Professional Documents

Culture Documents

Certificate of Conformance: Ilc Dover Quality Systems Procurement Clauses

Certificate of Conformance: Ilc Dover Quality Systems Procurement Clauses

Uploaded by

frdnOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Certificate of Conformance: Ilc Dover Quality Systems Procurement Clauses

Certificate of Conformance: Ilc Dover Quality Systems Procurement Clauses

Uploaded by

frdnCopyright:

Available Formats

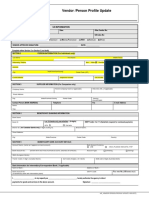

ILC DOVER

QUALITY SYSTEMS PROCUREMENT CLAUSES

CERTIFICATE OF CONFORMANCE

COMPANY NAME:

STREET ADDRESS:

CITY: STATE: ZIP CODE:

PURCHASE ORDER NO: ILC PART NO:

DRAWING NO: REVISION LEVEL:

SOURCE (MANUFACTURER’S) COMPANY NAME (If Different From Supplier):

MANUFACTURER’S PART NO:

MANUFACTURER’S LOT NO:

DATE OF MANUFACTURE: QUANTITY SHIPPED:

DATE SHIPPED (When Applicable):

DESCRIPTION:

SPECIFICATIONS/SPECIAL PROCESSES:

SERIAL NO(S):

THIS IS TO CERTIFY THAT THE PRODUCTS AND/OR SERVICES CONTRACTED BY THE PURCHASE

ORDER HAVE BEEN MANUFACTURED, PROCESSED, INSPECTED, AND TESTED IN ACCORDANCE

WITH ALL REQUIREMENTS OF THE PURCHASE ORDER AND SPECIFIED ON REFERENCED

DOCUMENTS. FURTHERMORE, INSPECTION AND TEST RESULTS SIGNIFY THAT THE ITEMS

DELIVERED ARE FULLY ACCEPTABLE AND IN COMPLETE CONFORMANCE TO ALL PURCHASE

ORDER REQUIREMENTS.

OTHER DATA, NOT ENCLOSED WITH THIS SHIPMENT, ARE MAINTAINED ON FILE AND ARE

AVAILABLE UPON REQUEST.

SIGNATURE: DATE:

TITLE:

FORM 328 (08/09) F1 OF F4 SOP 8111

ILC DOVER

QUALITY SYSTEMS PROCUREMENT CLAUSES

The clauses contained in this document identify the commonly used quality/certification/data requirements. By reference in the

text of this order, they become a part thereof. Additional requirements may be included by specific statements within the text of

the Purchase Order. All shipments received at ILC Dover are subject to receiving inspection. Shipments may be returned to the

seller at the seller’s expense.

1. SUPPLIER CERTIFICATE OF CONFORMANCE (Code “A”) OR COMPLETED CERTIFICATION SUPPLIED

When required by the Purchase Order, a legible and reproducible copy of the SUPPLIER’S “Certificate of Conformance” shall be completed

listing the following mandatory items:

• Company name and address

• Purchase Order number

• Part / drawing number

• Description

• Revision (If other than Initial Release)

• Quantity shipped

• Signature of a responsible representative of the supplier

• Representative’s Title

• Date

• A statement certifying to the effect that the products or services provided under the Purchase Order have been manufactured,

processed, inspected, and tested in accordance with the provisions of the Purchase Order and as specified in all attached or

referenced documents, and are fully acceptable and in complete conformance to all Purchase Order requirements.

• This certification shall be furnished to ILC DOVER with each shipment of parts and/or materials. Similar certifications from each

subcontractor supplying materials or processing to this product shall be furnished with each shipment. When items are serialized,

serial numbers shall be listed on the certification.

• Materials furnished by ILC DOVER, for production of items shall be referenced on this certification by ILC DOVER lot number

and shipper number.

The following items shall be completed when applicable:

• Source Manufacturer’s Company Name (If different from supplier)

• Manufacturer’s Part Number

• Manufacturer’s Lot Number

• Serial Number

• Date of Manufacture

• Date Shipped from Manufacturer

2. INSPECTION/TEST REPORTS (CERTIFICATES OF ANALYSIS)

When required by the Purchase Order, a legible and reproducible copy of the supplier’s actual inspection/test report for the acceptance of items

under this Purchase Order shall be furnished with each shipment, for each supplier’s lot shipped or as specified in the Purchase Order and

attached or referenced documents. All such documents must be in English or accompanied by a legible English translation and signed by the

responsible agent of the supplier. Each inspection/test report/data document shall evidence compliance with the applicable drawing and/or

specification requirements and shall include the part number, applicable drawing and/or specification number with revision letter or number, and

the signature and title of the responsible agent of the supplier. When serialization has been imposed by the Purchase Order, such serialization

shall be a part of the inspection/test report data.

• Chemical test data report (Code “B”)

• Physical properties test data report (Code “C”)

• Visual/dimensional inspection data report (Code “D”)

• Functional test data report (Code “E”) (defined as operative performance, e.g. mechanical,

electronic, hydraulic, salt spray testing, etc.)

FORM 328 (08/09) F2 OF F4 SOP 8111

ILC DOVER

QUALITY SYSTEMS PROCUREMENT CLAUSES

3. SOURCE INSPECTION, ILC DOVER (Code “F”)

When required by the Purchase Order, all items supplied under this Purchase Order are subject to inspection at the seller’s facility, or at the

facility of a subcontractor to the seller, by an ILC DOVER Quality Representative prior to shipment. The seller shall, perform selected

inspections and/or tests in the presence of the source inspector as specified on Purchase Order, when required. Detailed parts of assemblies may

be subject to source inspection by the quality representative prior to assembly, when requested by Purchase Order. Inspection of such detailed

parts does not, however, negate inspection of the finished item prior to shipment. The seller shall make available his inspection records,

facilities and appropriate equipment to the ILC DOVER Quality Representative at the time of presentation of the produced items. The seller

shall provide no less than forty-eight (48) hours advance notice to the ILC DOVER Quality Representative to permit proper scheduling of

source inspection. Evidence of ILC DOVER source inspection must be shown on the shipping documents.

4. SOURCE INSPECTION, GOVERNMENT (Code “G”)

When required by the Purchase Order, all items supplied under this Purchase Order are subject to inspection at the seller’s facility, or at the

facility of a subcontractor to the seller, by a Government Quality Representative prior to shipment. Detailed parts of assemblies are subject to

inspection by the quality representative prior to assembly. Inspection of such detailed parts does not, however, negate inspection of the finished

item prior to shipment. The seller shall make available his inspection records to the Government Quality Representative at the time of

presentation of the produced items. The seller shall notify the Government Quality Representative who has been delegated quality systems

functions on this procurement immediately upon receipt of this order. The Government Representative shall also be notified no less than forty-

eight (48) hours in advance of the time items are ready for inspection or test, if in residence at your facility, or no less than seven (7) days in

advance if your facility is serviced by an itinerant Government representative.

In the event that a Government Representative cannot be located, immediately inform ILC DOVER’s purchasing department. Evidence of

Government source inspection must be shown on the shipping documents.

5. PROCESS CONTROL (CODE “H”)

When required by the Purchase Order, a legible and reproducible copy of all SPC/SQC data/charts used for controlling and analyzing processes

shall be provided with each shipment. These data must be identifiable to each lot/batch of parts or material shipped and must include detailed

analyses of the causes of process anomalies and the corrective actions taken to prevent recurrence.

6. PROCESS CERTIFICATION (Code “I”)

When required by the Purchase Order, each shipment must be accompanied by a legible and reproducible copy of a certification of the processes

covered by the applicable specifications such as, but not limited to heat treating, welding, electroplating, electropolishing, nondestructive

testing, surface preparation or treatment, etc., stating that the processing was performed to specification requirements and referencing the

Purchase Order and appropriate traceability identification. The certification shall list the applicable specifications including the revision letter(s)

or number(s) to which the processes conform, the name of the agency that performed them, if other than the seller, the date, and the signature

and title of the responsible agent of the seller. When parts are serialized, the serial number shall be listed on the certification.

7. TRACEABILITY (Code “J”)

When required by the Purchase Order, materials used must be identifiable by lot number, material type, specification and revision, heat number,

melt number, run number, mix number, batch number, etc., as appropriate, and be traceable to the records of quality acceptance. Items

fabricated by the seller shall be identified with the lot of material used. When two (2) or more parts are joined in assembly, the seller shall

prepare an assembly parts list identifying each item in the assembly. Traceability records must be provided with each shipment and must be

available, in file, for review by ILC DOVER and Government Quality Representatives.

The seller shall maintain and report the ILC DOVER traceability identification information on all materials provided by ILC DOVER for the

production of items under this order.

The seller shall serialize parts and/or materials at the seller’s facility when serialization is designated by the Purchase Order. No two (2) items

of the same part number (on this or any other ILC DOVER Purchase Order) are to be assigned the same serial number.

FORM 328 (08/09) F3 OF F4 SOP 8111

ILC DOVER

QUALITY SYSTEMS PROCUREMENT CLAUSES

8. SHELF-LIFE MATERIALS IDENTIFICATION (Code “K”)

When required by the Purchase Order, the seller shall identify each item, package or container of age-sensitive, limited-life, or shelf-life items or

materials with the cure or manufacturing date, expiration date, and special handling conditions, in addition to the normal identification

requirements. This identification, including special handling conditions, shall be recorded on the certifications and shipping documents, the

seller shall furnish a legible and reproducible copy of a certification with each shipment of items incorporating a shelf-life material that does not

require age control after installation (e.g., adhesives, resins, paints, etc.). These certifications shall state that the shelf-life materials were

properly controlled prior to use and within the shelf-life period when incorporated. The certification shall be identified with the Purchase Order

number and the item(s) produced. It must also contain the signature and title of the responsible seller agent.

9. NDT/E, NON DESTRUCTIVE TEST/EVALUATION REPORTS

When required by the Purchase Order, each shipment must be accompanied by a legible and reproduceable copy of the suppliers actual NDT/E

report. Each NDT/E report shall evidence compliance with the applicable drawing and/or specification requirement.

• Nondestructive data test report (Code “O”)

• Radiographic report (Code “P”)

When radiographic inspection is specified, the supplier’s reading and interpreting of the X-ray film shall be performed by

certified personnel. The supplier’s findings shall be reported on an appropriate form, including the name of the reader and the

signature and title of a responsible agent of the supplier. The X-ray film and report shall accompany the shipment of items. An

adequate method of identifying and cross-referencing each film exposure, report, and item must be provided.

FORM 328 (08/09) F4 OF F4 SOP 8111

You might also like

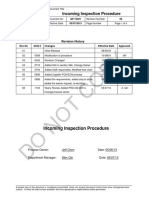

- QMS Inspection ProcedureDocument5 pagesQMS Inspection ProcedureSang Hà100% (1)

- Automotive Iatf 16949Document51 pagesAutomotive Iatf 16949sumit_saraf_5100% (2)

- Baofeng Uv-5r Ce Certificate 18-211428Document3 pagesBaofeng Uv-5r Ce Certificate 18-211428anshadNo ratings yet

- Hamley Digital InnovationDocument7 pagesHamley Digital InnovationamitNo ratings yet

- 8.5.1 Corrective Action FormDocument1 page8.5.1 Corrective Action FormvishvendanNo ratings yet

- SOP (Standard Operating Procedure) "WELDING PROCESS": Shoes Hand Glows GogglesDocument3 pagesSOP (Standard Operating Procedure) "WELDING PROCESS": Shoes Hand Glows GogglesMagesh Waran100% (1)

- Accenture Belux Corporate BrochureDocument24 pagesAccenture Belux Corporate BrochureAsaduzzaman Polash100% (1)

- .0 Inspection of Input MaterialsDocument22 pages.0 Inspection of Input MaterialsSPH PURCHASENo ratings yet

- Material Controller ProcedureDocument10 pagesMaterial Controller ProcedureAmos FiestaNo ratings yet

- 504H0015 (GS-0015) - Initial Sample Inspection ReportDocument5 pages504H0015 (GS-0015) - Initial Sample Inspection ReportsamNo ratings yet

- CorrectiveDocument8 pagesCorrectivevg_vvgNo ratings yet

- QMS Internal Auditor Course SyllabusDocument2 pagesQMS Internal Auditor Course SyllabusRaviLifewideNo ratings yet

- Prds & Piping QapDocument2 pagesPrds & Piping QapPavul RajNo ratings yet

- Flow Chart For General PurchasingDocument1 pageFlow Chart For General PurchasingSachin KumbharNo ratings yet

- Weekly Timecard TemplateDocument2 pagesWeekly Timecard TemplateMatt Tupper100% (1)

- Title: Flow Chart For Calibration Activity.: Prepartion of List of Instruments & Test EquipmentsDocument1 pageTitle: Flow Chart For Calibration Activity.: Prepartion of List of Instruments & Test EquipmentsSachin KumbharNo ratings yet

- CSR Map ToolDocument51 pagesCSR Map ToolSarah JohnsonNo ratings yet

- Foreign Material ExclusionDocument22 pagesForeign Material ExclusionBahim BahimanNo ratings yet

- IQA Audit PlanDocument1 pageIQA Audit PlanSachin RamdurgNo ratings yet

- METHODOLOGY FOR Vendor Rating SystemDocument5 pagesMETHODOLOGY FOR Vendor Rating SystemRangaNo ratings yet

- QSP.7.5 Control of Documented Information (Preview) PDFDocument3 pagesQSP.7.5 Control of Documented Information (Preview) PDFmahm.taha0% (2)

- Sample Process DefinitionDocument4 pagesSample Process DefinitionAnkur Dhir0% (1)

- Supplier Capability Self Assessment Form 2015 PROTECTEDDocument24 pagesSupplier Capability Self Assessment Form 2015 PROTECTEDClutch And FlywheelNo ratings yet

- Appendis3 IQA Incoming Material Inspection Flow ChartDocument1 pageAppendis3 IQA Incoming Material Inspection Flow ChartnguyencaohuygmailNo ratings yet

- NCR, Corrections & Corrective Action Log: Doc. AKI-EHS-P03-F02 Rev. 0 Date: 15.12.2013Document2 pagesNCR, Corrections & Corrective Action Log: Doc. AKI-EHS-P03-F02 Rev. 0 Date: 15.12.2013MohamedNo ratings yet

- Supply Packaging Approve FormDocument1 pageSupply Packaging Approve Formcong daNo ratings yet

- Supplier Deviation Request FormDocument2 pagesSupplier Deviation Request Formjainik shahNo ratings yet

- Malpani Alloy & Extrusions PVT LTD QSP - 02: 1.0 PurposeDocument4 pagesMalpani Alloy & Extrusions PVT LTD QSP - 02: 1.0 PurposeANBUNo ratings yet

- Container Loading Procedure PDFDocument8 pagesContainer Loading Procedure PDFZAHID UMARNo ratings yet

- Environment Improvement PlanDocument2 pagesEnvironment Improvement PlanmuhinNo ratings yet

- Calibration - Future State MapDocument1 pageCalibration - Future State Mapdayanand yadavNo ratings yet

- T-ENG CardDocument14 pagesT-ENG CardViswaChaitanya NandigamNo ratings yet

- Procedure For Iden & TraceDocument3 pagesProcedure For Iden & TraceMohammed ZubairNo ratings yet

- Vendor Profile-IndividualDocument1 pageVendor Profile-IndividualCasana MandalNo ratings yet

- Procedure - Outsourced ProcessesDocument1 pageProcedure - Outsourced Processesdellanadia putriNo ratings yet

- Environmental Assessment ReportDocument6 pagesEnvironmental Assessment ReportTichaona KwazvichasvikaNo ratings yet

- Quality ManualDocument21 pagesQuality ManualqualityNo ratings yet

- Management Review-Qmp-Sys-03Document3 pagesManagement Review-Qmp-Sys-03Rohit VishwakarmaNo ratings yet

- CounterfeitDocument5 pagesCounterfeitVivek GoudNo ratings yet

- KQP 16 Inspection & Testing Rev 04Document11 pagesKQP 16 Inspection & Testing Rev 04Mohd Isa HarunNo ratings yet

- Quality Control Form - 1Document1 pageQuality Control Form - 1ravi ajithNo ratings yet

- Production 1.0 Purpose: Work InstructionDocument2 pagesProduction 1.0 Purpose: Work Instructionvikasphopale1No ratings yet

- ISO 9001 - Document Control 4.2.3Document3 pagesISO 9001 - Document Control 4.2.3Arun KumarNo ratings yet

- Quality PlanDocument2 pagesQuality PlanSekar KrishNo ratings yet

- Car & Par ReportDocument1 pageCar & Par ReporthabibrgfNo ratings yet

- Quality Specifications For Purchased PartsDocument29 pagesQuality Specifications For Purchased PartsDheeraj Kumar100% (1)

- Manufacturing Process Audit: Pro QC's ClientDocument18 pagesManufacturing Process Audit: Pro QC's Clientmakubuya nasser100% (1)

- QUALITY CONTROL PROCEDURE FOR Access Control System InstallationDocument8 pagesQUALITY CONTROL PROCEDURE FOR Access Control System InstallationAbdul JabbarNo ratings yet

- Quality Assurance PlanDocument3 pagesQuality Assurance PlanNESTOR YUMULNo ratings yet

- Bgl-Pm-Qa-12 Control of Non Conforming OutputsDocument4 pagesBgl-Pm-Qa-12 Control of Non Conforming OutputsMohit SinghNo ratings yet

- QP 74301 Rev 08 Incoming Inspection ProcedureDocument9 pagesQP 74301 Rev 08 Incoming Inspection ProcedureAngeline D'AlmaidaNo ratings yet

- Calibration Training: ReferencesDocument5 pagesCalibration Training: ReferenceshoussNo ratings yet

- QMS 1004255 SENSATA GSQM - Rev P No Markup BLACK PDFDocument54 pagesQMS 1004255 SENSATA GSQM - Rev P No Markup BLACK PDFJossie FuentesNo ratings yet

- BN-CO-107 Standard Procedure For Material Control and WarehousingDocument20 pagesBN-CO-107 Standard Procedure For Material Control and WarehousingAli HajirassoulihaNo ratings yet

- Global Supplier Quality Manual-Second EditionDocument43 pagesGlobal Supplier Quality Manual-Second EditionSuhas ChinchanikarNo ratings yet

- Process Flow of Slitting, Packaging, DispatchDocument1 pageProcess Flow of Slitting, Packaging, DispatchShubham Kumar100% (2)

- UL's ISO 9000 Registration Program ISO 9001:2000 Quality System ChecklistDocument50 pagesUL's ISO 9000 Registration Program ISO 9001:2000 Quality System ChecklistJayant Kumar JhaNo ratings yet

- Quality System ManualDocument50 pagesQuality System ManualrajshakeeNo ratings yet

- Line Rejection Process Flow Local PartsDocument1 pageLine Rejection Process Flow Local Partsabdul qadeer100% (1)

- First Article Inspection - PROCEDUREDocument9 pagesFirst Article Inspection - PROCEDUREsrinivigna0% (1)

- IQA-Incoming Inspection Flow ChartDocument1 pageIQA-Incoming Inspection Flow ChartmohNo ratings yet

- Temecula Quality Plating AS9100 REV C MANUALDocument13 pagesTemecula Quality Plating AS9100 REV C MANUALHoang TanNo ratings yet

- EC SM210 ProcurProcurement-Quality-Requirementsment Quality RequirementsDocument10 pagesEC SM210 ProcurProcurement-Quality-Requirementsment Quality RequirementsShazwan ZakiNo ratings yet

- NY Supplier Quality Requirements and InstructionsDocument9 pagesNY Supplier Quality Requirements and InstructionspacifficNo ratings yet

- Control Plan FormatDocument1 pageControl Plan FormatMagesh WaranNo ratings yet

- Supplier Evaluation - (WIER MINIRALS)Document8 pagesSupplier Evaluation - (WIER MINIRALS)Magesh WaranNo ratings yet

- House Keeping Trent Chart 2Document1 pageHouse Keeping Trent Chart 2Magesh WaranNo ratings yet

- Contingency Plan: Accutech Laser Incase of EMERGENCY, Contact The Following Persons Over PhoneDocument4 pagesContingency Plan: Accutech Laser Incase of EMERGENCY, Contact The Following Persons Over PhoneMagesh WaranNo ratings yet

- House Keeping Trend Chart: Accutech EnterprisesDocument3 pagesHouse Keeping Trend Chart: Accutech EnterprisesMagesh WaranNo ratings yet

- Housing Keeping Audit Check List: Area: MonthDocument4 pagesHousing Keeping Audit Check List: Area: MonthMagesh WaranNo ratings yet

- House Keeping Year Plan 2013Document6 pagesHouse Keeping Year Plan 2013Magesh WaranNo ratings yet

- Process: Accutech Laser PVT LTD Master List of MachinesDocument11 pagesProcess: Accutech Laser PVT LTD Master List of MachinesMagesh WaranNo ratings yet

- Phone Number Modification FormDocument1 pagePhone Number Modification FormMagesh WaranNo ratings yet

- Safety Images of Welding ProcessDocument1 pageSafety Images of Welding ProcessMagesh WaranNo ratings yet

- Daily MopDocument7 pagesDaily MopMagesh WaranNo ratings yet

- Certificate of Compliaence: Specification - Range Test ResultsDocument1 pageCertificate of Compliaence: Specification - Range Test ResultsMagesh WaranNo ratings yet

- Major Project Report Quick Start Guide: Background InformationDocument7 pagesMajor Project Report Quick Start Guide: Background InformationMagesh WaranNo ratings yet

- Callibration Report: Linearity and HysteresisDocument2 pagesCallibration Report: Linearity and HysteresisMagesh WaranNo ratings yet

- Daily Work Log Sheet TemplateDocument1 pageDaily Work Log Sheet TemplateMagesh WaranNo ratings yet

- In House Implented WorksDocument7 pagesIn House Implented WorksMagesh WaranNo ratings yet

- Metal Detector Check ListDocument2 pagesMetal Detector Check ListMagesh WaranNo ratings yet

- Bin Card: Product Name: Project Name: Totsl Stock QtyDocument2 pagesBin Card: Product Name: Project Name: Totsl Stock QtyMagesh WaranNo ratings yet

- IC Project Risk Register 9419Document2 pagesIC Project Risk Register 9419Magesh WaranNo ratings yet

- Trancedence Automation PVT LTD Daily Progress ReportDocument2 pagesTrancedence Automation PVT LTD Daily Progress ReportMagesh WaranNo ratings yet

- Transcedence Automation PVT LTD Transcedence Automation PVT LTDDocument2 pagesTranscedence Automation PVT LTD Transcedence Automation PVT LTDMagesh WaranNo ratings yet

- 5S Implementation: Zone 1 Team Member Area Effected ChampianDocument1 page5S Implementation: Zone 1 Team Member Area Effected ChampianMagesh WaranNo ratings yet

- ISO 9001 2015 Timing PlanDocument2 pagesISO 9001 2015 Timing PlanMagesh WaranNo ratings yet

- Checklist RFQ For Utility Water TankDocument2 pagesChecklist RFQ For Utility Water TankRisyda PutriNo ratings yet

- Tableau Sales Play Ring CardsDocument55 pagesTableau Sales Play Ring CardsBayCreativeNo ratings yet

- Case Study - Zara: Apparel Manufacturing and RetailDocument2 pagesCase Study - Zara: Apparel Manufacturing and RetailElizabeth OwolabiNo ratings yet

- 5.2.7 Aqueous Wash Reference PFMEA - v2Document7 pages5.2.7 Aqueous Wash Reference PFMEA - v2RangaNo ratings yet

- Profile Matching and Competency Based Human Resources Management Approaches For Employee Placement Decision Support SystemDocument13 pagesProfile Matching and Competency Based Human Resources Management Approaches For Employee Placement Decision Support SystemRisca Septi WNo ratings yet

- Quality Assurance Plan (Qap)Document3 pagesQuality Assurance Plan (Qap)Kingston RivingtonNo ratings yet

- GRP 17 - Atlantic Computer Case StudyDocument7 pagesGRP 17 - Atlantic Computer Case StudyAmitesh Priolkar100% (8)

- Mktg5 5Th Edition Joe F Hair Full ChapterDocument67 pagesMktg5 5Th Edition Joe F Hair Full Chaptermaria.ramos952100% (22)

- Training Schedule April 2021 To March 22 - 0Document18 pagesTraining Schedule April 2021 To March 22 - 0sanrexiNo ratings yet

- Kotler Pom17e PPT 04updatedDocument29 pagesKotler Pom17e PPT 04updatedMinh Quân Đặng LêNo ratings yet

- Senior Staff CandidatesDocument6 pagesSenior Staff CandidatesWitdya RahmanNo ratings yet

- Strategic Lead-Time ManagementDocument27 pagesStrategic Lead-Time ManagementkanjanaNo ratings yet

- Jaypee Business School: Corporate Internship ReportDocument99 pagesJaypee Business School: Corporate Internship Reportpriti_guptagNo ratings yet

- Electrostatic Powder PaintingDocument9 pagesElectrostatic Powder PaintingfirdausNo ratings yet

- SOP List With AttachmentsDocument6 pagesSOP List With AttachmentsjignashaNo ratings yet

- Publicaţie: Revista Romana de Jurisprudenta 6 Din 2017: C. Civ. C. CivDocument8 pagesPublicaţie: Revista Romana de Jurisprudenta 6 Din 2017: C. Civ. C. CivBgd BogdanNo ratings yet

- Manufacturing Process-Ii: Lab Manual 01Document8 pagesManufacturing Process-Ii: Lab Manual 01Abdul Rehman FaisalNo ratings yet

- Pros: Outsource More: 1. Highlight The Pros and Cons of The Production Model Followed by Boeing Prior To The 787 ProjectDocument10 pagesPros: Outsource More: 1. Highlight The Pros and Cons of The Production Model Followed by Boeing Prior To The 787 ProjectAnubhavNo ratings yet

- Pacific Paint (Boysen) Philippines, Inc., - Two-Component Epoxy Based Coatings - BOYSEN - Sup - ® - Sup - Epoxy EnamelDocument1 pagePacific Paint (Boysen) Philippines, Inc., - Two-Component Epoxy Based Coatings - BOYSEN - Sup - ® - Sup - Epoxy EnamelJojo CalimlimNo ratings yet

- Project StartupDocument45 pagesProject StartupbvitalNo ratings yet

- Production and Cost AnalysisDocument28 pagesProduction and Cost Analysisdurgesh7998No ratings yet

- PreheatDocument4 pagesPreheatShaikh IbrahimNo ratings yet

- Ebk8 7 Best Practices For Planning CPQ ProjectDocument20 pagesEbk8 7 Best Practices For Planning CPQ ProjectNarendra ReddyNo ratings yet

- QuizDocument2 pagesQuizAnas TubailNo ratings yet

- Advanced Automotive Systems: BITS PilaniDocument40 pagesAdvanced Automotive Systems: BITS Pilaniswarna mayuri kumar100% (1)

- Thesis MRPDocument7 pagesThesis MRPSandra Long100% (2)

- Housing.comDocument4 pagesHousing.comSuraj DasNo ratings yet