Professional Documents

Culture Documents

Er 10 4 01

Uploaded by

Mohammad Shafaet JamilOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Er 10 4 01

Uploaded by

Mohammad Shafaet JamilCopyright:

Available Formats

ER-10.4.

01 ECN: 202000205 VER: 11 - 03-02-2020

Warranty Notification - Installation List Data and Start Up Check

Lists for Reciprocating Compressors

JG:A:M:P:N:Q:R:J:H:E:K:T:C:D:F, KBE:K:T, & KB100

The following forms are designed to ensure a successful start-up of Ariel reciprocating compressors. Ariel

warranty coverage requires these completed forms be sent to:

Administrative Assistant - Sales, Ariel Corporation

35 Blackjack Road • Mount Vernon, Ohio 43050 USA

Phone: 740-397-0311 • FAX: 740-397-3856

Email: warrantyregistration@arielcorp.com

Warranty Notification - Installation List Data

Date:___________________ Name:____________________________________________________

Unassigned Resale Direct Sale Lease-Purchase Rental/Lease Unit

Compressor Frame

Frame Model:_____________________ Frame Serial #:____________________________________

Frame Lubricant Make and Grade:______________________________________________________

Package Startup Date:________________________________

Distributor/Fabricator

Company:_________________________________ Name:_________________________________

Address:_________________________________________________________________________

City:______________________________ State:_____ Zip:_________ Country:__________________

Fabricator Unit Number:_______________________________________

Application

Air/Nitrogen CNG/GNC FPSO Gathering Fuel Gas Booster

Refrigeration Pipeline PRC Injection Storage/Withdrawal Miscellaneous

Elevation:__________ H2S%:_____ CO2%:_____ Specific Gravity:_______ Non-Lube: Yes No

Unit Location

Customer Name:__________________________________________________________________

Project/Lease Name: _______________________________________________________________

Closest Town:____________________________________ State:______ Country:______________

Offshore: Yes No

ER-10.4.01, Ver. 11 888-397-7766 (toll free USA & Canada) or Page 1 of 8

740-397-3602 (International)

www.arielcorp.com | arc@arielcorp.com

Frame Serial #:_______________________________________________

Directions to Location or GPS:__________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

Customer Contact Person:_________________________ Contact Phone:____________________

Contact Email:________________________________________________ OK to contact: Yes No

Driver

Driver Manufacturer:______________________________________ Driver Model:________________

Driver Type:_____________________________ Applied RPM:______ Name Plate HP (kW):________

Coupling Manufacturer:________________________________ Coupling Model:_________________

Compressor Cylinders and Operating Conditions

Cylinder Stage Throw Serial Bore Dia. Inlet Temp. Inlet Pres. Disc. Temp Disc. Pres.

Class Number Number Number In. (mm) °F (°C) psig (barg) °F (°C) psig (barg)

________ ________ ________ ________ ________ ________ ________ ________ ________

________ ________ ________ ________ ________ ________ ________ ________ ________

________ ________ ________ ________ ________ ________ ________ ________ ________

________ ________ ________ ________ ________ ________ ________ ________ ________

________ ________ ________ ________ ________ ________ ________ ________ ________

________ ________ ________ ________ ________ ________ ________ ________ ________

Cylinder Lubricant Make and Grade:______________________________________________

Documentation and Accessories

Check all items included in the shipment:

Maintenance and Repair Yes No Recommended Parts List Yes No

Manual

Start-Up Parts Yes No Unit Start and Stop Procedures Yes No

Toolbox w/Ariel Tools Yes No Toolbox with Hydraulic Tools Yes No

(optional)

Unit Parts List Yes No Toolbox with SAE Hand Tools Yes No

(optional)

Commissioning Agent

Name:__________________________________ Company:_________________________________

Address:__________________________________________________________________________

City:______________________________ State:_____ Zip:________ Country:___________________

Phone:______________________ Email:________________________________________________

ER-10.4.01, Ver. 11 888-397-7766 (toll free USA & Canada) or Page 2 of 8

740-397-3602 (International)

www.arielcorp.com | arc@arielcorp.com

Frame Serial #:_______________________________________________

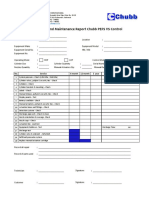

START-UP CHECK LIST - ITEMS TO CHECK IN THE FIELD AT COMMISSIONING

Description Date Checked Date Verified

1. Check and verify the top cover data plate of the compressor frame for com- Commissioning Agent: Distributor:

pressor design limitations such as rod load, maxi-mum and minimum speed, ________________ ________________

and maximum lube oil temperature.

2. Check and verify the availability of correct start-up parts, hand tools, special Commissioning Agent: Distributor:

tools, compressor parts list and drawings, and technical manuals at installation. ________________ ________________

3. Check and verify the Ariel lube sheet and Lubrication Specification matches Commissioning Agent: Distributor:

the recommended oil grade and viscosity for the service. ________________ ________________

4. Check and verify all lube oil piping cleanliness per Ariel lubrication spe- Commissioning Agent: Distributor:

cifications (see ER-56.06). ________________ ________________

5. Verify lube oil storage and supply line cleanliness per ER-56.06). Verify Commissioning Agent: Distributor:

crankcase oil supply isolation valve is open. ________________ ________________

6. Verify pre-lube piping cleanliness per ER-56.06) and correct circuit oper- Commissioning Agent: Distributor:

ation. ________________ ________________

7. Verify there is an oil cooler and high temperature shutdown for the oil into the Commissioning Agent: Distributor:

compressor frame. ________________ ________________

8. Verify whether the temperature control valve installation is blending or divert- Commissioning Agent: Distributor:

ing (blending preferred). _________________ ________________ ________________

9. Check compressor crankcase oil level controller for proper installation, oper- Commissioning Agent: Distributor:

ation, levelness, and venting. ________________ ________________

10. If applicable, check cooling water circuit cleanliness for the oil cooler and Commissioning Agent: Distributor:

cooled packing per Maintenance and Repair Manual. Verify correct routing and ________________ ________________

test pump rotation. Set pressure appropriately per Maintenance and Repair

Manual and leak test.

11. Verify correct filter element installation. Prime the oil filter element and all Commissioning Agent: Distributor:

lube oil piping with oil. ________________ ________________

12. Verify proper compressor crankcase oil level before starting (about 7/8 full Commissioning Agent: Distributor:

in site glass). ________________ ________________

13. Verify correct installation of a low oil pressure shutdown tubed to the down- Commissioning Agent: Distributor:

stream side of the oil filter. ________________ ________________

14. Operate pre-lube system. Commissioning Agent: Distributor:

________________ ________________

15. OPTIONAL STEP: Record “out of plane” readings (pre-grout) - see ER-82.

_________ _________ _________ _________ _________ _________

Drive End _________ _________ _________ _________ _________ _________ Auxiliary End

Flatness measuring device Manufacturer / Model:____________________________________

Date of last calibration:_____________________ Calibration Due:_______________________

Commissioning Agent: Distributor:

________________ ________________

16. Record soft foot readings. Over 0.002 inches (0.05 mm) pull-down on any frame foot requires correction.

_________ _________ _________ _________ _________ _________

Drive End _________ _________ _________ _________ _________ _________ Auxiliary End

Commissioning Agent: Distributor:

________________ ________________

ER-10.4.01, Ver. 11 888-397-7766 (toll free USA & Canada) or Page 3 of 8

740-397-3602 (International)

www.arielcorp.com | arc@arielcorp.com

Frame Serial #:_______________________________________________

START-UP CHECK LIST - ITEMS TO CHECK IN THE FIELD AT COMMISSIONING

Description Date Checked Date Verified

17. Check crosshead guide shimming for correct pre-load and hold down bolt Commissioning Agent: Distributor:

torque. ________________ ________________

18. Record piston end clearances with feeler gages (see Maintenance and Repair Manual, Appendix B).

Throw 1 2 3 4 5 6

Head End ___________ ___________ ___________ ___________ ___________ ___________

Crank End ___________ ___________ ___________ ___________ ___________ ___________

NOTE: Pre-lube compressor before turning crankshaft. Commissioning Agent: Distributor:

________________ ________________

19. Measure and record rod runout (see Maintenance and Repair Manual for maximum acceptable readings).

Throw 1 2 3 4 5 6

Vertical

Piston @ CE __________ __________ __________ __________ __________ __________

Mid-Stroke __________ __________ __________ __________ __________ __________

Piston @ HE __________ __________ __________ __________ __________ __________

Horizontal:

Piston @ CE __________ __________ __________ __________ __________ __________

Mid-Stroke __________ __________ __________ __________ __________ __________

Piston @ HE __________ __________ __________ __________ __________ __________

NOTE: Pre-lube compressor before turning crankshaft. Commissioning Agent: Distributor:

________________ ________________

20. Measure crosshead clearances with cylinders mounted. To check top, Commissioning Agent: Distributor:

insert 0.5 inch (12.7 mm) wide feelers from one side edge across to the oppos- ________________ ________________

ite side, at both ends. See Maintenance and Repair Manual, Appendix B for lim-

its. To check bottom, insert a 0.0015 inch (0.038 mm) feeler at the four corners;

feeler should insert no more than 0.50 (13 mm). Record values:

Throw Top Min. Top Max. Bottom Max. (Corners)

1 _________ _________ _________

2 _________ _________ _________

3 _________ _________ _________

4 _________ _________ _________

5 _________ _________ _________

6 _________ _________ _________

21. For electric motor drivers, check and verify the motor shaft is set at its mag- Commissioning Agent: Distributor:

netic center before positioning axial clearance. With the coupling disconnected, ________________ ________________

check and verify driver rotation matches the compressor rotation arrow.

22. Check coupling bolt torque to coupling manufacturer Commissioning Agent: Distributor:

recommendations. ________________ ________________

ER-10.4.01, Ver. 11 888-397-7766 (toll free USA & Canada) or Page 4 of 8

740-397-3602 (International)

www.arielcorp.com | arc@arielcorp.com

Frame Serial #:_______________________________________________

START-UP CHECK LIST - ITEMS TO CHECK IN THE FIELD AT COMMISSIONING

Description Date Checked Date Verified

23. Check and verify compressor to driver alignment (installed on site, cold). Commissioning Agent: Distributor:

Record dial indicator readings in inches (mm) at the 3, 6, 9 and 12 o’clock pos- ________________ ________________

itions or attach alignment tool print-out.

If using a laser alignment tool, make a print out and attach it to this document.

24. Check and verify compressor crankshaft thrust clearance. The shaft should Commissioning Agent: Distributor:

remain stationary after thrusting each direction (see appropriate ER-96.3.x ________________ ________________

series document).

_______________________ ________________________

START-UP CHECK LIST - PROCESS PIPING VENTS AND DRAINS

Description Date Checked Date Verified

1. Verify the bottle and process pipe installation contains no bolt bound flanges Commissioning Agent: Distributor:

or elevation differences that may stress the compressor cylinders ________________ ________________

2. Verify cold adjustment of any bottle or cylinder supports. Commissioning Agent: Distributor:

________________ ________________

3. Verify correct inlet screen orientation in process piping. Commissioning Agent: Distributor:

________________ ________________

4. Check and verify vents and drains of the primary and secondary packing- Commissioning Agent: Distributor:

case and the crosshead distance piece are open and tubed to a safe atmo- ________________ ________________

sphere.

5. Check and verify safety relief valve installation to protect cylinders, piping, Commissioning Agent: Distributor:

and cooler for each compression stage. ________________ ________________

6. Record method of suction pressure control and valve size. Commissioning Agent: Distributor:

________________________ ________________________ ________________ ________________

7. Check and verify crankcase breather element is open to atmosphere and Commissioning Agent: Distributor:

clean. ________________ ________________

8. Check and verify torque to spec on all gas containment and other fasteners Commissioning Agent: Distributor:

where loosening may result in a safety hazard or equipment failure including: ________________ ________________

gas nozzle flanges, valve caps, cylinder heads, compressor rod packing, and

crosshead guide support. See appropriate ER-96.2.x series document.

ER-10.4.01, Ver. 11 888-397-7766 (toll free USA & Canada) or Page 5 of 8

740-397-3602 (International)

www.arielcorp.com | arc@arielcorp.com

Frame Serial #:_______________________________________________

START-UP CHECK LIST - INSTRUMENTATION

Description Date Checked Date Verified

1. Check and verify the set point for the high compressor oil temperature shut- Commissioning Agent: Distributor:

down at 190°F (88°C) maximum. ________________ ________________

2. Check and verify proper vibration shutdown installation and operation. Commissioning Agent: Distributor:

Record alarm and shut down settings. ________________ ________________

____________________________________________________

____________________________________________________

3. Verify operation of suction, inter-stage, and discharge pressure shutdowns. Commissioning Agent: Distributor:

Record alarm and shutdown settings. ________________ ________________

____________________________________________________

____________________________________________________

4. Check, verify, and record the over speed setting: __________ Commissioning Agent: Distributor:

________________ ________________

START-UP CHECK LIST - FORCE FEED LUBRICATION SYSTEM

Description Date Checked Date Verified

1. Check and verify force feed lubricator box for proper oil level. Commissioning Agent: Distributor:

________________ ________________

2. Prime the force feed lubrication system through the purge port at the force Commissioning Agent: Distributor:

feed pump discharge manifold. Check and verify each tube connection for tight- ________________ ________________

ness.

3. Check and verify operation of force feed lubrication system no flow shut- Commissioning Agent: Distributor:

downs. ________________ ________________

4. Record color of force feed blow out discs (see ER-96.0.5 for disc ratings): _ Commissioning Agent: Distributor:

____________________________. If fitted with an ARV, verify the cracking ________________ ________________

pressure marked on the relief valve and the pin indicator color match the lube

sheet specification.

5. Check, verify, and record recommended lube feed rates from lubricator data Commissioning Agent: Distributor:

plate or “Parts Book” Cylinder Lubrication sheet. ________________ ________________

____________________________________________________

FINAL PRE-START CHECK LIST

Description Date Checked Date Verified

1. Operate pre-lube system. Record pre-lube pressure:________ Commissioning Agent: Distributor:

________________ ________________

2. For engine driven units, disable ignition and roll the engine with the starter to Commissioning Agent: Distributor:

check and verify the compressor rolls freely. Check and verify oil pressure ________________ ________________

increases noticeably while rolling on starter.

3. For electric motors, bar the compressor over manually to check and verify it Commissioning Agent: Distributor:

rolls freely. ________________ ________________

4. For machines compressing a combustible gas, purge the entire system Commissioning Agent: Distributor:

including the piping, by-pass, recycle line, and compressor cylinders of all air. ________________ ________________

5. Review start-up instructions for all other package components. Commissioning Agent: Distributor:

________________ ________________

6. Complete the required review of the Start-Up and Operating Instructions for Commissioning Agent: Distributor:

the unit with the unit operator. ________________ ________________

ER-10.4.01, Ver. 11 888-397-7766 (toll free USA & Canada) or Page 6 of 8

740-397-3602 (International)

www.arielcorp.com | arc@arielcorp.com

Frame Serial #:_______________________________________________

INITIAL POST START-UP CHECK LIST

Description Date Checked Date Verified

1. Check and verify immediate oil pressure increase. Enable oil pressure shut- Commissioning Agent: Distributor:

down and bearing temperature shutdowns. Record initial pressure at operating ________________ ________________

speed.____________________

2. Check and verify oil filter pressure gauges. Record initial differential: ______ Commissioning Agent: Distributor:

__________________________________ ________________ ________________

3. Check and verify the low oil pressure shutdown is active and set at 45 psig Commissioning Agent: Distributor:

(3.1 barg). ________________ ________________

4. Check and verify lube oil pressure set at 50 to 60 psig (3.5 to 4.2 barg) at Commissioning Agent: Distributor:

operating speed and temperature (see Maintenance and Repair Manual, "Oil ________________ ________________

Pressure"). Record final setting:__________

5. Record oil filter maximum differential reference value listed on the com- Commissioning Agent: Distributor:

pressor top cover filter data plate: _________________ ________________ ________________

6. Listen and feel for any strange noises or vibration in the compressor or pip- Commissioning Agent: Distributor:

ing. Record any occurrences. ________________ ________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

7. Check and verify high discharge gas temperature shutdowns are set about Commissioning Agent: Distributor:

10% above normal operating temperature (350 °F (177 °C) maximum) and func- ________________ ________________

tioning.

8. Check and verify distribution block cycle time indicator and set lubricator Commissioning Agent: Distributor:

pump for proper break-in rate. ________________ ________________

9. Check and verify the unit and piping is free from any gas or fluid leaks. Commissioning Agent: Distributor:

Record any occurrences. ________________ ________________

____________________________________________________

____________________________________________________

____________________________________________________

10. Check and verify scrubber high level shutdowns operation and check scrub- Commissioning Agent: Distributor:

ber dumps operation and frequency. ________________ ________________

11. Check, verify, and record tank levels that indicate the amount of liquids Commissioning Agent: Distributor:

removed from the gas. ___________________ ________________ ________________

12. Check and verify piston rod packings seal properly in the primary packing Commissioning Agent: Distributor:

vents. ________________ ________________

13. Check and verify operation of all safety functions to ensure unit shutdown Commissioning Agent: Distributor:

upon indication. ________________ ________________

14. If applicable, check and verify main bearing temperatures and record. Commissioning Agent: Distributor:

Watch for even bearing temperature increase. ________________ ________________

15. During various operational conditions, use the Ariel performance program to Commissioning Agent: Distributor:

check and verify operational characteristics of various load steps. ________________ ________________

ER-10.4.01, Ver. 11 888-397-7766 (toll free USA & Canada) or Page 7 of 8

740-397-3602 (International)

www.arielcorp.com | arc@arielcorp.com

Frame Serial #:_______________________________________________

24-HOUR POST START-UP CHECK LIST

Description Date Checked Date Verified

1. Record "hot" alignment readings after reaching normal operating tem- Commissioning Agent: Distributor:

peratures and components become heat soaked. Shutdown and vent gas sys- ________________ ________________

tem. Within 30 minutes and while components are still hot, record dial indicator

readings in inches (mm) at the 3, 6, 9 and 12 o’clock positions on lines

provided below:

If using a laser alignment tool, make a print out and attach it to this document.

2. If using a discharge bottle or head end cylinder supports, adjust when com- Commissioning Agent: Distributor:

ponents are heat soaked to ensure no excessive forces exist to cause det- ________________ ________________

rimental cylinder deflection.

3. Check and verify torque on gas nozzle flange, valve cap, cylinder head, com- Commissioning Agent: Distributor:

pressor rod packing flange, and guide to frame bolting. ________________ ________________

4. Verify inlet screens are clean by monitoring differential pressure across the Commissioning Agent: Distributor:

screen. If differential pressure is unavailable, a visual inspection may be ________________ ________________

required. Remove and replace damaged inlet screens. Clean inlet screens reg-

ularly to avoid increased pressure that may collapse them. More debris in the

screen may dictate more frequent inspections.

5. Complete Ariel’s “Compressor Warranty Notification - Installation List Data” Commissioning Agent: Distributor:

(pages 1 and 2). ________________ ________________

Document contents are proprietary and confidential. They are the property of Ariel Corporation and may not be dis-

closed, reproduced, or used for manufacture in part or in whole without written permission from Ariel Corporation.

DATE: VER: ECN: DESCRIPTION:

03-02-2020 11 202000205 Title: "KBE:K:T" was "KBK:T".

ER-10.4.01, Ver. 11 888-397-7766 (toll free USA & Canada) or Page 8 of 8

740-397-3602 (International)

www.arielcorp.com | arc@arielcorp.com

You might also like

- Disassembly and Assembly 3500C Marine Engines PDFDocument132 pagesDisassembly and Assembly 3500C Marine Engines PDFlancaster27100% (5)

- Thor Hurricane Owners Manual 2012Document131 pagesThor Hurricane Owners Manual 2012glenrgNo ratings yet

- Ariel Start-Up Check List (Er-10.4.0)Document6 pagesAriel Start-Up Check List (Er-10.4.0)Jose RattiaNo ratings yet

- Monthly Plate Compactor Check ListDocument2 pagesMonthly Plate Compactor Check Listmuthuswamy7783% (6)

- River CrossingDocument119 pagesRiver CrossingMohammad Shafaet JamilNo ratings yet

- Quick Setup Guide for Damper Dynamometer SoftwareDocument75 pagesQuick Setup Guide for Damper Dynamometer SoftwareapronelloNo ratings yet

- Parts PDFDocument96 pagesParts PDFviraj arjun ghadage100% (1)

- Honda Activa PartsDocument10 pagesHonda Activa PartsPentaVision73% (30)

- Overhaul Manual 60294-7Document149 pagesOverhaul Manual 60294-7Mohamed HusseinNo ratings yet

- 5 Cylinder Engine InstructionsDocument90 pages5 Cylinder Engine InstructionsFabio GiliiNo ratings yet

- ER-10-4-01 EN Installation List Data and Start Up ChecksDocument9 pagesER-10-4-01 EN Installation List Data and Start Up ChecksCamilo Andres Cardozo FajardoNo ratings yet

- Warranty Installation Checklists: Ariel Reciprocating Compressors JG:A:M:N:P:Q:R:J:H:E:K:T:C:D:FDocument9 pagesWarranty Installation Checklists: Ariel Reciprocating Compressors JG:A:M:N:P:Q:R:J:H:E:K:T:C:D:FMandava Subrahmanya Sivarama PrasadNo ratings yet

- Check List CompresorDocument6 pagesCheck List CompresorYoaida Marte CanelaNo ratings yet

- Ariel WarrantyDocument9 pagesAriel WarrantyMuhammadShadabNo ratings yet

- Form Blank Kelengkapan Data SampleDocument1 pageForm Blank Kelengkapan Data SampleVin DieselNo ratings yet

- Service ReportDocument1 pageService ReportMohammed R. Al Khaz'alyNo ratings yet

- DELIVERYDocument2 pagesDELIVERYBrayan Calcina BellotNo ratings yet

- ESI Oil Sampling SheetDocument1 pageESI Oil Sampling SheetGM PNo ratings yet

- Er-10 4 0Document6 pagesEr-10 4 0Dibyendu ChakrabortyNo ratings yet

- Preventive Maintenance Checklist: Biomedical. EngDocument150 pagesPreventive Maintenance Checklist: Biomedical. EngJuli AgustonoNo ratings yet

- Er-10 4 0 PDFDocument6 pagesEr-10 4 0 PDFANKIT DUBEYNo ratings yet

- PREVENTIVE MAINTENANCE INSPECTION SHEETDocument2 pagesPREVENTIVE MAINTENANCE INSPECTION SHEETArnulfo LavaresNo ratings yet

- Delivery Checklist RecordDocument2 pagesDelivery Checklist RecordMahmmod Al-Qawasmeh100% (1)

- SECTION 04 After Sales Service PolicyDocument14 pagesSECTION 04 After Sales Service PolicyRFamDamilyNo ratings yet

- Compressor Start-Up Check ListDocument6 pagesCompressor Start-Up Check ListCokro YudhaNo ratings yet

- Application To Install Elevator Manlift DumbwaiterDocument3 pagesApplication To Install Elevator Manlift Dumbwaiterryan fernandezNo ratings yet

- 520 Fuel Trailer Operators ManualDocument80 pages520 Fuel Trailer Operators ManualTECHNICALNo ratings yet

- Job Sheet: Name: Date: Use of A VoltmeterDocument5 pagesJob Sheet: Name: Date: Use of A VoltmeterJonephine Gonzales PortonNo ratings yet

- Pump Installation Report: 30 Damascus Road, Suite 115 Bedford, Nova Scotia B4A 0C1Document1 pagePump Installation Report: 30 Damascus Road, Suite 115 Bedford, Nova Scotia B4A 0C1Yosif BabekerNo ratings yet

- Weekly Monthly Inspection-Pdf-En PDFDocument1 pageWeekly Monthly Inspection-Pdf-En PDFMohamed Moustafa ElashwahNo ratings yet

- Fire Alarm System Inspection and Testing FormDocument4 pagesFire Alarm System Inspection and Testing FormBrahim SemariNo ratings yet

- Installation Application for Elevator, Manlift or DumbwaiterDocument2 pagesInstallation Application for Elevator, Manlift or DumbwaiterRuel Baria67% (3)

- Samet Daily Crane Safety Inspection ReportDocument1 pageSamet Daily Crane Safety Inspection ReportmuraliNo ratings yet

- Burner Nozzle SelectionDocument108 pagesBurner Nozzle SelectionNiral GajjarNo ratings yet

- Vehicle Pass Application FormatDocument1 pageVehicle Pass Application FormatmukeshNo ratings yet

- Form 2207 - Page 1: Submersible Motor Installation RecordDocument2 pagesForm 2207 - Page 1: Submersible Motor Installation Recordwpt_me100% (1)

- NDT Certificate Inspection ReportsDocument9 pagesNDT Certificate Inspection ReportsikponmwonsaNo ratings yet

- Application For Crane and Hoist Installation: Department of Labor and EmploymentDocument1 pageApplication For Crane and Hoist Installation: Department of Labor and EmploymentCharlie MendozaNo ratings yet

- General Inspection FormDocument1 pageGeneral Inspection FormBernadette Lou LasinNo ratings yet

- Dredge Fox River Operators Daily ReportDocument15 pagesDredge Fox River Operators Daily ReportPhilip NguyenNo ratings yet

- PMCL VS Control PDFDocument1 pagePMCL VS Control PDFHandrean Yudya PratamaNo ratings yet

- Water System O&M GuideDocument24 pagesWater System O&M GuideR ShindeNo ratings yet

- Jackaroo 4JX1 Engine Manual 2014 Ver 2.2Document65 pagesJackaroo 4JX1 Engine Manual 2014 Ver 2.2João Guardado100% (3)

- Pressure Vessel FabricationDocument1 pagePressure Vessel FabricationRaul Dela Cerna VentenillaNo ratings yet

- B2.1 B2.1M 2014 AMD1 Stud Welding WPS PQR or WQR FormDocument1 pageB2.1 B2.1M 2014 AMD1 Stud Welding WPS PQR or WQR FormtuanNo ratings yet

- Compressor Start-Up and Warranty ValidationDocument3 pagesCompressor Start-Up and Warranty ValidationAhmed SofaNo ratings yet

- Septage Pump Truck InspFormDocument1 pageSeptage Pump Truck InspFormjclark13010No ratings yet

- Application STEAM GAS HYDRO TURBINE InstallationDocument2 pagesApplication STEAM GAS HYDRO TURBINE InstallationEfren Jr. FloresNo ratings yet

- 9 PDFDocument2 pages9 PDFMahmmod Al-QawasmehNo ratings yet

- Preventive Maintenance Checklists For Construction EquipDocument3 pagesPreventive Maintenance Checklists For Construction EquipGA JonNo ratings yet

- IMO Test Reports LSADocument12 pagesIMO Test Reports LSAMd AmirulNo ratings yet

- CW FUSION PM Checklist - M-QF-75-11 Rev ADocument2 pagesCW FUSION PM Checklist - M-QF-75-11 Rev AbaileybancroftNo ratings yet

- Ops Plan TempDocument21 pagesOps Plan TempTiago HenriquesNo ratings yet

- Automotive-Maintenance Merit Badge WorksheetDocument10 pagesAutomotive-Maintenance Merit Badge WorksheetgivenjwNo ratings yet

- 036-00196-003 (CC3x5 - Ing) - RV02 - OUT2019 - OTM PDFDocument23 pages036-00196-003 (CC3x5 - Ing) - RV02 - OUT2019 - OTM PDFMuhamedomar Jojo JojoNo ratings yet

- 88 - SeriesDocument336 pages88 - SeriesChad TerrettNo ratings yet

- Portable Dehumidifier Operating InstructionsDocument10 pagesPortable Dehumidifier Operating InstructionsDon WarrenNo ratings yet

- TMW 124 APC Diagnostic ChecklistDocument1 pageTMW 124 APC Diagnostic ChecklistweldsaidiNo ratings yet

- Aws Form E-9 Stud Welding Procedure Specification (WPS) or Procedure Qualification Record (PQR) or Welder Qualification Record (WQR) 000 PDFDocument1 pageAws Form E-9 Stud Welding Procedure Specification (WPS) or Procedure Qualification Record (PQR) or Welder Qualification Record (WQR) 000 PDFrajNo ratings yet

- Start-Up Sheet For CompressorsDocument1 pageStart-Up Sheet For CompressorsGreg LundyNo ratings yet

- Installation Oxygen ConcentratorDocument1 pageInstallation Oxygen Concentratordean HaroldNo ratings yet

- Vertical Screw Data SheetDocument3 pagesVertical Screw Data SheetMIGUELNo ratings yet

- Application For New Registration Full Motor - Vehicle - Forms - 59e8427ab4f4e PDFDocument2 pagesApplication For New Registration Full Motor - Vehicle - Forms - 59e8427ab4f4e PDFAsaad ChughtaiNo ratings yet

- F4-WPS PQR Stud WeldingDocument1 pageF4-WPS PQR Stud WeldingBernardo LeorNo ratings yet

- Motor Vehicle Forms 59e8427ab4f4eDocument2 pagesMotor Vehicle Forms 59e8427ab4f4eRahila AlaviNo ratings yet

- Hacking for Beginners: Comprehensive Guide on Hacking Websites, Smartphones, Wireless Networks, Conducting Social Engineering, Performing a Penetration Test, and Securing Your Network (2022)From EverandHacking for Beginners: Comprehensive Guide on Hacking Websites, Smartphones, Wireless Networks, Conducting Social Engineering, Performing a Penetration Test, and Securing Your Network (2022)No ratings yet

- Tender Document For Lab EquipmentsDocument70 pagesTender Document For Lab EquipmentsMohammad Shafaet JamilNo ratings yet

- Dala 2015Document11 pagesDala 2015Mohammad Shafaet JamilNo ratings yet

- Dala 2015Document11 pagesDala 2015Mohammad Shafaet JamilNo ratings yet

- Report and Recommendation of The President To The Board of DirectorsDocument18 pagesReport and Recommendation of The President To The Board of DirectorsMohammad Shafaet JamilNo ratings yet

- SPE-160924-MS - To Develop The Optimum Field Development Plan For Condensate Well Using IPMDocument12 pagesSPE-160924-MS - To Develop The Optimum Field Development Plan For Condensate Well Using IPMHafiz AsyrafNo ratings yet

- SPE 162988 Well Predictive Material Balance Evaluation: A Quick Tool For Reservoir Performance AnalysisDocument7 pagesSPE 162988 Well Predictive Material Balance Evaluation: A Quick Tool For Reservoir Performance AnalysisMohammad Shafaet JamilNo ratings yet

- Nodal AnalysisDocument9 pagesNodal AnalysisPETROLEROS 2021No ratings yet

- Spe 1 Well P 162973 Performa Nce Optim Mization Using Ex Xperimen Ntal Desig GN Appro AchDocument8 pagesSpe 1 Well P 162973 Performa Nce Optim Mization Using Ex Xperimen Ntal Desig GN Appro AchMohammad Shafaet JamilNo ratings yet

- Roll Sheet 2017-18Document18 pagesRoll Sheet 2017-18Mohammad Shafaet JamilNo ratings yet

- En 62058-11Document11 pagesEn 62058-11Mahmoud ShaheenNo ratings yet

- IPSDSDocument1 pageIPSDSMohammad Shafaet JamilNo ratings yet

- Effect of Pulsation BottleDocument18 pagesEffect of Pulsation BottleluisNo ratings yet

- Using Pulsation Damper With A Reciprocating PumpDocument4 pagesUsing Pulsation Damper With A Reciprocating PumpIkechukwu EjimNo ratings yet

- The Politics of Large-Scale Ccs Deployment: SciencedirectDocument15 pagesThe Politics of Large-Scale Ccs Deployment: SciencedirectMohammad Shafaet JamilNo ratings yet

- Simulation of Bangladesh's Natural Gas Pipeline NetworkDocument77 pagesSimulation of Bangladesh's Natural Gas Pipeline NetworkMohammad Shafaet JamilNo ratings yet

- En 50464-4Document3 pagesEn 50464-4Mahmoud ShaheenNo ratings yet

- 520 I PDFDocument2 pages520 I PDFjkpothabathula4581No ratings yet

- En 50464-4Document3 pagesEn 50464-4Mahmoud ShaheenNo ratings yet

- A Review of Explicit Approximations of Colebrook's Equation: Srbislav GenićDocument5 pagesA Review of Explicit Approximations of Colebrook's Equation: Srbislav GenićLutfi LailaNo ratings yet

- Free Water KO Drum Flow Assurance: Computational Fluid Dynamics (CFD)Document1 pageFree Water KO Drum Flow Assurance: Computational Fluid Dynamics (CFD)Mohammad Shafaet JamilNo ratings yet

- A Computational Fluid Dynamics Investigation of The Flow Behavior Near A Wellbore Using Three-Dimensional Navier-Stokes EquationsDocument12 pagesA Computational Fluid Dynamics Investigation of The Flow Behavior Near A Wellbore Using Three-Dimensional Navier-Stokes EquationsMohammad Shafaet JamilNo ratings yet

- Summary Rupture Disc StudyDocument10 pagesSummary Rupture Disc StudyMohammad Shafaet JamilNo ratings yet

- A Review of Explicit Approximations of Colebrook's Equation: Srbislav GenićDocument5 pagesA Review of Explicit Approximations of Colebrook's Equation: Srbislav GenićLutfi LailaNo ratings yet

- Instructions For NON-EU Master ITqqq23Document1 pageInstructions For NON-EU Master ITqqq23Mohammad Shafaet JamilNo ratings yet

- NORSOK P-001 Process Design PDFDocument26 pagesNORSOK P-001 Process Design PDFMarcelNo ratings yet

- Protected Upload PDFDocument2 pagesProtected Upload PDFMohammad Shafaet JamilNo ratings yet

- First Semester CoursesDocument1 pageFirst Semester CoursesMohammad Shafaet JamilNo ratings yet

- Entrance TestDocument3 pagesEntrance Testgonzalo samaniegoNo ratings yet

- Ignition ControlDocument48 pagesIgnition ControlYdelkadiasmela Dominguezmorel100% (1)

- Mazda - 5 - Engine - Workshop - Manual - l8 - LF l3 - 0202200726Document1 pageMazda - 5 - Engine - Workshop - Manual - l8 - LF l3 - 0202200726info.tf.montNo ratings yet

- GIXXER L6 PartsDocument84 pagesGIXXER L6 PartsJuanNo ratings yet

- S46MC-C, Edition 2Document168 pagesS46MC-C, Edition 2Nghia Duongdinh50% (2)

- Medidas Cigüeñal KTA 38Document20 pagesMedidas Cigüeñal KTA 38Chardy Jarith Piragua AlvaradoNo ratings yet

- Engine, Dismantling D11MDocument23 pagesEngine, Dismantling D11MAMIT SINGHNo ratings yet

- Caterpillar Parts Manual 3304Document6 pagesCaterpillar Parts Manual 3304Jovie GrohlNo ratings yet

- 3 VHP - Packaging - Guide - 6 30 v4Document222 pages3 VHP - Packaging - Guide - 6 30 v4Alfred Lam100% (1)

- Cummins Ism, QSMDocument11 pagesCummins Ism, QSMibnu67% (6)

- Greaves parts catalog for 10KVA gensetDocument54 pagesGreaves parts catalog for 10KVA genseteichermguptaNo ratings yet

- Radial EngineDocument89 pagesRadial EnginevikramNo ratings yet

- 1.1 Objective:: Experiment - 1Document7 pages1.1 Objective:: Experiment - 1firebird9No ratings yet

- Parts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 21R807-0012-B5Document27 pagesParts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 21R807-0012-B5pepiperepalo3No ratings yet

- Unit-5 - Balancing of Reciprocating MassesDocument83 pagesUnit-5 - Balancing of Reciprocating MassesHareesha N GNo ratings yet

- m1100 Manual 2 RedDocument470 pagesm1100 Manual 2 RedMikael KarlssonNo ratings yet

- Clark Gts 20 30 DDocument204 pagesClark Gts 20 30 DImpera Maq100% (1)

- Dynamic BalancingDocument9 pagesDynamic BalancingAbhiruchi PatilNo ratings yet

- SOHC Engine Specs and Repair GuideDocument155 pagesSOHC Engine Specs and Repair GuideAndrea Molina LezamaNo ratings yet

- 7 95860 Linked975 - EN PDFDocument352 pages7 95860 Linked975 - EN PDFandro plaNo ratings yet

- IC Engine NotesDocument21 pagesIC Engine NotesVishal MishraNo ratings yet

- GENSET1500 K WDocument40 pagesGENSET1500 K Wirvan82No ratings yet

- Tvs - 3w Global Parts ListDocument55 pagesTvs - 3w Global Parts ListSamseer U100% (1)

- Ajuste y DiagnosticoDocument79 pagesAjuste y Diagnosticojulio cesarNo ratings yet

- Ek9.9dmh'12 Ek15dmh'12 Ek9.9jmh'12 Ek15pmh'12: (6B79) (6B89) (6B99) (6C09)Document41 pagesEk9.9dmh'12 Ek15dmh'12 Ek9.9jmh'12 Ek15pmh'12: (6B79) (6B89) (6B99) (6C09)Muhammad hardaniNo ratings yet