Professional Documents

Culture Documents

pDRIVE Basic MX

Uploaded by

Thang VuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

pDRIVE Basic MX

Uploaded by

Thang VuCopyright:

Available Formats

>pDRIVE<

Procedural Instructions in addition to Operating Instructions 8 074 127

>pDRIVE< MX basic

>pDRIVE< MX plus

>pDRIVE< MX plus-hydro

>pDRIVE< MX multi-basic

>pDRIVE< MX multi-plus

>pDRIVE< MX top

>pDRIVE< MX top-hydro

Backdrive & Maindrive

with software PDZ6

Safety Instructions

The following symbols should assist you in handling the instructions:

General information, note exactly!

Dangerous voltages! Danger of life!

Advice, tip!

The requirements for successful commissioning are correct selection of the unit, proper projection and mounting. If you have any further

questions, please contact the supplier or call the manufacturer of the unit directly.

Capacitor Discharge!

Before performing any work on or in the unit, disconnect from the mains and wait at least 5 minutes until the D.C. link capacitors have

been fully discharged, to make sure that the device is no longer live.

Automatic Restart!

With certain parameter settings it may happen that the frequency inverter starts up automatically when the mains supply returns after a

power failure. Make sure that no persons and no other equipment is in danger.

Commissioning and Service!

Work on or in the unit must be done only by duly qualified staff and in full compliance with the appropriate instructions and pertinent

regulations. Note that a fault may cause potential-free contacts and/or PCBs to carry mains potential. To avoid any risk to humans, obey

the regulations concerning ”Work on Live Equipment” explicitly.

Terms of delivery:

Our deliveries and services are based on the ”General Terms of Delivery of the Austrian Electrical Industries” in the latest edition.

Specifications in this instruction:

We are constantly striving to improve our products and adapt them to the latest state of technical development. Therefore, we reserve the

right to modify the specifications given in this instruction at any time, particular those referring to measures and dimensions. All planning

recommendations and connection examples are non-binding suggestions for which we cannot accept any liability, particularly since the

regulations to be complied with depend on the type and location of the plant and on the use of instruments.

Regulations:

It is the user’s responsibility to ensure that the instrument and its component parts are used in compliance with applicable regulations. It is

not permitted to use these instruments in residential areas without special measures to suppress radio frequency interference.

Patents and trademarks:

Please note that we do not guarantee any connections, instruments or processes described herein to be free from patent or trademark

rights of third parties.

Keep this instruction at hand near the unit!

Operating the Frequency inverter

Backdrive

>pDRIVE< MX plus

with Decanter Software for Backdrive Systems

These Operating Instructions describe the functions of the following software:

PDZ6 version 8 783 080.00 and higher

Macros

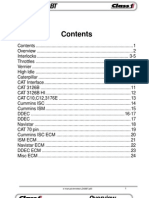

Topic Page

Backdrive

Structure and Mechanism 2

Control 4

Macros

Maindrive 6

Parameter description

Backdrive 9

Parameter description

Detailled Description of procedural parameters 13

Parameter list 20

This manual is a supplement to the operating instructions for frequency inverters with software PDZ6.

Please inform your supplier or insurance company in the case of damage or incomplete delivery. The

manufacturer shall not accept responsibility for damage caused during shipment or unpacking.

Parameter list

>pDRIVE< MX plus with PDZ6 for Backdrive – 8 074 128.00/00 – Page 1

Preface

This operating instructions explain how to use the >pDRIVE< MX frequency inverter as maindrive and

backdrive for decanter centrifuges.

The following brief description of the structure and mechanism of decanter centrifuges is intended to promote

understanding of the individual application, and thus to allow you to parametrize and start up the drive

component more efficiently.

Structure and Mechanism

Decanter centrifuges are a special form of centrifuges which allow, as a result of their design, continuous

separation of the solid content and centrifugate of the suspension.

Thereby, the suspension is filled into the rotating chamber through a pipe, accelerated in the direction of

rotation, and fed into the bowl through openings in the conveyor screw.

Separation takes place in the rotating bowl as a result of the ensuing centrifugal force, whereby the solid

particles are deposited on the inner wall of the bowl. In the bowl, the solid particles are transported to the solid

discharge via the cone of the bowl by a rotating conveyor screw.

The centrifugate drains off through the liquid discharge.

A major factor in this separation process is the differential speed between the rotating bowl and the conveyor

screw. This speed is calculated and set automatically by selecting a procedural steady state characteristic and

by complex control models depending on the screw load (torque).

>pDRIVE< MX plus with PDZ6 for Backdrive – 8 074 128.00/00 – Page 2

In the electric backdrive system, the differential speed is influenced by changing the speed of the backdrive

motor, which is connected with the conveyor screw and bowl via the tappets of the planetary gear.

Backdrive

In accordance with the mathematical formula the following steady state characteristic is obtained depending on

the bowl speed.

nbowl − n tappet

∆n =

i gear

>pDRIVE< MX plus with PDZ6 for Backdrive – 8 074 128.00/00 – Page 3

Depending on the rotational direction of the backdrive, the backdrive motor operates in the generator quadrant

or in the motor quadrant.

(

nbowl − + n tappet )

Backdrive forward: ∆n =

i gear

(

nbowl − − n tappet )

Backdrive reverse: ∆n =

i gear

A centrifuge drive with generator capacity can thus switch to motor operation at any time (e. g. at high

differential speeds or during the acceleration and deceleration phase).

A backdrive with motor capacity, on the other hand, will always operate only in motor mode.

In backdrive systems with generator capacity, a d.c. supply link to the maindrive must be installed in the

backdrive inverter instead of the mains supply. It provides the energy released by the backdrive to the

bowldrive.

Control

The control process for the screw drive is designed in such a way that the differential speed is defined using a

procedural steady state characteristic. This steady state characteristic is defined by two points (dn min/T1, dn

max/T2), and can be set to linear, convex, concave or digital.

Thus, the differential speed is automatically adjusted to the load situation. If the load increases, the clearance

effect is increased by increasing the differential speed.

If an torque limit, which is adjustable, is reached, a digital output (T > T1) is set and thus the suspension supply

is stopped. If the load increases to a further adjustable torque limit, a second digital output (T > T2) is set. This

signal can be used for safety shutdown.

Low differential speeds provide good separation and a higher degree of dryness of the separated solid content

depending on the set pool depth.

Procedural steady state characteristic (linear)

If the differential speed defined by the steady state characteristic is too low or as a result of changes in the

material composition (temperature and solid content of the suspension; quantity, type and temperature of

flocculant added, etc.), the differential speed must be modified regardless of the actual load situation.

>pDRIVE< MX plus with PDZ6 for Backdrive – 8 074 128.00/00 – Page 4

This intervention is possible by "shifting" the set steady state characteristic (offset), whereby the drive remains in

automatic control mode.

Backdrive

The offset standard is set with an analog reference value (4...20mA).

100% offset correspond with the nominal motor torque.

An increase in offset therefore results in an increase in differential speed. The offset can only be shifted within

the min. and max. differential speed limits!

It is possible to switch from steady state characteristic control mode to Dn mode, where the differential speed is

defined using an analog value (4...20 mA) (load-independent ∆n standard) at any time (even during

operation).

In addition, a speed mode is available in electric backdrive systems. The bowl must be at a standstill before

switching to this mode.

In this mode, the following procedural processes are possible:

– vibration

– washing

– CIP programs

– rinsing, etc.

Prinziple schema

>pDRIVE< MX plus with PDZ6 for Backdrive – 8 074 128.00/00 – Page 5

Maindrive

B2.03 Macro selection VICB → (0) … Maindrive

To activate the functions for the maindrive, it is necessary th set parameter B2.03 to "0…Maindrive" !

Parameters which always have to be adjusted:

Parameter Name Setting Remark

A2.11 Machine scaling 1.000 belt ratio maindrive/bowl

E2.00 Thermistor input Activ. not active thermal motor protection !

Parameters which have to be adjusted if required:

Parameter Name Setting Remark

C2.00 Accel. ramp 1 360.0 s time from 0 Hz to f max

C2.01 Decel. ramp 1 1800.0 s

C3.00 Minimum frequency 2.00 Hz defines speed range

C3.01 Maximum frequency 50.00 Hz

C6.46 Stop delay 0.0 s only affects to Remote-commands !

D1.11 AI_2 value 0% 0.00 Hz defines range of reference value

D1.12 AI_2 value 100% 50.00 Hz

E2.04 Imax at 0 Hz 50% adjust for motors with separate cooling

E2.05 Imax at fnom 100% thermal motor protection !

E2.07 Motor time constant 5 min thermal motor protection !

E3.03 Loss of 4mA Activation not active set to Ready + Run if required

>pDRIVE< MX plus with PDZ6 for Backdrive – 8 074 128.00/00 – Page 6

Parameters which have to be set only after modifying configuration:

Parameter Name Setting Remark

A6.00 Selection of zone 1 Machine speed

C3.02 Direction enable Disable REV

C6.17 T 100%= 0 Nm

C6.22 Control angle 0.0°

D1.09 AI_2 selection f-ref Auto

D1.10 AI_2 level 4-20 mA monitored

D2.00 DI1 selection Start FWD

D2.01 DI2 selection External fault

D2.02 DI3 selection External Reset

D3.00 AO1 selection |Speed|

D3.03 AO1 max. value 100 %

Macros

D3.04 AO2_2 selection |Speed|

D4.01 Relay output 1 Trip

D4.02 Relay output 2_2 Output Logic 5

D4.03 Relay output 3_2 Run

E3.11 Ext. fault Activation N.O. Run

F4.44 L5 signal to D1 f=fref

F4.45 L5 signal to D2 Run

F4.46 L5 logic function AND

F4.47 L5 time function ON-delay

F4.48 L5 time set 5.0 s

Simplified diagram of reference value use

>pDRIVE< MX plus with PDZ6 for Backdrive – 8 074 128.00/00 – Page 7

Remarks:

The bowl starts up in accordance with the set acceleration ramp. If it is set too short, the start-up is carried out

at the internal current limitation (120 % IN”P”for 60 s, then IN”P”usually =nominal motorcurrent).

Check the rotational direction of the drive motor before start-up.

To change the direction, two motor phases must be crossed or parameter C3.03 Phase rotation must

be adjusted.

At motors with separate cooling, the thermal motor model must be adjusted (set parameter E2.04 to

100%).

If operating speeds below 5 Hz are required for longer time periods (e.g. during a wash program), the

stall protection must be adjusted accordingly. See parameters E2.08 to E2.10.

The bowl starts up in accordance with the set acceleration ramp. If it is set too short, the start-up is

carried out at the internal current limitation (120 % IN"P" for 60 s, then IN"P" is usually equal to nominal

motor current).

Start-up current in accordance

with set acceleration ramp

Start-up current at the

current limit

Ein Zu- und Abschalten des Antriebes während der Trommelhochlaufphase ist jederzeit möglich.

Der Frequenzumrichter synchronisiert sich innerhalb weniger Millisekunden automatisch auf die in

Drehung befindliche Trommel.

Zur Einbindung von anlagenseitig erfaßten Schutzabschaltungen wie Vibrocontrolauswertung,

Schmierungswächter, Lagertemperaturerfassung usw. in das Umrichterschutzkonzept steht der

Digitaleingang “Externe Störung” zur Verfügung. Je nachdem, ob es sich bei der Störkette um Öffner-

oder Schließerkontakte handelt, ist Parameter E3.11 anzupassen.

>pDRIVE< MX plus with PDZ6 for Backdrive – 8 074 128.00/00 – Page 8

Backdrive

B2.03 Macro selection VICB → (3) … Backdrive

To activate the functions for the backdrive, it is necessary th set parameter B2.03 to "3…Backdrive" !

Macros

Parameters which always have to be adjusted:

Parameter Name Setting Remark

C6.17 T 100% = 0 Nm reference torque

C6.18 dn min 0.0 rpm point 1 of steady state characteristic

C6.19 T1 0%

C6.20 dn max 0.0 rpm point 2 of steady state characteristic

C6.21 T2 0%

C6.22 Control angle 0° alternatively to T2 (C6.21)

2

C6.26 Inertia 1.0 kgm of Backdrive system x 1.5

C6.27 Torque limit 1 85 % 100% = nom. motor torque

C6.28 Hysteresis 1 15 %

C6.29 Torque limit 2 120 % 100% = nom. motor torque

C6.30 Hysteresis 2 0%

C6.32 Bowl speed 100%= 1 rpm scaling of bowl speed

C6.33 i-belt 1.000

C6.34 i gearbox 1 1.000

C6.35 dn-stoping 0.0 rpm for Backdrives in generator operation

limitation to valid mechanical torque

E1.01 Torque max. value 120%

120% = nom. motor torque !

E2.00 Thermistor input Activ. not active thermal motor protection !

>pDRIVE< MX plus with PDZ6 for Backdrive – 8 074 128.00/00 – Page 9

Parameters which have to be adjusted if required:

Parameter Name Setting Remark

C2.02 Accel. ramp 2 0.0 s for Dn-preset operation or jolt operation

C2.03 Decel. ramp 2 0.0 s

C3.01 Maximum frequency 50.00 Hz for f>50 Hz !

C6.16 dn 100%= 50.0 rpm scaling of speed difference

C6.23 Curve Linear selection of steady state characteristic

C6.24 Distortion 0%

C6.25 Dig. Hysteresis 10 %

C6.31 Filter time 10.0 s filter for load monitoring

C6.36 Friction torque 0% compensation of friction torque

C6.37 f/t-destination f-ref Manual

C6.38 Jolt frequency 15 Hz jolt mode

C6.39 FWD time 8.0 s

C6.40 REV time 4.0 s

E2.04 Imax at 0 Hz 50% adjust for motors with separate cooling

E2.05 Imax at fnom 100% thermal motor protection !

E2.07 Motor time constant 5 min thermal motor protection !

E3.03 Loss of 4mA Activation not active set to Ready + Run if required

Parameters which have to be set only after modifying configuration:

Parameter Name Setting Remark

A6.00 Selection of zone 1 dn-act calculation

A6.01 Selection of zone 2 bowl speed

A6.02 Selection of zone 3 ⏐Load⏐

C1.02 Stop mode Free wheel

C2.00 Accel. ramp 1 3.0 s

C2.01 Decel ramp 1 3.0 s

C3.02 Direction enable Enable FWD/REV

C6.15 f-ref destination f-ref Auto

C6.47 i-gearbox 2 -1.000 must not be adjusted !

C6.48 Belt factor 0.000 must not be adjusted !

D1.04 AIC selection Offset 1

D1.05 AIC level 4-20 mA monitored

D1.06 AIC value 0% 0%

D1.07 AIC value 100% 100 %

D1.09 AI_2 selection Bowl speed

D1.10 AI_2 level 4-20 mA monitored

D1.11 AI_2 value 0% 0.00 %

D1.12 AI_2 value 100% 100.00 %

D1.14 AI_3 selection dn-preset

D1.15 AI_3 level 4-20 mA ignored set to "monitored" if required

D1.16 AI_3 value 0% 0.00 %

D1.17 AI_3 value 100% 100.00 %

D2.00 DI1 selection Start FWD

>pDRIVE< MX plus with PDZ6 for Backdrive – 8 074 128.00/00 – Page 10

Parameter Name Setting Remark

D2.01 DI2 selection External fault

D2.02 DI3 selection External Reset

D2.03 DI4 selection Stoping

D2.04 DI6 selection ∆n-preset operation

D2.05 DI7 selection Manual (Auto)

D2.06 DI8 selection 2. ramp

D3.00 AO1 selectionl dn-act calculation

D3.03 AO1 max. value 100 %

D3.04 AO2_2 selection ⏐Load⏐

D3.07 AO2_2 max. value 150%

D3.08 AO2_3 selection |Speed|

D3.11 AO2_3 max. value 100%

D4.01 Relay output 1 Trip

D4.02 Relay output 2_2 T>T1

Macros

D4.03 Relay output 3_2 Run

D4.04 Relay output 2_3 T>T2

E3.11 Ext. fault Activation N.O. Run

E5.00 Skip frequency 1 0.00 Hz

E5.01 Hysteresis 1 2.00 Hz

Simplified diagram of reference value use

>pDRIVE< MX plus with PDZ6 for Backdrive – 8 074 128.00/00 – Page 11

Remarks:

Check the rotational direction of the backdrive motor before starting up. During bowl standstill, take

notice that…

– The gear tappet in a generator backdrive system turns in the opposite direction from the bowl drive.

– The gear tappet in a motor backdrive system and the bowl drive rotate in the same direction.

A wrong rotational direction of the backdrive can be identified if the differential speed decreases in

steady state characteristic mode with increasing load (torque).

To change the rotational direction of the backdrive motor, two motor phases must be crossed or

parameter C3.03 Phase rotation must be adjusted.

In order to allow deceleration with a higher differential speed in generator backdrive systems, the

Start/Stop command must be integrated in the main drive as deceleration command, and the stop

delay must be set on the main drive (C6.46).

Operation of the frequency inverter at frequencies less than ± 2 Hz is not permissible for static reasons.

This range is avoided with an active frequency mask.

In order to avoid overloading the mechanical system, please make sure that the torque provided by the

motor is lower than the mechanically permissible torque.

The maximum torque is set with parameter E1.01. 100% correspond to the nominal motor torque.

At backdrive motors with separate cooling, the thermal motor model must be adjusted (set parameter

E2.04 to 100%).

>pDRIVE< MX plus with PDZ6 for Backdrive – 8 074 128.00/00 – Page 12

Detailled Description of procedural parameters

B2.03 Macro selection VICB Maindrive

0 .... Maindrive y

3 .... Backdrive

C6.15 f-ref destination VCB not used

0 ... not used y Hz

1 ... f-ref Manual Hz

2 ... f-ref Auto Hz

3 ... f-correction Hz

4 ... Torque limit %

5 ... PID reference %

6 ... PID feedback %

9 ... Offset 1 %

10 . Offset 2 %

11 . Bowl speed %

12 . dn preset %

The parameter is set automatically depending on the selected macro.

See chapter Macros "Simplified diagram of reference value use " or chapter "D1 – Analog inputs" in

the operating instructions for PDZ6.

C6.16 dn 100% = VCB 1...50...200

Represents the internal standard for differential speed. This parameter also has an effect on the setting of

parameters C6.17, C6.19 and C6.33.

Parameter description

The set value only needs to be adjusted, if:

a) differential speeds of over 100 rpm are required

b) a high resolution for the Dn-preset reference is required.

C6.17 T 100% = VCB 1...50...200

By adjusting this parameter, the %-values of the parameters below are not related to the nominal motor torque

any longer. Then they are related to the set "Reference torque".

Typically, the parameter is adjusted to the nominal torque of the gear (related to the motor shaft):

Nom. torque of gear [Nm]

C6.17 =

i

Gearbox 1

C6.17 has effect on following parameters:

Parameter: C6.19 T1 Actual values: Load

C6.21 T2 ⏐Load⏐

C6.27 Torque limit 1

C6.28 Hysteresis 1

C6.29 Torque limit 2

C6.30 Hysteresis 2

>pDRIVE< MX plus with PDZ6 for Backdrive – 8 074 128.00/00 – Page 13

Example: Motor: 30 kW; 1475 rpm

Gear box: TN = 38 000 Nm; i = 221

30 38000

TNom.,Motor = 9550 ⋅ = 194 Nm TGear box = ≈ 172 Nm

1475 221

C6.17 = 0 Nm C6.17 = 172 Nm

100 % = Nom. motor torque = 194 Nm Torque of gear box = 172 Nm

Parameters in % are related to the nominal motor torque or to the internal reference torque, which is

defined with parameter C6.17.

C6.18 dn min VCB -100...0...+100 rpm

C6.19 T1 VCB -200...0...+200 %

C6.20 dn max VCB -100...0...+100 rpm

C6.21 T2 VCB -200...0...+200 %

C6.22 Control angleα VCB 0...0...90°

The procedural characteristic differential speed/torque can be adjusted by two different methods:

Method 1

defined by:

point 1 at characteristic: ∆nMIN/T1

point 2 at characteristic: ∆nMAX/T2

Method 2

defined by:

∆nMIN, ∆nMAX

start of control at T1

control angle α

scaling x: 2,54 pm/cm

scaling y: 10%/cm

If parameter C6.22 Control angle is adjusted > 0, the characteristic is automatically generated according to

method 2. In this case, parameter C6.21 T2 is without effect.

100 % torque correspond to the reference torque C6.17 "T 100% =" or to the nominal motor torque,

if C6.17 = 0.

The adjustable range of parameters C6.18 and C6.20 depends on the ∆n standard C6.16.

>pDRIVE< MX plus with PDZ6 for Backdrive – 8 074 128.00/00 – Page 14

C6.23 Curve VCB linear

0 ... linear y

1 ... convex

2 ... concave

3 ... digital

To comply with the procedural requirements, the steady state characteristic can be adjusted with parameters

C6.18 to C6.22 as follows.

C6.24 Distortion VCB 0...0...100 %

C6.23 = 1…convex

C6.23 = 2…concave

Parameter description

C6.23 = 3…digital

C6.25 Dig. Hysteresis VCB 0...10...50 %

The degree of distortion can be adjusted with parameter C6.22: 0 % = linear

100 % = digital

Parameter C6.23 adjusts the response hysteresis, which is only active at digital steady state characteristic.

C6.26 Inertia VCB 0.0...1.0...25 kgm2

In order to keep the differential speed control dynamically stable, the centrifugal mass of the backdrive system

must be set.

Centrifugal mass of the motor + Coupling or pulley

typically 3 x Jmotor

>pDRIVE< MX plus with PDZ6 for Backdrive – 8 074 128.00/00 – Page 15

Typical centrifugal mass of motors

Power Nominal speed

[kW] VN·3000 rpm VN·1500 rpm VN·1000 rpm

2.2 0.002 0.005 0.010

3.0 0.003 0.006 0.027

4.0 0.005 0.010 0.034

5.5 0.010 0.022 0.040

7.5 0.014 0.030 0.078

11 0.032 0.06 0.12

15 0.04 0.1 0.17

18.5 0.05 0.12 0.19

22 0.07 0.14 0.24

30 0.12 0.24 0.42

37 0.14 0.36 0.64

45 0.21 0.44 1.00

55 0.34 0.64 1.15

75 0.51 0.89 2.5

90 0.63 1.05 3.1

110 1.0 1.9 3.6

132 1.2 2.2 4.3

160 1.4 2.5 6.8

C6.27 Torque limit 1 VCB 0...85...200 %

C6.28 Hysteresis 1 VCB 0...15...50 %

C6.29 Torque limit 2 VCB 0...120...200 %

C6.30 Hysteresis 2 VCB 0...0...50 %

C6.31 Filter time VCB 0.0...10.0...100.0 s

The motor torque is monitored by 2 limit value comparators, each with symmetrical hysteresis.

The response sensitivity can be changed using parameter C6.31 if necessary.

100 % torque correspond to the reference torque C6.17 "T 100% =" or to the nominal motor torque,

if C6.17 = 0.

>pDRIVE< MX plus with PDZ6 for Backdrive – 8 074 128.00/00 – Page 16

C6.32 Bowl speed 100% VCB 1...1...6000 rpm

The speed at which the maximum speed (C3.01) of the maindrive on the bowl is reached must be set.

Example:

C6.33 i-belt VCB 0.000...1.000...1000.0

nmotor pulley diameter tappet

ibelt = =

n tappet pulley diametermotor

Example:

v-belt drive

Parameter description

directly coupled backdrive

If the backdrive motor is coupled directly with the shaft, the transmission factor i = 1.

C6.34 i-gearbox 1 VCB 0.000...0.000...1000.0

Transmission factor of the backdrive gear.

Negative values (in case of odd number of reduction levels) have to be set as positive values !

C6.35 dn-stoping VCB -100...0.0...+100.0 rpm

In order to achieve a good clearance of the screw during stoping the centrifuge, there is a changeover to a

load-independent "Stoping differential speed" when stoping.

At generator backdrive systems, this parameter must be set high enough so that the rotational direction of the

backdrive changes, i.e. switch over to motor mode.

The adjustment range depends on parameter C6.16!

>pDRIVE< MX plus with PDZ6 for Backdrive – 8 074 128.00/00 – Page 17

C6.36 Friction torque VCB -50...0...+50 %

The friction torque arising between the screw and the inside of the bowl can be compensated using this

parameter.

This compensation is only necessary in generator backdrives with a flat steady state characteristic.

C6.37 f/t-destination VCB not used

0 ... not used y Hz

1 ... f-ref Manual Hz

2 ... f-ref Auto Hz

3 ... f-correction Hz

4 ... Torque limit %

5 ... PID reference %

6 ... PID feedback %

9 ... Offset 1 %

10 . Offset 2 %

11 . Bowl speed %

12 . dn preset %

Mithilfe dieses Parameters kann ein einstellbarer Frequenz/Zeit-Rechteckgenerator im Drehzahlmodus

als Quelle für eine Rüttelfrequenz an den SW-Kanal f-SW Hand gelegt werden.

In order to release the screw at stucking centrifuges, a changeover to speed control mode is possible when the

bowl is at a standstill. As long as the start command is applied to the backdrive inverter, it will alternate

forward/reverse rotations with small ramps and maximum torque, whereby the time period for rotation in

direction of screw output must be set longer.

During the jolt process, 150 % of the motor torque are available.

Check the gear regarding short-time shock overload!

C6.38 Jolt frequency VCB 0.0...15.0...100.0 Hz

C6.39 FWD time VCB 0.1...8.0...150.0 s

C6.40 REV time VCB 0.1...4.0...150.0 s

The screw discharge direction (FWD/REV)

depends on the machine !

C6.46 Stop delay VCB 0.0...0.0...30.0 s

In order to enable deceleration with high differential speed in generator backdrive systems, a switch of the

backdrive motor to motor mode is necessary before the actual deceleration process on the main drive.

The time required for this switch-over must be set as stop delay time (see parameter C6.35).

>pDRIVE< MX plus with PDZ6 for Backdrive – 8 074 128.00/00 – Page 18

C6.47 i-gearbox 2 VCB -1.000...-1.000...1000.0

C6.48 Belt factor VCB 0.000...0.000...1000.0

Parameters C6.47 and C6.48 are reserved for adjustments in special applications and must not be

modified !

In order to keep lucidity in the four procedural instructions, we omitted the description of parameters

which are not relevant for this process. Please keep this parameters at their default values !

Parameter description

>pDRIVE< MX plus with PDZ6 for Backdrive – 8 074 128.00/00 – Page 19

>pDRIVE< MX plus with software PDZ6 Parameter list

General Data of the Frequency Inverter

Voltage: 400 V 440 V 460 (480) V 500 V

Inverter type: 04 05 07 11 15/18

75/90 90/110 110/132 132/160 160/200

315/380 315/400 400/500 500/630 630/800

800/1000 1000/1200 1200/1500

Serial number: Code:

Customer / Company: Supplier / Company:

Delivery date: Start-up date:

Parameter Maindrive User macro 1 Backdrive User macro 2

Standard Standard

Parameter name, Settings stored Settings stored

settings for the settings for the

parameter number by the user by the user

maindrive backdrive

A2 Motor values

A2.10 Process scaling +1.000 +1.000

A2.11 Machine scaling +1.000 +0.000

A3 Inverter values

A3.05 Drive reference depends on drive depends on drive

A3.06 Nominal current "C" depends on drive depends on drive

A3.07 Hardware version depends on drive depends on drive

A3.08 Software type depends on drive depends on drive

A3.09 Software version depends on drive depends on drive

A3.10 Serial number depends on drive depends on drive

A5 Time / kWh

A5.04 Maintenance at 0h 0h

A6 Display configuration

A6.00 Selection of zone 1 (10) Mach. speed (23) dn-act.calc.

A6.01 Selection of zone 2 (11) Speed ref. (25) bowl speed

A6.02 Selection of zone 3 (5) Motor current (30) ⏐Load⏐

A6.03 View limitation (0) not visible (0) not visible

>pDRIVE< MX plus with PDZ6 for Backdrive – 8 074 128.00/00 – Page 20

Parameter Maindrive User macro 1 Backdrive User macro 2

B1 Language selection

B1.00 Select language (0) German (0) German

B2 Macro configuration

B2.00 Macro selected (0) Maindrive (3) Backdrive

B2.01 Store Usermacro UM1 (0) Start 0 → 1 (0) Start 0 → 1

B2.02 Store Usermacro UM2 (0) Start 0 → 1 (0) Start 0 → 1

B2.03 Macro selection (0) Maindrive (3) Backdrive

B2.04 Multi-configuration (0) not active (0) not active

B3 Motor data

B3.00 Nominal power depends on drive depends on drive

B3.01 Nominal current depends on drive depends on drive

B3.02 Nominal voltage depends on drive depends on drive

B3.03 Nominal frequency depends on drive depends on drive

B3.04 Nominal speed depends on drive depends on drive

B3.05 Line voltage (3) 500V; 50Hz (3) 500V; 50Hz

B3.06 Operation with IR (0) No (0) No

B3.08 Sine motor filter (0) not used (0) not used

B3.09 Heating current 15 % 15 %

B4 Auto tune

B4.00 Start tuning (0) Start 0 → 1 (0) Start 0 → 1

B4.01 Rotor coefficient depends on drive depends on drive

B4.02 Rotor time constant depends on drive depends on drive

B4.03 Stator resistor depends on drive depends on drive

B4.04 Fluxing current depends on drive depends on drive

B6 Communications menu

B6.00 Select bus (0) No bus (0) No bus

B6.01 Select remote (0) Terminals (0) Terminals

B6.02 Slave address 0 0

B6.03 Stop Mode Time out (0) Alarm only (0) Alarm only

B6.04 Time OUT 0.0 s 0.0 s

B6.05 ON after OFF1,3 (1) possible (1) possible

B6.06 Main-reference 1 (0) not used (0) not used

B6.07 Aux.-reference 2 (0) not used (0) not used

B6.08 Aux.-reference 3 (0) not used (0) not used

Parameter list

B6.09 Aux.-reference 4 (0) not used (0) not used

B6.10 Aux.-reference 5 (0) not used (0) not used

B6.11 Actual value 1 (28) bowl speed (28) bowl speed

B6.12 Actual 1 filter time 0.10 s 0.10 s

>pDRIVE< MX plus with PDZ6 for Backdrive – 8 074 128.00/00 – Page 21

Parameter Maindrive User macro 1 Backdrive User macro 2

B6.13 Aux. actual value 2 (26) dn-act.calc. (26) dn-act.calc.

B6.14 Actual 2 filter time 0.10 s 0.10 s

B6.15 Aux. actual value 3 (4) Torque (4) Torque

B6.16 Actual 3 filter time 0.10 s 0.10 s

B6.17 Aux. actual value 4 (1) Output frequ. (1) Output frequ.

B6.18 Actual 4 filter time 0.10 s 0.10 s

B6.19 Aux. actual value 5 (3) Outp.current (3) Outp.current

B6.20 Actual 5 filter time 0.10 s 0.10 s

B6.21 Bit 11 Control word (0) not used (0) not used

B6.22 Bit 12 Control word (0) not used (0) not used

B6.23 Bit 13 Control word (0) not used (0) not used

B6.24 Bit 14 Control word (0) not used (0) not used

B6.25 Bit 15 Control word (0) not used (0) not used

B6.26 Bit 11 Status word (15) Out.log.L5 (15) Out.log.L5

B6.27 Bit 12 Status word (43) T>T1 (43) T>T1

B6.28 Bit 13 Status word (44) T>T2 (44) T>T2

B6.29 Bit 14 Status word (22) DI6_2 (22) DI6_2

B6.30 Bit 15 Status word (23) DI7_2 (23) DI7_2

B6.34 Communicat. PPO Type (1) Type 2 (1) Type 2

C1 General functions

C1.00 Increase start torque 1% 1%

C1.01 Increase steady torque 10 Hz 10 Hz

C1.02 Stop mode (1) Decel. ramp (2) Fast-stop

C1.03 Braking mode (0) no brak.funct. (0) no brak.funct.

C1.04 Braking level 790 V 790 V

C1.05 BU parallel operation (0) not active (0) not active

C1.06 Preset reference (0) not used (0) not used

C1.07 Pre-set reference 1 +0.00 Hz +0.00 Hz

C1.08 Pre-set reference 2 +0.00 Hz +0.00 Hz

C1.09 Pre-set reference 3 +0.00 Hz +0.00 Hz

C1.10 Pre-set reference 4 +0.00 Hz +0.00 Hz

C1.11 Pre-set reference 5 +0.00 Hz +0.00 Hz

C1.12 Pre-set reference 6 +0.00 Hz +0.00 Hz

C1.13 Pre-set reference 7 +0.00 Hz +0.00 Hz

C1.14 Pre-set reference 8 +0.00 Hz +0.00 Hz

C1.15 Jog-frequency +0.00 Hz +0.00 Hz

>pDRIVE< MX plus with PDZ6 for Backdrive – 8 074 128.00/00 – Page 22

Parameter Maindrive User macro 1 Backdrive User macro 2

C2 Ramps

C2.00 Acceleration ramp 1 360.0 s 3.0 s

C2.01 Deceleration ramp 1 1800.0 s 3.0 s

C2.02 Acceleration ramp 2 20.1 s 0.0 s

C2.03 Deceleration ramp 2 20.1 s 0.0 s

C2.04 S-ramp (0) no S-ramp (0) no S-ramp

C2.05 S-ramp mode (0) Begin + End (0) Begin + End

C2.06 Switch 1./2. Accelerat. 0.00 Hz 0.00 Hz

C2.07 Umschalt. 1./2. Tiefl. 0.00 Hz 0.00 Hz

C2.08 Deceleration persistant f 0.00 Hz 0.00 Hz

C2.09 Deceleration persistant t 0.0 s 0.0 s

C3 Speed range

C3.00 Minimum frequency 2.00 Hz 2.00 Hz

C3.01 Maximum frequency 50.00 Hz 50.00 Hz

C3.02 Direction Enable (0) Disable REV (2) En.FWD/REV

C3.03 Phase rotation (0) U-V-W/A-B-C (0) U-V-W/A-B-C

C4 PID configuration

C4.04 PID active (0) No (0) No

C4.05 Proportional gain (kp) 0.0 % 0.0 %

C4.06 Integration time (Tn) 0.00 s 0.00 s

C4.07 Derive time (Tv) 0.00 s 0.00 s

C4.08 Ref. acceleration ramp 0.0 s 0.0 s

C4.09 Ref. deceleration ramp 0.0 s 0.0 s

C4.10 Output scaling - +0.00 Hz +0.00 Hz

C4.11 Output scaling + +0.00 Hz +0.00 Hz

C5 Catch on the fly

C5.00 Detection level 0.6 % 0.6 %

C6 Special functions

C6.00 Contactor control (0) not active (0) not active

C6.15 f-ref. destination (0) not used (2) f-ref Auto

C6.16 dn 100% = 0.0 rpm 50.0 rpm

C6.17 T 100% = 0 Nm 0 Nm

Parameter list

C6.18 dn min 0.0 rpm 0.0 rpm

C6.19 T1 0% 0%

C6.20 dn max 0.0 rpm 0.0 rpm

C6.21 T2 0% 0%

>pDRIVE< MX plus with PDZ6 for Backdrive – 8 074 128.00/00 – Page 23

Parameter Maindrive User macro 1 Backdrive User macro 2

C6.22 Control angle 0° 0°

C6.23 Curve (1) convex (0) linear

C6.24 Distortion 1% 0%

C6.25 Dig. Hysteresis 0% 10 %

C6.26 Inertia 0.0 kgm2 1.0 kgm2

C6.27 Torque limit 1 0% 85 %

C6.28 Hysteresis 1 0% 15 %

C6.29 Torque limit 2 0% 120 %

C6.30 Hysteresis 2 0% 0%

C6.31 Filter time 0.0 s 10.0 s

C6.32 Bowl speed 100% 0 rpm 1 rpm

C6.33 i-belt 0.000 1.000

C6.34 i-gearbox 1 0.000 1.000

C6.35 dn-stoping 0.0 rpm 0.0 rpm

C6.36 Friction torque 0% 0%

C6.37 f/t-destination (0) not used (1) f-ref Manual

C6.38 Jolt frequency 0.0 Hz 15.0 Hz

C6.39 REV time 0.0 s 8.0 s

C6.40 FWD time 0.0 s 4.0 s

C6.41 Pump volume 0.10 0.10

C6.42 Ballast volume 0.10 l/rotation 0.10 l/rotation

C6.43 Calibration factor 0.000 0.000

C6.44 Vol. Efficiency 0% 0%

C6.45 dn-reference destination (0) not used (0) not used

C6.46 Stop delay 0.0 s 0.0 s

C6.47 i-gearbox 2 0.000 -1.000

C6.48 Belt factor 0.010 0.000

C6.49 i-gearbox 4 0.000 0.000

D1 Analog inputs

D1.00 AIV Selection (0) not used (0) not used

D1.01 AIV-value 0% +0.01 Hz +0.01 Hz

D1.02 AIV-value 100% +0.01 Hz +0.01 Hz

D1.03 AIV-filter time 0.05 s 0.05 s

D1.04 AIC-selection (0) not used (9) Offset 1

D1.05 AIC-level (0) 0-20mA (1) 4-20mA monit.

D1.06 AIC-value 0% +0.01 Hz +0.00 %

>pDRIVE< MX plus with PDZ6 for Backdrive – 8 074 128.00/00 – Page 24

Parameter Maindrive User macro 1 Backdrive User macro 2

D1.07 AIC-value 100% +0.01 Hz +100.00 %

D1.08 AIC-filter time 0.05 s 0.05 s

D1.09 AI_2-selection (2) f-ref Auto (11) Bowl speed

D1.10 AI_2-level (1) 4-20mA monit. (1) 4-20mA monit.

D1.11 AI_2-value 0% 0.00 Hz 0.00 Hz

D1.12 AI_2-value 100% +50.00 Hz +100.00 Hz

D1.13 AI_2-filtertime 0.05 s 0.05 s

D1.14 AI_3-selection (0) not used (12) dn-Stell

D1.15 AI_3-level (0) 0-20mA (2) 4-20mA ignor.

D1.16 AI_3-value 0% +0.01 Hz 0.00 %

D1.17 AI_3-value 100% +0.01 Hz +100.00 Hz

D1.18 AI_3-filtertime 0.05 s 0.05 s

D2 Logic inputs

D2.00 DI1-selection (1) Start FWD (1) Start FWD

D2.01 DI2-selection (22) Ext. fault (22) Ext. fault

D2.02 DI3-selection (26) Ext. Reset (26) Ext. Reset

D2.03 DI4-selection (0) not used (42) Stoping

D2.04 DI6_2-selection (0) not used (43) dn-preset op.

D2.05 DI7_2-selection (0) not used (17) Man. (Auto)

D2.06 DI8_2-selection (0) not used (19) 2. ramp

D2.07 DI5_3-selection (0) not used (0) not used

D2.08 DI6_3-selection (0) not used (0) not used

D2.09 DI7_3-selection (0) not used (0) not used

D2.10 DI8_3-selection (0) not used (0) not used

D3 Analog outputs

D3.00 AO1-selection (9) ⏐Speed⏐ (24) dn-act.calc.

D3.01 AO1_level (1) 4-20mA (1) 4-20mA

D3.02 AO1-minimum value +0 % +0 %

D3.03 AO1-maximum value +100 % +100 %

D3.04 AO2_2-selection (9) ⏐Speed⏐ (30) ⏐Load⏐

D3.05 AO2_2-level (1) 4-20mA (1) 4-20mA

D3.06 AO2_2-minimum value +0 % +0 %

D3.07 AO2_2-maximum value +100 % +150 %

Parameter list

D3.08 AO2_3-selection (0) not used (9) ⏐Speed⏐

D3.09 AO2_3-level (1) 4-20mA (1) 4-20mA

D3.10 AO2_3-minimum value +0 % +0 %

D3.11 AO2_3-maximum value +100 % +100 %

>pDRIVE< MX plus with PDZ6 for Backdrive – 8 074 128.00/00 – Page 25

Parameter Maindrive User macro 1 Backdrive User macro 2

D4 Logic outputs

D4.00 +24 digital output (25) ON (+24V) (25) ON (+24V)

D4.01 Relay output 1 (3) Trip (3) Trip

D4.02 Relay output 2_2 (17) Out.log. L5 (41) T>T1

D4.03 Relay output 3_2 (2) RUN (2) RUN

D4.04 Relay output 2_3 (0) not used (42) T>T2

D4.05 Relay output 3_3 (0) not used (0) not used

D4.06 f-Level ON 0.01 Hz 0.01 Hz

D4.07 f-Level OFF 0.01 Hz 0.01 Hz

D4.08 Hysteresis f=f-ref 0.5 Hz 0.5 Hz

D5 Encoder configuration

D5.00 Encoder/Slipcompensat. (0) No encoder (0) No encoder

D5.01 Dynamic Slipcompens. (0) low (0) low

D6 Electronic potentiometer

D6.00 Local MP selection (0) f-reference (0) f-reference

D6.01 Local MP min. value +0.00 Hz +0.00 Hz

D6.02 Local MP max. value +50.00 Hz +50.00 Hz

D6.03 Local MP acceler. time 10.0 s 10.0 s

D6.04 Local MP deceler. time 10.0 s 10.0 s

D6.05 Local ref. storage (0) not active (0) not active

D6.06 Remote MP selection (0) not used (0) not used

D6.07 Remote MP min. value 0.00 Hz 0.00 Hz

D6.08 Remote MP max. value 0.00 Hz 0.00 Hz

D6.09 Remote MP accel. time 0.1 s 0.1 s

D6.10 Remote MP decel. time 0.1 s 0.1 s

D6.11 Remote MP control (1) keypad (1) keypad

D6.12 Remote ref. storage (0) not active (0) not active

E1 Drive overload

E1.00 Current max. value 150 % 150 %

E1.01 Torque max. value 200 % 120 %

E2 Motor protection

E2.00 Thermistor input Activat. (0) not active (0) not active

E2.01 Thermistor input Resp. (0) Trip (0) Trip

E2.02 Motoroverload Response (0) Current limit. (0) Current limit.

E2.03 Level of motor overload 118 % 118 %

E2.04 I max at 0 Hz 50 % 50 %

>pDRIVE< MX plus with PDZ6 for Backdrive – 8 074 128.00/00 – Page 26

Parameter Maindrive User macro 1 Backdrive User macro 2

E2.05 I max at f nom. 100 % 100 %

E2.06 Thermal f-limitation 30 Hz 30 Hz

E2.07 Motor-time constant 5 min 5 min

E2.08 Stalling time 60 s 60 s

E2.09 Stalling frequency 5 Hz 5 Hz

E2.10 Stalling current 80 % 80 %

E2.11 n>> protection (1) Trip (1) Trip

E2.12 n max motor 3200 rpm 3200 rpm

E2.13 Ext. motor fault Activat. (0) not active (0) not active

E2.14 Ext. motor fault Response (0) Trip (0) Trip

E2.15 Ext. motor fault time del. 1.0 s 1.0 s

E2.16 Underload Response (0) not active (0) not active

E2.17 Underload f-nom/2 15 % 15 %

E2.18 Underload f-nom 55 % 55 %

E2.19 Underload PID Error 50 % 50 %

E2.20 Underload Start time 10.0 s 10.0 s

E2.21 Underload Filter time 3.0 s 3.0 s

E3 Fault configuration

E3.00 Autorestart (0) not active (0) not active

E3.01 Local reset (1) active (1) active

E3.02 Reaction at trip (0) free wheel (0 free wheel

E3.03 Loss of 4mA Activation (2) Ready + Run (2) Ready + Run

E3.04 Loss of 4mA Response (0) Trip (0) Trip

E3.05 Loss of 4mA fixed frequ. 10.00 Hz 10.00 Hz

E3.06 BR overload Response (0) not active (0) not active

E3.07 BR continuous power 1.0 kW 1.0 kW

E3.08 BR Ohm value 10.0 Ohm 10.0 Ohm

E3.09 Ext. BS fault Activation (0) not active (0) not active

E3.10 Ext. BS fault time delay 5.0 s 5.0 s

E3.11 External fault Activation (3) N.O. Run (3) N.O. Run

E3.12 External fault Response (0) Trip (0) Trip

E3.13 External fault time delay 0.0 s 0.0 s

Parameter list

E3.14 Process fault Activation (0) not active (0) not active

E3.15 Process fault Response (0) Trip (0) Trip

E3.16 Process fault t1 delay 0.0 s 0.0 s

E3.17 Process fault t2 delay 0.0 s 0.0 s

>pDRIVE< MX plus with PDZ6 for Backdrive – 8 074 128.00/00 – Page 27

Parameter Maindrive User macro 1 Backdrive User macro 2

E3.18 Insulation fault Activation (0) not active (0) not active

E3.19 Insulation fault Response (0) Trip (0) Trip

E3.20 Insulation fault time del. 10.0 s 10.0 s

E3.21 Undervoltage Response (0) not active (0) not active

E3.22 Undervoltage time delay 2.0 s 2.0 s

E3.23 InverterTemp. Response (0) I-limit to 50% (0) I-limit to 50%

E4 Control configuration

E4.00 Local/Remote reference (0) Local/Remote (0) Local/Remote

E4.01 Local/Remote control (0) Local/Remote (0) Local/Remote

E4.02 Local/Remote-switch (0) Keypad (0) Keypad

E4.03 Control mode local (0) Keypad (0) Keypad

E4.04 Local STOP-Key (0) Loc active only (0) Loc active only

E5 Skip frequency

E5.00 Skip frequency 1 5.00 Hz 0.00 Hz

E5.01 Hysteresis 1 0.00 Hz 2.00 Hz

E5.02 Skip frequency 2 25.00 Hz 25.00 Hz

E5.03 Hysteresis 2 0.00 Hz 0.00 Hz

E6 Switching frequency

E6.00 Min. switching frequency (0) 2.5 kHz (0) 2.5 kHz

E6.01 Max. switching frequency (0) 2.5 kHz (0) 2.5 kHz

F1 Help

F1.00 Test power part (0) Start 0→1 (0) Start 0→1

F1.01 Test-control part (0) Start 0→1 (0) Start 0→1

F2 Factory settings

F2.00 Return factory applicat. (0) Start 0→1 (0) Start 0→1

F2.01 Return factory motor (0) Start 0→1 (0) Start 0→1

F3 Fault memory

F3.01 Review (0) newest event (0) newest event

F4 Function blocks

F4.00 C1 signal to E1 (0) 0.0 % (0) 0.0 %

F4.01 C1 filter for E1 0.1 s 0.1 s

F4.02 C1 reference +0.0 % +0.0 %

F4.03 C1 function (0) E1 > E2 (0) E1 > E2

F4.04 C1 Hysteresis/Band +5.0 % +5.0 %

F4.05 C1 time-function (0) ON-delay (0) ON-delay

>pDRIVE< MX plus with PDZ6 for Backdrive – 8 074 128.00/00 – Page 28

Parameter Maindrive User macro 1 Backdrive User macro 2

F4.06 C1 time-set 0.0 s 0.0 s

F4.07 C1 selection (0) not used (0) not used

F4.08 C2 signal to E1 (0) 0,0 % (0) 0,0 %

F4.09 C2 filter for E1 0.1 s 0.1 s

F4.10 C2 reference +0.0 % +0.0 %

F4.11 C2 function (0) E1 > E2 (0) E1 > E2

F4.12 C2 Hysteresis/Band +5.0 % +5.0 %

F4.13 C2 time-function (0) ON-delay (0) ON-delay

F4.14 C2 time-set 0.0 s 0.0 s

F4.15 C2 selection (0) not used (0) not used

F4.16 C3 signal to E1 (0) 0.0 % (0) 0.0 %

F4.17 C3 filter for E1 0.1 s 0.1 s

F4.18 C3 signal to E2 (0) Ref. value (0) Ref. value

F4.19 C3 filter for E2 0.1 s 0.1 s

F4.20 C3 reference +0.0 % +0.0 %

F4.21 C3 function (0) E1 > E2 (0) E1 > E2

F4.22 C3 Hysteresis/Band +5.0 % +5.0 %

F4.23 C3 Input D1 (0) State ZERO (0) State ZERO

F4.24 C3 Input D2 (0) State ZERO (0) State ZERO

F4.25 C3 logic 'a' function (1) OR (1) OR

F4.26 C3 logic 'b' function (1) OR (1) OR

F4.27 C3 time-function (0) ON-delay (0) ON-delay

F4.28 C3 time-set 0.0 s 0.0 s

F4.29 C3 selection (0) not used (0) not used

F4.30 C4 signal to E1 (0) 0.0 % (0) 0.0 %

F4.31 C4 filter for E1 0.1 s 0.1 s

F4.32 C4 signal to E2 (0) Ref. value (0) Ref. value

F4.33 C4 filter for E2 0.1 s 0.1 s

F4.34 C4 reference +0.0 % +0.0 %

F4.35 C4 function (0) E1 > E2 (0) E1 > E2

F4.36 C4 Hysteresis/Band +5.0 % +5.0 %

F4.37 C4 Input D1 (0) State ZERO (0) State ZERO

F4.38 C4 Input D2 (0) State ZERO (0) State ZERO

F4.39 C4 logic 'a' function (1) OR (1) OR

Parameter list

F4.40 C4 logic 'b' function (1) OR (1) OR

F4.41 C4 time-function (0) ON-delay (0) ON-delay

F4.42 C4 time-set 0.0 s 0.0 s

F4.43 C4 selection (0) not used (0) not used

>pDRIVE< MX plus with PDZ6 for Backdrive – 8 074 128.00/00 – Page 29

Parameter Maindrive User macro 1 Backdrive User macro 2

F4.44 L5 signal to D1 (9) f=fref (0) State ZERO

F4.45 L5 signal to D2 (2) Run (0) State ZERO

F4.46 L5 logic function (0) AND (1) OR

F4.47 L5 time-function (0) ON-delay (1) OFF-delay

F4.48 L5 time-set 5.0 s 0.0 s

F4.49 L5 selection (0) not used (0) not used

F4.50 L6 signal to D1 (0) State ZERO (0) State ZERO

F4.51 L6 signal to D2 (0) State ZERO (0) State ZERO

F4.52 L6 logic function (1) OR (1) OR

F4.53 L6 time-function (0) ON-delay (0) ON-delay

F4.54 L6 time-set 0.0 s 0.0 s

F4.55 L6 selection (0) not used (0) not used

F6 Code

F6.00 Code 0 0

F6.01 Code value 0 0

F6.02 Parameter-Access (0) Keypad (0) Keypad

F6.03 Pulse inhibit (0) No (0) No

Data stored into the USER macro ? Commissioned by:

yes Date:

no Signature:

>pDRIVE< MX plus with PDZ6 for Backdrive – 8 074 128.00/00 – Page 30

Schneider Electric Power Drives GmbH

Ruthnergasse 1

A-1210 Vienna

Phone: +43 (0)1 29191 0

Fax: +43 (0)1 29191 15

www.pdrive.com

Motor Inverter Reference Time Display

Display Home

Values Values Values kWh Configurat.

Language Macro Motor Auto Short Comm.

Setup Selection Configurat. Data tune Menu Menu

General Speed PID Catch on Special

Settings Ramps

Functions Range Configurat. the fly Functions

Analogue Logic Analogue Logic Encoder Electronic

I/O Inputs Inputs Outputs Outputs Configurat. Potentiom.

The right to make technical changes is reserved.

Drive Motor Fault Control Skip Switching

Drive Overload Protection Configurat. Configurat. Frequency Frequency

Factory Fault Function Code

Debug Test-Help Settings Memory Blocks Lock

8 074 128.00/00a HFSM

You might also like

- Dynamometer: Theory and Application to Engine TestingFrom EverandDynamometer: Theory and Application to Engine TestingNo ratings yet

- 8 074 410-00-00Document170 pages8 074 410-00-00gaby2003No ratings yet

- Sensorless Vector ControlDocument6 pagesSensorless Vector ControlDavid MartinNo ratings yet

- Manual de Transmision de TL642 Y TL943 CAT ZF - Powershift Trans - 4 WG-92-98 TSCDocument38 pagesManual de Transmision de TL642 Y TL943 CAT ZF - Powershift Trans - 4 WG-92-98 TSCWilson garcia100% (5)

- Tuning Gemini DriveDocument4 pagesTuning Gemini Drivejmzf1979No ratings yet

- CVT Thruster Delta Module Isolation and TestsDocument3 pagesCVT Thruster Delta Module Isolation and TestsmaheshachanNo ratings yet

- SmartGen MGC100 User ManualDocument16 pagesSmartGen MGC100 User ManualDennis RobinsonNo ratings yet

- W7619en DS7 ProductInfoDocument6 pagesW7619en DS7 ProductInfore marNo ratings yet

- EM,EP ENGLISH 매뉴얼Document224 pagesEM,EP ENGLISH 매뉴얼Bình Nguyễn DuyNo ratings yet

- Torque Follower Setup Rev 1Document7 pagesTorque Follower Setup Rev 1NelsonNo ratings yet

- Triac Application NoteDocument10 pagesTriac Application Notewizardgrt1No ratings yet

- Variador Carlo GavazziDocument107 pagesVariador Carlo GavazziPepe ChampiiNo ratings yet

- Intelligent Stepper Motor Driver With DRV8824Document22 pagesIntelligent Stepper Motor Driver With DRV8824RintheGreatNo ratings yet

- 03 Hoisting GearDocument89 pages03 Hoisting GearpablodcabreraNo ratings yet

- Eet 4217 Lab1Document6 pagesEet 4217 Lab1Dilrangi HerathNo ratings yet

- CT Speed Loop TuningDocument6 pagesCT Speed Loop TuningM. Hakan KocakNo ratings yet

- Sensorless Speed Controlled Brushless DC Drive Using The TMS320C242 DSP ControllerDocument17 pagesSensorless Speed Controlled Brushless DC Drive Using The TMS320C242 DSP ControllerVladv123No ratings yet

- Chapter 1. General Information: Installation and OperationDocument10 pagesChapter 1. General Information: Installation and OperationGustavo PereiraNo ratings yet

- m640 ReinicializacionDocument24 pagesm640 ReinicializacionRafał BugalskiNo ratings yet

- Project Report On Speed Control of DC Motor by Using PWM TechniqueDocument75 pagesProject Report On Speed Control of DC Motor by Using PWM Techniquepandyamech80% (15)

- 828D Servo OptimisationDocument64 pages828D Servo OptimisationMateus Mugnol toigoNo ratings yet

- Throttle Information Reference Guide PDFDocument24 pagesThrottle Information Reference Guide PDFJohn Rivera100% (1)

- Manual - Conversor CACC - WNTCDocument148 pagesManual - Conversor CACC - WNTCRafael GarciaNo ratings yet

- Carlos Gavazzi RVCF Drive Advanced User ManualDocument122 pagesCarlos Gavazzi RVCF Drive Advanced User ManualCarlos PNo ratings yet

- AXOR Manuals 3565Document72 pagesAXOR Manuals 3565Florian CiprianNo ratings yet

- Workshopman 03Document33 pagesWorkshopman 03Mohand Oubélaid Ait HammouNo ratings yet

- ServoCAT Manual V10-4Document28 pagesServoCAT Manual V10-4torot67No ratings yet

- Motion ControlDocument2 pagesMotion ControlSam SamovarkovNo ratings yet

- Caterpillar PRELUB Diagnostics (1469) : Cerrar SIS Pantalla AnteriorDocument16 pagesCaterpillar PRELUB Diagnostics (1469) : Cerrar SIS Pantalla Anteriorfabio andres albor del villarNo ratings yet

- Droop CalculationDocument3 pagesDroop CalculationAnonymous CO7aaHrNo ratings yet

- MSLC-2 Master Synchronizer and Load Control: ManualDocument226 pagesMSLC-2 Master Synchronizer and Load Control: ManualChristopher Morales HerreraNo ratings yet

- MurphyDocument18 pagesMurphyRoger Pozo AriasNo ratings yet

- Operating Mannual of Digital Automatic Voltage Regulator (Davr)Document31 pagesOperating Mannual of Digital Automatic Voltage Regulator (Davr)ArvindPrasadNo ratings yet

- Allied Polisher - Multiprep - ManualDocument44 pagesAllied Polisher - Multiprep - ManualNikhilKotibhaskarNo ratings yet

- MaxTune Intelligent Servo DriveDocument14 pagesMaxTune Intelligent Servo DrivejuliangoalNo ratings yet

- Noliac PAD DatasheetDocument15 pagesNoliac PAD DatasheetBercea MihaiNo ratings yet

- Startup of A Synchronous non-SEW Motor Setting The Motor EncoderDocument21 pagesStartup of A Synchronous non-SEW Motor Setting The Motor EncoderrezakaihaniNo ratings yet

- Constant Settable Droop Design Standard of GEDocument4 pagesConstant Settable Droop Design Standard of GEPraveen PeethambaranNo ratings yet

- Mech Vibrartion Lab2Document13 pagesMech Vibrartion Lab2Edryna AntasyaNo ratings yet

- Manual Do Usuario L?-V-SD SeriesDocument340 pagesManual Do Usuario L?-V-SD SeriesEdimilson RodriguesNo ratings yet

- Tuning Three-Phase BLDC Motor Sensorless Control Application Using The MKV10xDocument21 pagesTuning Three-Phase BLDC Motor Sensorless Control Application Using The MKV10xMaikel WilkeNo ratings yet

- DCS800 Winder Applications PDC2 en REVA 2008Document2 pagesDCS800 Winder Applications PDC2 en REVA 2008LeonardoAcevedoNo ratings yet

- WEG Regulador Automatico de Tensao Grt7 Th4Document51 pagesWEG Regulador Automatico de Tensao Grt7 Th4rayxonga14No ratings yet

- Kawasaki VN1500 '87-'99 Service ManualDocument270 pagesKawasaki VN1500 '87-'99 Service ManualДимитър Димитров75% (4)

- DAD0001 Drive by Wire Electronic Throttle SetupDocument17 pagesDAD0001 Drive by Wire Electronic Throttle SetupshayNo ratings yet

- Manuel For 2hss Close Loop Step DriverDocument35 pagesManuel For 2hss Close Loop Step DriverTuấn Nguyễn TrungNo ratings yet

- User Manual: 1305 Adjustable Frequency AC Drive (Series C)Document170 pagesUser Manual: 1305 Adjustable Frequency AC Drive (Series C)6612poolNo ratings yet

- User Manual For Speed Control of BLDC Motor Using DspicDocument12 pagesUser Manual For Speed Control of BLDC Motor Using DspicTrung TrựcNo ratings yet

- A 4 N Manual ProgramDocument61 pagesA 4 N Manual ProgramStevYamamotoNo ratings yet

- Case Parameters Monitoring Diesel GeneratorsDocument2 pagesCase Parameters Monitoring Diesel GeneratorsJerNo ratings yet

- Md380 SeriesDocument298 pagesMd380 SeriesRulo Hdez LazoNo ratings yet

- DBR CalculatorDocument69 pagesDBR CalculatorSURJIT SINGHNo ratings yet

- Deif Set-Up For Synchronising and LoadsharingDocument3 pagesDeif Set-Up For Synchronising and LoadsharingPierre Eyebe100% (1)

- Steering Pump - Test and Adjust: Shutdown SIS Previous ScreenDocument16 pagesSteering Pump - Test and Adjust: Shutdown SIS Previous Screenardan fadilahNo ratings yet

- Allen-Bradley 1305 FRN 6.01Document170 pagesAllen-Bradley 1305 FRN 6.01SebNo ratings yet

- Distributed Process Control ReportFrom EverandDistributed Process Control ReportNo ratings yet

- AC Electric Motors Control: Advanced Design Techniques and ApplicationsFrom EverandAC Electric Motors Control: Advanced Design Techniques and ApplicationsFouad GiriNo ratings yet

- User Guide - SMI2 - 2020.07 - 0250 - ENDocument12 pagesUser Guide - SMI2 - 2020.07 - 0250 - ENThang VuNo ratings yet

- User Guide - ITP14 - 2021.06 - 0322 - ENDocument11 pagesUser Guide - ITP14 - 2021.06 - 0322 - ENThang VuNo ratings yet

- User Guide - ITP11 (M04) - 2018.07 - 0284 - ENDocument10 pagesUser Guide - ITP11 (M04) - 2018.07 - 0284 - ENThang VuNo ratings yet

- Process Indicator 4-20 Ma: Functions and FeaturesDocument2 pagesProcess Indicator 4-20 Ma: Functions and FeaturesThang VuNo ratings yet

- Manual ITP16Document12 pagesManual ITP16Thang VuNo ratings yet

- User Guide - ITP16 - 2021.06 - 0323 - ENDocument12 pagesUser Guide - ITP16 - 2021.06 - 0323 - ENThang VuNo ratings yet

- Universal Process Display: Functions and FeaturesDocument2 pagesUniversal Process Display: Functions and FeaturesThang VuNo ratings yet

- List Flowmetter For MFCDocument3 pagesList Flowmetter For MFCThang VuNo ratings yet

- Product Flyer SMI2 enDocument2 pagesProduct Flyer SMI2 enThang VuNo ratings yet

- Power Supplies Programmable Controllers Hybrid Ics: Toshiba Photocoupler Ired & Photo-TransistorDocument13 pagesPower Supplies Programmable Controllers Hybrid Ics: Toshiba Photocoupler Ired & Photo-TransistorThang VuNo ratings yet

- Cable Tray Fitting ScheduleDocument1 pageCable Tray Fitting ScheduleThang VuNo ratings yet

- Alfa Laval Manual Sep. Aldec 45Document134 pagesAlfa Laval Manual Sep. Aldec 45Leonel SilvaNo ratings yet

- HMI Decanter W530Document38 pagesHMI Decanter W530Thang VuNo ratings yet

- Cable Tray ScheduleDocument1 pageCable Tray ScheduleThang VuNo ratings yet

- LCU DOKU enDocument88 pagesLCU DOKU enAmina SuljicNo ratings yet

- Model 1456 Operations and Maintenance Manual With Parts ListDocument132 pagesModel 1456 Operations and Maintenance Manual With Parts ListThang Vu0% (1)

- Library With PLC Data Types For Peripheral / Technology Modules and Profidrive Drives (LPD)Document53 pagesLibrary With PLC Data Types For Peripheral / Technology Modules and Profidrive Drives (LPD)Luis Ortiz CicuéndezNo ratings yet

- Sample Library For Instructions-V16 DOC v1 05 S7BasPro enDocument21 pagesSample Library For Instructions-V16 DOC v1 05 S7BasPro enSergNo ratings yet

- LibraryOfBasicControls LBC V1 0 0 enDocument94 pagesLibraryOfBasicControls LBC V1 0 0 enThang VuNo ratings yet

- S1200CPU LAxesGrpCtrl DOC v11 enDocument62 pagesS1200CPU LAxesGrpCtrl DOC v11 enDavid JimenezNo ratings yet

- Sample Library For Instructions-V16 DOC v1 05 S7BasPro enDocument21 pagesSample Library For Instructions-V16 DOC v1 05 S7BasPro enSergNo ratings yet

- Selecting The Right CentrifugeDocument13 pagesSelecting The Right CentrifugeThang VuNo ratings yet

- GEA Varipond Tcm11-42317Document14 pagesGEA Varipond Tcm11-42317Thang VuNo ratings yet

- Drycake Centrifuge Technology OverviewDocument16 pagesDrycake Centrifuge Technology OverviewThang VuNo ratings yet

- ACS880 Centrifuge Decanter Control Program (+N5150) : SupplementDocument50 pagesACS880 Centrifuge Decanter Control Program (+N5150) : SupplementThang VuNo ratings yet

- pDRIVE Basic MXDocument33 pagespDRIVE Basic MXThang VuNo ratings yet

- Model 1456 Operations and Maintenance Manual With Parts ListDocument132 pagesModel 1456 Operations and Maintenance Manual With Parts ListThang Vu0% (1)

- GEA Varipond Tcm11-42317Document14 pagesGEA Varipond Tcm11-42317Thang VuNo ratings yet

- Selecting The Right CentrifugeDocument13 pagesSelecting The Right CentrifugeNils Schwarz100% (5)

- Iec 61287-1Document55 pagesIec 61287-1Lokesh Kuppili100% (2)

- Asanor Compact Iran 2 PDFDocument71 pagesAsanor Compact Iran 2 PDFSatisNo ratings yet

- Icing On TransmissionDocument7 pagesIcing On Transmission1SI18EE012 HARSHDEEP SINGHNo ratings yet

- Generalized D Q Model of N Phase Induction Motor Drive PDFDocument10 pagesGeneralized D Q Model of N Phase Induction Motor Drive PDFRenuka DeviNo ratings yet

- Laboratory 1 - Inverter Design ManualDocument110 pagesLaboratory 1 - Inverter Design Manualece thesisNo ratings yet

- 6th Semester Syllabus PDFDocument13 pages6th Semester Syllabus PDFSarthak Swaroop DashNo ratings yet

- A/A DC Inverter U-MATCH Air Conditioners Service Manual: T1/R410A/50HzDocument264 pagesA/A DC Inverter U-MATCH Air Conditioners Service Manual: T1/R410A/50HzglomazicsNo ratings yet

- Multiple Choice Questions With Answers On Power Electronics and DrivesDocument32 pagesMultiple Choice Questions With Answers On Power Electronics and DrivesRahul Sharma100% (1)

- Power Electronics and DrivesDocument120 pagesPower Electronics and DrivesArchana Diwakar Ranjish100% (1)

- Comparison Between VSI and CSI Fed Induction Motor Drives in MATLAB Environment Based On THD PerformanceDocument71 pagesComparison Between VSI and CSI Fed Induction Motor Drives in MATLAB Environment Based On THD Performancethegopal100% (2)

- Hybrid SystemDocument8 pagesHybrid SystempriyadarshniNo ratings yet

- ACS2000 CatalogoDocument34 pagesACS2000 Catalogolquinter75No ratings yet

- Submersible+Borehole+Pumps 60+HzDocument114 pagesSubmersible+Borehole+Pumps 60+HzNong Noc100% (1)

- Series and Shunt CompensationDocument65 pagesSeries and Shunt CompensationLighto LastoNo ratings yet

- Kub T120 - en PDFDocument6 pagesKub T120 - en PDFoelbergluisNo ratings yet

- AC DC200 ManualDocument16 pagesAC DC200 Manualning ningNo ratings yet

- 12797fisa Tehnica - Invertor Hibrid Growatt SPF 5000ES - Invertor Care Nu Necesita Acumulatori - Sistem Fotovoltaic - Alaska Energies RomaniaDocument4 pages12797fisa Tehnica - Invertor Hibrid Growatt SPF 5000ES - Invertor Care Nu Necesita Acumulatori - Sistem Fotovoltaic - Alaska Energies RomaniaMircea MoisaNo ratings yet

- Juha-Pekka Ström: Active Du/Dt Filtering For Variable-Speed Ac DrivesDocument131 pagesJuha-Pekka Ström: Active Du/Dt Filtering For Variable-Speed Ac Drivesbrian nelsonNo ratings yet

- Installation Instructions 06T Semi-Hermetic Screw CompressorDocument8 pagesInstallation Instructions 06T Semi-Hermetic Screw CompressorKiril AckovskiNo ratings yet

- Fuzzy Logic Control For A Speed Control of Induction Motor Using Space Vector Pulse Width ModulationDocument7 pagesFuzzy Logic Control For A Speed Control of Induction Motor Using Space Vector Pulse Width ModulationIr Solly Aryza MengNo ratings yet

- AN1543/D Electronic Lamp Ballast Design: Application NoteDocument35 pagesAN1543/D Electronic Lamp Ballast Design: Application NoteprovolissimaNo ratings yet

- Reference Manual of Dynamic Voltage Stability PDFDocument370 pagesReference Manual of Dynamic Voltage Stability PDFsonNo ratings yet

- Esquema InversorDocument18 pagesEsquema Inversorx3roNo ratings yet

- 04 Parameters Config T2S Definitions UK Rev14Document16 pages04 Parameters Config T2S Definitions UK Rev14leonardomarinNo ratings yet

- Solar InverterDocument18 pagesSolar InverterPradip Magar100% (1)

- MD 280Document229 pagesMD 280nhu@nhuNo ratings yet

- Abraham MesfinDocument113 pagesAbraham Mesfinaravinth.iitmNo ratings yet

- Final Year ProjectDocument15 pagesFinal Year ProjectMuhammad AyazNo ratings yet

- Esquemas Puma SX 35131Document11 pagesEsquemas Puma SX 35131costelchelariuNo ratings yet

- Crown Micro-ELO-VI-6KWDocument68 pagesCrown Micro-ELO-VI-6KWApower Engg.100% (2)