Professional Documents

Culture Documents

Integrated Project Jan2020 PDF

Uploaded by

Ahmed AlwaqediOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Integrated Project Jan2020 PDF

Uploaded by

Ahmed AlwaqediCopyright:

Available Formats

CEB/CDB 2043/YAB 4123 CEB 2053 CEB/CDB 2063

INTEGRATED DESIGN PROJECT

1. Overview

KURIN Energy SDN BHD is an energy company that currently interested in producing

hydrogen (H2) from natural gas using steam methane reforming (SMR) technology (Figure 1).

The company is now opening a tender for a project to design H2 production of 30,000

tonnes/year with a purity of 99.9% via SMR technology.

Figure 1: Simplified SMR Process

2. Project Task

As a group of engineers, you are given a task to bid the tenders with the design shall specify

the followings:

CEB/CDB 2043 Reaction Engineering 1

YAB4123 Fundamentals of Reactor System

1. Type of the reactor and catalyst used.

2. The description of how the chosen reactor works for the H2 production

3. The strategy to maximize the selectivity & yield of H2 and minimize the side reaction,

if any.

4. The optimum operating conditions and sizing of the reactor.

CEB/CDB 2063 Separation Process 2

1. It is compulsory to use the Absorption system for the CO2 Removal Unit and

Adsorption system for the H2 Enrichment Unit.

2. For the Adsorption system, identify the type of adsorbent used, the isotherm and

design of the adsorption column (MTZ, diameter, and total height).

CEB/CDB 2043/YAB 4123 CEB 2053 CEB/CDB 2063

3. Strategy to achieve 99.9% of the H2 production and desorption/regeneration process.

CEB 2053 Process Modelling & Simulation

1. Verification based on the comparison between manual mass balance (individual unit

and overall) with ICON simulation on CO2 separation system.

2. Detailed simulation of the absorption-based CO2 separation system using a suitable

amine as the solvent.

3. Project Timeline

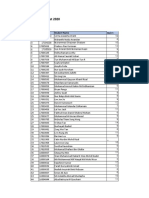

The important milestones are detailed in Table 1. It is compulsory to closely follow all the

due dates.

Table 1: Timeline for the Project

Activity Date

Progress Report Submission Week 9 : 4 March 2020

-Softcopy

- Reaction Engineering 1: Type of reaction

involved & kinetic data.

- Separation Process 2: Identification of the

type of adsorbent used & isotherm.

- Process Modelling & Simulation:

Preliminary PFD and calculations.

Report Submission Week 11: 18 March 2020

-Softcopy

- Executive summary, Introduction

(Literature), SMR Reactor, CO2 Removal,

H2 Enrichment, Verification via Simulation.

Presentation Day Week 11: 20 March 2020

-Pitching

-10mins presentation & 10 mins Q&A.

CEB/CDB 2043/YAB 4123 CEB 2053 CEB/CDB 2063

Reading materials

Holladay, J. D., Hu, J., King, D. L., & Wang, Y. (2009). An overview of hydrogen production

technologies. Catalysis Today, 139(4), 244-260.

doi:https://doi.org/10.1016/j.cattod.2008.08.039

Dincer, Ibrahim, & Acar, Canan. (2015). Review and evaluation of hydrogen production

methods for better sustainability. International Journal of Hydrogen Energy, 40(34),

11094-11111. doi:https://doi.org/10.1016/j.ijhydene.2014.12.035

Li, H., Haas-Santo, K., Schygulla, U., & Dittmeyer, R. (2015). Inorganic microporous

membranes for H2 and CO2 separation—Review of experimental and modeling

progress. Chemical Engineering Science, 127, 401-417.

doi:https://doi.org/10.1016/j.ces.2015.01.022

Boyano, A., Blanco-Marigorta, A. M., Morosuk, T., & Tsatsaronis, G. (2011).

Exergoenvironmental analysis of a steam methane reforming process for hydrogen

production. Energy, 36(4), 2202-2214.

doi:https://doi.org/10.1016/j.energy.2010.05.020

Geankoplis C. J., Transport Processes and Separation Process Principles (includes unit

operations) 4th Ed, Prentice Hall, 2003.

D. Y Leung, G. Caramanna, and M. M Maroto-Valer (2014). An overview of current status of

carbon dioxide capture and storage technologies. Renewable and Sustainable Energy

Reviews, 39, 426 – 443.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Test 1 - CEB2093 - Reaction Engineering 2Document10 pagesTest 1 - CEB2093 - Reaction Engineering 2Ahmed AlwaqediNo ratings yet

- Wafer Biscuit PlantDocument9 pagesWafer Biscuit Planttechnocrat_vspNo ratings yet

- Quiz 3Document1 pageQuiz 3Ahmed AlwaqediNo ratings yet

- Methodology Ex 4Document3 pagesMethodology Ex 4Ahmed AlwaqediNo ratings yet

- Test 1 September 2020 SemesterDocument3 pagesTest 1 September 2020 SemesterAhmed AlwaqediNo ratings yet

- Test 1 September 2020 SemesterDocument3 pagesTest 1 September 2020 SemesterAhmed AlwaqediNo ratings yet

- Test 2 ECE CDB3022 - CEB3013 May 2020Document3 pagesTest 2 ECE CDB3022 - CEB3013 May 2020Ahmed AlwaqediNo ratings yet

- Assignment Ece May 2020 - WastewaterDocument4 pagesAssignment Ece May 2020 - WastewaterAhmed AlwaqediNo ratings yet

- CEB 2083 Assignment 3Document3 pagesCEB 2083 Assignment 3Ahmed AlwaqediNo ratings yet

- Quiz 1 - G1Document2 pagesQuiz 1 - G1Ahmed AlwaqediNo ratings yet

- Test 2 September 2020 SemesterDocument3 pagesTest 2 September 2020 SemesterAhmed AlwaqediNo ratings yet

- CEB1013 Organic Chemistry Assignment #1Document3 pagesCEB1013 Organic Chemistry Assignment #1Ahmed AlwaqediNo ratings yet

- Quiz 2 - Model Formulation Lumped ParametersDocument1 pageQuiz 2 - Model Formulation Lumped ParametersAhmed AlwaqediNo ratings yet

- Test 1 ECE CDB3022 - CEB3013 - May 2020Document7 pagesTest 1 ECE CDB3022 - CEB3013 - May 2020Ahmed AlwaqediNo ratings yet

- H, Should Be Maintained at Their Respective Desired Operating Conditions. The Variables Q, T and PDocument3 pagesH, Should Be Maintained at Their Respective Desired Operating Conditions. The Variables Q, T and PAhmed AlwaqediNo ratings yet

- Tutorial 1Document9 pagesTutorial 1Ahmed AlwaqediNo ratings yet

- Tutorial 2Document7 pagesTutorial 2Ahmed AlwaqediNo ratings yet

- Extended Assignment May 2020 SemesterDocument6 pagesExtended Assignment May 2020 SemesterAhmed AlwaqediNo ratings yet

- Science Checkpoint Revision Y8Document16 pagesScience Checkpoint Revision Y8Mark ZuckerburgNo ratings yet

- Amol Raj PDFDocument10 pagesAmol Raj PDFGaurav SinghNo ratings yet

- (Autex Research Journal) Analysis of Moisture Evaporation From Underwear Designed For Fire-FightersDocument13 pages(Autex Research Journal) Analysis of Moisture Evaporation From Underwear Designed For Fire-FightersHafez HawasNo ratings yet

- Corrosion Science Volume 3 Issue 4 1963-Potentiokinetic and Corrosimetric Investigations of The Corrosion Beha PDFDocument22 pagesCorrosion Science Volume 3 Issue 4 1963-Potentiokinetic and Corrosimetric Investigations of The Corrosion Beha PDFbafoncio13579No ratings yet

- VSEPR ShortcutDocument3 pagesVSEPR ShortcutSubhojyotiDasNo ratings yet

- List 25 Big Refineries in AsiaDocument4 pagesList 25 Big Refineries in Asiatrantam88No ratings yet

- Dennis Hendershot SACHE Inherently Safer DesignDocument87 pagesDennis Hendershot SACHE Inherently Safer Designanon-196321100% (3)

- Aspen Internet Process Manual2006 - 5-Usr PDFDocument18 pagesAspen Internet Process Manual2006 - 5-Usr PDFBabak Mirfendereski100% (1)

- Additives in Australian FoodsDocument11 pagesAdditives in Australian FoodsSarah AnnesleyNo ratings yet

- Service Manual: First Edition Second Printing Part No. 52709Document440 pagesService Manual: First Edition Second Printing Part No. 52709Jhon Hever Benitez100% (1)

- 40MF End Suction BrochureDocument4 pages40MF End Suction Brochurerhusseinpos4765No ratings yet

- Geotechnical EngineeringDocument5 pagesGeotechnical EngineeringNicole ForrosueloNo ratings yet

- Journal of Manufacturing ProcessesDocument7 pagesJournal of Manufacturing ProcessesDiditOctianoNo ratings yet

- 2019 MFG Industries India 667Document6 pages2019 MFG Industries India 667Uday kumarNo ratings yet

- Lamitex CE Tube Metric DataDocument1 pageLamitex CE Tube Metric Dataabdulloh_99No ratings yet

- 2021 Raptor CatalogDocument12 pages2021 Raptor CatalogLoc BuiNo ratings yet

- NAAMM NOMMA Finishes Manual PDFDocument116 pagesNAAMM NOMMA Finishes Manual PDFMichaelTorresNo ratings yet

- O-Rings and SealsDocument10 pagesO-Rings and SealsManuel CarvalloNo ratings yet

- Paracetamol e Ibuprofeno Como Contaminantes EmergentesDocument27 pagesParacetamol e Ibuprofeno Como Contaminantes EmergentesElmer VargasNo ratings yet

- Lab 7 - BioeactorDocument43 pagesLab 7 - Bioeactornur athilahNo ratings yet

- 1.0 Reaction Kinetic 22 - 23 (REVIEWED)Document115 pages1.0 Reaction Kinetic 22 - 23 (REVIEWED)alyaainsyirah04No ratings yet

- 1267497350933Document18 pages1267497350933anon_166797875No ratings yet

- E-Waste Management in Indian Cities-Problems and Solutions: Anand3162@yahoo - Co.inDocument18 pagesE-Waste Management in Indian Cities-Problems and Solutions: Anand3162@yahoo - Co.inanand3162No ratings yet

- Pvi PDFDocument3 pagesPvi PDFBharat ChatrathNo ratings yet

- Studi Kasus Kerusakan Silinder Liner Engine PC PDFDocument46 pagesStudi Kasus Kerusakan Silinder Liner Engine PC PDFApril KukuhNo ratings yet

- PNSC0021Document12 pagesPNSC0021romerobernaNo ratings yet

- ConcreteDocument23 pagesConcreteHein ZanNo ratings yet

- There Are Three Main Groups of Resin:: Polyester ResinsDocument1 pageThere Are Three Main Groups of Resin:: Polyester ResinsmukeshNo ratings yet

- TID00019 Manual Acople Falk FLDDocument7 pagesTID00019 Manual Acople Falk FLDNatalia BeltránNo ratings yet