Professional Documents

Culture Documents

Pressure Transmitter With Ceramic Sensor, Accuracy 0,5%

Uploaded by

Phượng NguyễnOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pressure Transmitter With Ceramic Sensor, Accuracy 0,5%

Uploaded by

Phượng NguyễnCopyright:

Available Formats

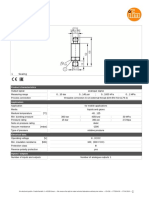

ST 18

pressure transmitter with ceramic sensor,

accuracy 0,5%

Compliance to requirements of directives:

EMC 2014/30/EU - PED 2014/68/EU - RoHS 2011/65/EU

The ST18 model is an electronic transmitter with ceramic sensor, with adjustable zero and span, for air, industrial and technical gases, water and oil.

When assembled to diaphragm seals, it measures the pressure of corrosive, highly viscous and hot fluids.

8.ST18

Ranges Overpressure

Measuring ranges: 0...1/0...600 bar, relative; -1...0/-1...+24 bar, relative; bar, relative bar, relative

0...1/0..25 bar, absolute. 0...1 5

Output signals: 4...20 mA, 0...5 Vcc, 0...10 Vcc. 0...1,6 5

Non-linearity (BFSL): ≤ ± 0,25 % of the range, according to IEC 61298-2. 0...2,5 5

Non-repeatability: ≤ 0,1 % of the range, according to IEC 61298-2. 0...4 8

Accuracy: ≤ ± 0,5% of the range (1). 0...6 12

Thermal drift: between 0 and 80°C, 1% of span; 2,5% of span, max (2). 0...10 20

Long term drift: ≤ 0,1 % of span. 0...16 32

Zero and span adjustement: ± 10 % span typical. 0...25 50

Process fluid temperature: -25...+100 °C. 0...40 80

Ambient temperature: -25...+85 °C. 0...60 120

Stocking temperature: -30...+85 °C. 0...100 200

Response time: <4 ms (measuring); <150 ms (switching on). 0...160 320

Emission and immunity: according to EN 61326, 0...250 500

(group 1 - class B; industrial applications).

0...400 600

Vibration resistance: 20g (10...2000 Hz, according to IEC 60068-2-6).

0...600 800

Shock resistance: 40g (6 ms, according to IEC 60068-2-27).

Sensor: ceramic in Al2O3. Other ranges available on demand. Units of

measurement available in psi, MPa, kPa too.

Case: in AISI 316L, vented up to 16 bar.

Protection degree: IP 65 according to IEC 60529 (3).

Process connection: in AISI 316L, hole ø 2,5 mm (with restrictor ø 0,7

mm for measuring ranges ≥ 60 bar).

Weight: 0,18 kg ....

(1) max measuring error according to IEC 61298-2, including non-linearity and hysteresis

(limit-point calibration and reference conditions according to IEC 61298-1); accuracy ≤ ±

0,75% of span for measuring ranges 0...1 bar and 0...600 bar.

(2) + 0,5% of span for measuring range 1 bar

(3) with properly assembled electric connection

ISO 9001 : 2008

Cert. nr. 0433/6

-1-

pressure transmitter with ceramic sensor,

accuracy 0,5%

ST 18

RC8 - 01/15

~48

M12x1

~104

ø34 ø34 ø34

~95

~89

~88

IN ORDER TO IMPROVE THEIR PRODUCTION, MESSRS. NUOVA FIMA RESERVE THE RIGHT TO THEMSELVES TO MAKE ALL THE MODIFICATIONS THAT THEY DEEM INDISPENSABLE AT ANY TIME. UPDATED DATA-SHEETS ARE AVAILABLE ON SITE: www.nuovafima.com

24 24 24 24

Torque 20...30 Nm

21M - G 1/4 A 23M - 1/4-18 NPT 43M - 1/2-18 NPT 41M - G 1/2 A

13

15

20

F 23

F

F

F

4...20 mA 0...5 Vdc 0...10 Vdc

Output signals

1 4 5

N. of wires 2 3 3

Load max (Ohm) RL ≤ (Ub-8)/0,02 RL ≥ 5 KΩ RL ≥ 10 KΩ

Supply: +Ub (Vdc) 8…30 8…30 14…30

Absorbed current (mA) < 25 < 10 < 10

All output signals are provided of protection against short cicuit and polarity inversion. Insulation tension 500 Vdc.

WIRING

DIN 175301-803 A M12 x 1 Cable exit

N. of wires 2 3 2 3 2 3

Supply connector: Ub 1 1 1 1 brown brown

Negative connector: 0V 2 2 3 3 white white

Signal: S + - 3 - 4 - green

Ground GND GND 2 2 grey grey

OPTIONS

M12 - Connector M12 x 1, 4 poles EPD - EPDM gasket for sensor

PVC - Cable exit, with 1 mt PVC cable NBR - NBR gasket for sensor

U68 - Cable exit IP68, with 1 mt polyurethane cable C01 - Calibration certificate

FPM - FPM gasket for sensor VS3 - Restrictor ø 0,3 mm

CRP - CR gasket for sensor

“HOW TO ORDER” SEQUENCE

Section / Model / Range / Process connection / Output signal / Gasket / Options

8 S18 41M 1 FPM C01...VS3

43M 4 CRP

21M 5 EPD

23M NBR

Copyright © Nuova Fima srl. All rights reserved. Any part of this publication should not be reproduced without a written Nuova Fima’s srl approval

NUOVA FIMA S.p.A. - www.nuovafima.com

P.O. BOX 58 - VIA C. BATTISTI 59 - 28045 INVORIO (NO) ITALY

TEL. +39 0322 253200 - FAX +39 0322 253232

You might also like

- Data Sheet SX18 @enDocument2 pagesData Sheet SX18 @enSatria GoNo ratings yet

- Intrinsically Safe Pressure Transmitter, ATEX Version, Accuracy 0,35 %Document2 pagesIntrinsically Safe Pressure Transmitter, ATEX Version, Accuracy 0,35 %Satria GoNo ratings yet

- Data Sheet SX09 @enDocument2 pagesData Sheet SX09 @enSatria GoNo ratings yet

- Манометры ТМ (ТВ,ТМВ) Серия10 РОСМАDocument4 pagesМанометры ТМ (ТВ,ТМВ) Серия10 РОСМАSergNo ratings yet

- OEM Pressure Transmitters GuideDocument6 pagesOEM Pressure Transmitters GuideKaungMyint MyatNo ratings yet

- Valvula Proporcional Norgren 101xDocument2 pagesValvula Proporcional Norgren 101xBase SistemasNo ratings yet

- General Purpose Pressure Transmitters GuideDocument4 pagesGeneral Purpose Pressure Transmitters GuideQc BudijayaMSNo ratings yet

- SRS-008 SCA128T DatasheetDocument7 pagesSRS-008 SCA128T DatasheetmiqbalNo ratings yet

- Oem Pressure SensorDocument3 pagesOem Pressure SensorDedy hermawanNo ratings yet

- Cylinder Pressure SensorDocument2 pagesCylinder Pressure SensorSaasiNo ratings yet

- LMK487Document5 pagesLMK487Sanjay m PillayNo ratings yet

- SML 10 AdznaganoDocument2 pagesSML 10 AdznaganoReyn EzraNo ratings yet

- NTC Thermistors PDFDocument37 pagesNTC Thermistors PDFKumarNo ratings yet

- Trafag Pressure Transmitters Catalogue 2015Document154 pagesTrafag Pressure Transmitters Catalogue 2015FazleMasoodNo ratings yet

- Model T3000 Resistance Temperature Transmitters: BCM Sensor TechnologiesDocument5 pagesModel T3000 Resistance Temperature Transmitters: BCM Sensor TechnologiesAndika PratamaNo ratings yet

- Smart Relay - Zelio Logic SR2 - SR3 - SR3XT43BD PDFDocument5 pagesSmart Relay - Zelio Logic SR2 - SR3 - SR3XT43BD PDFasimasim123No ratings yet

- H7625, H7635, H7655 Series 2000: Humidity/Temperature SensorsDocument4 pagesH7625, H7635, H7655 Series 2000: Humidity/Temperature SensorsasdaFNo ratings yet

- P1A Data Sheet LetterDocument7 pagesP1A Data Sheet LetterGovind RaoNo ratings yet

- RDAB20-A PRSH enDocument2 pagesRDAB20-A PRSH enMarcosNo ratings yet

- Alia APT3000 Pressure TransmitterDocument2 pagesAlia APT3000 Pressure TransmitterRexCrazyMindNo ratings yet

- RCE Series: Digital Pressure TransducersDocument6 pagesRCE Series: Digital Pressure Transducerszakaria alhosinyNo ratings yet

- PT9550-01_EN-GBDocument3 pagesPT9550-01_EN-GBkhangphucNo ratings yet

- SPKT0031D0Document2 pagesSPKT0031D0Rafael CruzNo ratings yet

- Ultra High Purity Transducer For Explosion-Protected Areas, Ex Na Ic Models WUC-10, WUC-15 and WUC-16Document8 pagesUltra High Purity Transducer For Explosion-Protected Areas, Ex Na Ic Models WUC-10, WUC-15 and WUC-16MohammadNo ratings yet

- Kde en 923 0862Document32 pagesKde en 923 0862joseloaiza378No ratings yet

- A2 Pressure Transmitter: Data SheetDocument4 pagesA2 Pressure Transmitter: Data SheetpatrickNo ratings yet

- Ector: P D S SDE-P Programmable Differential Pressure TransmitterDocument4 pagesEctor: P D S SDE-P Programmable Differential Pressure TransmitterAyMën TØûßænëNo ratings yet

- Tecsis P3276Document4 pagesTecsis P3276benNo ratings yet

- ATM/T - Analog Transmitter: Pressure and Temperature TransmittersDocument8 pagesATM/T - Analog Transmitter: Pressure and Temperature TransmittersAdiyatma DjatnikaNo ratings yet

- Dwg Vendor 3 - Trafag - h72303ag_en_8252_nat_indusDocument14 pagesDwg Vendor 3 - Trafag - h72303ag_en_8252_nat_indushapidzNo ratings yet

- Pressure SensorDocument15 pagesPressure SensorRenata LouhNo ratings yet

- PT5504 Pressure Transmitter Spec SheetDocument4 pagesPT5504 Pressure Transmitter Spec SheetSuryadiNo ratings yet

- SPIR STAR® - Your Specialists in High-Pressure Hose - High-Pressure Hose - Thermoplastic Hose - Thermoplastic HighDocument2 pagesSPIR STAR® - Your Specialists in High-Pressure Hose - High-Pressure Hose - Thermoplastic Hose - Thermoplastic HighmarcosNo ratings yet

- High-Quality Pressure Transmitter For General Industrial Applications Model S-10Document8 pagesHigh-Quality Pressure Transmitter For General Industrial Applications Model S-10gliga vasileNo ratings yet

- Asco Series 44 Pressure Sensor CatalogDocument2 pagesAsco Series 44 Pressure Sensor CatalogAnonymous uXxyCieO3100% (1)

- Robust Stainless Steel Pressure Transmitters for Harsh EnvironmentsDocument4 pagesRobust Stainless Steel Pressure Transmitters for Harsh EnvironmentsRodica PuscauNo ratings yet

- Catálogo generalDocument18 pagesCatálogo generalHector0412No ratings yet

- Temperature IndicatorDocument7 pagesTemperature IndicatorCaptain hopiNo ratings yet

- Trh70A Series: 70W Switching AdapterDocument3 pagesTrh70A Series: 70W Switching AdapterSiriwat PatchimasiriNo ratings yet

- Digital Tach/Hourmeter W/adjustable Overspeed Trip Point: SHD30 and SHD30-45 ModelsDocument2 pagesDigital Tach/Hourmeter W/adjustable Overspeed Trip Point: SHD30 and SHD30-45 ModelsRoger TorrejonNo ratings yet

- Pressure Transmitter For Shipbuilding and Offshore: Stainless Steel SensorDocument5 pagesPressure Transmitter For Shipbuilding and Offshore: Stainless Steel SensorVariya DharmeshNo ratings yet

- Process Transmitter Model UPT-20, With Pressure Port Model UPT-21, With Flush DiaphragmDocument8 pagesProcess Transmitter Model UPT-20, With Pressure Port Model UPT-21, With Flush DiaphragmPercy CordovaNo ratings yet

- Pressure Transmitter Model ECO-1: ApplicationsDocument4 pagesPressure Transmitter Model ECO-1: ApplicationsМихаил БеребердинNo ratings yet

- Digital Hour Meters & Counters GuideDocument30 pagesDigital Hour Meters & Counters Guidejeffv65No ratings yet

- SEMIKRON DataSheet SKN 600 02644670Document3 pagesSEMIKRON DataSheet SKN 600 02644670petriNo ratings yet

- Surface Mount Aluminum Electrolytic Capacitors: NACE SeriesDocument5 pagesSurface Mount Aluminum Electrolytic Capacitors: NACE SeriesNICCompNo ratings yet

- Industrial accelerometers for widespread applicationsDocument13 pagesIndustrial accelerometers for widespread applicationsLutfi NurafifNo ratings yet

- Microtherm R25R26R35R36 enDocument4 pagesMicrotherm R25R26R35R36 enLuis Fernando Garcia SanchezNo ratings yet

- DRDN20: 20A DIN Rail Type Redundancy ModuleDocument5 pagesDRDN20: 20A DIN Rail Type Redundancy ModuleRachid JKININo ratings yet

- Schneider Electric_Harmony-Timer-Relays_RE17RAMUDocument10 pagesSchneider Electric_Harmony-Timer-Relays_RE17RAMUAli ZafarNo ratings yet

- Zelio Logic SR3B101FUDocument6 pagesZelio Logic SR3B101FUAlexcgNo ratings yet

- Nat SpecsDocument10 pagesNat SpecsAndre CabralNo ratings yet

- AD586 - High Precision 5 V ReferenceDocument8 pagesAD586 - High Precision 5 V ReferenceJavierPariNo ratings yet

- WIKA Ecco 1Document4 pagesWIKA Ecco 1Chandra NugrahaNo ratings yet

- ElemcoDocument11 pagesElemcoAlaa MohammedNo ratings yet

- DS SP6014 GB 51924Document6 pagesDS SP6014 GB 51924dennyyusufNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Applsci 09 01627Document17 pagesApplsci 09 01627Phượng NguyễnNo ratings yet

- Huang Control and Design DOFDocument9 pagesHuang Control and Design DOFgatzkeNo ratings yet

- Catalysts 11 00833Document15 pagesCatalysts 11 00833Phượng NguyễnNo ratings yet

- Sondex Heat Exchangers: Danfoss Ref: SD-2019-87 Date: 23 Anh Minh Technology Trading Co., LTDDocument4 pagesSondex Heat Exchangers: Danfoss Ref: SD-2019-87 Date: 23 Anh Minh Technology Trading Co., LTDPhượng NguyễnNo ratings yet

- Applsci 09 01627Document17 pagesApplsci 09 01627Phượng NguyễnNo ratings yet

- Bơm Chiller 80m3, 5bargDocument5 pagesBơm Chiller 80m3, 5bargPhượng NguyễnNo ratings yet

- Iq, Oq, PQ, DQDocument17 pagesIq, Oq, PQ, DQsiruslara649167% (3)

- Applsci 09 01627Document17 pagesApplsci 09 01627Phượng NguyễnNo ratings yet

- Bơm Chiller 80m3, 5bargDocument5 pagesBơm Chiller 80m3, 5bargPhượng NguyễnNo ratings yet

- Energies: On The Optimization of Electrical Water Heaters: Modelling Simulations and ExperimentationDocument12 pagesEnergies: On The Optimization of Electrical Water Heaters: Modelling Simulations and ExperimentationPhượng NguyễnNo ratings yet

- S9A - Datasheet - Cooking TankDocument1 pageS9A - Datasheet - Cooking TankPhượng NguyễnNo ratings yet

- Lọc YDocument13 pagesLọc YPhượng NguyễnNo ratings yet

- Technical data for 80x65 FSGA pumpDocument5 pagesTechnical data for 80x65 FSGA pumpPhượng NguyễnNo ratings yet

- Design and Analysis of U-Shaped Ribbon Blender With Screw ConveyorDocument9 pagesDesign and Analysis of U-Shaped Ribbon Blender With Screw ConveyorPhượng NguyễnNo ratings yet

- PH Transmitter - CM444 - Endress & HauserDocument52 pagesPH Transmitter - CM444 - Endress & HauserPhượng NguyễnNo ratings yet

- Proximity - IGT205 - IFMDocument3 pagesProximity - IGT205 - IFMPhượng NguyễnNo ratings yet

- Temperature Transmitter - TMR35 - Endress & HauserDocument20 pagesTemperature Transmitter - TMR35 - Endress & HauserPhượng NguyễnNo ratings yet

- Pressure Transmitter With Ceramic Sensor, Accuracy 0,5%Document2 pagesPressure Transmitter With Ceramic Sensor, Accuracy 0,5%Phượng NguyễnNo ratings yet

- All Stainless Steel Pressure Gauge Bayonet Ring (Open Front) : Since 1971Document9 pagesAll Stainless Steel Pressure Gauge Bayonet Ring (Open Front) : Since 1971Phượng NguyễnNo ratings yet

- Industrial Bimetal Thermometer Bottom Connection: Since 1971Document6 pagesIndustrial Bimetal Thermometer Bottom Connection: Since 1971Phượng NguyễnNo ratings yet

- Calcium Silicate Insulation BrochureDocument52 pagesCalcium Silicate Insulation Brochureibson045001256No ratings yet

- Gasket ChìDocument8 pagesGasket ChìPhượng NguyễnNo ratings yet

- Cảm Biến Nhiệt ĐộDocument2 pagesCảm Biến Nhiệt ĐộPhượng NguyễnNo ratings yet

- PH Sensor - CPS77D - Endress & HauserDocument16 pagesPH Sensor - CPS77D - Endress & HauserPhượng NguyễnNo ratings yet

- 1.02.E.DT42S Thermodynamic Steam Traps DN15-25Document2 pages1.02.E.DT42S Thermodynamic Steam Traps DN15-25Son Trinh PhuongNo ratings yet

- Processes: Analysis of Power Input of An In-Line Rotor-Stator Mixer For Viscoplastic FluidsDocument15 pagesProcesses: Analysis of Power Input of An In-Line Rotor-Stator Mixer For Viscoplastic FluidsPhượng NguyễnNo ratings yet

- DN 2K2 CurveDocument1 pageDN 2K2 CurvePhượng NguyễnNo ratings yet

- AN ISO 9001, ISO 14001, OHSAS 18001, PED 2014/68/EU, Ad 2000 Merkblatt W0 Certified CompanyDocument12 pagesAN ISO 9001, ISO 14001, OHSAS 18001, PED 2014/68/EU, Ad 2000 Merkblatt W0 Certified CompanyPhượng NguyễnNo ratings yet

- Training Course ComsolDocument3 pagesTraining Course ComsolPhượng NguyễnNo ratings yet

- High Strength Bolts - KulakDocument21 pagesHigh Strength Bolts - KulakalmeteckNo ratings yet

- Install InfoDocument8 pagesInstall InfoMarcin B.No ratings yet

- Air Circuit Breaker Construction.Document7 pagesAir Circuit Breaker Construction.hane zawNo ratings yet

- Testing-Commissioning-Checklist-for-Fuel-PumpDocument1 pageTesting-Commissioning-Checklist-for-Fuel-PumpMoh'd SameerNo ratings yet

- Baseband Shaping for Data TransmissionDocument60 pagesBaseband Shaping for Data Transmissionrahul guptaNo ratings yet

- Basic CH 1 Second Part 2010Document7 pagesBasic CH 1 Second Part 2010Nebiyou KorraNo ratings yet

- Make It, Take It, But Don'T Waste It: Saving Electricity Presentation by Alice, Aubery, Desiree & ArkarDocument27 pagesMake It, Take It, But Don'T Waste It: Saving Electricity Presentation by Alice, Aubery, Desiree & ArkarAlice WangNo ratings yet

- Air Conditioner: Owner'S ManualDocument120 pagesAir Conditioner: Owner'S Manualdown loadNo ratings yet

- Sect. 4.1.1 Single-Quadrant SwitchesDocument11 pagesSect. 4.1.1 Single-Quadrant SwitchesThinh NguyenNo ratings yet

- 160GB Playstation 3 CECHP01Document100 pages160GB Playstation 3 CECHP01dayne81sNo ratings yet

- 2019 WLP Safran Power Spares - Catalogue PDFDocument12 pages2019 WLP Safran Power Spares - Catalogue PDFWilmar Andres Chaparro RianoNo ratings yet

- 6-Port Antenna Frequency Range Dual Polarization HPBW Adjust. Electr. DTDocument6 pages6-Port Antenna Frequency Range Dual Polarization HPBW Adjust. Electr. DTВладимир МишаченкоNo ratings yet

- Unit-V Blocking Oscillators and Time Base Generators Two Marks Question & AnswerDocument3 pagesUnit-V Blocking Oscillators and Time Base Generators Two Marks Question & AnswerJayed Ahmed LaskarNo ratings yet

- CX Series Amplifier Service ManualDocument90 pagesCX Series Amplifier Service ManualJohn EstradaNo ratings yet

- Dell Emc Poweredge Mx750c E04b E04b003 Dell Regulatory and Environmental Datasheet En-UsDocument10 pagesDell Emc Poweredge Mx750c E04b E04b003 Dell Regulatory and Environmental Datasheet En-UsAlexandru ParvuletNo ratings yet

- Loading The Search BoxDocument24 pagesLoading The Search Boxbhalaji1991No ratings yet

- Beijing Ruizhitianhong S&T Co.,Ltd Engraving Machine Motion Control System A11:Three-axis Mechanical Carving User's ManualDocument68 pagesBeijing Ruizhitianhong S&T Co.,Ltd Engraving Machine Motion Control System A11:Three-axis Mechanical Carving User's ManualJacpro Automation SacNo ratings yet

- Hearing Protectors Standards: Alberto Behar1 and Willy Wong1Document2 pagesHearing Protectors Standards: Alberto Behar1 and Willy Wong1facundo toledoNo ratings yet

- SGP 6Document7 pagesSGP 6Soumajit PoddarNo ratings yet

- Sirona Orthophos 3 Dental X-Ray - Maintenance InstructionsDocument32 pagesSirona Orthophos 3 Dental X-Ray - Maintenance InstructionsHAITHM MURSHEDNo ratings yet

- rws100 3Document1 pagerws100 3Alexis Sepond AlexisNo ratings yet

- Sony Hcd-Shake33 Hcd-Shake77 Ver1.0 SMDocument120 pagesSony Hcd-Shake33 Hcd-Shake77 Ver1.0 SMElectronica Leon Espinoza100% (3)

- Datasheet HP 30Document1 pageDatasheet HP 30kyawoo.sgNo ratings yet

- Shift registers: storage and movement of digital data in sequential logic circuitsDocument22 pagesShift registers: storage and movement of digital data in sequential logic circuitschoprahridyeshNo ratings yet

- Sec8 LHDDocument390 pagesSec8 LHDMarc MarcelleNo ratings yet

- Masterload Ii: Electronic Meter Controller For Aviation Fueling ApplicationsDocument8 pagesMasterload Ii: Electronic Meter Controller For Aviation Fueling ApplicationskhalidNo ratings yet

- Microprocessor and Interfacing - Question Paper May 2016 - Electronics & Telecomm (Semester 4) - Gujarat Technological University (GTU)Document4 pagesMicroprocessor and Interfacing - Question Paper May 2016 - Electronics & Telecomm (Semester 4) - Gujarat Technological University (GTU)YESHUDAS MUTTUNo ratings yet

- HackSpace - June 2021Document116 pagesHackSpace - June 2021Somnath100% (1)

- DC20D MKII Genset Controller Upgrade Version For Diesel - Gasoline Engine - EbayDocument2 pagesDC20D MKII Genset Controller Upgrade Version For Diesel - Gasoline Engine - EbayAliNo ratings yet

- Techniques For Insect Detection in Stored Food Grains: An OverviewDocument11 pagesTechniques For Insect Detection in Stored Food Grains: An Overviewmib_579No ratings yet

- Caution !: If Your Lift System UsesDocument4 pagesCaution !: If Your Lift System UsesAn as akrasNo ratings yet