarm ChartDocument4 pages555 Audio Alarm Chartnasty_beerNo ratings yet

- Technical Data 1 2. Inputs and Ouputs 2 - 4 3. Function of The Safety System 4 - 6 4. Plung - in Pcbs 6 - 8 5. Function Diagram 9-11Document12 pagesTechnical Data 1 2. Inputs and Ouputs 2 - 4 3. Function of The Safety System 4 - 6 4. Plung - in Pcbs 6 - 8 5. Function Diagram 9-11Ilham WaskitoNo ratings yet

- DTC 27 (ALL Diagnostic Trouble Codes (DTC) ) - ALLDATA RepairDocument6 pagesDTC 27 (ALL Diagnostic Trouble Codes (DTC) ) - ALLDATA Repairmuhammad AkramNo ratings yet

- EMS2 DeutzDocument42 pagesEMS2 DeutzLuis Segovia Cortes63% (8)

- Atm 72Document8 pagesAtm 72muhammad arifNo ratings yet

- E3632 SerDocument128 pagesE3632 ServishiwizardNo ratings yet

- Automatic Transfer Switch EssentialsDocument5 pagesAutomatic Transfer Switch EssentialsCandiano PopescuNo ratings yet

- Ac Voltage ControllerDocument2 pagesAc Voltage ControllerJoe RanteNo ratings yet

- P0562-Battery Voltage LowDocument7 pagesP0562-Battery Voltage Lowguillermoal539100% (1)

- Dkg-205 Automatic Mains Failure UnitDocument20 pagesDkg-205 Automatic Mains Failure UnitRafatNo ratings yet

- Sensor Signal (Analog, Active) - Test: Localización y Solución de ProblemasDocument7 pagesSensor Signal (Analog, Active) - Test: Localización y Solución de ProblemasCEVegaONo ratings yet

- G - Tests W/Codes - 1.6L & 2.0L Article TextDocument25 pagesG - Tests W/Codes - 1.6L & 2.0L Article TextKoeswara SofyanNo ratings yet

- 116 UserDocument4 pages116 UserWinston diaz valeraNo ratings yet

- Soft Starters SSW04 Technical Data GuideDocument8 pagesSoft Starters SSW04 Technical Data GuideAlberto Hern JimNo ratings yet

- CodigosDocument6 pagesCodigosAdán Castro GallegosNo ratings yet

- Universal 16 Amp Self Excited Automatic Voltage Regulator ManualDocument9 pagesUniversal 16 Amp Self Excited Automatic Voltage Regulator ManualJuan José Tovar Pérez100% (1)

- Customer Options Digital Voltage RegulatorDocument4 pagesCustomer Options Digital Voltage Regulatorbenjir shuvoNo ratings yet

- Agilent E3632ADocument107 pagesAgilent E3632ACtopherNo ratings yet

- Thymatron® System Iv Service Manual: WarningDocument33 pagesThymatron® System Iv Service Manual: WarningJiThiN vPNo ratings yet

- KUHSEDocument25 pagesKUHSESyed Mohammad Naveed100% (1)

- SAILOR Battery Panel BP4680Document16 pagesSAILOR Battery Panel BP4680IGOR100% (2)

- Generator Automatic Voltage Regulator Operation ManualDocument9 pagesGenerator Automatic Voltage Regulator Operation Manualsabrahima100% (1)

- LMS Plus 7.5 Fault CodeDocument10 pagesLMS Plus 7.5 Fault CodeNguyễn Văn Hùng100% (2)

- Troubleshoot Throttle Position Sensor 2 FaultsDocument5 pagesTroubleshoot Throttle Position Sensor 2 FaultsWillie AustineNo ratings yet

- E3632a Doc 4Document109 pagesE3632a Doc 4SửaĐồĐiệnNo ratings yet

- Solcon MV Thyristor Power Controller SpecificationsDocument55 pagesSolcon MV Thyristor Power Controller SpecificationsSaidi CalalaNo ratings yet

- Deep Sea Electronics PLC: Model 606 Comprehensive Amf ModuleDocument4 pagesDeep Sea Electronics PLC: Model 606 Comprehensive Amf ModulemohammedalathwaryNo ratings yet

- SAILOR Battery Panel BP4680Document16 pagesSAILOR Battery Panel BP4680Md Sanaul Karim ShohelNo ratings yet

- ESR 3.1 User Manual - enDocument6 pagesESR 3.1 User Manual - enMinaSaeedNo ratings yet

- Interface Spec NY 20080318 Komplett Ver2 PDFDocument28 pagesInterface Spec NY 20080318 Komplett Ver2 PDFDuy Kha100% (1)

- Códigos de Falhas Hyundai R3607ADocument13 pagesCódigos de Falhas Hyundai R3607AGuemep GuemepNo ratings yet

- Mc31a Rev5Document33 pagesMc31a Rev5sanju939No ratings yet

- Benshaw Motor StarterDocument228 pagesBenshaw Motor Starterhennry_8307No ratings yet

- C5-DTC P0463 Fuel Level Sensor Circuit High VoltageDocument7 pagesC5-DTC P0463 Fuel Level Sensor Circuit High Voltage100a100aNo ratings yet

- 116 UserDocument4 pages116 UserMohamed Yahya100% (1)

- HGM501Document15 pagesHGM501Thao Nguyen XuanNo ratings yet

- MH, MSC 12 PFC PDFDocument21 pagesMH, MSC 12 PFC PDFMyokoko Zaw100% (2)

- Gen7 Level 1 - TroubleshootingDocument22 pagesGen7 Level 1 - TroubleshootingDrago LugonjaNo ratings yet

- NT538 Instruction ManualDocument15 pagesNT538 Instruction ManualHubert Maraza JaliriNo ratings yet

- 5-9 - Autodiagnostico HYUNDAI 360Document12 pages5-9 - Autodiagnostico HYUNDAI 360Milton IngTec Tecnologia100% (1)

- IFES Alarm Panel Operator Manual V17.01 - 055612Document15 pagesIFES Alarm Panel Operator Manual V17.01 - 055612DiNo ratings yet

- A L L Diagnostic Trouble Codes (DTC) : P Code Charts P2135Document4 pagesA L L Diagnostic Trouble Codes (DTC) : P Code Charts P2135PeterNo ratings yet

- dokumen.tips_cumins-ps0500-service-manualpdfDocument33 pagesdokumen.tips_cumins-ps0500-service-manualpdfMuthalagu J (Aravindh)No ratings yet

- Agilent E3640A E3641A E3642A Power Supply Service ManualDocument207 pagesAgilent E3640A E3641A E3642A Power Supply Service ManualFrancisco Javier Barreto MartínNo ratings yet

- VMD421H Series: Digital Voltage, Frequency, Asymmetry, and Phase Loss Relay For Three-Phase AC SystemsDocument6 pagesVMD421H Series: Digital Voltage, Frequency, Asymmetry, and Phase Loss Relay For Three-Phase AC SystemsjjcanoolivaresNo ratings yet

- Gen Auto XMDocument47 pagesGen Auto XMCameron Ledingham100% (1)

- 4 6035040594093408727Document13 pages4 6035040594093408727امین پارساNo ratings yet

- FrostBYTE V3Document16 pagesFrostBYTE V3apple.baxterNo ratings yet

- BLR CMT Short ManualDocument8 pagesBLR CMT Short ManualGUSGPNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Manual Iom Bombas Franklin 150 Ssi Impulsion PDFDocument24 pagesManual Iom Bombas Franklin 150 Ssi Impulsion PDFAndres CortesNo ratings yet

- FICHA TECNICA CONTROLADOR MetronMPT430-435 PDFDocument4 pagesFICHA TECNICA CONTROLADOR MetronMPT430-435 PDFAndres CortesNo ratings yet

- FICHA TECNICA CONTROLADOR MetronMP15 PDFDocument2 pagesFICHA TECNICA CONTROLADOR MetronMP15 PDFAndres CortesNo ratings yet

- Ficha Tecnica Bombas Franklin 150 Ssi Impulsion PDFDocument6 pagesFicha Tecnica Bombas Franklin 150 Ssi Impulsion PDFAndres CortesNo ratings yet

- MPT Fire Pump Controller Alarm GuideDocument22 pagesMPT Fire Pump Controller Alarm GuideAndres CortesNo ratings yet

- Manual Iom Bombas Franklin 150 Ssi Impulsion PDFDocument24 pagesManual Iom Bombas Franklin 150 Ssi Impulsion PDFAndres CortesNo ratings yet

- 2 - Serie 40 - 45Document10 pages2 - Serie 40 - 45Andres CortesNo ratings yet

- VCTF10KDocument2 pagesVCTF10KgeekcourseonlineNo ratings yet

- Ansaldo Electric Drives 15/30 kW Technical SpecsDocument4 pagesAnsaldo Electric Drives 15/30 kW Technical SpecsMr.K ch50% (2)

- Redundant Power Supply Installation Guide EP-DCX205Document38 pagesRedundant Power Supply Installation Guide EP-DCX205Anonymous zLwP4FjLNo ratings yet

- Unesco-Eolss Sample Chapters: Insulation Co-Ordination in Power SystemsDocument30 pagesUnesco-Eolss Sample Chapters: Insulation Co-Ordination in Power Systemstawanda daniel denguNo ratings yet

- Maintenance Manual: OperationDocument12 pagesMaintenance Manual: OperationzéNo ratings yet

- Working Principle Miniature Circuit Breaker Breaker.: Electric CurrentDocument28 pagesWorking Principle Miniature Circuit Breaker Breaker.: Electric CurrentPrashant ShahNo ratings yet

- APT - Line CB (E3) : Service ManualDocument100 pagesAPT - Line CB (E3) : Service ManualDavid EguezNo ratings yet

- SMD Power Mosfet Transistor (N-Channel)Document7 pagesSMD Power Mosfet Transistor (N-Channel)Rodolfo LaraNo ratings yet

- GM4500FCDocument8 pagesGM4500FCJoaquim Filipe GanhaoNo ratings yet

- SW190 Catalogue Data SheetDocument1 pageSW190 Catalogue Data SheetgusmilexaNo ratings yet

- Copper THHN/THWN-2 PriorityDocument1 pageCopper THHN/THWN-2 PriorityLuis DGNo ratings yet

- Panasonic Inverter ManualDocument8 pagesPanasonic Inverter Manualsamernet2100% (1)

- N Type Coaxial Cable ConnectorDocument1 pageN Type Coaxial Cable ConnectorAqeel GardeziNo ratings yet

- Error CodesDocument1 pageError CodesTimkenNo ratings yet

- Irf 9640Document8 pagesIrf 9640Saeid AbraziNo ratings yet

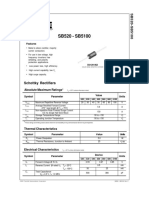

- SB520 - SB5100: Schottky RectifiersDocument3 pagesSB520 - SB5100: Schottky RectifiersHéctor Eduardo Baptista CastilloNo ratings yet

- Chapter 5 - ConsumerizationDocument51 pagesChapter 5 - ConsumerizationFaiz MohdNo ratings yet

- NA2XSEYBY 3 x (35-300) mm 12/20 cable specificationDocument1 pageNA2XSEYBY 3 x (35-300) mm 12/20 cable specificationMario SitorusNo ratings yet

- Instrument Transformers GuideDocument11 pagesInstrument Transformers GuideIkhuosho AbodeNo ratings yet

- Xlpe Insulated Cables Need Power ConnectDocument32 pagesXlpe Insulated Cables Need Power ConnectTesfahun GirmaNo ratings yet

- M10 Hieff Twin Mono: High EfficiencyDocument2 pagesM10 Hieff Twin Mono: High EfficiencyMeel Electic GeneralNo ratings yet

- Contacts: Northstar Solar Opzv BatteriesDocument2 pagesContacts: Northstar Solar Opzv BatteriesmjmardonesNo ratings yet

- 6 Griffith Double Acting Hydraulic Mechanical Drilling Jar Series 431 428 440 441 480 411 437 Operating ManualDocument32 pages6 Griffith Double Acting Hydraulic Mechanical Drilling Jar Series 431 428 440 441 480 411 437 Operating Manualmahmod alrousanNo ratings yet

- Power System ProtectionDocument2 pagesPower System ProtectionEkramul Khan ChowdhuryNo ratings yet

- 2N60 PDFDocument7 pages2N60 PDFFady HachemNo ratings yet

- MSD 6A 6AL Installation 6201Document20 pagesMSD 6A 6AL Installation 6201Michael LloydNo ratings yet

- REHS9792 - Installation Procedure For Excitation Modules 10 and 15 (4467) PDFDocument10 pagesREHS9792 - Installation Procedure For Excitation Modules 10 and 15 (4467) PDFHafid AnwarNo ratings yet

- Design of Electrical Machines Course TransformersDocument3 pagesDesign of Electrical Machines Course TransformersDEVINo ratings yet

- VFD Troubleshooting ATV 212Document15 pagesVFD Troubleshooting ATV 212Muhammad azeemNo ratings yet

- TM 11-5820-510-35P an-PRC-41A Radio Set (Parts and Tools) (1964) WWDocument55 pagesTM 11-5820-510-35P an-PRC-41A Radio Set (Parts and Tools) (1964) WWpatrick8167No ratings yet