Professional Documents

Culture Documents

GM4500FC

Uploaded by

Joaquim Filipe GanhaoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GM4500FC

Uploaded by

Joaquim Filipe GanhaoCopyright:

Available Formats

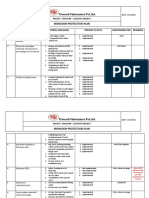

GM 4500-D/4700-D DIAGNOSTIC FAULT CODE QUICK REFERENCE TABLE

Directions:

Perform the Service Actions in the order they are presented. Every Service Action has the potential to repair the fault completely. Test the machine after

the completion of each Service Action to verify the active fault remains. If the fault is still active, perform the next Service Action step. Continue this

process until the fault is no longer reported.

Fault Fault Title Controller Fault Condition/Circuit Additional Notes Service Actions

Number Affected Description

1 Engine Coolant Master This fault is reported when the The PTO is disabled. 1) Test the cooling fan function.

Overheat- PTO engine coolant temperature has 2) Inspect the radiator airflow

Shutdown reached 105 °C. passages to ensure they are

clear.

3) Check the coolant level.

2 Engine Coolant Master This fault is reported when the The engine is turned 1) Test the cooling fan function.

Overheat- Engine engine coolant temperature has off. 2) Inspect the radiator airflow

Shutdown reached 115 °C. passages to ensure they are

clear.

3) Check the coolant level.

3 Fuse Failure Master/Slave This fault is reported when the 1) Check the 7.5 amp fuse F-A1

fuse has failed for one of the protecting outputs 1–4 on the

output circuits on the master or master TEC.

slave TEC. 2) Check the 7.5 amp fuse F-B1

protecting outputs 5–10 on the

master TEC.

3) Check the 7.5 amp fuse F-C1

protecting outputs 11–14 on the

master TEC.

4) Check the 7.5 amp fuse F-A2

protecting outputs 1–4 on the

slave TEC.

5) Check the 7.5 amp fuse F-B2

protecting outputs 5–10 on the

slave TEC.

6) Check the 7.5 amp fuse F-C2

protecting outputs 11–14 on the

slave TEC.

GM 4500-D/4700-D DIAGNOSTIC FAULT CODE QUICK REFERENCE TABLE Page 1 of 8

Fault Fault Title Controller Fault Condition/Circuit Additional Notes Service Actions

Number Affected Description

4 IPE Voltage Low Master This fault is reported when the Engine will be disabled 1) Replace the master TEC.

inputs or outputs on the master by this fault.

TEC are not working correctly.

5 Main Power Relay Master/Slave This fault is reported when the This fault may also 1) Test all of the 7.5 amp fuses.

Failure main power relay on the master generate Fault 11. 2) Test the functionality of the main

or slave TEC has failed. power relay.

3) If the relay test passes, verify that

the master TEC is getting 12 Vdc

from the relay.

4) If the relay test passes, verify that

the slave TEC is getting 12 Vdc

from the relay.

6 Key Start Timeout Master This fault is reported when the If the key was held for 1) Check the key switch for any

ignition key has been stuck or more than 30 seconds, shorts.

held in the “Start” position for returning key to the run 2) Test the key switch for any

more than 30 seconds. position will clear the mechanical malfunction.

fault.

7 Software Master This fault is reported when one or 1) Update the machine firmware

Incompatible more of the component firmware using Toro DIAG.

programs is incompatible with the

firmware in the Master TEC.

8 Charging Voltage Master and/or This fault is reported when the 1) Check alternator voltage output.

High Slave charging system (alternator) is 2) Refer to alternator specification

producing a voltage that the TEC for typical output voltage.

has determined to be out-of-

range on the high side.

9 Charging Voltage Master and/or This fault is reported when 1) Check alternator voltage output.

Low Slave charging system (alternator) is 2) Refer to alternator specification

producing a voltage that the TEC for typical output voltage.

has determined to be out-of-

range on the low side.

10 CAN Bus Timeout – Master This fault is reported when the The master TEC 1) Check the resistance of the CAN

Engine ECU master TEC has lost CAN reviews incoming CAN network.

communication with the engine messages from all of 2) Check the CAN connections at

electronic control unit (ECU) for the components on the TEC 5002, engine controller, and

at least 10 seconds. network. all junctions.

3) Verify power to the engine control

unit (ECU).

GM 4500-D/4700-D DIAGNOSTIC FAULT CODE QUICK REFERENCE TABLE Page 2 of 8

Fault Fault Title Controller Fault Condition/Circuit Additional Notes Service Actions

Number Affected Description

11 CAN Bus Timeout - Master This fault is reported when the The master TEC 1) Check the resistance of the CAN

Slave TEC master TEC has lost CAN reviews incoming CAN network.

communication with the slave messages from all of 2) Check the CAN connection at the

TEC for at least 1 second. the components on the slave TEC.

network. 3) Verify power to the slave TEC.

12 CAN Bus Timeout - Master This fault is reported when the The master TEC 1) Check the resistance of the CAN

Mini InfoCenter master TEC has lost CAN reviews incoming CAN network.

communication with the messages from all of 2) Check the CAN connection at the

InfoCenter for at least 3 seconds. the components on the InfoCenter.

network. 3) Verify power to the InfoCenter.

13 Key Switch Broken Master This fault is reported when the 1) Check for a loose wire or a loose

ignition key “Start” input is active, connector.

but the ignition key “Run” input is 2) Check for corrosion due to water.

off. 3) Check the master TEC

harness/connector for loose

wires.

4) Check the ignition key switch.

14 Traction Pedal Master This fault is reported when the 1) Verify neutral switch function

Neutral Switch master TEC is receiving “Neutral through InfoCenter traction pedal

Broken Forward” and “Neutral Reverse” diagnostics.

signals simultaneously. 2) Check the traction pedal

potentiometer, harness wiring,

and connection points to the

potentiometer and controller.

15 Engine Throttle Master This fault is reported when the 1) Check the switch. There could be

Switch Broken master TEC is receiving a short in the switch.

“Increase RPM” and “Decrease 2) Test the speed request input

RPM” signals simultaneously. circuits from the switch to the

master TEC (pins 11 and 12).

3) Check the harness/connector for

a loose wire or corrosion.

16 Range High/Low Master This fault is reported when the 1) Check the switch. There could be

Switch Broken master TEC is receiving “Range a short in the switch.

High” and “Range Low” signals 2) Test the “Range High” and

simultaneously. “Range Low” input circuits from

the switch to the master TEC

(pins 5 and 10).

3) Check the harness/connector for

a loose wire or corrosion.

GM 4500-D/4700-D DIAGNOSTIC FAULT CODE QUICK REFERENCE TABLE Page 3 of 8

Fault Fault Title Controller Fault Condition/Circuit Additional Notes Service Actions

Number Affected Description

17 Pedal Sensor Out of Master This fault is reported when the 1) Check the traction pedal

Range master TEC is receiving “Neutral potentiometer.

Forward” and “Neutral Reverse” 2) Check the harness wiring.

signals simultaneously. 3) Check the connection points to

the potentiometer

4) Check the connection points to

the master TEC (pins 1 and 2).

18 Hydraulic Master This fault is reported when the 1) Check for loose wires or a loose

Temperature Sensor hydraulic temperature sensor connector.

Out of Range reading is not within range. 2) Test the 5V reference at the

temperature sensor.

20 Counterbalance Master This fault is reported when the 1) Check for loose wires or a loose

Pressure Sensor counterbalance pressure sensor connector.

Out of Range reading is not within range. 2) Inspect all connections for

corrosion.

3) Test the counterbalance pressure

sensor.

4) Test the 5V reference at the

hydraulic pressure transducer.

21 Center Deck Switch Master This fault is reported when the 1) Test the switch. There could be a

Broken “Center Deck Raise” and “Center short in the switch.

Deck Lower” inputs are active 2) Check the harness/connector for

simultaneously. a loose wire or corrosion

22 Left Deck Switch Slave This fault is reported when the 1) Test the switch. There could be a

Broken “Left Deck Raise” and “Left Deck short in the switch.

Lower” inputs are active 2) Check the harness/connector for

simultaneously. a loose wire or corrosion

23 Right Deck Switch Slave This fault is reported when the 1) Test the switch. There could be a

Broken “Right Deck Raise” and “Right short in the switch.

Deck Lower” inputs are active 2) Check the harness/connector for

simultaneously. a loose wire or corrosion

26 Engine Start Out Master This fault is reported when the 1) Test the output circuit for a short.

measured current through the 2) Test for proper resistance in the

“Engine Start” output is too high. component connected to the

master TEC (pin 8).

3) Replace the master TEC.

GM 4500-D/4700-D DIAGNOSTIC FAULT CODE QUICK REFERENCE TABLE Page 4 of 8

Fault Fault Title Controller Fault Condition/Circuit Additional Notes Service Actions

Number Affected Description

27 Engine Run Out Master This fault is reported when the 1) Test the output circuit for a short.

measured current through the 2) Test for proper resistance in the

“Engine Run” output is too high. component connected to the

master TEC (pin 10).

3) Replace the master TEC.

28 Range High Out Master This fault is reported when the 1) Test the output circuit for a short.

measured current through the 2) Test for proper resistance in the

“Range High” output is too high. component connected to the

master TEC (pin 2).

3) Replace the master TEC.

33 Hydro Forward Out Master This fault is reported when the 1) Test the output circuit for a short.

measured current through the 2) Test for proper resistance in the

traction forward coil is too high. component connected to the

master TEC (pin 44).

3) Replace the master TEC.

34 Hydro Reverse Out Master This fault is reported when the 1) Test the output circuit for a short.

measured current through the 2) Test for proper resistance in the

traction reverse coil is too high. component connected to the

master TEC (pin 46).

3) Replace the master TEC.

35 Fan Reverse Out Master This fault is reported when the 1) Test the output circuit for a short.

measured current through the fan 2) Test for proper resistance in the

reverse output is too high. component connected to the

master TEC (pin 7).

3) Replace the master TEC.

39 Left PTO Out Slave This fault is reported when the 1) Test the output circuit for a short.

measured current through the 2) Test for proper resistance in the

“Left Deck PTO” output is too component connected to the

high. slave TEC (pin 42).

3) Replace the slave TEC controller.

40 Right PTO Out Slave This fault is reported when the 1) Test the output circuit for a short.

measured current through the 2) Test for proper resistance in the

“Right Deck PTO” output is too component connected to the

high. slave TEC (pin 41).

3) Replace the slave TEC.

GM 4500-D/4700-D DIAGNOSTIC FAULT CODE QUICK REFERENCE TABLE Page 5 of 8

Fault Fault Title Controller Fault Condition/Circuit Additional Notes Service Actions

Number Affected Description

41 Enable S1 Out Slave This fault is reported when the 1) Test the output circuit for a short.

measured current through the 2) Test for proper resistance in the

“Enable” output is too high. component connected to the

slave TEC (pin 4).

3) Replace the slave TEC.

42 Left Raise S2 Out Slave This fault is reported when the 1) Test the output circuit for a short.

current measured through the 2) Test for proper resistance in the

“Left Deck Raise” output is too component connected to the

high. slave TEC (pin 8).

3) Replace the slave TEC.

43 Left Lower S3 Out Slave This fault is reported when the 1) Test the output circuit for a short.

current measured through the 2) Test for proper resistance in the

“Left Deck Lower” output is too component connected to the

high. slave TEC (pin 10).

3) Replace the slave TEC.

44 Left Float S4 Out Slave This fault is reported when the 1) Test the output circuit for a short.

current measured through the 2) Test for proper resistance in the

“Left Deck Float” output is too component connected to the

high. slave TEC (pin 7).

3) Replace the slave TEC.

45 Center Raise S5 Out Master This fault is reported when the 1) Test the output circuit for a short.

current measured through the 2) Test for proper resistance in the

“Center Deck Raise” output is too component connected to the

high. master TEC (pin 3).

3) Replace the master TEC.

46 Center Float S6 Out Master This fault is reported when the 1) Test the output circuit for a short.

current measured through the 2) Test for proper resistance in the

“Center Deck Lower/Float” output component connected to the

is too high. master TEC (pin 4).

3) Replace the master TEC.

47 Right Raise S7 Out Slave This fault is reported when the 1) Test the output circuit for a short.

current measured through the 2) Test for proper resistance in the

“Right Deck Raise” output is too component connected to the

high. slave TEC (pin 6).

3) Replace the slave TEC.

GM 4500-D/4700-D DIAGNOSTIC FAULT CODE QUICK REFERENCE TABLE Page 6 of 8

Fault Fault Title Controller Fault Condition/Circuit Additional Notes Service Actions

Number Affected Description

48 Right Lower S8 Out Slave This fault is reported when the 1) Test the output circuit for a short.

current measured through the 2) Test for proper resistance in the

“Right Deck Lower” output is too component connected to the

high. slave TEC (pin 44).

3) Replace the slave TEC.

49 Right Float S9 Out Slave This fault is reported when the 1) Test the output circuit for a short.

current measured through the 2) Test for proper resistance in the

“Right Deck Float” output is too component connected to the

high. output pin 45.

3) Replace the slave TEC.

50 PTO 1 Out Master This fault is reported when the 1) Test the output circuit for a short.

current measured through the 2) Test for proper resistance in the

center deck PTO 1 output is too component connected to the

high. master TEC (pin 45).

3) Replace the master TEC.

51 PTO 2 Out Master This fault is reported when the 1) Test the output circuit for a short.

current measured through the 2) Test for proper resistance in the

center deck PTO 2 output is too component connected to the

high. master TEC (pin 43).

3) Replace the master TEC.

52 Fan Out Master This fault is reported when the 1) Test the output circuit for a short.

current measured through the fan 2) Test for proper resistance in the

output is too high. component connected to the

master TEC (pin 41).

3) Replace the master TEC.

62 Counterbalance Out Master This fault is reported when the 1) Test the output circuit for a short.

current measured through the 2) Test for proper resistance in the

counterbalance output is too component connected to the

high. master TEC (pin 42).

3) Replace the master TEC.

63 Potentiometer Master This fault is reported when the 1) Verify traction pedal voltage

Voltage Out of pedal potentiometer is reading a through InfoCenter diagnostic

Range voltage outside the 0.25 Vdc to screen.

4.75 Vdc design range. 2) Check the traction pedal

potentiometer, harness wiring,

and connection points to the

potentiometer and controller.

GM 4500-D/4700-D DIAGNOSTIC FAULT CODE QUICK REFERENCE TABLE Page 7 of 8

Fault Fault Title Controller Fault Condition/Circuit Additional Notes Service Actions

Number Affected Description

64 Potentiometer Master This fault is reported when the The pedal 1) Verify traction pedal voltage

Analog Digital TEC determines that the traction potentiometer uses an through InfoCenter diagnostic

Conflict pedal potentiometer analog and analog signal to screen.

digital signals are in conflict with indicate pedal angle 2) Check the traction pedal

one another. and two digital signals potentiometer, harness wiring,

to indicate pedal and connection points to the

direction (“FWD” or potentiometer and controller.

“REV”).

65 Potentiometer Master This fault is reported when the The pedal 1) Verify traction pedal voltage

Forward Reverse TEC is receiving “FWD” and potentiometer uses two through InfoCenter diagnostic

Digital Conflict “REV” digital signals from the digital signals to screen.

traction pedal potentiometer indicate pedal direction 2) Check the traction pedal

simultaneously. (“FWD” or “REV”). potentiometer, harness wiring,

and connection points to the

potentiometer and controller.

66 TEC Traction Master This fault is reported when the An overcurrent has 1) Verify continuity in the traction

Overcurrent traction coil overcurrent has been detected in either circuit loop. This includes the coil

caused the master TEC to the forward or reverse itself, harness wiring, and

automatically limit the output output circuit. connection points to the coil and

current. controller.

2) Replace the master TEC.

67 Traction Current Master This fault is reported when the Either an open or a 1) Verify continuity in the traction

Validation Failure TEC measures an unexpected short in the traction circuit loop. This includes the coil

variance between the desired circuit loop will itself, the harness wiring, and

level of current to the traction coil generate this fault. connection points to the coil and

and the actual level of current to controller.

the traction coil. 2) Replace the master TEC.

70 Machine Number(s) Master This fault is reported when the 1) Update machine firmware using

Unknown master TEC does not recognize Toro DIAG.

the model number or serial

number that was written during

manufacturing run-up.

71 Master Address Master This fault is reported when the 1) Reprogram the machine using

Contention slave TEC has been replaced Toro DIAG.

with a preprogrammed master

TEC.

GM 4500-D/4700-D DIAGNOSTIC FAULT CODE QUICK REFERENCE TABLE Page 8 of 8

You might also like

- DTC P0200-97 Injector Circuit - Open PDFDocument9 pagesDTC P0200-97 Injector Circuit - Open PDFMortada AlsonniNo ratings yet

- JW7 F8197 00Document229 pagesJW7 F8197 00Joaquim Filipe GanhaoNo ratings yet

- DTC P0135 Oxyge (A/F) Sensor Heater Circuit (Bank 1 Sensor 1)Document3 pagesDTC P0135 Oxyge (A/F) Sensor Heater Circuit (Bank 1 Sensor 1)Erln LimaNo ratings yet

- AE101 4AGE 20 Valve Pins 2019Document5 pagesAE101 4AGE 20 Valve Pins 2019jorgeNo ratings yet

- Error TableDocument19 pagesError TableJesús David Diaz MontesNo ratings yet

- Emi EmcDocument15 pagesEmi Emcapi-3703592100% (1)

- DTC P0560 System Voltage: DescriptionDocument4 pagesDTC P0560 System Voltage: DescriptionInyectronix Vyh100% (1)

- Trimurti Fabricators PVT LTD.: Monsoon Protection PlanDocument4 pagesTrimurti Fabricators PVT LTD.: Monsoon Protection Planalla malikNo ratings yet

- YDRA/ YDRA 2009: Service ManualDocument359 pagesYDRA/ YDRA 2009: Service ManualJoaquim Filipe Ganhao100% (1)

- BW HR AuthorizationDocument20 pagesBW HR AuthorizationKamal RafiNo ratings yet

- Fault CodesDocument6 pagesFault CodesAnonymous zF4syKOrJNo ratings yet

- Service Support Quick ReferenceDocument3 pagesService Support Quick ReferencemrcyberNo ratings yet

- Interlock Protection Pocket Diary JPLDocument77 pagesInterlock Protection Pocket Diary JPLNishant Chaudhary100% (1)

- GRPC For WCF DevelopersDocument109 pagesGRPC For WCF Developerschaba dealsNo ratings yet

- FD Dci 001 Daily CheckDocument7 pagesFD Dci 001 Daily ChecksubinperuvallurNo ratings yet

- Split Units AlaramDocument27 pagesSplit Units AlaramnihaalNo ratings yet

- HPN0211PA04BDocument13 pagesHPN0211PA04BkentNo ratings yet

- Matrix 2003 2zz 6Document4 pagesMatrix 2003 2zz 6alan lantiguaNo ratings yet

- Aruugx URE-A: Ical FicationDocument4 pagesAruugx URE-A: Ical FicationVishalNo ratings yet

- Diagnostic Trouble Code (DTC) (Flash DTC 41) Ignition Coil Driver "B" Short To BatteryDocument4 pagesDiagnostic Trouble Code (DTC) (Flash DTC 41) Ignition Coil Driver "B" Short To BatteryDavid MendezNo ratings yet

- SPN 4334 - Fmi 4 - GHG17Document5 pagesSPN 4334 - Fmi 4 - GHG17Francisco Javier TorresNo ratings yet

- Efi Relay: On-Vehicle InspectionDocument1 pageEfi Relay: On-Vehicle InspectionslayerokinNo ratings yet

- 5 Check Harness and Connector (Mass Air Flow Sensor - Efi Relay)Document1 page5 Check Harness and Connector (Mass Air Flow Sensor - Efi Relay)Clodoaldo BiassioNo ratings yet

- Additive Foam Pump ControllerDocument12 pagesAdditive Foam Pump ControllerAdeel AslamNo ratings yet

- Foam (Additive) Fire Pump Controllers 1.4Document64 pagesFoam (Additive) Fire Pump Controllers 1.4Emmanuel ToretaNo ratings yet

- PS05805010K - B - JOCKEY Touch - Ver Jun 2015 - NS - 05-25-15Document1 pagePS05805010K - B - JOCKEY Touch - Ver Jun 2015 - NS - 05-25-15Fernando KatayamaNo ratings yet

- Anbarasu C&I PDFDocument42 pagesAnbarasu C&I PDFDeepak Saheb GuptaNo ratings yet

- ML C 650 c65mm379Document4 pagesML C 650 c65mm379operacionesNo ratings yet

- Tristar Fault and Alarm Codes 1Document2 pagesTristar Fault and Alarm Codes 1marco rodriguezNo ratings yet

- 2 Inspect Efi Relay: StandardDocument1 page2 Inspect Efi Relay: StandardClodoaldo BiassioNo ratings yet

- PRE-Commissioning Check ListDocument6 pagesPRE-Commissioning Check ListSrikanta NayakNo ratings yet

- 9 - Exercise SolutionsDocument16 pages9 - Exercise SolutionsmmblakoshaNo ratings yet

- Regulacion Tarjeta b3 Rev 019 05042021Document4 pagesRegulacion Tarjeta b3 Rev 019 05042021francisco saez moraNo ratings yet

- Generator Protection CheckDocument3 pagesGenerator Protection CheckSesotya MahardhikaNo ratings yet

- Cabin Ramp Spot Check List Form No MNT 1399: Item Description Task Description RemarkDocument2 pagesCabin Ramp Spot Check List Form No MNT 1399: Item Description Task Description RemarkMICHAEL AYELENo ratings yet

- DTC P1600 ECM BATT Malfunction: Circuit DescriptionDocument2 pagesDTC P1600 ECM BATT Malfunction: Circuit DescriptionDesron SamuelNo ratings yet

- Clutch Switch CircuitDocument3 pagesClutch Switch CircuitKari MohamedNo ratings yet

- Bcu 460, Bcu 465Document4 pagesBcu 460, Bcu 465Adrian BNo ratings yet

- Service Manual: Detector /sentinel ControlsDocument121 pagesService Manual: Detector /sentinel ControlsAlex100% (1)

- Micro 20Document18 pagesMicro 20danielradu27No ratings yet

- Additions, Revisions, or Updates: Subject DateDocument9 pagesAdditions, Revisions, or Updates: Subject DateDilroy seebalackNo ratings yet

- A - DEH - PR-2018-1113-GB - FGAC1005-1014CD4-1 - DA - R4-03-2020 - 150dpi Mini Chiller PDFDocument8 pagesA - DEH - PR-2018-1113-GB - FGAC1005-1014CD4-1 - DA - R4-03-2020 - 150dpi Mini Chiller PDFEldin JelecNo ratings yet

- p18 5s Fe+Engine+Repair+ManualDocument96 pagesp18 5s Fe+Engine+Repair+ManualAnh Kiệt Nguyễn HoàngNo ratings yet

- Electrical Component Locations ECL-23: (FromDocument2 pagesElectrical Component Locations ECL-23: (FromchechenniketoutNo ratings yet

- Error Codes For Commercial MicrowavesDocument4 pagesError Codes For Commercial MicrowavesJavier Garcia DelgadoNo ratings yet

- Features: LMR PLUS Electric Fire Pump ControllersDocument11 pagesFeatures: LMR PLUS Electric Fire Pump ControllersDecsih RuizNo ratings yet

- KITCHEN AID Range/Stove FAULT CODESDocument2 pagesKITCHEN AID Range/Stove FAULT CODESMelNo ratings yet

- Analog Input ModuleDocument2 pagesAnalog Input Modulelucian1961No ratings yet

- Codigos de Error Climas ZartechDocument28 pagesCodigos de Error Climas Zartechscs.trefrig9614No ratings yet

- ML C 650 c65mm382Document4 pagesML C 650 c65mm382operacionesNo ratings yet

- A - Syntec Driver Alarm ManualDocument291 pagesA - Syntec Driver Alarm ManualInduk HanNo ratings yet

- Man FunctionGenerator Wavetek-FG3CDocument11 pagesMan FunctionGenerator Wavetek-FG3CJorge AntonioNo ratings yet

- A - Syntec Driver Alarm ManualDocument291 pagesA - Syntec Driver Alarm Manualphạm minh hùngNo ratings yet

- Controls Manual Standard 1 Fan CP PrintDocument10 pagesControls Manual Standard 1 Fan CP PrintecutronicNo ratings yet

- Servo Directional Valve of 4-Way Design Type 4WS.2EDocument20 pagesServo Directional Valve of 4-Way Design Type 4WS.2EbuddhivasuNo ratings yet

- VHF FM Repeater: S-14425XZ-C1 Jun. 2008Document44 pagesVHF FM Repeater: S-14425XZ-C1 Jun. 2008Jorge Enrique Anzola CarrilloNo ratings yet

- FPF2281 FairchildSemiconductorDocument7 pagesFPF2281 FairchildSemiconductorjuanNo ratings yet

- FPF2281 Over-Voltage Protection Load Switch: Features DescriptionDocument8 pagesFPF2281 Over-Voltage Protection Load Switch: Features DescriptionJosé RepuestoNo ratings yet

- Materi Ajar Praktek 4 Manaj - Op.Kelistrikan, Elektronik Dan Sistem KontrolDocument2 pagesMateri Ajar Praktek 4 Manaj - Op.Kelistrikan, Elektronik Dan Sistem Kontrolwidi discusNo ratings yet

- Avions Marcel Dassault: Maintenance ManualDocument8 pagesAvions Marcel Dassault: Maintenance ManualFederico KronenbergNo ratings yet

- Hochiki H-5001 Rev F FNV 25-50-100 Install (11.07)Document8 pagesHochiki H-5001 Rev F FNV 25-50-100 Install (11.07)eolorojasNo ratings yet

- Microlok II System Maintenance Check List Rev 2 (1) .0 (3) - Merged PDFDocument7 pagesMicrolok II System Maintenance Check List Rev 2 (1) .0 (3) - Merged PDFSûmìt KúmãrNo ratings yet

- Lexe0225 00Document1 pageLexe0225 00dinukaeeNo ratings yet

- HVAC Preventive Maintenance Checklists-12Document61 pagesHVAC Preventive Maintenance Checklists-12JawadNo ratings yet

- Report of Inspection, Testing & Maintenance of Fire Pump Assemblies ContinuedDocument1 pageReport of Inspection, Testing & Maintenance of Fire Pump Assemblies ContinuedMark Louie GuintoNo ratings yet

- Fault Code - Elektra & Superia HW InverterDocument9 pagesFault Code - Elektra & Superia HW Invertersomnath serviceNo ratings yet

- Workman® 200 Spray System: For Heavy-Duty Workman VehiclesDocument56 pagesWorkman® 200 Spray System: For Heavy-Duty Workman VehiclesJoaquim Filipe GanhaoNo ratings yet

- Greensmaster 3250-D: (Models 04384)Document307 pagesGreensmaster 3250-D: (Models 04384)Joaquim Filipe GanhaoNo ratings yet

- Flex-Force Power System 60V MAX String Trimmer: Form No. 3457-614 Rev ADocument20 pagesFlex-Force Power System 60V MAX String Trimmer: Form No. 3457-614 Rev AJoaquim Filipe GanhaoNo ratings yet

- Multimedia Class Reflection QuestionsDocument3 pagesMultimedia Class Reflection Questionsapi-492026394No ratings yet

- Maxeff Motor by Adventech Technology WhitepaperDocument5 pagesMaxeff Motor by Adventech Technology Whitepaperingdimitriospino_110No ratings yet

- LG l1755s Chassis Lm72aDocument31 pagesLG l1755s Chassis Lm72aEmmanuel Dos santosNo ratings yet

- 9b08632658f770f4c7060b50226d6724Document76 pages9b08632658f770f4c7060b50226d6724Vani NathanNo ratings yet

- Learning Typescript FudamentalsDocument43 pagesLearning Typescript FudamentalsHafsa Tufail100% (1)

- Data Table 1: Readings For BJT AmplifierDocument2 pagesData Table 1: Readings For BJT AmplifierSanjid ElahiNo ratings yet

- HalliburtonDocument2 pagesHalliburtonLinda Livia AgzhataNo ratings yet

- Alcatel-Lucent Lte 700Mhz Trdu 2X40W Transmit Receive Duplexer Unit (Trdu) Design AnalysisDocument12 pagesAlcatel-Lucent Lte 700Mhz Trdu 2X40W Transmit Receive Duplexer Unit (Trdu) Design Analysisablemathew173974No ratings yet

- Ms Word Notes TemplateDocument4 pagesMs Word Notes Templatestraw b33ryNo ratings yet

- Used Car Price Prediction: B.E. (CSE) VI Semester Case StudyDocument30 pagesUsed Car Price Prediction: B.E. (CSE) VI Semester Case StudyAjayNo ratings yet

- Mandatory DisclosureDocument153 pagesMandatory Disclosurerages56No ratings yet

- Patari: Pakistan's Largest Pakistani Music Streaming PlatformDocument57 pagesPatari: Pakistan's Largest Pakistani Music Streaming PlatformMohsin ChaudharyNo ratings yet

- Health Management Different Approaches SolutionsDocument508 pagesHealth Management Different Approaches SolutionsمرتديلامرتديلاNo ratings yet

- CM400DX1-24A: Details PDFDocument1 pageCM400DX1-24A: Details PDFSergio MuriloNo ratings yet

- Design and Analysis of IoT-Based Intelligent Robot For Real-Time Monitoring and ControlDocument13 pagesDesign and Analysis of IoT-Based Intelligent Robot For Real-Time Monitoring and Controlhamed razaNo ratings yet

- Ijsred V5i3p21Document11 pagesIjsred V5i3p21Samuel AbraghamNo ratings yet

- Seating Plan For PH.D Students During Mid Semester (Odd) Exam 2018-19Document6 pagesSeating Plan For PH.D Students During Mid Semester (Odd) Exam 2018-19Aakash PathakNo ratings yet

- Aim-To Develop An ELECTRO HYDRAULIC Circuit Apparatus:: SwitchesDocument8 pagesAim-To Develop An ELECTRO HYDRAULIC Circuit Apparatus:: SwitchesashishNo ratings yet

- Iso 27001 05 - 10 - 2021Document28 pagesIso 27001 05 - 10 - 2021Leary John Herza TambagahanNo ratings yet

- Computer Science Overview: The FieldDocument13 pagesComputer Science Overview: The Fielddhana_selvamNo ratings yet

- LCD S830 Manual Control Panel User Manual The Latest Version 2018Document7 pagesLCD S830 Manual Control Panel User Manual The Latest Version 2018suresh08072172No ratings yet

- Timing Analysis of Keystrokes and Timing Attacks On SSH - RevisitedDocument19 pagesTiming Analysis of Keystrokes and Timing Attacks On SSH - RevisitedRihards KubilisNo ratings yet

- A 65nm 4Kb Algorithm-Dependent Computing-inMemory SRAM Unit-Macro With 2.3ns and PDFDocument3 pagesA 65nm 4Kb Algorithm-Dependent Computing-inMemory SRAM Unit-Macro With 2.3ns and PDFChiragNo ratings yet

- Ui Dveloper: JohnyDocument11 pagesUi Dveloper: Johnys ramuNo ratings yet

- Topic 1 - Electronics FundamentalsDocument12 pagesTopic 1 - Electronics FundamentalsKiro Da rareNo ratings yet