Professional Documents

Culture Documents

Installation Manual Steeringgear Shipkits B.V. Hull No SK120

Uploaded by

craponzelOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installation Manual Steeringgear Shipkits B.V. Hull No SK120

Uploaded by

craponzelCopyright:

Available Formats

Technical specification

Steering Gear

Type Rolls-Royce steering gear

SR722 FCP

Date : 21.08.2012

Id : 10-12-00938

Rev : 00

Customer : Shipkits B.V.

Customer reference : CON-01331, 4200 dwt Heavy Lift Vessel

Shipyard : Shipkits B.V.

Hull no. : SK120

Type of vessel : Construction - Heavy Lift Ship

Class : BV

Contract manager : Marie Kristine Longvastrand,

marie.longvastrand@rolls-royce.com

Order : 12S000638

This document is the property of Rolls-Royce and may not be redistributed or reproduced in any way, without the written permission of Rolls-Royce.

Failure to do so is a violation of copyright laws.

Tech.spec. 12S000638 (Master rev. 03.2010-03-17) generated: 23/05/2012

Page 1 of 9

Table of contents

01.00 System description ........................................................................................................... 3

02.00 Scope of supply/technical description ............................................................................... 4

02.01 General ....................................................................................................................... 4

02.02 Steering gear .............................................................................................................. 6

02.03 Start/stop and control system ...................................................................................... 7

02.04 Alarm system .............................................................................................................. 8

02.05 Rudder angle indicator system .................................................................................... 8

02.06 Spare parts and special tools pr. ship set. ................................................................... 9

This document is the property of Rolls-Royce and may not be redistributed or reproduced in any way, without the written permission of Rolls-Royce.

Failure to do so is a violation of copyright laws.

Tech.spec. 12S000638 (Master rev. 03.2010-03-17) generated: 23/05/2012

Page 2 of 9

01.00 System description

Rolls-Royce steering gear

Type: SR722 FCP

Rudder actuator

Effective torque : 275 kNm

Max working pressure : 125 bar

Allowable axial load : 370 kN

Allowable radial load : 855 kN

Rudder stock diameter : 320 mm

Max. mechanical rudder angle : 2x72°

Max. electrical rudder angle : 2x65°

Additional rudder angle limitation (class requirement) : 2x35°

Steering time at 30° - 0° - 35° : 28 s with one pump unit in line

Steering time at 30° - 0° - 35° : 14 s with two pump units in line

Electric motor

Power : 15.0 kW (S1)

Current : I N = 30 A

Rotational speed : 1450 rpm

Voltage : 3x380-400 V

Frequency : 50 Hz

Type : M3AA 160 MLB-4

Protection : IP 55

Design : B35

Insulation class :F

Heating : Yes, (through the windings)

Start/stop and control system

Control panels for console mounting in the bridge

Control system unit for bulkhead mounting with interface to analogue autopilot.

Panel for run/stop indication

Motor controllers for bulkhead mounting in the steering gear room

The system is powered internally from motor controllers

Limit switches and potentiometers for the follow-up system are mounted in feed back units

Alarm system

Panels for console mounting.

Interface to Voyage Data Recorder (VDR) and ship’s main alarm system

Interface to alarm sensor

24VDC external power supply (100W)

Rudder angle indicator system

Panorama type for ceiling mounting

Console mounting types

Rudder angle indicator amplifiers

Feed back potentiometers in feed back unit

Interface to VDR

Accuracy according to class 1.5

Type approved by MED (Marine Equipment Directive)

24VDC external power supply (50W)

This document is the property of Rolls-Royce and may not be redistributed or reproduced in any way, without the written permission of Rolls-Royce.

Failure to do so is a violation of copyright laws.

Tech.spec. 12S000638 (Master rev. 03.2010-03-17) generated: 23/05/2012

Page 3 of 9

Classification requirements

Society-notation: BV (Notation according to project requirement).

The equipment is dimensioned in accordance with the above classification society rules valid on

the date of this specification.

Painting and colours:

According to RRCM standards if not other specified.

Panels : RAL 9011

Cabinets : RAL 7035

Electric motor : RAL 5014

Mechanical components : primer

02.00 Scope of supply/technical description

02.01 General

Equipment not supplied

Scope of supply is defined in the technical specification.

Not included in scope of supply are:

- Foundation and fastening bolts for equipment supplied.

- Autopilot, DP and joystick

- Piping

- Wiring

Technical information - Drawings

Dimension drawings, hydraulic diagram, electrical diagram and technical data for the steering

gear system will be delivered. All according to documentation list issued for each order.

Steering gear design

The steering gear design is based on well-proved technology as well as long experience.

Workshop testing

The steering gear system is workshop tested according to the class requirement and RRM

standard.

Corrosion protection and surface treatment

The steering gear actuator is provided with corrosion preventing coat, which is intended for

protection under normal transport conditions. The rotor is finish treated according to RRM

standard.

Shipment

Depending on transport methods and delivery times components may be shipped separately.

Installation into the ship and mounting of components are customer's responsibility if not

otherwise is stated.

This document is the property of Rolls-Royce and may not be redistributed or reproduced in any way, without the written permission of Rolls-Royce.

Failure to do so is a violation of copyright laws.

Tech.spec. 12S000638 (Master rev. 03.2010-03-17) generated: 23/05/2012

Page 4 of 9

Safe storage

All equipment are prepared for storage in dry and dust free environments up to 6 months from

delivery.

Piping and cabling

Connections between components supplied by RRM are the customer's responsibility. However,

type of pipes and cables are given in the diagrams and mounting instructions.

Installation, inspection, starting up and sea trial

Installation of the steering gear system in the ship and mounting of components are the

customer's responsibility if not otherwise stated.

Instruction manuals – Language

1 CD with English user/installation manuals

2 pcs. Installation manuals covering the mechanical/hydraulic parts in English language

2 pcs. Installation manuals covering the electrical parts in English language

2 pcs. Users manuals covering the mechanical/hydraulic parts in English language

2 pcs. Users manuals covering the electrical parts in English language

All drawings, documents and sign plates on the equipment will also be delivered in English

language. All drawings will be delivered in PDF-format.

This document is the property of Rolls-Royce and may not be redistributed or reproduced in any way, without the written permission of Rolls-Royce.

Failure to do so is a violation of copyright laws.

Tech.spec. 12S000638 (Master rev. 03.2010-03-17) generated: 23/05/2012

Page 5 of 9

02.02 Steering gear

0010 1 pc. Rudder actuator (rotary vane) type SR722 FCP

Complete with spherical self-aligning rudder carrier; pressure pumps; non-return

valves; load control valves; valve block with sensors for hydraulic lock alarm; filter

units and mechanical rudder angle indicator; feed back units with limit switches,

transmitters for the steering control system and the rudder angle indicating system.

Oil included.

Drawing numbers: A-9909, A-9161, W-1601-00-06, 0002-1515, 0002-5397

0020 1 pc. Sleeve for hydraulic coupling

Complete with mounting piston. Rudder stock diameter: 320 mm.

Drawing number: A-9295

0030 1 pc. Expansion tank

60 litres without oil, with gauge glasses, low oil level switches, cocks and fittings.

Drawing number: A-9417

0040 1 pc. Storage tank

Storage tank, volume 120 litres with hand pump, level indicator and necessary

connections.

Drawing number: A-9807

This document is the property of Rolls-Royce and may not be redistributed or reproduced in any way, without the written permission of Rolls-Royce.

Failure to do so is a violation of copyright laws.

Tech.spec. 12S000638 (Master rev. 03.2010-03-17) generated: 23/05/2012

Page 6 of 9

02.03 Start/stop and control system

0050 2 pcs. Motor controllers (FCP) (IP44)

For bulkhead mounting in the steering gear room. Vibration dampers included. Plastic

cable glands included.

Motor controller is numbered from the port side.

Drawing numbers: 0002-1731, L-1799-00-16

0060 2 pcs. Frequency converters (IP44)

For bulkhead mounting in the steering gear room with ammeter, hour counter

indication and power supply for heating of electrical motor through the windings.

Drawing numbers: 0000-0319, 0000-0322

0070 1 pc. Control system unit (IP44)

For bulkhead mounting in the bridge with interface to analogue autopilot. Plastic cable

glands included.

Drawing numbers: W-1221-01-00, L-1299-00-01

0080 1 pc. Control panel (IP22)

For desk mounting in the forward bridge console with start/stop push buttons, dimmer,

steering mode selections, non-follow-up push buttons for emergency steering and

follow-up controller.

Drawing numbers: 0002-0626, L-1320-01-05

0090 2 pcs. Indoor follow-up controller (IP22)

For desk mounting in the bridge wing console with in command push button and

dimmer.

Drawing numbers: 0002-1028, 0002-1247

0100 1 pc. Indication panel (IP22)

For run/stop/autostart indication and for desk mounting in the engine control room

console.

Drawing numbers: 0002-1030, 0002-1251

This document is the property of Rolls-Royce and may not be redistributed or reproduced in any way, without the written permission of Rolls-Royce.

Failure to do so is a violation of copyright laws.

Tech.spec. 12S000638 (Master rev. 03.2010-03-17) generated: 23/05/2012

Page 7 of 9

02.04 Alarm system

0110 1 pc. Alarm panel (IP22)

For desk mounting in engine control room with alarm lights for overload, phase failure,

low oil level, power failure and hydraulic lock and push buttons for alarm test, alarm

acknowledge, alarm buzzer and with one common steering gear failure alarm contact

(voltage free) to ship’s main alarm system.

Drawing number: W-1802-00-01

0120 1 pc. Alarm panel (IP22)

For desk mounting in bridge console with alarm light and push buttons for alarm test,

alarm acknowledge, alarm buzzer and with interface to VDR on RS422 NMEA.

Drawing number: W-1802-00-01

02.05 Rudder angle indicator system

0130 1 pc. Rudder angle indicator amplifier

For mounting inside the console.

Drawing number: W-2010-00-01

0140 1 pc. Rudder angle indicator, 144x144 (IP22)

For desk mounting in forward bridge console.

Drawing number: W-1430-00-07

0150 1 pc. Panorama rudder angle indicator, Ø370 (3-face) (IP22)

With dimmer for overhead mounting in the wheelhouse.

Drawing number: W-1430-00-05

0160 2 pcs. Indoor rudder angle indicator, 144x144 (IP22)

For desk mounting in bridge wing console.

Drawing number: W-1430-00-15

This document is the property of Rolls-Royce and may not be redistributed or reproduced in any way, without the written permission of Rolls-Royce.

Failure to do so is a violation of copyright laws.

Tech.spec. 12S000638 (Master rev. 03.2010-03-17) generated: 23/05/2012

Page 8 of 9

02.06 Spare parts and special tools pr. ship set.

0170 1 set Standard spare parts

Set of Standard Spare parts.

0190 1 pc. Mounting tools

Complete set of hydraulic mounting tools, including hydraulic pump, two (2) injector

pumps, hose, fittings, gauge and wrench for the hydraulic coupling.

Drawing number: A-9803

1 set Manuals

- 2 Printed mechanical user manuals in English language.

- 2 Printed electrical user manuals in English language.

- 2 Printed mechanical installation manuals in English language.

- 2 Printed electrical installation manuals in English language.

- 1 CD with English user/installation manuals.

Piping diagram: A-8798

Cable diagram: 0003-2550

This document is the property of Rolls-Royce and may not be redistributed or reproduced in any way, without the written permission of Rolls-Royce.

Failure to do so is a violation of copyright laws.

Tech.spec. 12S000638 (Master rev. 03.2010-03-17) generated: 23/05/2012

Page 9 of 9

APPENDIX A - TECHNICAL DATA SPECIFICATION

Revision A

Rolls-Royce Steering Gear

TYPE SR722 FCP

Steering gear

Type SR722 FCP

Shipyard Shipkits B.V.

Hull No. SK120

Rudder Actuator:

Type SR722

Max. working pressure 125 bar

Design pressure 156 bar

Max. torque 275 kNm

Test pressure 234 bar

Rudder stock diameter 320 mm

Rudder angle electrical 2x35 / 2x65° electrical stop

(Rudder angle limitation included)

Rudder angle mechanical 2x72° (approx.)

Manoeuvring time one/two pumps 28/14 seconds (30°- 0 - 35°)

Setting of relief valves 156 bar

Hydraulic Oil Shrink Coupling:

Rudder stock diameter Ø 320 g7

Sleeve diameter Ø 320 E8

Pull-up lenght 28 mm

Max allowed injection pressure 1305 bar

Max allowed mounting pressure 417 bar

Pump unit:

Make Rolls-Royce

Type FCP-44

Pressure pump type Sauer Danfoss SNM3-44

Setting of relief valves 125 bar

Testing pressure 188 bar

This document is the property of Rolls-Royce and may not be redistributed or reproduced in any way, without the written permission of Rolls-

Royce. Failure to do so is a violation of copyright laws.

0003-2421 (Master rev. 02.2011-07-02) generated: 11.07.2012

Page 1 of 2

Electric motor:

Type NORM IEC 160MLB - 4

Speed 1465 r.p.m.

Rating output 15,00 kW (S1)

Voltage 3x380 V, 50Hz

Protection class IP55

Insolation class F

This document is the property of Rolls-Royce and may not be redistributed or reproduced in any way, without the written permission of Rolls-

Royce. Failure to do so is a violation of copyright laws.

0003-2421 (Master rev. 02.2011-07-02) generated: 11.07.2012

Page 2 of 2

INSTALLATION MANUAL

Rolls-Royce Steering Gear SR

Mechanical and hydraulic system

Type:

Yard and hull no. :Shipkits B.V. : SK120

Project no. :12S000638

Date 24. August 2012

Page 2 of 55 Installation Manual Rolls-Royce Steering Gear

TABLE OF CONTENTS

1 INTRODUCTION ...................................................................................... 5

1.1 Purpose .............................................................................................................................5

1.2 Warranty ............................................................................................................................5

1.3 Structure of this manual ....................................................................................................5

1.4 Abbreviations .....................................................................................................................6

2 SAFETY ................................................................................................... 7

2.1 General statement .............................................................................................................7

2.2 Safety Annotations ............................................................................................................8

2.3 Declaration of conformity...................................................................................................8

3 SYSTEM DESCRIPTION ......................................................................... 9

3.1 System overview ...............................................................................................................9

3.2 Design .............................................................................................................................11

3.2.1 Rudder actuator ...............................................................................................................12

3.2.2 Pump unit ........................................................................................................................13

3.2.3 Cylindrical rudderstock connection..................................................................................13

3.2.4 Valve block ......................................................................................................................14

3.2.5 Rudder stock ...................................................................................................................15

3.2.6 Feed back units ...............................................................................................................15

3.2.7 Exspansion tank ..............................................................................................................16

3.3 Function ...........................................................................................................................17

4 DELIVERY SPECIFICATIONS............................................................... 18

5 TECHNICAL DATA ................................................................................ 19

5.1 Steering gear, SR-series .................................................................................................19

5.2 Oil recommendations ......................................................................................................20

5.2.1 System oil volume ...........................................................................................................21

5.3 Standard painting specifications......................................................................................22

6 HANDLING AND PRESERVATION ....................................................... 23

6.1 Delivery check .................................................................................................................23

6.2 Storage ............................................................................................................................23

7 INSTALLATION ..................................................................................... 24

7.1 Installation overview ........................................................................................................25

7.2 Lifting ...............................................................................................................................26

7.3 Installation of Steering gear.............................................................................................27

7.3.1 Filling of oil / “Pulling up” .................................................................................................30

7.4 Installation of expansion tank ..........................................................................................34

7.5 Piping instructions ...........................................................................................................35

7.6 De-airing ..........................................................................................................................37

7.7 Dismantling and re-installation (hydraulic coupling) ........................................................38

8 COMMISSIONING .................................................................................. 41

8.1 Precautions before start-up .............................................................................................41

8.2 Activities performed by the shipyard personnel ..............................................................42

Rolls-Royce Steering Gear Installation Manual Page 3 of 55

9 CONTACT LIST .....................................................................................43

10 FINAL INSPECTION AND TEST PROCEDURE....................................47

10.1 Function test.................................................................................................................... 47

10.2 Harbor acceptance test ................................................................................................... 47

10.3 Sea acceptance test ....................................................................................................... 52

11 TOOLS ...................................................................................................53

12 DESIGN DRAWINGS .............................................................................54

12.1 Mechanical ...................................................................................................................... 54

12.2 Hydraulic ......................................................................................................................... 54

13 REVISION ..............................................................................................55

Page 4 of 55 Installation Manual Rolls-Royce Steering Gear

1 INTRODUCTION

1.1 Purpose

The Installation manual provides the information necessary to plan and install the delivered

system safely and correctly. It also enables you to verify the functionality of the equipment.

Also included are instructions for handling of the goods after they have been received at the yard.

It is important that the instructions be followed carefully to avoid problems during outfitting and

commissioning. This manual also provides instructions for all activities essential for

commissioning.

1.2 Warranty

The product has a limited warranty. Please note that the warranty will be void if the equipment is

misused or not handled in accordance to prescribed standards, for example dismantling the

equipment to a level greater than described.

1.3 Structure of this manual

The first part of this manual describes the Rolls-Royce Steering gear. This helps in understanding

the maintenance procedures in the subsequent chapters.

Chapter 3 and 4 provide project specific information.

Chapter 5 provides technical data.

Chapter 7 includes all installation procedures.

Chapter 8 and 10 provide all information related to commissioning and sea trial.

Note!

A separate user manual is available, and may be ordered specifically from Rolls-Royce Marine as

required.

Note!

All pictures used in this manual are for illustration only.

Rolls-Royce Steering Gear Installation Manual Page 5 of 55

1.4 Abbreviations

Abbreviation Description

ºC Centigrade

cSt Centistokes (oil viscosity)

CCW Counter Clock Wise

CW Clockwise

DP Dynamic Position

E0 General alarm

EP-additives Extreme Pressure additives

FCP Frequency Controlled Pumps

Follow-Up. Rudder moves to the rudder angel set by

FU

the operator,(Analog steering signal)

Hz Hertz (frequency)

Kg Kilogram (weight)

kW Kilowatt (power)

l/min Liters per minute (flow)

mm Millimeters (lengths and diameters)

Non-Follow-Up. Time dependent steering. Rudder

NFU moves as long as the operator activates the steering

lever. (on/off steering signal).

RPM Revolutions Per Minute (rotation speed)

SV Spherical Vane

V Volt (voltage)

WSC Welding Sequence Chart

Page 6 of 55 Installation Manual Rolls-Royce Steering Gear

2 SAFETY

Please take the time to read this chapter carefully, as it concerns your safety.

2.1 General statement

"UNDERTAKING ANY WORK ENVISAGED BY THIS DOCUMENT MAY EITHER DIRECTLY OR

INDIRECTLY CREATES RISKS TO:

[1] THE SAFETY AND HEALTH OF THE PERSON UNDERTAKING THE WORK OR,

[2] THE PRODUCT AND/OR ITS COMPONENTS WHILST THE WORK IS BEING

UNDERTAKEN.

IT IS THE RESPONSIBILITY OF THE USER TO ENSURE THAT APPROPRIATE CONTROLS

AND PRECAUTIONS ARE IDENTIFIED AND APPLIED IN RELATION TO THE WORK

ENVISAGED BY THIS DOCUMENT IN ACCORDANCE WITH RELEVANT STATUTORY, LEGAL

AND INDUSTRY REQUIREMENTS TO PROTECT THE HEALTH AND SAFETY OF THE

PERSONS UNDERTAKING THE WORK.

IT IS ALSO THE USER’S RESPONSIBILITY TO ENSURE THAT APPROPRIATE CONTROLS

AND PRECAUTIONS ARE IDENTIFIED AND APPLIED IN RELATION TO WORK ENVISAGED

BY THIS DOCUMENT TO PROTECT AGAINST RISKS TO THE ROLLS-ROYCE STEERING

GEAR AND/OR ITS COMPONENTS WHILST THE WORK IS BEING UNDERTAKEN.

NEITHER THIS DOCUMENT, NOR ITS USE, IN ANY WAY ABSOLVES THE USER FROM

THEIR RESPONSIBILITY TO ENSURE THAT THE CONTROLS AND PRECAUTION

REFERRED TO ABOVE ARE IMPLEMENTED.

IF, WHILST UNDERTAKING ANY WORK ENVISAGED BY THIS DOCUMENT, YOU BECOME

AWARE OF ANY ROLLS-ROYCE MARINE PRODUCT DESIGN RELATED FEATURE WHICH

COULD CREATE RISK TO A PERSON UNDERTAKING WORK OR TO THE PRODUCT

AND/OR ITS COMPONENTS PLEASE CONTACT THE RESPECTIVE TECHNICAL PRODUCT

MANAGER AT ROLLS-ROYCE MARINE AS IMMEDIATELY."

Rolls-Royce Steering Gear Installation Manual Page 7 of 55

2.2 Safety Annotations

All safety directions must be respected in order to avoid damage to personnel, environment and

equipment. In this user manual the following annotations are used with belonging signification:

Warning

Indicates possibilities for hazards or unsafe practices, which COULD result in fatal

or severe personnel injuries or substantial product or property damage, if the

required precautions are not taken.

CAUTION!

CAUTION indicates possibilities for hazards or unsafe practices, which COULD result in minor

personnel injuries and/or property damage, if the required precautions are not taken.

Note!

Note draws attention to specific information of technical significance which might not be obvious

to specialist personnel, or points at important remarks in the procedures to follow.

2.3 Declaration of conformity

Rolls-Royce Steering Gears are designed and built as per the following standards according

existing requirements from:

IMO

SOLAS

The Steering gears are also designed according to requirements by the following classification

societies:

Det Norske Veritas (DNV).

American Bureau of Shipping (ABS).

Lloyds Register (LR).

Germanisher Lloyds (GL).

Bureau Veritas (BV).

RINA

ClassNK (Nippon Kaiji Kyokai)

China Classification Society (CCS)

Russian Maritime Register of Shipping (RS)

Korean Register of Shipping (KR)

A Class Certificate is issued for each Steering gear in accordance with the Class of the vessel.

Page 8 of 55 Installation Manual Rolls-Royce Steering Gear

3 SYSTEM DESCRIPTION

The purpose of this section is to give a better understanding of the different parts of the Steering

gear and to ensure safe and efficient operations.

3.1 System overview

The Rolls Royce Steering gear, SR- FCP; is a slow running hydraulic motor with high torque.

Rolls-Royce Steering Gear Installation Manual Page 9 of 55

The complete Steering gear is normally integrated with two frequency controlled reversible pump

units, valve block and electrical feed back units. The Steering gear has a very compact design,

which minimizes the pipe work during installation at yard.

Compared with a conventional steering gear system where the pump is continuously running and

oil is controlled by a maneuvering valve, the FCP-system works quite different. The normal

situation for FCP is that pump/electric motor not is running. This means that the pump/electric

motor starts when a rudder command signal is given and stops when the rudder has reached the

desired position. The advantages will be lower running time, less energy consumption, less noise,

lower temperature, less wear, a cleaner system and a longer lifetime.

The motor controller (frequency converter) for the electric motor

on each pump unit has separate and independent supply from

the switch boards. The two systems are therefore both

hydraulically and electrically separate and independent. A fault in

one system will therefore not interfere with the operation of the

other unit. As illustrated in the picture.

The steering gear is also equipped with a unique vane sealing

design. The sealings are arranged in a manner that allows them

to absorb spherical movement. The Steering gear absorbs all

radial and axial forces from the rudder.

Page 10 of 55 Installation Manual Rolls-Royce Steering Gear

3.2 Design

The Rolls-Royce Steering Gear SR - FCP design is based on long experience. The unique

spherical design with cylindrical rudderstock is patented in most of the world.

The Steering gear consists of five main parts; rudder actuator [1] pump unit [2], cylindrical

rudderstock connection [3], valve block [4], and rudder stock [5]. Additionally the system consists

of feed back units and expansion tank, if installed, emergency wheel pump.

Pos. Component Chapter

1 Rudder actuator 3.2.1

2 Pump unit 3.2.2

3 Cylindrical rudderstock connection 3.2.3

4 Valve block 3.2.4

5 Rudder stock 3.2.5

(6) Feed back units 3.2.6

(7) Expansion tank 3.2.7

(8) Emergency wheel pump 3.2.8

Rolls-Royce Steering Gear Installation Manual Page 11 of 55

3.2.1 Rudder actuator

The Rudder actuator consists mainly of:

[1] = Rotor,

[2] = Ring shaped cylinder with vanes and dividing walls

fastened to the rotor,

[3] = Housing (upper and lower),

[5] = ”U” seal on each piston,

[6] = Spherical bearings situated on the rotor.

The vanes work in a ring shaped cylinder with the rudder

stock as the centre. The pistons [2] are fastened to the

rotor in a manner; witch allows them to absorb and adjust

to the spherical deflection of the rotor due to misalignment

in installation or deflection of the rudder stock.

The housing [3] is a cast cylinder with oil channels [4] leading the oil to the different

chambers. The upper and lower housing parts are connected with several bolts.

The synthetic bearing pads maintain 100% surface contact

at all times even as the rudder stock flexes. It will also

absorb and suppress vibrations and shock pulses. The

bearing surface is continuously lubricated by the hydraulic

oil, which ensures long lifetime of the bearings.

The rudder actuator can be delivered with two or three

pistons, which give different rudder angles and developed

torque. The unit develops a constant torque over the full

rudder angle.

Page 12 of 55 Installation Manual Rolls-Royce Steering Gear

3.2.2 Pump unit

The motor [2] for each pump unit starts when a rudder

command signal is given and stops when the rudder has

reached the desired position. The power for operating

control and steering systems are both hydraulically and

electrically separated and independent.

The power pump units consist of four main parts:

[1] = Reversible pump,

[2] = Electric motor,

[3] = Bell house,

[4] = Flexible coupling.

When both pump units are running the ship will achieve 100% speed condition in proportion to

the size of the pump units. The most common pump is the gear wheel pump. Some pump models

have extra accessories.

3.2.3 Cylindrical rudderstock connection

Rolls-Royce Steering Gear Installation Manual Page 13 of 55

The rudder stock connection is based on hydraulic sleeve coupling by use of an intermediate

sleeve between the steering gear rotor and the rudder stock.

The design provides the obvious advantage that the rudder stock is cylindrical, parallel,

through the coupling without keyway, threads or taper complicating the production. The main

advantage with this principle is that there is only one producer of the two conical parts; rotor

bore and sleeve outer surface.

The coupling consists of the following main components:

[1] = Mounting piston,

[2] = Seal ring,

[3] = Rotor,

[4] = Tapered sleeve,

[5] = Rudderstock,

[6] = O-ring.

3.2.4 Valve block

The integrated valve block with filter units has fewer and less complex valves due to the

reversible pumps.The distributing valve housing is flanged to the housing of the Steering gear

and contains:

Non-return valves,

Load sense valves,

Solenoid operated isolating valves,

Relief valves,

Return filters unit.

The relief valves are adjusted at the factory to the design pressure stated in the technical

information.

Page 14 of 55 Installation Manual Rolls-Royce Steering Gear

3.2.5 Rudder stock

The cylindrical rudder stock simplifies the manufacturing

and eliminates the blue fit tests and allows for rudder stock

height adjustment.

Accurate length of rudder stock is not required.

3.2.6 Feed back units

The Steering gear is equipped with two separate feed

back units, one for each system. The feed back unit

contains:

Transmitter for the rudder indicating system

Switches for limitation of the rudder travel

Transmitter for the control system.

The unit is factory fitted to a bracket flanged to the top of

the actuator. The drive for the feedback unit is provided as

a chain/belt drive to the rotor. The chain/belt is pre-

tensioned by a spring to eliminate play.

The drive shaft follows the turning of the rudder stock and

transfer the movement to the potentiometers and the

tripping releaser for the limit switches.

The potentiometers can be single, double or triple

depending on the installation. The tripping cams are

adjusted to interrupt the steering signal about 2 degrees

before the rotor reaches mechanical stop.

Rolls-Royce Steering Gear Installation Manual Page 15 of 55

3.2.7 Exspansion tank

The expansion tank must be installed according to

specifications by Rolls-Royce Marine.

The expansion tank contains gauge glasses indicating

minimum and maximum level during normal operation of

the Steering gear, and two electrical level switches

monitoring the oil level.

The expansion tank comes in three different sizes, 25, 60

or 120 liters. The 60 and 120 liters expansions tanks are

equipped with two extra plugs for use if the pump unit is

fitted with accessories.

The lower section of the expansion tank is divided internally into two separate sections by a

dividing wall. This is to prevent both pump units from losing oil, in case there is a leakage

from the unit or corresponding piping. The volume of the upper section is common for the

total hydraulic system. In case of leakage from one of the pump units the other pump can

continue operating without interruption.

Apart from the cocks for connecting the expansion pipes, the expansion tank also contains

connections for storage tank, drain plug, inspection cover with filler cap, strainer and air filter.

Page 16 of 55 Installation Manual Rolls-Royce Steering Gear

3.3 Function

The ring shaped cylinder is divided into chambers by dividing walls. The rudder command signal

controls the maneuvering pump and directs the oil flow to the chambers of the rotor. The rotor

will then turn in the direction corresponding to the control signal. When the ordered position is

reached, the maneuvering pump will stop and a hydraulic blocking valve will lock the position of

the rudder.

The built-in blocking spools in the maneuvering valve and the wheel pump automatically lock

the rudder in any desired position. They also prevent outside forces from being transferred to

the wheel pump.

If follow-up steering (analogue steering) is installed, the steering lever is turned to the desired

rudder angle; the rudder will then travel until the selected angle is reached. The steering system

can be supplied to accept either analogue or on/off command signal from the autopilot, joysticks

or dynamic positioning system.

Rolls-Royce Steering Gear Installation Manual Page 17 of 55

4 DELIVERY SPECIFICATIONS

Please refer to Technical Specification.

Page 18 of 55 Installation Manual Rolls-Royce Steering Gear

5 TECHNICAL DATA

This chapter contains technical data, and similar relevant information.

5.1 Steering gear, SR-series

Model Number of Max working Max mechanical Weight approx

Vanes torque [kNm] rudder angel [kg]

SR 562 2 40 2 x 61 o 450

o

SR 622 2 70 2 x 72 800

SR 642 2 110 2 x 72 o 1200

o

SR 662 2 170 2 x 72 1800

SR 722 2 275 2 x 72 o 2750

o

SR 723 3 412 2 x 44 2800

o

SR 742 2 433 2 x 74 3700

o

SR 743 3 650 2 x 44 3800

Rolls-Royce Steering Gear Installation Manual Page 19 of 55

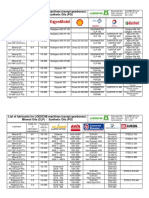

5.2 Oil recommendations

. Warning

Using oil other than specified by Rolls-Royce Marine may cause

malfunctions when manoeuvring the vessel. This may cause personal

injury and equipment damage.

Before using other brands, please contact Rolls-Royce Marine.

Note!

The oil is one of the main components in a hydraulic steering gear, and must therefore be

selected and handled with this in mind. The performance of the unit is highly depended on the

viscosity of the oil. The surrounding temperatures of the hydraulic components when operating at

extreme temperature conditions, tropic or arctic waters, shall be taken into account when

selecting type of oil.

General requirement to the hydraulic fluids used on Rolls Royce Steering Gear should meet DIN

51524.

The viscosity index improve must not be broken down and effect flow and lubrication

properties

Pour point should be below -30o centigrade.

The oil must contain the following additives.

Performance qualities:

a. Anti-wear properties

b. Water and foaming resistance

The following hydraulic oils are approved and recommended by Rolls Royce marine

Manufacturer Type

AGIP AGIP ARNICA 32

BEVEROL HV-ISO32

BP BARTRAN HV32

CALTEX RANDO HDZ32

CASTROL HYSPIN AWH-M 32

CENTURY NEVIS 7

CEPSA CEPSA HV 32

CHEVRON RANDO HDZ32

SHELL TELLUS T32

STATOIL HYDRAWAY HVXA 32

TEXACO RANDO HD Z32

Page 20 of 55 Installation Manual Rolls-Royce Steering Gear

Manufacturer Type

YUKONG ZIC SUPERVIS X32

EXXON MOBIL DTE10 EXCEL 32

NYNÄS HYDOL 32

ESSO (Exxon) UNIVIS N 32

HISPANO

HYDRO DRIVE HP150

QUIMICA, S.A

LUB MARINE

VISGA 32

(TOTAL)

MOBIL SYNTHETIC MOBIL SHC 524

CAUTION!

Do not mix hydraulic oil with other types of oil. Even very small amounts of other oil in the

hydraulic oil, will considerably lower the quality of these oils.

Change the oil when laboratory tests show:

High neutralizing number

Low remaining amount of EP-additives

High amounts of insoluble particles in the oil

Oil cleanliness no longer is within 17/14 or better according to ISO standard 4406, class 8 or

better according to NAS 1638

If components of the hydraulic system have been broken down.

5.2.1 System oil volume

Model Oil volume

SR 562 Approx 35 litre

SR 622 Approx 45 litre

SR 642 Approx 50 litre

SR 662 Approx 65 litre

SR 722 Approx 125 litre

SR 723 Approx 120 litre

SR 742 Approx 160 litre

SR 743 Approx 150 litre

Rolls-Royce Steering Gear Installation Manual Page 21 of 55

5.3 Standard painting specifications

The paint coating offers protection against corrosion under normal transportation, storage,

and outfitting periods.

The yard carries out the final treatment according to the total painting system for the ship.

Paint and color according to RRCM standard, if not other specified.

Preparation before coating must adhere to the following specifications:

Specification Applies to

ISO 8501-1 Surface preparation.

ISO-8503—1 Steel roughness. (Medium (G) Ry 50-80 micron.)

ISO 8502-3 Dust-free testing before painting

ISO 8502-4 Climatic conditions during painting

Page 22 of 55 Installation Manual Rolls-Royce Steering Gear

6 HANDLING AND PRESERVATION

6.1 Delivery check

Immediately upon arrival, the equipment must be unpacked and inspected. If there are any

complaints, you must inform Rolls-Royce Marine as soon as possible.

During the testing before delivery, the unit has been filled with hydraulic oil.

The oil should meet the requirements stated in chapter 5.1. In chapter 5 you can also find the

volume of oil.

6.2 Storage

The equipment is packed and conserved for shipment and storage for 6 months - unless

otherwise agreed in writing. Storage days are counted as delivery date to first start-up.

During storage, it is important to protect the equipment against corrosion as well as moisture and

dust.

At the shipyard, store all goods indoors. Temporary built shelters with good ventilation can be

used for some heavy components. Dust free environment is necessary for storing electrical

equipment. However, assembled machinery and electric motors must be stored in an area

without ground excitation.

Immediately after installation, the hydraulic system and Steering gear has to be filled with oil.

All openings and pipes are to be sealed off at all times. Fill the pipes with oil to inhibit rust.

Preferably use oil specified by Rolls-Royce Marine.

The Steering gear must be rotated at intervals if installed or stored in an area close to working

machinery which causes ground excitations.

Electronic equipment should be protected from excessive dust and humidity.

Rolls-Royce Steering Gear Installation Manual Page 23 of 55

7 INSTALLATION

Note!

Note!

It is highly recommended to read this entire chapter before starting any installation work.

Warning

Never work alone when installing heavy components, even when using

secure lifting equipment such as lockable block and tackle. Most lifting

devices require two people, one to operate the lifting device and another

to ensure that the components do not get caught and damaged.

Using hydraulic oil other than that specified in this manual may cause

malfunctions when manoeuvring the Steering gear. This may cause

injuries to the personnel and damage to equipment.

Always wear protective goggles if there is a risk of splinters, grinding

sparks and splashes from acids or other chemicals. Eyes are extremely

sensitive and an injury to them can result in loss of sight.

CAUTION!

Each Steering gear has its own serial number stamped on; the sign is fastened to the upper

housing. The hydraulic coupling; sleeve and mounting piston, corresponding to the actual

Steering gear are stamped with the same serial number.

For twin installations it is important that the correct hydraulic coupling is connected to the

correct Steering gear. (The sleeve has its serial no. in the lower end, and the mounting piston

on top).

The upper cylindrical part of the rudderstock has to be checked for correct diameter and

tolerance G7. The hydraulic coupling; sleeve and mounting piston, is supplied in a separate

box during consignment. The covers covering the Steering gear rotor bore must be removed.

The parts have to be handled with great care to avoid any damage. All scores and marks

have to be removed carefully by polishing. Without being able to maintain a sufficient oil film,

the sleeve and rotor will come in contact when the sleeve is driven up by the mounting pump.

This may cause scuffing of the surfaces and the coupling will get stuck before the prescribed

pull up length is obtained.

Note!

Page 24 of 55 Installation Manual Rolls-Royce Steering Gear

7.1 Installation overview

Component Seq. Procedure Tools Reference Cha.

1 Lifting Lifting equipment 7.2

2 Installation of Mounting piston “Dimension drawing” 7.3

Steering gear Wrench “Appendix A”

with locking ring

Measuring clock “Foundation drawing”

assemblies (if

applicable)

3 Installation of Chain tackles. “Dimension drawing” 7.3

Steering gear Mounting piston “Appendix A”

with hydraulic Wrench “Foundation drawing”

coupling (if

Support wedges

applicable)

4 Filling of oil / Mounting pump 7.3.1

“pulling – up” Injector pump

Wrench

5 Installation of “Dimension drawing” 7.4

Steering exspansion tank “Piping diagram”

Gear

6 Piping Bending machine “Piping diagram” 7.5

instructions Wrench

7 De-airing “Assembly drawing” 7.6

“Piping diagram”

8 Dismantling and Chain tackles “Dimension drawing” 7.7

re-installation of Mounting pump “Appendix A”

Steering gear Injector pump “Foundation drawing”

with locking ring

Wrench

assemblies (if

applicable)

9 Dismantling and Chain tackles “Dimension drawing” 7.7

re-installation of Mounting piston “Appendix A”

Steering gear

Wrench “Foundation drawing”

with hydraulic

coupling (if Measuring clock

applicable)

Rolls-Royce Steering Gear Installation Manual Page 25 of 55

7.2 Lifting

Spare parts Ref. no Special tools and test Qty

equipment

Lifting equipment

Reference documents Consumables Qty

The actual Steering gear unit is delivered in one part. The mounting piston and sleeve coupling

are delivered as separate parts. For weights see Chapter 5.1.

Use the three lifting eyebolts [1] on top of the mounting piston,

as illustrated in the picture to the right.

Use the four lifting eyebolts[2] fitted on the Steering gear

housing as shown in the picture to the right

Note!

Lifting equipment is the ship yard`s responsibility.

Page 26 of 55 Installation Manual Rolls-Royce Steering Gear

7.3 Installation of Steering gear

Spare parts Ref. no Special tools and test Qty

equipment

Mounting piston tool 1

Support wedges As req.

Reference documents Consumables Qty

“Dimension drawing”

“Appendix A“

Pos Description

1 Mounting piston (nut)

2 Sleeve coupling

3 Support wedge

Rolls-Royce Steering Gear Installation Manual Page 27 of 55

Pos Description

4 O-ring

(5) Spacer

(6) Adjusting screws

(7) Bolts

Note!

The rudderstock has to be locked and secured by chain tackles outside the hull at the correct

level and alignment.

1. The sleeve, mounting piston, rotor bore and rudderstock has to be thoroughly cleaned,

de-greased and inspected carefully.

2. The rudder stock can be wetted by marine diesel oil to simplify lowering of the sleeve.

CAUTION!

Do never use any lubricant other than marine diesel oil between the sleeve and rudderstock,

as this may cause the coupling to slip

3. After thoroughly inspection, lubricate the outside of the sleeve with oil.

4. Fit the mounting piston [1] to the sleeve [2] and lift the

assembly by the eyebolts in the bores provided in the

mounting piston.

5. Enter the sleeve [2] over the rudderstock. Lower it

carefully until the lower end of the sleeve is approx

150 mm below top of foundation.

Page 28 of 55 Installation Manual Rolls-Royce Steering Gear

6. Support the sleeve [2] by using support wedges [3] to

the rudderstock

7. Remove the mounting piston

8. Lubricate rotor bore with oil.

9. Centre the actuator, hanging in chain tackles over the

rudderstock, as accurate as possible. Check that

alignments of rudderstock and rotor centre line is as

close as possible

10. Lower the actuator carefully over the rudderstock until

it sits lightly on the sleeve`s cone. Do not allow the

actuator to sit on the sleeve by its full weight.

11. The seal between the mounting piston [1] and sleeve

[2] is provided by an o-ring [4] in the groove on top of

the sleeve.

12. Ensure that the o-ring [4] is in good condition prior to

installation.

13. Lubricate threads on sleeve [2] and mounting piston

[1] by Moly Coat (MoS2).

14. Fit the o-ring [4] into the groove in sleeve [2] upper end.

15. Lower the mounting piston [1] and turn it carefully tight against the sleeve, using the

wrench provided for the purpose, and knock it tight lightly using a hammer.

The steering gear must remain hanging in the tackles during the further procedure.

16. Lift the Steering gear just a little to remove the supporting wedges.

17. Check that the level of the rudderstock is correct and adjust level of actuator in order to

obtain clearance between foundation and bedplate equal to height of spacers plus “pull-

up” length.

Rolls-Royce Steering Gear Installation Manual Page 29 of 55

7.3.1 Filling of oil / “Pulling up”

Spare parts Ref. no Special tools and test Qty

equipment

High pressure pipe 2

Injector pump 2

Mounting pump 1

Adapter block 2

Reference documents Consumables Qty

Note!

The mounting pump and the injector pump shall use the same oil. The oil provides lubrication

of the outside of the sleeve during pull-up and lowering.

Recommended viscosity is about 300 cst at 20°C at normal tempered conditions. Working at

lower temperatures, the oil should be tempered or use thinner oil (100 cst at 50°C). Low

viscosity oil will spread easier over the contact surfaces between rotor and sleeve. This is of

vital importance both during assembly and dismantling of the coupling.The oil type and

viscosity used must follow the Rolls-Royce Marine instructions.

1. Fill the injector pump [1] and the mounting pump [2] with

the prescribed oil.

Note!

The oil type and viscosity used must follow the Rolls-Royce

Marine instructions.

2. Connect the injectors to the Steering gear. Connect the injector pump [1] to the rotor, and

mounting pump [2] to the mounting piston, by the extension high-pressure pipe/hoses [3].

The rotor is locked mechanically in zero-position by transport brackets consignment and

assembly. This is to keep the rotor in place until the hydraulic coupling is fitted.

3. Build up the oil film between the sleeve and rotor by operating the injectors [1] and [2]. Start

to operate the mounting pump and injector simultaneously and slowly.

Page 30 of 55 Installation Manual Rolls-Royce Steering Gear

4. Find and mark the reference height, “zero-point”, when the

sleeve is tight against the rudderstock.

5. Move / rotate the Steering gear forward and backward a

little during the pulling.

Correct “zero-point” is when the actuator is tight (fixed) and the

injector pressure is drained.

6. At this point the distance between base of the Steering

gear (base of eye bolt foundation) and top of foundation

should be the actual “pull-up” plus the thickness of chock

fast / spacer. As illustrated in the picture.

7. Start to operate the mounting pump and injector pump

simultaneously and slowly. The chain must be lowered

simultaneously during “pull up”.

CAUTION!

If the sleeve enters in steps, i.e. jumping, when the mounting pump is operated, this indicates

that the oil film between the sleeve and rotor is not sufficient. This may cause scuffing of the

surface. Stop operating the mounting pump while operating the injector to restore the oil film

before continuing operating the mounting pump. The travel of the sleeve must be smooth and

even.

Note!

An increase of pressures will be noticed on both pumps during the “pulling” and is monitored

by the pressure gauges equipped.

When the actual “pull-up” length is reached, the operation has to be stopped and injection

pressure must be drained.

8. Mark the position of mounting piston below the zero point for further reference. The drive-

up/pull-up length will differ from one coupling to another depending on the rudder stock

diameter and classification requirement.

CAUTION!

Rolls-Royce Steering Gear Installation Manual Page 31 of 55

Do not exceed the required drive-up/pull-up as this may deform the coupling.

9. Remove the pipe / hoses and plug all connecting points not in use.

10. Remove transport brackets [5] and adjust level and

alignment of actuator by the adjusting screws [6] on the

foundation brackets - according to tolerances as described

in step 10 below.

11. Fit a ruler [4] on top of the rotor. Use a micrometer to

monitor relative vertical movement between the top edge of

the rotor and the mounting piston, as illustrated on the

picture. Maximum divergence should be within +/- 0, 25.

12. Monitor movement to front, sides and rear as illustrated in

the picture.

13. Check alignment of rudder stock lower bearings and neck bearing, to centre the actuator on

the foundation.

Note!

Do not apply turning force on housing, as this may disturb the zero angel position of the rotor.

14. Use a rag over the by-pass screw for protection. Remain the mounting pressure for half an

hour and re-check the “pull-up” distance. Bleed the pressure and re-check the distance

Page 32 of 55 Installation Manual Rolls-Royce Steering Gear

15. Re-check alignment of housing and weld side stoppers to foundation and fit wedges. Spot-

weld.

16. Adjust steel spacers if steel are intended.

17. Disconnect pressure pipes between the hydraulic pump and valve block, and plug all

connections by blend plugs.

18. Loosen and remove the electric motor.

19. Drill and ream for foundation bolts.

20. Fit foundation bolts [8], and nuts [7] to correct torque. Nuts

to be locked by counter nuts.

Note!

If epoxy resin is intended follow producers/manufacturers

procedure.

CAUTION!

Neither load nor torque should be applied to the coupling within 24 hours after assembly. The

bores for the injector pump and mounting pump have to remain open in order to evacuate the oil

film and thus obtain the required friction between the surfaces.

21. After the installation of Steering gear is completed, some classification authorities

recommend that two alignment marks should be stamped, one on the rudderstock and one

on the rotor eventually on the housing. This to easier observe if the connection should slide

a bit. (If the rudder for instance has touched the sea floor).

22. Refit the electric motors and connect all pipes correctly.

23. Perform the de-airing procedure as described in chapter 7.7.

Rolls-Royce Steering Gear Installation Manual Page 33 of 55

7.4 Installation of expansion tank

Spare parts Ref. no Special tools and test equipment Qty

Reference documents Page Consumables Qty

”Dimension drawing”

1. The expansion tank is to be fitted on a vertical bulkhead

as close to the Steering gear as practically possible.

2. Install the expansion tank 0-2m above the top of the

Steering gear.

3. Connect the expansion tank by separate pipes to each

pump unit and one to the Steering gear.

4. The filter [1] and filler cap [1] situated on top of the

expansion tank must be easy accessible for oil filling.

5. Connect the fixed storage tank [5] for hydraulic oil to the

connection [2] provided on the side wall of the

expansion tank. The expansion tank is always to be

connected to a storage tank, normally located below the

expansion tank. On the pipe line between the two tanks

there is a manual pump [6].

6. Test the oil level alarm [3] by removing the two fixing

bolts and lifting it out of the oil.

CAUTION!

The cocks [4] flanged to the bottom of the tank must be easy

accessible for operation in case of emergency.

Page 34 of 55 Installation Manual Rolls-Royce Steering Gear

7.5 Piping instructions

Spare parts Ref. no Special tools and test equipment Qty

Bending machine 1

Reference documents Consumables Qty

”Piping diagram”

Note!

The components have nut and cone ring fittings according to DIN 2353 or welding flanges.

If welded pipes are to be used, the following procedure is to be followed:

1. Thoroughly clean and pickle the welded pipes in 20% sulpheric acid for at least 4 hours.

2. Flush thoroughly with water, and then fill with hot solution of sodium carbonate. Leave the

solution for 1 hour.

3. Flush the pipes once more with hot water, and then dry the inside of the pipes.

4. Cover inside surface pipe surface with oil

When laying pipes, the following guidelines are to be followed:

5. Clean pipe ends well after the pipe has been cut at right angles.

6. Remove any burrs

7. Lubricate the fitting with oil before the nut and cone ring is pushed on to the pipe.

8. Press the end of the pipe hard into the fitting to get the pipe into the right position.

9. Tighten the nut so that the cone ring cuts into the correct position.

10. Tighten the nut so that the cone ring cuts into the pipe, and tighten a further 1-1, 5 turns.

11. Undo the nut and check that the cone ring has cut properly into the pipe. Re-tighten the nut.

Rolls-Royce Steering Gear Installation Manual Page 35 of 55

Note!

Cleanliness during installation is essential.

All pipes must be thoroughly cleaned for swarf, dust, welding slag etc. before fitting to ensure

safe and trouble free operation of the unit.

All pipes must be well shaped and installed with only the minimum of bends.

To adjust pipe dimensions to national standards, it may be necessary to use caliper pipes to

enter the pipe couplings provided on the components.

Approved welding flanges are recommended for large pipe diameters.

All pipes should be laid with an incline to ease de-airing of the system.

Avoid air pockets, where this is not possible; install de-airing plugs at the highest points.

Do not use filler material and heat when bending pipes, but bend in cold condition using

suitable tube bending equipment.

Page 36 of 55 Installation Manual Rolls-Royce Steering Gear

7.6 De-airing

Spare parts Ref. no Special tools and test equipment Qty

Wrench

Reference documents Page Consumables Qty

”Assembly drawing”

”Piping diagram”

Warning

Never operate the Steering gear too hard over position, or against

mechanical stop when de-airing the unit.

Running against mechanical stop will give full pressure in the system

depending on the setting of the relief valves.

If air is left in the system this may be heard as increasing noise from the

pumps. They must then be stopped to avoid damage.

1. All FCP Steering gears are delivered from factory filled with oil. However, due to piping and

assembling work the pumps and pressure pipes have to be refilled and de-aired after the

installation of the Steering gear is completed.

2. Loosen all pipe connections on the pumps and turn the corresponding cocks on the

expansion tank to open position.

3. When clean oil appears tighten the connection correctly.

4. Check that the power supply from the main switchboard to each motor controller is correct

and each electric motor is connected for the correct supply.

5. Turn the switch on the motor controller to position 3 “local control”. Check that the direction of

the Steering gear is correct by operating the manual emergency push buttons in front of the

motor controller.

6. Start one pump, unscrew starboard de-airing plugs on the Steering gear 2-3 turns and make a

brief manoeuvres to port by operating the emergency push buttons.

Rolls-Royce Steering Gear Installation Manual Page 37 of 55

7.7 Dismantling and re-installation (hydraulic coupling)

Spare parts Ref. no Special tools and test Qty

equipment

High pressure pipe/hose 2

Injector pump 2

Mounting pump 1

Mounting piston tool/ wrench 1

Adapter block 2

Reference documents Consumables Qty

“Dimension drawing”

“Appendix A”

“Foundation drawing”

The principles for dismantling are that the oil injection pump will expand the rotor and build up

an oil film between the rotor bore and the sleeve. When the parts are separated the coupling

sleeve will shut down, driven by the tension and taper until arrested by the mounting piston.

1. Provide arrangement for carrying the weight of the rudderstock and to perform controlled

lowering.

2. Ensure all connecting oil pipes are disconnected.

3. Check that the mounting piston [1] can be loosened on

the sleeve with the wrench [2] provided for the

purpose. If the mounting piston should be found stuck

on the sleeve, it must be checked while the sleeve is

still locked to the shaft. Re - tighten the nut by hand

only.

4. Operate the Steering gear to mid position.

5. Fill up the mounting pump [5] with clean oil

6. Connect the hoses [4] to the bore leading to the

cylinder formed by the mounting piston and the rotor.

7. Fill the mounting piston with oil by using the mounting

pump [5]. This in order to hold the sleeve when free.

Breathing of cylinder can be performed by inserting a

thin feeler gauge pass the seal.

Page 38 of 55 Installation Manual Rolls-Royce Steering Gear

8. Fill up the injector pump [3] with oil and air bleed.

9. Connect the injectors via the enclosed extension high-

pressure houses to the bores on the rotor, leading to

the surface between the sleeve and the rotor. As

illustrated in the picture [6].

10. Further air bleed the injector pump by taking a few

pump strokes, with the by-pass screw open, until air

free oil is flowing from the screw.

11. Build up a pressure of 30 - 40 bars at the mounting pump, and maintain this pressure by

compensating for possible leaks.

12. Operate the injector slowly to spread an oil film between the sleeve and the inside of rotor

surface. If the pump shaft has a spring action, breathe further.

CAUTION!

It takes a certain amount of time to spread the oil film, and a too rapid and inpatient pumping

at this step might damage the coupling. It should be possible to notice a gradually increase of

the required force when operating the injector.

When the oil film is spread, and the rotor is loose, the pressure at the mounting pump might

have a sudden increase from the pre-set pressure of 30 - 40 bars to 150 - 200 bars.

13. Continue to maintain the film by working the injector pump slowly.

14. Lower the coupling sleeve and rudderstock by throttling the by-pass and cock on the

mounting pump.

Note!

The rudderstock will drop free when the sleeve is lowered the original pull up length.

Suitable arrangement has to be provided to avoid damage.

During lowering of the sleeve, the injector has to be worked rapidly as it takes all the

delivery of oil they can give to maintain the oil film when the coupling slides down.

CAUTION!

It is extremely important to maintain the oil film at this stage as contact between the sleeve

and rotor bore may score the surfaces.

15. Operate the injector until the sleeve can be turned on the shaft.

Rolls-Royce Steering Gear Installation Manual Page 39 of 55

Warning

Do never attempt to remove the coupling without the mounting piston

. properly fitted and 30 to 40 bars on the mounting pump. If this is

omitted the sleeve and shaft will shoot off by an acceleration force in

way of 400kN. (Approx. value for rudderstock diameter of 360 mm).

16. Dismantle all piping connected.

17. Dismantle the foundation bolts and welded side chocks.

18. Lift the Steering gear free from the foundation by the

eye bolts.

19. Lift the sleeve of the rudder stock by the eye bolts

provided on the mounting piston.

20. The sleeve, mounting piston, rotor bore and rudderstock has to be thoroughly cleaned,

de-greased and inspected carefully after each dismantling.

Note!

It may be possible to enter the rudder stock while the Steering gear remains on the

foundation, but the sleeve can easily be damaged when attempting to enter the rudderstock.

To re-install the Steering gear and hydraulic coupling, follow the installation and oil filling/

“pulling-up” procedures.

Page 40 of 55 Installation Manual Rolls-Royce Steering Gear

8 COMMISSIONING

8.1 Precautions before start-up

Warning

In the event of a malfunction during the test program for the control system and

the hydraulic system, investigate and remedy the malfunction immediately.

Operating a vessel with a malfunction in the control system or in the hydraulic

system may cause personal injury and equipment damage.

Caution!

CAUTION!

Check that all mechanic and hydraulic components are mounted as specified (in case of

any alterations since the installation period) and that nothing is missing.

Check that all electrical connections are completed.

Check that all cabinet earthing are made properly.

Check that electric power is available (but do not power up!).

Ensure that the work will not be disturbed by testing of other machinery or painting.

Keep the appropriate type of oil available for topping up.

If services of other companies are used to run the prime mover, make necessary

arrangement to organize this.

Rolls-Royce Steering Gear Installation Manual Page 41 of 55

8.2 Activities performed by the shipyard personnel

Items to be checked off before startup Checked Sign.

Is the Steering gear installed on foundation/rudderstock

Are the Steering gear and rudder blade both installed on leading line for

mid-ship position

Are transport bracket removed

Is the Steering gear aligned to makers specification

Have fitted foundation bolts been used

Are proper side chocks welded in place

Are all hydraulic pipelines installed and flushed

Is correct hydraulic oil filled to whole system

All electric cables installed in steering gear room

Correct electrical supply available in steering gear room

All cables/wiring connected in ECR

Correct electrical supply available in ECR

All equipment / wiring installed on bridge

Correct el supply available on bridge

Any breakages/defects noted on any equipment

Can the rudder be turned freely during commissioning

Please list any damaged items here with probable cause of damage:

Date:

Stamp/Sign:

Page 42 of 55 Installation Manual Rolls-Royce Steering Gear

9 CONTACT LIST

Country Address Telephone Fax

Rolls-Royce Marine AS +47 815 20 070* +47 70 20 86 00

Deck Machinery & Steering gear

Brattvaag

Serviceboks 1522

Norway

N-6025 ÅLESUND, NORWAY

Deck.machinery.brattvaag@rolls-

royce.com

* 24 hr emergency

North America

Rolls-Royce Canada Ltd +1 902 468 2883 +1 902 468 2759

(GSN Commercial Marine)

196 Joseph Zatzman Drive, Unit 9

Canada

Dartmouth, Nova Scotia B3B 1N4

Canada B3B 1N4

UMLH@rolls-royce.com

Rolls-Royce Marine Inc. New Orleans +1 504 464 4561 +1 504 464 4565

200 James Drive West

St. Rose, LA 70087 USA

marianne.leine@rolls-royce.com

Rolls-Royce Commercial Marine +1 954 436 7100 +1 954 436 7101

10125 USA Today Way

Miramar, Fort Lauderdale

Florida 33025 USA

USA marianne.leine@rolls-royce.com

Rolls-Royce Marine Inc +1 508 668 9610 +1 508 668 2497

110 Norfolk Street

Walpole, MA 02081 USA

marineinfo@rolls-royce.com

Rolls-Royce Marine Seattle +1 206 782 9190 +1 206 782 0176

1731 – 13th Avenue SW

Seattle, WA 98134-1009

seattle.marine@rolls-royce.com

South America

Rolls-Royce Marine Ltda +55 21 3860 8787 +55 21 3860 4410

Rua General Jose Cristino 31

20921—400 São Cristovão

Brazil

RIO DE JANEIRO RJ, Brazil

marineinfo@rolls-royce.com

Rolls-Royce Steering Gear Installation Manual Page 43 of 55

Asia

Rolls-Royce Marine Shanghai +86 21 5818 8899 +86 21 5818 9388

No. 1 Xuan Zhong Road - Nan Hui

Industrial

China

Zone

201300 SHANGHAI

Merchant.marine@rolls-royce.com

Rolls-Royce Maine Hong Kong Ltd +852 2526 6937 +852 2868 5344

Rm. 4103 41st Floor, Hopewell Centre

Hong Kong 183 Queen`s Rd East,

Wanchai, HONG KONG SAR

service.hongkong@rolls-royce.com

Rolls-Royce Mumbai, +91 22 6640 38 38 +91 22 6640 38 18

103, Windsor, Kalina, Santacruz

India (East)

Mumbai-400 098

marine.india@rolls-royce.com

Rolls-Royce Marine Japan K.K +81 3 3237 6861 +81 3 3237 6846

Tobunsha Bldg. 4F

2-5-1, Kudan-Minami

Japan

Chiyoda-ku

TOKYO 102-0074 JAPAN

tokyo@rolls-royce.com

Rolls-Royce Marine Korea Ltd +8 251 831 4100 +8 251 831 4101

Noksan Industrial Complex 18B-2L

1578-1, Songjeong-dong,

Korea

Gangseo-gu

BUSAN 618-270 Korea

jane.park@rolls-royce.com

Rolls-Royce Marine +7 4232 495 484 +7 4232 495 484

Vladivostok Rep Office

Russia 5F, 3-B, Streinikova Str.

Vladivostok 690065, Russia

ulstein@mail.primorye.ru

Rolls-Royce Marine Singapore Pte Ltd +65 686 21 901 +65 686 32 165

No 6 Tuas Drive 1,

Singapore

SINGAPORE 638673

marineinfo@rolls-royce.com

Europe

Rolls-Royce Marine Benelux B.V. +31 10 40 90 920 +31 10 40 90 921

Werfdijk 2 (Port 2828)

Benelux

3195 HV Pernis Netherlands

benelux.service@rolls-royce.com

Page 44 of 55 Installation Manual Rolls-Royce Steering Gear

Rolls-Royce Marine AS +45 9930 3600 +45 9930 3601

Vaerftsvej 23

Denmark

DK-9000 AALBORG Denmark

denmark.marin@rolls-royce.com

Rolls-Royce Marine Oy Ab +358 2 83791 +358 2 8379 4808

PO Box 220 (Suojantie 5)

Finland

FIN-26100 RAUMA Finland +358 4 006 66678

rolls-royce.finlanf@rolls-royce.com

Rolls-Royce Marine France +33 1 468 62811 +33 1 468 79398

Immeuble de Monaco

France 4 Place des Etas-Unis, Silic 261

F-94578 RUNGIS Cedex France

mariann.leine@rolls-royce.com

Rolls-Royce Marine Deutschland +49 40 381 277 +49 40 389 2177

Stettiner Strasse 3

Germany

D-22850 Norderstedt

sales.hamburg@rolls-royce.com

Kaminco Overseas Inc +30 1 45 28 240 +30 1 42 94 887

Presented by KAMINIS Co Ltd

Greece

57 Akti Miaouil PO Box 80115 +30 1 42 93 355

GR-PIRAEUS 18510 Greece

Rolls-Royce Marine Italia s.r.l. +39 010 749 391 +39 010 749 3950

Via Castel Morrone, 13

Italy

16161 Genova

genova.marine@rolls-royce.com

Rolls-Royce Marine Poland +48 58 782 06 55 +48 58 782 06 56

Alfa Plaza Building

Poland

28-32 Batorego Street

81 366 GDYNIA Poland

agnieszka.werra@rolls-royce.com

Rolls-Royce Espana SA +34 977 296 444 +39 977 296 450

Poligono Industrial de Constanti

Spain c/Dinamarca

E-43120 Tarragona

rrme.spain@rolls-royce.com

Rolls-Royce AB +46 550 84000 +46 550 18190

Box 1010

Sweden

S-681 29 Kristinehamn Sweden 46 70 528 6566*

rrab.Sweden@rolls-royce.com

Rolls-Royce Commercial Marine Ltd +44 1322 312028 +44 1322 212054

UK Nucleus, London Science and

Business Park

Brunel Way, Dartford, Kent DA1 5GA

Rolls-Royce Steering Gear Installation Manual Page 45 of 55

sales.Dartford@Rolls-Royce.com

Australia

Perth Office +61 8 9336 7910 +61 8 9336 7920

Unit 2, 8 Wallace Way

Fremantle, WA 6160, Perth +61 418 567 523*

doug.brice@rolls-royce.com

Australia

Melbourne Office +61 3 9873 0988 +61 3 9873 0866

Unit 1, 87 Heatherdale Road

Ringwood, Victoria 3134, Melbourne +61 417 323 077*

doug.brice@rolls-royce.com

Page 46 of 55 Installation Manual Rolls-Royce Steering Gear

10 FINAL INSPECTION AND TEST PROCEDURE

10.1 Function test

Test Checked

Make sure that the “Installation checklist”, chapter 8, has been thoroughly run

through.

Browse through the installation and verify that everything is according to the

instructions and specifications. Check the oil filling, the electrical connections, the

shaft alignments and the piping.

Power up the hydraulic units and verify that all set points on pressure switches,

transmitters, indicators and sensors are according to specifications/drawings.

Check remote start/stop, alarms and shut down signals.

Test the different systems applicable to this particular installation and preliminary

tune to best behavior.

10.2 Harbor acceptance test

This form is to be properly filled in and returned to the Rolls Royce Marine, if any problems should

occur to the Steering gear or the belonging system.

Harbor acceptance test is to be found on the following pages.

Rolls-Royce Steering Gear Installation Manual Page 47 of 55

Make: Rolls-Royce Marine AS

Steering gear type:

HARBOUR

Yard:

ACCEPTANCE TEST

Hull no:

Rolls-Royce Marine AS Our order no:

Date:

dept. Deck Machinery &

Steering gear

Responsible: Rolls-Royce Marine AS

Yard:

Purpose of functional test:

The unit was tested to ensure that all system functioned satisfactory.

Following system shall be tested:

1. Hydraulic test

2. Emergency steering from steering gear room

3. Alarm system

4. Main steering position.

5. Aft steering position

6. Port wing steering position.

7. Stbd steering position.

8. External connection.

How to fill in the form:

Not applicable

Test accepted V

Test not accepted FAILED

Hydraulic test

Hydraulic test Pump 1. Pump 2. Pump 3. Pump 4.

o

Maneuvering time (65 <28sec) [Sec]

Safety valves on pump unit [Bar]

Safety valves on rudder motor [Bar]

Emergency steering from the steering gear room

1. Turn the selector switch in front of each motor controller to position 3. “Local control”.

2. Alarm for “power failure control system” will occur.

Page 48 of 55 Installation Manual Rolls-Royce Steering Gear

3. Operate the emergency push buttons in front of the motor controllers:

Emergency Pump 1. Pump 2. Pump 3. Pump 4.

steering

Operate

emergency push

buttons

Alarm system

Main alarm panel (engine control room):

1. Push the “system test” button on the alarm panel for more than 5 seconds.

All alarm lights and buzzers both on the slave alarm panel and on the main alarm panel will now

be tested. All Steering gear control system will be turned on through the auto-start feature (if

delivered). In this way the complete alarm system will be tested.

2. Push the aud./ack.-button once

The buzzer in the main alarm panel will stop if an alarm has occurred.

3. Push the button once more and the auto start loop opening and if the alarm condition is still

present, the alarm lights goes from flashing to steady light, otherwise it is turned off.

Slave alarm panel (bridge):

4. Push the “panel-test” button in the control panel for more than 5 seconds.