Professional Documents

Culture Documents

Baldor-Reliance AC & DC Motor Installation & Maintenance

Uploaded by

Ariawan HasnanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Baldor-Reliance AC & DC Motor Installation & Maintenance

Uploaded by

Ariawan HasnanCopyright:

Available Formats

Baldor-Reliance AC & DC Motor Installation & Maintenance

Note! The manufacturer of these products, Baldor Electric Company, became ABB Motors and Mechanical

Inc. on March 1, 2018. Nameplates, Declaration of Conformity and other collateral material may contain the

company name of Baldor Electric Company and the brand names of Baldor-Dodge and Baldor-Reliance until

such time as all materials have been updated to reflect our new corporate identity.

Safety Notice: Be sure to read and understand all of the Safety Notice statements in MN408 or Product Specific

manual for your motor. A copy is available at: http://www.baldor.com/support/product_manuals.asp

ACCEPTANCE Flange mounted machines should be properly seated

Thoroughly inspect this equipment before accepting and aligned. Note: If improper rotation direction is

shipment from the transportation company. If any detrimental to the load, check rotation direction prior to

damage or shortage is discovered do not accept until coupling the load to the motor shaft.

noted on the freight bill. Report all damage to the freight For V-belt drive, mount the sheave pulley close to the

carrier. motor housing. Allow clearance for end to end movement

SAFETY of the motor shaft. Do not overtighten belts as this may

Eye bolts, lifting lugs or lifting openings, if provided, are cause premature bearing failure or shaft breakage.

intended only for lifting the motor and motor mounted Direct coupled machines should be carefully aligned and

standard accessories not exceeding, in total 30% of the the shaft should rotate freely without binding.

motor weight. These lifting provisions should never GENERAL

be used when lifting or handling the motor and driven The user must select a motor starter and overcurrent

equipment. Eye bolt lifting capacity rating is based on a protection suitable for this motor and its application.

lifting alignment coincident with eye bolt center line. Eye Consult motor starter application data as well as the

bolt capacity reduces as deviation from this alignment is National Electric Code and/or applicable local codes.

increased. Be sure eye bolts are tight and prevented from Special motors for use by United States Government

turning before lifting. including special specifications, master plans, etc. refer to

INSTALLATION OUTSIDE THE USA: the applicable master plans and specifications involved.

Refer to MN408 and MN1383 for Compliance with On motors received from the factory with the shaft

European Directives. Copies are available at: blocked, remove blocking before operating the motor.

http://www.baldor.com/support/product_manuals.asp If motor is to be reshipped alone or installed to another

piece of equipment, the shaft block must be installed

MOTOR ENCLOSURE to prevent axial movement and prevent brinelling of the

ODP, Open drip proof motors are intended for use in bearings during shipment.

clean, dry locations with adequate supply of cooling air.

These motors should not be used in the presence of TESTING

flammable or combustible materials. Open motors can If the motor has been in storage for an extensive period

emit flame and/or molten metal in the event of insulation or has been subjected to adverse moisture conditions,

failure. check the motor insulation resistance with a meg ohm

TEFC, totally enclosed motors are intended for use where meter. Depending on storage conditions it may be

moisture, dirt and/or corrosive materials are present in necessary to regrease or change rusted bearings. Contact

indoor and outdoor locations. your local sales office if resistance is less than 5 meg

Explosion protected motors, as indicated by a Nationally ohms.

Recognized Testing Laboratory Certification mark and WARNING: Do not touch electrical connections before

marking with Class, Division and Temperature Code are you first ensure that power has been

intended for installation in hazardous locations as disconnected. Electrical shock can cause

described in Article 500 of the NEC. Refer to MN408 for serious or fatal injury.

more details.

WARNING: Be sure the system is properly grounded

MOUNTING before applying power. Electrical shock

Foot mounted machines should be mounted to a rigid can cause serious or fatal injury.

foundation to prevent excessive vibration. Shims may be

INSTALLATION

used if location is uneven.

This motor must be installed in accordance with National

Electric Code, NEMA MG-2, IEC standards or local codes.

MN416A01 Installation & Maintenance 1

WIRING MOUNTING

Connect the motor as shown in the connection diagrams. Mount the motor on a foundation sufficiently rigid to

If this motor is installed as part of a motor control drive prevent excessive vibration. Grease lubricated ball

system, connect and protect the motor according to the bearing motors may be mounted with the feet at any

control manufacturers diagrams. Refer to MN408 for angle. After careful alignment, bolt motor securely in

additional details on lead marking. The wiring, fusing and place. Use shim to fill any unevenness in the foundation.

grounding must comply with the National Electrical Code Motor feet should sit solidly on the foundation before

or IEC and local codes. When the motor is connected mounting bolts are tightened.

to the load for proper direction of rotation and started, IP (Ingress Protection)

it should start quickly and run smoothly. If not, stop the IP designations include two numerals, the first

motor immediately and determine the cause. Possible characteristic numeral is for ingress solid bodies and

causes are: low voltage at the motor, motor connections from dust. The second for ingress protection from liquid

are not correct or the load is too heavy. Check the motor - water. Motors marked less than IP23 require additional

current after a few minutes of operation and compare the protection from water.

measured current with the nameplate rating. GUARDING

After motor installation is complete, a guard of suitable

GROUNDING dimensions must be constructed and installed around the

Ground the motor according to NEC and local codes. In motor/gearmotor. This guard must prevent personnel

the USA consult the National Electrical Code, Article 430 from coming in contact with any moving parts of the

for information on grounding of motors and generators, motor or drive assembly but must allow sufficient cooling

and Article 250 for general information on grounding. air to pass over the motor. If a motor mounted brake is

In making the ground connection, the installer should installed, provide proper safeguards for personnel in case

make certain that there is a solid and permanent metallic of brake failure. Brush inspection plates and electrical

connection between the ground point, the motor or connection cover plates or lids, must be installed before

generator terminal housing, and the motor or generator operating the motor.

frame. In non-USA locations consult the appropriate

national or local code applicable. STARTING

ADJUSTMENT Before starting motor remove all unused shaft keys and

The neutral is adjustable on some DC motors. AC motors loose rotating parts to prevent them from flying off.

have no adjustable parts. Check direction of rotation before coupling motor to load.

Noise The motor should start quickly and run smoothly and with

For specific sound power or pressure level information, little noise. If the motor should fail to start the load may

contact your local sales office. be too great for the motor, the voltage is low or the motor

has been miswired. In any case immediately shut motor

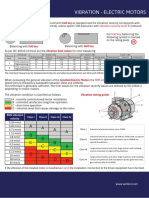

VIBRATION off and investigate the cause.

This motor is balanced to NEMA MG1, Part 7 standard. ROTATION

BRUSHES (DC Motors) To reverse the direction of rotation, disconnect and

Periodically, the brushes should be inspected and all lockout power and interchange any two of the three AC

brush dust blown out of the motor. If a brush is worn power leads for three phase motors. For two-phase four

1/2, (length specified in renewal parts data), replace the wire, disconnect and lockout power and interchange the

brushes. AC line leads on any one phase. For two phase three

WARNING: Guards must be installed for rotating wire, disconnect and lockout power and interchange

parts such as couplings, pulleys, external phase one and phase two AC line leads.

fans, and unused shaft extensions, Maintenance Procedures

should be permanently guarded to WARNING: Do not touch electrical connections

prevent accidental contact by personnel. before you first ensure that power has been

Accidental contact with body parts or disconnected. Electrical shock can cause

clothing can cause serious or fatal injury. serious or fatal injury.

Reassemble and seat the new brushes using a brush WARNING: Surface temperatures of motor enclosures

seating stone. Be sure the rocker arm is set on the may reach temperatures which can cause

neutral mark. discomfort or injury to personnel accidentally

coming into contact with hot surfaces.

INSPECTION Protection should be provided by the user to

Before connecting the motor to an electrical supply, protect against accidental contact with hot

inspect for any damage resulting from shipment. Turn the surfaces. Failure to observe this precaution

shaft by hand to ensure free rotation. Motor leads must could result in bodily injury.

be isolated before the shaft will turn freely on permanent

magnet motors. Lubrication Information

DRAIN PLUGS Refer to motor nameplate for recommended lubricant. If

One or more condensation drain plugs are provided on none is shown, the recommended lubricant for

each endplate for various motor mounting configurations. anti-friction bearings (-15°F to 120°) is POLYREX EM.

For Washdown and totally enclosed, fan cooled or For Min Start Temp -100°F use AEROSHELL #7.

non-ventilated motors, the plugs in the lowest portion of For roller bearings is ExxonMobil SHC-220.

the ends shields should be removed for operation (unless

the motor has special stainless steel drains). All drains

are located in the lowest portion of the ends shields.

2 Installation & Maintenance MN416A01

Relubrication Intervals LUBRICATION PROCEDURE

(For motors with regrease capability) Bearings should be lubricated while stationary and the

New motors that have been stored for a year or more motor is warm.

should be relubricated. Lubrication is also recommended 1. Locate the grease inlet, clean the area, and replace

at Table 1 intervals. the pipe plug with a grease fitting.

LUBRICATION INSTRUCTIONS 2. Locate and remove the grease drain plug, if

Cleanliness is important in lubrication. Any grease used provided.

to lubricate anti friction bearings should be fresh and free 3. Add the recommended volume of the recommended

from contamination. Properly clean the grease inlet area grease.

of the motor to prevent grease contamination. 4. Replace the grease inlet plug and run the motor for

1. Select service conditions from Table 2. 15 minutes.

2. Select lubrication interval (Table 1). 5. Replace the grease drain plug.

3. Adjust lubrication interval with multiplier from Table SPECIAL APPLICATIONS

3. For special temperature applications, contact your local

4. Select volume of grease from Table 4. sales office.

Relubrication Intervals

Recommended relubrication intervals are shown in

Table 1. It is important to realize that the recommended

intervals of Table 2 are based on average use. Refer to

additional information contained in Tables 2, 3 and 4.

Table 1 Relubrication Interval

NEMA (IEC) Frame Size Rated Speed (RPM)

3600 1800 1200 900

Up to 210 incl. (132) 5500Hrs. 12000Hrs. 18000Hrs. 22000Hrs.

Over 210 to 280 incl. (180) 3600Hrs. 9500Hrs. 15000Hrs. 18000Hrs.

Over 280 to 360 incl. (225) 2200Hrs. 7400Hrs. 12000Hrs. 15000Hrs.

Over 360 to 5800 incl. (400) 2200Hrs. 3500Hrs. 7400Hrs. 10500Hrs.

* Relubrication intervals are for ball bearings.

For vertically mounted motors and roller bearings, divide the relubrication interval by 2.

** For motors operating at speeds greater than 3600 RPM, contact your local sales office for relubrication

recommendations.

Table 2 Service Conditions

Severity of Service Hours per day of Ambient Temperature Atmospheric

Operation Maximum Contamination

Standard 8 40° C Clean, Little Corrosion

Severe 16 Plus 50° C Moderate dirt, Corrosion

Extreme 16 Plus >50° C* or Severe dirt, Abrasive dust, Corrosion,

Class H Insulation Heavy Shock or Vibration

Low Temperature <-29 ° C **

* Special high temperature grease is recommended (Dow Corning DC44).

** Special low temperature grease is recommended (Aeroshell 7).

Note: Different grease types are generally incompatible and should not be mixed. Mixing different types can cause

lubricant and bearing failure. Thoroughly clean bearing and cavity before changing grease type.

Table 3 Lubrication Interval Multiplier

Severity of Service Multiplier

Standard 1.0

Severe 0.5

Extreme 0.1

Low Temperature 1.0

Some motor designs use different bearings on each motor end. This is normally indicated on the motor nameplate.

In this case, the larger bearing is installed on the motor Drive endplate. For best relubrication results, only use the

appropriate amount of grease for each bearing size (not the same for both).

MN416A01 Installation & Maintenance 3

Table 4 Amount of Grease to Add

Bearing Description (These are the “Large” bearings (Shaft End) in each

Frame Size frame size)

NEMA (IEC) of Grease to add * oz Volume of grease to be added

Bearing Weight

(Grams) in3 teaspoon

56 to 140 (90) 6203 0.08 (2.4) 0.15 0.5

140 (90) 6205 0.15 (3.9) 0.2 0.8

180 (100−112) 6206 0.19 (5.0) 0.3 1.0

210 (132) 6307 0.30 (8.4) 0.6 2.0

250 (160) 6309 0.47 (12.5) 0.7 2.5

280 (180) 6311 0.61 (17) 1.2 3.9

320 (200) 6312 0.76 (20.1) 1.2 4.0

360 (225) 6313 0.81 (23) 1.5 5.2

400 (250) 6316 1.25 (33) 2.0 6.6

440 (280) 6318 1.52(40) 2.5 8.2

440 (280) 6319 2.12 (60) 4.1 13.4

5000 to 5800 (315−400) 6328 4.70 (130) 9.2 30.0

5000 to 5800 (315−400) NU328 4.70 (130) 9.2 30.0

360 to 449 (225−280) NU319 2.12 (60) 4.1 13.4

AC Induction Servo

76 Frame 180 (112) 6207 0.22 (6.1) 0.44 1.4

77 Frame 210 (132) 6210 0.32 (9.0) 0.64 2.1

80 Frame 250(160) 6213 0.49 (14.0) 0.99 3.3

Typical IEC vs NEMA Lead Marking

Single Phase Non-Reversible Three Phase

Refer to the connection diagram provided on the motor. For single winding 3 phase motors, lead markings can be

U1(T1) directly translated between IEC and NEMA designations.

For these motors, the lead markings are:

U2(T4) U1=T1 U2=T4 U3=T7 U4=T10

Single Phase Reversible V1=T2 V2=T5 V3=T8 V4=T11

W1=T3 W2=T6 W3=T9 W4=T12

U1(T1) Z1(T8) Z2(T5)

Main

Winding Auxiliary Winding Refer to the connection diagram provided on the motor.

U2(T4) Some examples are as follows:

Dual Voltage Reversible

Three Leads

Z1(T8) Z2(T5) WYE Connected DELTA Connected Wiring Diagram

U1(T1) U(T1) U(T1)

Main Auxiliary Winding U(T1) V(T2) W(T3)

U2(T2)

Winding

U3(T3)

U4(T4) W(T3) V(T2) W(T3) V(T2) Line 1 Line 2 Line 3

WYE Connection

Six Leads DELTA Connection

DC Motors

U1(T1) W2(T6) U1(T1)

Lead markings can be translated between IEC and NEMA

designations as follows:

U2(T4)

NEMA IEC W2(T6) V2(T5) W1(T3)

U2(T4)

Armature A1, A2 A1, A2 W1(T3) V1(T2) V2(T5) V1(T2)

Series Field S1, S2 D1, D2

Wiring Diagram

Shunt Field F1, F2 E1, E2

W2(T6) U2(T4) V2(T5)

W2(T6) U2(T4) V2(T5)

Refer to the connection diagram provided on the motor.

U1(T1) V1(T2) W1(T3) U1(T1) V1(T2) W1(T3)

Line 1 Line 2 Line 3 Line 1 Line 2 Line 3

High Volts/Start Low Volts/Run

—

ABB Motors and Mechanical Inc.

5711 R. S. Boreham Jr. Street

Fort Smith, AR 72901

Ph: 1.479.646.4711

baldor.com

*MN416A01-0518*

© ABB Motors and Mechanical Inc. All Rights Reserved. Printed in USA.

MN416A01 5/18

You might also like

- Diesel Engine Care and Repair: A Captain's Quick GuideFrom EverandDiesel Engine Care and Repair: A Captain's Quick GuideRating: 5 out of 5 stars5/5 (1)

- MTR LincolnDocument4 pagesMTR LincolnJohn Renz Caling RetiroNo ratings yet

- Gear Motors Install Instruction V1.7 EngDocument2 pagesGear Motors Install Instruction V1.7 EnghopgiamtocrasNo ratings yet

- NEMA Induction motor Machine Instructions GB 3 Motores NEMA de jaula de ardilla Instrucciones ES 11 ABB AutomationDocument20 pagesNEMA Induction motor Machine Instructions GB 3 Motores NEMA de jaula de ardilla Instrucciones ES 11 ABB AutomationErik Huang100% (1)

- Baldor Freno Electromagnetico IemsaDocument4 pagesBaldor Freno Electromagnetico Iemsajuventino vazquezNo ratings yet

- Installation & Commissioning of 3phase AC MotorsDocument2 pagesInstallation & Commissioning of 3phase AC MotorsSIRUS ElectronetNo ratings yet

- End-Mount Brake InstructionsDocument12 pagesEnd-Mount Brake InstructionsRodolfo Garduño ColínNo ratings yet

- AC Motor Installation Maintenance GuideDocument4 pagesAC Motor Installation Maintenance GuideEkakitie EseNo ratings yet

- Starter Motor Application & Conditions of Use: 1. ApplicationsDocument2 pagesStarter Motor Application & Conditions of Use: 1. Applicationsalfa24161305No ratings yet

- Instructions Manual WEGDocument8 pagesInstructions Manual WEGhansNo ratings yet

- ASDA-B2 Anual PDFDocument311 pagesASDA-B2 Anual PDFALEXANDRU ZANOAGANo ratings yet

- ASDA A2 ManualDocument583 pagesASDA A2 ManualPaulo ColleNo ratings yet

- Hyundai Installation and Maintenance ManualDocument15 pagesHyundai Installation and Maintenance ManualHüseyin Vedat TekinNo ratings yet

- IEC Motor UserManual - Peru PDFDocument6 pagesIEC Motor UserManual - Peru PDFKritsanasak PoungchanNo ratings yet

- Delta Asda-Ab Series User ManualDocument355 pagesDelta Asda-Ab Series User ManualNui DirekNo ratings yet

- ASDA A2 ManualDocument583 pagesASDA A2 ManualClaudio Lourenço da Silva100% (1)

- Ac Servo Drive Asdaab PDFDocument357 pagesAc Servo Drive Asdaab PDFNguyễn Hồng PhướcNo ratings yet

- Catalog MPDocument28 pagesCatalog MPCARLOSWAR101No ratings yet

- Installing, Commissioning and Maintaining Three-Phase MotorsDocument11 pagesInstalling, Commissioning and Maintaining Three-Phase MotorsMuhja AljaserNo ratings yet

- ASDA AB ManualDocument357 pagesASDA AB ManualMoises Gonzales AlvaNo ratings yet

- Asda ADocument383 pagesAsda APhu, Le HuuNo ratings yet

- Install and operate ASDA-B2 AC servo drive and motorDocument337 pagesInstall and operate ASDA-B2 AC servo drive and motorVictor Solis Brevis0% (1)

- Delta AC Servo Manual Installation GuideDocument311 pagesDelta AC Servo Manual Installation GuideWill SousaNo ratings yet

- Integral Motor IOM ManualDocument8 pagesIntegral Motor IOM ManualE.E. / Mayurakshi E & M Division, SuriNo ratings yet

- Ac Servo Delta Asda-Ab - Manual - en - 20141106 PDFDocument343 pagesAc Servo Delta Asda-Ab - Manual - en - 20141106 PDFNguyễn Hồng PhướcNo ratings yet

- Asda A2Document37 pagesAsda A2Victor ChiareloNo ratings yet

- Installation, Operation and Maintenance InstructionsDocument15 pagesInstallation, Operation and Maintenance InstructionsDavid Alfonso CaraballoNo ratings yet

- Delta AC Servo Drive and Motor Installation ManualDocument357 pagesDelta AC Servo Drive and Motor Installation Manualimamsakroni048No ratings yet

- AC Servo ASD-B2Document337 pagesAC Servo ASD-B2Thai Trinh CongNo ratings yet

- 56 143 5TC Coupler Brake Installation Service InstructionsDocument4 pages56 143 5TC Coupler Brake Installation Service InstructionsIvan PachecoNo ratings yet

- ABB MotorDocument31 pagesABB MotorRudr ThakurNo ratings yet

- NEMA Motors - Manual PDFDocument20 pagesNEMA Motors - Manual PDFVilius BukysNo ratings yet

- Y-Series Brushless Servo Motor: Installation InstructionsDocument16 pagesY-Series Brushless Servo Motor: Installation InstructionsrafaelNo ratings yet

- Maintenance of Electrical Motors 1.4Document6 pagesMaintenance of Electrical Motors 1.4Sayed NagyNo ratings yet

- Schneider Atv303 PDFDocument112 pagesSchneider Atv303 PDFchidambaram kasiNo ratings yet

- Asda-A2 M en 20100429Document517 pagesAsda-A2 M en 20100429Mario Plinio CrivelliNo ratings yet

- en 02 BAL Getriebe C F K SDocument4 pagesen 02 BAL Getriebe C F K SMohamed RaslanNo ratings yet

- Asda-B M en 20090628Document321 pagesAsda-B M en 20090628basso4260No ratings yet

- 3043-PPV-001 Motor IomDocument22 pages3043-PPV-001 Motor IomMiguel Angel RodriguezNo ratings yet

- Vertical High Thrust Motors: Installation, Operation and Maintenance ManualDocument76 pagesVertical High Thrust Motors: Installation, Operation and Maintenance ManualEnrique ArmandoNo ratings yet

- Installation MaintenenceDocument11 pagesInstallation Maintenencekvramanan_1No ratings yet

- Manual MotorsDocument10 pagesManual Motorst_syamprasadNo ratings yet

- Euronorm Electricmotors Manual (ENG)Document8 pagesEuronorm Electricmotors Manual (ENG)Andjelko BrajkovicNo ratings yet

- Delta Asda-B2 M en 20130906Document335 pagesDelta Asda-B2 M en 20130906Joao RobertoNo ratings yet

- Cooling Tower Motor: User ManualDocument8 pagesCooling Tower Motor: User Manualgalih santosoNo ratings yet

- Mega TorqueDocument354 pagesMega TorqueGuilherme AugustoNo ratings yet

- ASDA-B2 Installation GuideDocument337 pagesASDA-B2 Installation GuideRonaldo Kanasiro BasilioNo ratings yet

- Delta ASDA B2 User ManualDocument337 pagesDelta ASDA B2 User ManualSeyhmus YklNo ratings yet

- Installation & Commissioning Procedures of AC Motors - 3 PhaseDocument5 pagesInstallation & Commissioning Procedures of AC Motors - 3 PhaseSIRUS ElectronetNo ratings yet

- Delta ASDA B2 User Manual PDFDocument337 pagesDelta ASDA B2 User Manual PDFSỹ HưởngNo ratings yet

- Delta ASDA A2 User ManualDocument606 pagesDelta ASDA A2 User ManualteknisiinverterpkNo ratings yet

- Ounting & Maintenance Instructions For Threephase Induction Motors - Types Dm1 / Dma1 / Dma2Document9 pagesOunting & Maintenance Instructions For Threephase Induction Motors - Types Dm1 / Dma1 / Dma2Chad HuntNo ratings yet

- Buw Rollg enDocument20 pagesBuw Rollg ensaranNo ratings yet

- High Voltage Motor Instruction Manual - REV 2.1 - 201208Document60 pagesHigh Voltage Motor Instruction Manual - REV 2.1 - 201208Andre Brama AlvariNo ratings yet

- Baldor Motor MaintenanceDocument4 pagesBaldor Motor Maintenanceessjrs1No ratings yet

- BLD3314HC - Pei Alternator Conditions of Use 0419Document2 pagesBLD3314HC - Pei Alternator Conditions of Use 0419FARLEY ELETRO INDUZIDOSNo ratings yet

- Генеральная информационная службаDocument10 pagesГенеральная информационная службаДенис СухаревNo ratings yet

- Delta AC servo manualDocument321 pagesDelta AC servo manualPham LongNo ratings yet

- H3CR-A: Model Number StructureDocument23 pagesH3CR-A: Model Number StructureAriawan HasnanNo ratings yet

- Nederman - The Optimum Choice For Your Dust Extraction SystemDocument24 pagesNederman - The Optimum Choice For Your Dust Extraction Systemcallus21No ratings yet

- Vibration Shaft Vs MotorDocument1 pageVibration Shaft Vs Motoralexmontell100% (1)

- Product Information Packet: 250HP, 1785RPM, 3PH, 60HZ, L449T, A44200M, TEFDocument17 pagesProduct Information Packet: 250HP, 1785RPM, 3PH, 60HZ, L449T, A44200M, TEFAriawan HasnanNo ratings yet

- 12-71 - 2020 Short Circuit in Electrical Cabinet During Intervention - BahasaDocument2 pages12-71 - 2020 Short Circuit in Electrical Cabinet During Intervention - BahasaAriawan HasnanNo ratings yet

- Identification & Action - RaymondDocument1 pageIdentification & Action - RaymondAriawan HasnanNo ratings yet

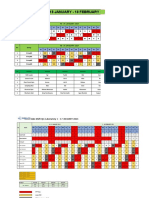

- Schedule 18 Jan - 18 Feb 2021Document3 pagesSchedule 18 Jan - 18 Feb 2021Ariawan HasnanNo ratings yet

- Operating Instructions FZA Pump PDFDocument14 pagesOperating Instructions FZA Pump PDFPipe RoblesNo ratings yet

- Form Travell ExpenseDocument1 pageForm Travell ExpenseAriawan HasnanNo ratings yet

- Main Equipment Critical Sparepart Recommendation With Risk Matrix 250305Document61 pagesMain Equipment Critical Sparepart Recommendation With Risk Matrix 250305Ariawan HasnanNo ratings yet

- Preventive CompressorDocument8 pagesPreventive CompressorAriawan HasnanNo ratings yet

- Form Current Before GreasingDocument3 pagesForm Current Before GreasingAriawan HasnanNo ratings yet

- Maintenance Observation 07122020Document4 pagesMaintenance Observation 07122020Ariawan HasnanNo ratings yet

- Schedule 1 - 17 Jan 2021Document2 pagesSchedule 1 - 17 Jan 2021Ariawan HasnanNo ratings yet

- Ampere Motors Document Lists Electrical Equipment RatingsDocument10 pagesAmpere Motors Document Lists Electrical Equipment RatingsAriawan HasnanNo ratings yet

- PAL Equipment List Criticality Analysis 190228Document63 pagesPAL Equipment List Criticality Analysis 190228Ariawan HasnanNo ratings yet

- Cash AdvanceDocument1 pageCash AdvanceAriawan Hasnan100% (1)

- Blower Speed CalculationDocument2 pagesBlower Speed CalculationAriawan HasnanNo ratings yet

- Daily operations meeting agendaDocument320 pagesDaily operations meeting agendaAriawan HasnanNo ratings yet

- Form Electrical InspectionDocument17 pagesForm Electrical InspectionAriawan HasnanNo ratings yet

- Pid Loop SimulatorDocument9 pagesPid Loop SimulatorAriawan HasnanNo ratings yet

- Brochure VC-920 enDocument34 pagesBrochure VC-920 enAriawan HasnanNo ratings yet

- Brochure VC-920 EN PDFDocument4 pagesBrochure VC-920 EN PDFAriawan HasnanNo ratings yet

- Electrical MaintenanceDocument7 pagesElectrical MaintenanceKHUSHBOO198450% (2)

- Work Instruction For Pressure Leak TestingDocument2 pagesWork Instruction For Pressure Leak TestingAriawan HasnanNo ratings yet

- Work Instruction For Pressure Leak TestingDocument1 pageWork Instruction For Pressure Leak TestingAshish ChoradiyaNo ratings yet

- ByPass Signal equipment level detection sensorsDocument2 pagesByPass Signal equipment level detection sensorsAriawan HasnanNo ratings yet

- DocumentDocument1 pageDocumentAriawan HasnanNo ratings yet

- 31 March ReportDocument14 pages31 March ReportAriawan HasnanNo ratings yet

- Vega 650 HandbookDocument34 pagesVega 650 Handbookvanhuong87No ratings yet

- ORCA - Universal Loose Tube Armoured CSTDocument1 pageORCA - Universal Loose Tube Armoured CSTMatteo Pio OlivieriNo ratings yet

- QUC-2252 - Sundar Industrial Estate HiAce SLSDocument8 pagesQUC-2252 - Sundar Industrial Estate HiAce SLSOmar ShahzadNo ratings yet

- User Manual: RELIANCE Inset Lights 12-Inch (RC-RZ-RX-RE-RT-RW-RN-RTN-AC-AS-SW-RS-TC)Document56 pagesUser Manual: RELIANCE Inset Lights 12-Inch (RC-RZ-RX-RE-RT-RW-RN-RTN-AC-AS-SW-RS-TC)Anorld WalkerNo ratings yet

- Cable calculation worked exampleDocument676 pagesCable calculation worked exampleagan sitompul100% (1)

- NFBUP NFXUP S-Sub1 PDFDocument2 pagesNFBUP NFXUP S-Sub1 PDFMihai Butnaru-PaladeNo ratings yet

- Workshop Practicals 11Document3 pagesWorkshop Practicals 11Namanya OsbertNo ratings yet

- Electrical TerminologiesDocument11 pagesElectrical TerminologiesVincent Ganasi LipawenNo ratings yet

- Diagnostic Trouble Codes - Chart Per Control Unit: Diagnostic Trouble Code(s) and Contact Your John Deere DealerDocument9 pagesDiagnostic Trouble Codes - Chart Per Control Unit: Diagnostic Trouble Code(s) and Contact Your John Deere Dealermiguelcastillo100% (4)

- Monarch User ManualDocument90 pagesMonarch User ManualMoh Aya100% (1)

- Everyday Practical Electronics 1999-01Document86 pagesEveryday Practical Electronics 1999-01Wagner SilvaNo ratings yet

- 4PWEN10931 1D - tcm135 30798Document12 pages4PWEN10931 1D - tcm135 30798Anonymous lB6SsHu5KNo ratings yet

- Difference Between Ground and NeutralDocument18 pagesDifference Between Ground and NeutralAbdul WasayNo ratings yet

- MTL8000 1-1 Encl PDFDocument1 pageMTL8000 1-1 Encl PDFapisituNo ratings yet

- FAULT CODE 144 (ISB/QSB Automotive and Industrial, ISC/QSC/ISL/QSL Automotive, Industrial, and Marine) Engine Coolant Temperature 1 Sensor Circuit - Voltage Above Normal or Shorted To High SourceDocument16 pagesFAULT CODE 144 (ISB/QSB Automotive and Industrial, ISC/QSC/ISL/QSL Automotive, Industrial, and Marine) Engine Coolant Temperature 1 Sensor Circuit - Voltage Above Normal or Shorted To High SourceAhmedmahNo ratings yet

- EN - Ditec E1T Control Panel Technical ManualDocument12 pagesEN - Ditec E1T Control Panel Technical ManualJocelyn VaccaniNo ratings yet

- SPECTRUM TX Standard Device: Operating InstructionsDocument92 pagesSPECTRUM TX Standard Device: Operating InstructionsFabioNo ratings yet

- Q7999A Controlinks™ Universal Wiring Subbase: FeaturesDocument4 pagesQ7999A Controlinks™ Universal Wiring Subbase: FeaturesAndrey VegaNo ratings yet

- Glafltlok: Cable Ties & Wire Accessories /2007Document41 pagesGlafltlok: Cable Ties & Wire Accessories /2007Manpreet SinghNo ratings yet

- F3SJ Safety Light Curtain Manual 2010 OhmronDocument230 pagesF3SJ Safety Light Curtain Manual 2010 OhmronIvAn Inti MoralesNo ratings yet

- 600-0067 Rev 07 Interconnects Wiring Diagram, FSDDocument13 pages600-0067 Rev 07 Interconnects Wiring Diagram, FSDamalecadanNo ratings yet

- CMD 2019 Power Modules Low ResDocument44 pagesCMD 2019 Power Modules Low ResDerek OngNo ratings yet

- Sub MC02 MC02CB02 Circuit Breaker ReportDocument1 pageSub MC02 MC02CB02 Circuit Breaker ReportAjai .T KochupurackalNo ratings yet

- Consultants/Contractors Confirmation Check List: Consultant/Contractor UndertakingDocument1 pageConsultants/Contractors Confirmation Check List: Consultant/Contractor Undertakingom_23123062No ratings yet

- Error Codes LWE140 - 160 - 180 - 200 - 250 - ERROR CODESDocument15 pagesError Codes LWE140 - 160 - 180 - 200 - 250 - ERROR CODESStian100% (20)

- Science PPT q3Document66 pagesScience PPT q3Jezer Dzi ArimaNo ratings yet

- CN400 Series ManualDocument78 pagesCN400 Series ManualHarry moesNo ratings yet

- CP18 Batch Plant InstructionsDocument74 pagesCP18 Batch Plant InstructionsJayantha parakrama Thennakoon50% (4)

- Abb Irbt 4003Document64 pagesAbb Irbt 4003borlixNo ratings yet