Professional Documents

Culture Documents

Features and Benefits: Technical Data Sheet

Uploaded by

Navshinder SinghOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Features and Benefits: Technical Data Sheet

Uploaded by

Navshinder SinghCopyright:

Available Formats

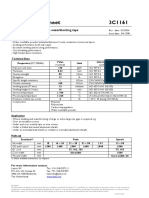

TECHNICAL DATA SHEET

FM® 300

ADHESIVE FILM

FM® 300

FM® 300 is a 350⁰F (177⁰C) curing modified epoxy film adhesive available with three different

moisture-resistant polyester carriers, and is designed for bonding metal-to-metal and sandwich

composite structures. To achieve ultimate environmental resistance in bonding aluminum details, use

pre-cured BR® 127 primer with FM® 300 film adhesive.

Extensively used as a surface finished ply on composite materials’ outside layers, FM® 300 film

adhesive has unique properties which drastically reduce, and in some cases virtually eliminate, time-

consuming sanding and filling operations.

FM® 300 film adhesive has high elongation and toughness with high ultimate shear strength. This

makes it particularly suitable for redistributing the high shear stress concentrations of graphite epoxy-

to-metal bonds, and allows it to accommodate the low inter-laminar shear strength of the composite. It

is particularly good in fatigue resistance in these joints. In properly designed and processed joints, the

tight- knit tricot carrier provides a degree of electrical isolation between metal and graphite

composites to reduce galvanic corrosion.

Typical applications for FM® 300 include metal-to-metal bonding, composite-to-composite bonding,

composite-to-metal bonding, and composite surfacing.

Features and Benefits

• Superior metal-to-metal peel strength, composite-to- • Allows x-ray inspection of assemblies due to natural

composite bonding and composite-to-metal joints opacity of adhesive formulations

• Extensively used as surfacing ply for composite • Available in a wide range of film thicknesses tailored to

materials specific applications

• Service temperature from -67°F to 300°F (-55°C to • Industry wide acceptance

•

149°C)

•

Compatible for co-cure or simultaneous autoclave with

Excellent moisture and corrosion resistance in high product FM® 61, FM® 96, and BR® 127

humidity environments with no significant reduction

in mechanical properties

FM® 300 ADHESIVE FILM

TECHNICAL DATA SHEET

FM® 300

ADHESIVE FILM

CHARACTERISTICS

Table 1 | Physical Properties

Shelf Life 12 months at or below 0°F (-18°C) from date of shipment for supported film

4 months at or below 40°F (4°C) from date of shipment for unsupported film

Shop Life 10 days at 90°F (32°C)

30 days at 75°F (24°C)

Volatiles 1.0% maximum

ASTM D 3530 250⁰F (121⁰C)

Outgassing Properties1 TWL - 0.92%

(after complete cure) CVCM - 0.07%

ASTM E 595 WVR – 0.63 %

1

Property reported for FM® 300K

Table 2 | Product Availability

Product Nominal Weight1 Nominal Thickness Color Carrier Characteristics

Form psf (gsm) in (mm)

FM® 300 0.08 (391) 0.013 (0.33) Blue Tight Knit Enhanced bond line thickness

0.10 (488) 0.015 (0.38) Blue control. Good blend of structural

and handling properties

FM® 300K 0.05 (244) 0.008 (0.20) Green Wide Open Highest overall performance.

0.08 (391) 0.013 (0.33) Green Knit

FM® 300M 0.03 (146) 0.005 (0.13) Green Random Mat Provides the best bond line and

0.08 (391) 0.013 (033) Green flow control. Reduces tendency

to trap air during lay-up.

FM® 300U 0.03 (146) 0.005 (0.13) Green Unsupported Can be reticulated.

0.055 (269) 0.008 (0.20) Green Film

1

Weight tolerance equals nominal weight ± 0.005 psf (± 25 gsm)

Table 3 | Physical Proerties: BR® 127 Corrosion Inhibiting Primer

Shelf Life 12 months at or below 0°F (-18°C) from date of shipment

Shop Life 10 days at 90°F (32°C)

Color Yellow

Solids 10% ± 1% sprayable

Density 7.3 lbs/gal (875 g/L)

Recommended Dry Primer 0.10 mil – 0.30 mil ( .0025 mm - .0076 mm )

Thickness

Recommended Cure Airy dry 30 minutes in ambient conditions

Cure 30 minutes at 250⁰F (121⁰C)

FM® 300 ADHESIVE FILM

TECHNICAL DATA SHEET

FM® 300

ADHESIVE FILM

PROPERTIES

Table 4 | Mechanical Properties with Primer BR® 127

Property Test Temp FM 300 FM 300K FM 300K FM 300M FM300M Substrate

0.08 psf 0.05 psf 0.08 psf 0.03 psf 0.08 psf

(391 gsm) (244 gsm) (391 gsm) (146 gsm) (391 gsm)

Lap Shear ⁰F (⁰C) psi (MPa) 0.063 in (1.60 mm)

ASTM D 1002 2024-T3 clad

-67 (-55) 5080 (35.0) – 5460 (37.7) – 4930 (34.0) aluminum

75 (24) 5150 (35.5) 5340 (36.8) 5850 (40.3) 4330 (29.8) 5280 (36.4)

250 (121) 4000 (27.6) 3580(24.7) 4200 (28.9) 3360 (23.2) 4040 (27.9)

300 (149) 2910 (20.0) 2970 (20.4) 3160(21.8) 2310 (15.9) 2960 (20.4)

Floating Roller Peel ⁰F (⁰C) lb/in (kN/m) 0.025 in (0.63 mm)

ASTM D 3167 and 0.064 in (1.63

-67 (-55) 28 (4.9) – 28 (4.9) – 29 (5.1) mm) 2024-T3 clad

75 (24) 29 (5.1) 23 (4.0) 28 (4.9) 26 (4.6) 29 (5.1) aluminum

250 (121) – – – – –

300 (149) 25 (4.4) – 26 (4.6) 27 (4.7) 26 (4.6)

Honeycomb ⁰F (⁰C) in-lb/3 in (N/m) 0.020 in (0.51 mm)

Sandwich Peel 2024-T3 clad

ASTM D 1781 -67 (-55) – 25 (37) 40 (58) – – aluminum skins;

75 (24) – 22 (32) 45 (66) 11 (16) – 0.002 (0.65 mm)

250 (121) – – – – – NP 5052, 0.1875 in

300 (149) – 22 (32) 28 (41) – – (4.76 mm) cell core

Flatwise Tensile ⁰F (⁰C) psi (MPa) 0.020 in (0.51 mm)

ASTM C 297 2024-T3 clad

-67 (-55) 1350 (9.3) – 1080 (7.4) – 1600 (11.0) aluminum skins;

75 (24) 1010 (7.6) – 1030 (7.1) 435 (3.0) 1390 (9.6) 0.0025 (0.65 mm)

250 (121) – – – – – NP 5052, 0.1875 in

300 (149) 345 (2.4) 340 (2.3) 470 (3.2) 125 (0.86) 513 (3.5) (4.76 mm) cell core

Table 5 | Humidity and Fluid Exposure with Primer BR® 127

Property FM 300 FM 300K FM 300M Substrate

0.08 psf 0.08 psf 0.08 psf

(391 gsm) (391 gsm) (391 gsm)

Lap Shear after 30 days psi (MPa) 0.063 in (1.60 mm)

at 120°F (49°C) 95 – 100% RH1 2024-T3 clad aluminum

5190 (35.8) 6230 (42.9) 5540 (38.2)

ASTM D 1002

Lap Shear after 7 days immersion in: 0.063 in (1.60 mm)

JP-4 fuel 5030 (34.7) 6240 (43.0) 5550 (38.3) 2024-T3 clad aluminum

Anti-icing fluid 4920 (33.9) 6280 (43.3) 5250 (36.2)

Hydraulic oil 5100 (35.2) 6130 (42.3) 5350 (36.9)

Hydrocarbon fluid 5160 (35.6) 6095 (42.0) 5130 (35.3)

Lap Shear after 200 hours 4940 (34.0) 6350 (43.8) 4860 (33.5) 0.063 in (1.60 mm)

2 2024-T3 clad aluminum

in Skydrol hydraulic fluid

at 150°F (66°C)

1

Tested at 75°F (24°C)

2

A product of Solutia, Inc.

FM® 300 ADHESIVE FILM

TECHNICAL DATA SHEET

FM® 300

ADHESIVE FILM

Table 6 | Effect of Humidity Exposure Prior to Bonding, FM® 300K 0.08 psf (391 gsm) with Primer BR® 127

Property Test Temp Control 15 Day Exposure at Substrate

(no exposure) 54% RH

Lap Shear ⁰F (⁰C) psi (MPa) 0.063 in (1.60 mm)

ASTM D 1002 75 (24) 4800 (33.1) 4900 (33.8) 2024-T3 clad aluminum

4700 (32.4) 4800 (33.1)

4650 (32.1) 5200 (35.9)

300 (149) 3400 (23.5) 2600 (17.9)

3300 (22.8) 2900 (20.0)

Floating Roller Peel ⁰F (⁰C) lb/in (kN/m) 0.025 in (0.63 mm) and 0.063 in

ASTM D 3167 75 (24) 28 (4.9) 28 (4.9) (1.60 mm) 2024-T3 clad aluminum

29 (5.1) 29 (5.1)

Honeycomb ⁰F (⁰C) in-lb/3 in (N/m) 0.020 in (0.51 mm) 2024-T3 clad

Sandwich Peel 75 (24) 75 (110) 75 (110) aluminum skins; 0.0025 (0.65 mm) NP

ASTM D 1781 68 (100) 69 (100) 5052, 0.1875 in (4.76 mm) cell core

Cure Cycle: Standard 350⁰F (177⁰C) cure. See details below.

Table 7 | Heat Aging Studiesat 300°F (150°C), FM® 300K 0.08 psf (391 gsm) with Primer BR® 127

Hours Lap Shear Lap Shear Honeycomb Sandwich Peel Flatwise Tensile

Exposure tested at 75°F (24°C) tested at 300°F (149°C) tested at 75°F (24°C) tested at 75°F (24°C)

ASTM D 1002 ASTM D 1002 ASTM D 1781 ASTM C 297

psi (MPa) in-lb/3 in (Nm/m) psi (MPa)

Control 6070 (41.8) 2980 (20.6) 64 (94) 1380 (9.5)

1440 4460 (30.8) 3720 (25.6) 35 (52) –

2880 4700 (32.4) 3400 (23.5) 41 (60) 960 (6.6)

4320 4300 (29.7) 3430 (23.7) 26 (39) 1000 (6.9)

5040 3910 (27.0) 3530 (24.4) 23 (34) 990 (6.8)

5760 3210 (22.1) 3450 (23.8) 20 (30) 950 (6.6)

7200 3580 (24.7) 3450 (23.8) 20 (30) –

7920 3270 (22.6) 2960 (20.4) 17 (25) 780 (5.4)

Substrate: Lap Shear: 0.063 in. (1.63 mm) 2024-T3 clad

Honeycomb Skins: 0.020 in (0.51 mm) 2024-T3 clad

Honeycomb Core: 0.1875 in (4.76 mm) 0.0025 (0.65 mm) NP 5052

Cure Cycle: Standard 350⁰F (177⁰C) cure. See details below.

FM® 300 ADHESIVE FILM

TECHNICAL DATA SHEET

FM® 300

ADHESIVE FILM

KGR STRESS STRAIN DATA

The heart of Solvay Engineered Materials new technology for structural adhesives is the KGR-1 extensometer. This

instrument provides the basic, definitive property of a structural adhesive – its shear stiffness. KGR-1 records the entire

stress strain curve for the adhesive in environments reproducible in the laboratory.

This technology benefits both the designer and the adhesive formulator. The designer and stress analyst use this technology

to predict the service performance of the adhesive bond, including strength, creep and fatigue in environments reproducible

in the laboratory.

Until Solvay Engineered Materials developed the KGR-1, test methods to obtain shear stiffness were either inaccurate or too

costly to allow sufficient data for statistical confidence. A measure of the difficulty in obtaining this stiffness is that

movements of one quarter of a micron (0.00001 inches) must be detected with clarity and reliability. KGR-1 does this over a

temperature range of -67°F (-55°C) to 500°F (260°C) in hostile environments reproducible in the laboratory.

The economy of operation of KGR-1 makes stiffness data affordable to the designer. This economy allows statistical

confidence necessary for practical analysis. In addition to stiffness, KGR-1 provides the shear stress strain relationship over

the entire non-linear range up to and including ultimate failure.

It has been established that fatigue life and residual static strength are dependent on strain at ultimate stress. The larger the

strain, the longer the fatigue life and the higher the residual static strength (the strength after the joint has seen the required

fatigue loads). This data defines limits for creep and fatigue conditions. It is possible to perform proper stress analysis of

bonded aircraft primary structure. Accurate predictions are now possible for the bond performance over the life of the

aircraft.

Apart from its value to the designer, KGR-1 technology is invaluable to the formulator of structural adhesives. Stress strain

properties beyond the linear range define the adhesive’s performance in fatigue and toughness.

If you are interested in acquiring a KGR-1 exensometer for help in your own work, please contact a Solvay

Engineered Materials representative.

Table 8 | KGR-1 Stress Strain Data for FM® 300K Adhesive Film, 0.06 psf (293 gsm) with BR® 127 Primer,

ASTM D 5656

[ƒ = Shear Stress, psi (MPa), Σ = Shear Strain, in/in, G = Shear Modulus, psi (Mpa)]

Test Temp Linear Limit (LL) Knee (KN) Ultimate Failure (UL)

⁰F (⁰C) ƒ Σ G ƒ Σ ƒ Σ

75 (24) 2060 (14.2) 0.0156 131,500 (907.5) 6100 (42.1) 0.0932 7210 (49.8) 0.5446

220 (104) 916 (6.32) 0.0150 64,700 (446.2) 3000 (20.8) 0.0835 5190 (35.8) 1.2073

1 745 (5.14) 0.0273 27,500 (189.8) 1880 (13.0) 0.1047 3100 (21.4) 1.0744

220 (104)

1

Postbond exposure to 100% RH at 140°F (60°C) until saturated

FM® 300 ADHESIVE FILM

TECHNICAL DATA SHEET

FM® 300

ADHESIVE FILM

PROCESSING

Recommended Cure Cycle

Autoclave Cure Cycle Apply full vacuum, 24 in Hg (0.081 MPa) minimum.

Apply 40 psi (0.28 MPa) pressure, vent vacuum at 20 psi (0.14 MPa).

Heat from 75ºF (24ºC) to 350°F (177°C) at 2°F - 5°F (1°C - 3°C)/minute.

Hold at 350°F (177°C) for 60 minutes.

Cool under pressure below 140°F (60°C) at 2°F - 5°F (1°C - 3°C)/minute.

FM® 300 film adhesive may also be bonded at pressures ranging from 15 psi – 100 psi (0.10 MPa – 0.69 MPa) depending

upon the application. For press, pressure diaphragm or vacuum bag curing use the following cure cycle:

Alternative Cure Cycle Heat from 75ºF (24ºC) to 350°F (177°C) in 60 minutes.

Hold at 350°F (177°C) for 60 minutes.

Surface Preparation

Aluminum Skins

A clean, dry, grease-free surface is required for bonding. FM® 300 can be used with standard cleaning techniques involving

a four step procedure of solvent degreasing, alkaline cleaning, chemical deoxidizing (etching), and phosphoric acid

anodizing*. General guidance for etching and phosphoric acid anodizing can be found in ASTM 2651 and ASTM 3433,

respectively. Best results for aluminum feature priming after appropiate surface preparation, with BR® 6747-1, BR® 6747-1

NC or BR® 127 primer.

*Boeing patent 4,085,012. April 1978. Phophoric acid anodizing is now being used by a large number of aircraft

manufacturers due to the improved surface bond durability it provides.

FM® 300 ADHESIVE FILM

TECHNICAL DATA SHEET

FM® 300

FILM ADHESIVE

Primer Application

Although not mandatory, BR® 127 corrosion inhibiting primer is recommended for use with FM® 300 adhesive in the bonding

of aluminum details. BR® 127 primer offers superior durability and resistance to hostile environments within the bond line

and also may be used as a protective coating outside the bonded areas. Apply BR® 127 as follows:

1. Allow BR® 127 material to warm to room temperature, 75⁰F (24⁰C), prior to opening container

2. Thoroughly mix before application and agitate during application

3. Spray or brush coat to a dry primer thickness of 0.0001 inch (0.0025 mm) nominal with a 0.0003 inch

(0.0076 mm) maximum thickness

4. Air dry 30 minutes minimum prior to using

5. Oven dry 30 minutes at 250°F ± 10°F (121°C ± 6°C)

LAY-UP PROCEDURE

1. When FM® 300 is removed from refrigerator storage, the adhesive must be allowed to reach room temperature [75ºF

(24ºC)] before the roll is unpackaged. Note that the adhesive film is sandwiched between release paper and polyliner.

2. Remove either of the interliners and place the adhesive against the surface to be bonded. Care should be taken to

prevent air entrapment between the film adhesive and substrate, especially in large area bonds.

3. If additional tack is desired, the adhesive may be heated to as high as 140°F (60°C) for up to 30 minutes without altering

the adhesive properties. Before heat tacking, ensure the film is properly positioned, otherwise removal will be difficult.

4. Complete the assembly after removing the other interliner.

Recommended Consumables

Table 7 below provides a list of Solvay’s consumable processing materials recommended for use with FM® 300.

Table 7 l Solvay’s Processing Materials

Sealant Tape SM5142BY, SM 5127, SM5126

Release Film A6200, A5000

Release Fabric 200 TFP, 200 TFNP

Breather/Bleeder Fabric RC3000-10, A3000-4

Peel Ply 60001, 60002, 51789

Bagging Film HS 8171, SV3000

Adhesive Tape Flashtape 1, Flashtape 2

Recommended processing materials listed above can be purchased through Solvay. Technical Data Sheets (TDS) and

additional information are available at www.solvay.com

HEALTH & SAFETY

Please refer to the product SDS for safe handling, personal protective equipment recommendations and disposal

considerations.

DISCLAIMER: The data and information provided in this document have been obtained from carefully controlled samples and are considered to be

representative of the product described. Solvay does not express or imply any guarantee or warranty of any kind including, but not limited to, the accuracy, the

completeness or the relevance of the data and information set out herein. Because the properties of this product can be significantly affected by the fabrication

and testing techniques employed, and since Solvay does not control the conditions under which its products are tested and used, Solvay cannot guarantee the

properties provided will be obtained with other processes and equipment. No guarantee or warranty is provided if the product is adapted for a specific use or

purpose. Solvay declines any liability with respect to the use made by any third party of the data and information contained herein. Solvay has the right to

change any data or information when deemed appropriate. All trademarks are the property of their respective owners. ©2018, Solvay. All rights reserved.

Solvay

Composite Materials HQ

4500 McGinnis Ferry Rd

Alpharetta, GA 30005-3914 USA

TDS FM® 300_2018_06_14

You might also like

- Personal Styling Service-Contract - No WatermarkDocument5 pagesPersonal Styling Service-Contract - No WatermarkLexine Emille100% (1)

- ICT Forex Trading NotesDocument110 pagesICT Forex Trading NotesLavier Trinta e Sete100% (4)

- AZ 4500 Thick Film Photoresists for Coatings up to 50 μmDocument3 pagesAZ 4500 Thick Film Photoresists for Coatings up to 50 μmahmed pashaNo ratings yet

- People v. ChuaDocument1 pagePeople v. ChuaErnie Gultiano100% (1)

- Epoxy Film Adhesive FM 73 CytecDocument10 pagesEpoxy Film Adhesive FM 73 CytecDenbe SantosNo ratings yet

- Kingspan ks1000rw Trapezoidal Roof Panel Data Sheet en AuDocument6 pagesKingspan ks1000rw Trapezoidal Roof Panel Data Sheet en AuShane BelongNo ratings yet

- Textured HDPE Geomembrane Technical Data SheetDocument1 pageTextured HDPE Geomembrane Technical Data SheetAndrew Zapanta Jr.No ratings yet

- MultimediaDocument4 pagesMultimediaVIVEK SAININo ratings yet

- FW300Document1 pageFW300miroslava mondragonNo ratings yet

- COLORBOND Spectrum Series Datasheet New V8Document2 pagesCOLORBOND Spectrum Series Datasheet New V8eng.ahmadrihawiNo ratings yet

- MOLYKOTE - HP-300 - Grease - 80-3103E-01Document2 pagesMOLYKOTE - HP-300 - Grease - 80-3103E-01jtelloNo ratings yet

- FEP & PFA Welding Grade Films: F E F W H SDocument2 pagesFEP & PFA Welding Grade Films: F E F W H SmansurudinNo ratings yet

- Ficha Tecnica Cinta de Juntas 930 35 50 PDFDocument3 pagesFicha Tecnica Cinta de Juntas 930 35 50 PDFfernando100% (1)

- HDPE All ThicnkenssDocument2 pagesHDPE All ThicnkenssmikeNo ratings yet

- ABS-M30i: Production-Grade Thermoplastic For Fortus 3D PrintersDocument2 pagesABS-M30i: Production-Grade Thermoplastic For Fortus 3D PrinterskaledioskoppNo ratings yet

- Sikawrap®-900 C: Carbon Fibre Fabric For Structural StrengtheningDocument2 pagesSikawrap®-900 C: Carbon Fibre Fabric For Structural StrengtheningRoberto Jimenez PerezNo ratings yet

- Protective & Marine Coatings: MetalatexDocument4 pagesProtective & Marine Coatings: MetalatexAna CabreraNo ratings yet

- Ldpe 2420H PDFDocument1 pageLdpe 2420H PDFjavadmohammadiNo ratings yet

- PolykenYG IIIDocument2 pagesPolykenYG IIISenthilkumar NarayananNo ratings yet

- 3M VHB F9460PC F9469PC F9473PCDocument4 pages3M VHB F9460PC F9469PC F9473PCAdam RifferNo ratings yet

- Colorbond Ultra Datasheet New V8Document2 pagesColorbond Ultra Datasheet New V8Gireesh Krishna KadimiNo ratings yet

- AB6000 3MElectronicsDocument4 pagesAB6000 3MElectronicsMOHSENNo ratings yet

- Features and Benefits: Technical Data SheetDocument6 pagesFeatures and Benefits: Technical Data SheetTaufiq SatrioNo ratings yet

- Insulated Roof & Wall Panels Ks103 SSF Data Sheet: Microlambri Superlambri SmoothlambriDocument5 pagesInsulated Roof & Wall Panels Ks103 SSF Data Sheet: Microlambri Superlambri SmoothlambriKhaled GamalNo ratings yet

- Foamular SpecsDocument1 pageFoamular SpecsalokNo ratings yet

- Geomembrane Technical DataDocument1 pageGeomembrane Technical DataYusufAliMuktiNo ratings yet

- Colorbond XRW Datasheet New V8Document2 pagesColorbond XRW Datasheet New V8Gireesh Krishna KadimiNo ratings yet

- Ferolite NAM 30Y Non Asbestos Gasket Jointing Sheet Technical Data SheetDocument2 pagesFerolite NAM 30Y Non Asbestos Gasket Jointing Sheet Technical Data SheetKalai SelvanNo ratings yet

- PL NB301Document5 pagesPL NB301Alaa ElsisiNo ratings yet

- TDS Nitoflor SL3000 UT IndiaDocument4 pagesTDS Nitoflor SL3000 UT IndiaqmsudhirNo ratings yet

- Sacrificial Tooling Material: Mechanical Properties Test Method English MetricDocument2 pagesSacrificial Tooling Material: Mechanical Properties Test Method English MetrickaledioskoppNo ratings yet

- Custom Made Movement Joint ProfileDocument2 pagesCustom Made Movement Joint Profileemrah turerNo ratings yet

- Tds - Jotun - Guard Classic EtDocument3 pagesTds - Jotun - Guard Classic Etvijh van niemannNo ratings yet

- Ldpe 2426K PDFDocument1 pageLdpe 2426K PDFjavadmohammadiNo ratings yet

- 3m VHB Tape 5958frDocument9 pages3m VHB Tape 5958frDonald A HuntNo ratings yet

- TDS Tape (NKHQ 60.50) BackupDocument1 pageTDS Tape (NKHQ 60.50) BackupTran Tuan anhNo ratings yet

- HD Smooth Geomembrane Technical Data SheetDocument1 pageHD Smooth Geomembrane Technical Data SheetAndreas Erdian WijayaNo ratings yet

- Flexitallic SF 3300 gasket sheet data sheetDocument2 pagesFlexitallic SF 3300 gasket sheet data sheetebastien2No ratings yet

- ABS-M30: Real Production-Grade ThermoplasticDocument2 pagesABS-M30: Real Production-Grade ThermoplasticqualityfreekNo ratings yet

- PP Clyrell Rc213m Random Cast FilmDocument1 pagePP Clyrell Rc213m Random Cast FilmTrung HoNo ratings yet

- Klinger Graphite Laminate PSM: Key Features: BenefitsDocument2 pagesKlinger Graphite Laminate PSM: Key Features: BenefitsHammad KhanNo ratings yet

- Sumitube Sa2fDocument2 pagesSumitube Sa2fNicacio LucenaNo ratings yet

- 3M Adhesive Transfer Tape 950Document6 pages3M Adhesive Transfer Tape 950Michael McQueenNo ratings yet

- TDS Infinam ST 6100 LDocument5 pagesTDS Infinam ST 6100 LKacperNo ratings yet

- PORON 4701-50 Firm - Supported MaterialsDocument2 pagesPORON 4701-50 Firm - Supported MaterialsLayeeq AhmedNo ratings yet

- Technical Datasheet Natura (3Mm) : Characteris C Standard Unit Requirement Values From Manufacturing ControlsDocument1 pageTechnical Datasheet Natura (3Mm) : Characteris C Standard Unit Requirement Values From Manufacturing Controlseromax1No ratings yet

- Tds-Tasnee LD 0725nDocument2 pagesTds-Tasnee LD 0725nأبو أميرNo ratings yet

- MST 33Document2 pagesMST 33Imawan WastNo ratings yet

- Ultimaker ABS (TDS)Document3 pagesUltimaker ABS (TDS)reinaldolubeNo ratings yet

- 3M VHB Adhesive Transfer Tape F9469PCDocument8 pages3M VHB Adhesive Transfer Tape F9469PCSaravanabhavan ChandrasekarNo ratings yet

- Tds Az Eci 3000 SeriesDocument11 pagesTds Az Eci 3000 SeriesIgor_uhuNo ratings yet

- Filmtec BW30-2540Document3 pagesFilmtec BW30-2540PT Deltapuro IndonesiaNo ratings yet

- Efs Lm6000cmpst-Efs 2015newDocument2 pagesEfs Lm6000cmpst-Efs 2015newMohamed AhmedNo ratings yet

- Water Swallable TapeDocument1 pageWater Swallable TapeSanthosh V RaajendiranNo ratings yet

- PC Abs Spec SheetDocument2 pagesPC Abs Spec SheetAli YudiNo ratings yet

- Tubo TermocontraíbleDocument3 pagesTubo TermocontraíbleALEXIS BRICEÑONo ratings yet

- Tds-Tasnee LD 1925asDocument2 pagesTds-Tasnee LD 1925asأبو أميرNo ratings yet

- Tencate Mirafi HP 370Document1 pageTencate Mirafi HP 370Tony_candyNo ratings yet

- Dow Corning 785 Technical DatasheetDocument4 pagesDow Corning 785 Technical DatasheetShuvenduNo ratings yet

- DTM Acrylic Coating: Protective & Marine CoatingsDocument4 pagesDTM Acrylic Coating: Protective & Marine CoatingsAna CabreraNo ratings yet

- Heat Load EstimateDocument2 pagesHeat Load EstimateNavshinder SinghNo ratings yet

- Weak and Strong Form of Trial EqnDocument1 pageWeak and Strong Form of Trial EqnNavshinder SinghNo ratings yet

- NCW NSKDocument4 pagesNCW NSKNavshinder SinghNo ratings yet

- TAJ Hotel RatesDocument7 pagesTAJ Hotel Ratesnavdeepsingh.india8849100% (5)

- Amarnath&The Soldier of The SnowDocument3 pagesAmarnath&The Soldier of The SnowNavshinder SinghNo ratings yet

- 125 128Document4 pages125 128Majdi JerbiNo ratings yet

- Technical Documentation: Ventilation GrilleDocument23 pagesTechnical Documentation: Ventilation GrilleGergő RáczNo ratings yet

- Importance of Social Administration for Social WorkersDocument7 pagesImportance of Social Administration for Social Workersanderson mahundiNo ratings yet

- List of COCDocument21 pagesList of COCjoan_padilla2000No ratings yet

- Wa0031 PDFDocument1 pageWa0031 PDFAnaNo ratings yet

- Ok 1889 - PDF PDFDocument40 pagesOk 1889 - PDF PDFIngeniería Industrias Alimentarias ItsmNo ratings yet

- Task 7 Family Disaster Risk Reduction and Management PlanDocument7 pagesTask 7 Family Disaster Risk Reduction and Management PlanHaise SasakiNo ratings yet

- 229 PGTRB Commerce Study Material Unit 15 and 16Document16 pages229 PGTRB Commerce Study Material Unit 15 and 16shareena ppNo ratings yet

- Conduct CardsDocument9 pagesConduct Cardsapi-248309459No ratings yet

- Impact On Cocoon Quality Improvement.1Document10 pagesImpact On Cocoon Quality Improvement.1Naveen NtrNo ratings yet

- Hcin 543 Entity Relationship Diagram For Diabetes DataDocument4 pagesHcin 543 Entity Relationship Diagram For Diabetes Dataapi-534036919No ratings yet

- Digital Undated Portrait Cosy MondayDocument133 pagesDigital Undated Portrait Cosy MondayholajackNo ratings yet

- Serena Berman PW Res - 2020Document2 pagesSerena Berman PW Res - 2020Serena BermanNo ratings yet

- Quiz ME 1Document4 pagesQuiz ME 1Radytia BimantaraNo ratings yet

- Unit 4:: Incident Commander and Command Staff FunctionsDocument16 pagesUnit 4:: Incident Commander and Command Staff FunctionsAntonio Intia IVNo ratings yet

- Three Wire MethodDocument4 pagesThree Wire MethodmaivizhiNo ratings yet

- NY Long Island Group - Jun 2008Document8 pagesNY Long Island Group - Jun 2008CAP History LibraryNo ratings yet

- Wiz107sr User Manual en v1.0Document29 pagesWiz107sr User Manual en v1.0Pauli Correa ArriagadaNo ratings yet

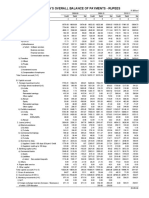

- Table 141: India'S Overall Balance of Payments - RupeesDocument2 pagesTable 141: India'S Overall Balance of Payments - Rupeesmahbobullah rahmaniNo ratings yet

- Elementos ElectrónicosDocument9 pagesElementos ElectrónicosKratt DeividNo ratings yet

- Newnew 151 ModelDocument1 pageNewnew 151 ModelCrestine Lily DongosaNo ratings yet

- Modern History Notes (Sample Notes For JPSC Mains Exam)Document21 pagesModern History Notes (Sample Notes For JPSC Mains Exam)Ijhar AhmadNo ratings yet

- 3 Kinds of de Facto Government:: CharacteristicsDocument10 pages3 Kinds of de Facto Government:: CharacteristicsAbigael SeverinoNo ratings yet

- UPT Unit 8 Vers ADocument12 pagesUPT Unit 8 Vers AValeria GarciaNo ratings yet

- Analysis and Design of BeamsDocument12 pagesAnalysis and Design of BeamsHasanain AlmusawiNo ratings yet

- Engine Tune-UpDocument43 pagesEngine Tune-UpЮра ПетренкоNo ratings yet

- Police Report Hearing RightsDocument7 pagesPolice Report Hearing RightsYatn BangadNo ratings yet