Professional Documents

Culture Documents

Wu W24x68: Red Font Indicates User Input

Uploaded by

clam2014Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wu W24x68: Red Font Indicates User Input

Uploaded by

clam2014Copyright:

Available Formats

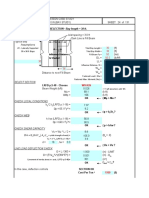

PROJECT: STEEL BUILDING DESIGN CASE STUDY

SUBJECT: Girder-to-column flange connection SHEET 118 of 131

All-bolted double connection for interior floor girder W24x68 to a W10x49 interior column flange

φ t = resistance factor relating to tensile strength

Rn = strength

Ru = Factored beam end reaction

g1= workable gage of angle

H2 = maximum shank extension

C1 = clearance for tighening

a1 = workable gage 2

a2 = distance from bolt to the tip of the angle leg attached to girder web

a3 = workable gage 1

a4 = distance from bolt to the tip of the angle leg attached to column flange

d1 = distance between bolts

Lev = vertical edge distance

Leh = horizontal edge distance

Fy = specified (ASTM) minimum yield stress

Fu = specified (ASTM) minimum tensile strength

d = diameter of the bolt

tf = flange thickness

tw = web thickness

t1 = one half decimal web thickness rounded to the next higher 1/16 in.

t = thickness of the angles

U = reduction coefficient

An = net area

Ag = gross cross-sectional area

Ae = U*An

Agv = gross area acted upon by shear

Agt = gross area acted upon by tension

Anv = net area acted upon by shear

Ant = net area acted upon by tension

Use A325-N bolts in standard holes. Assume ASTM A36 angle material with Fy=36ksi and Fu=58ksi.

Factored Load - Wu (sheet 23)= 5.2 (k/ft)

Girder length = 30 ft

Ru = 78 Kips

Girder: W24x68

tw = 0.415 in

Fy = 50 ksi

Wu

Fu = 65 ksi

W24x68 Column: W10x49

tf = 0.56 in

Fy = 50 ksi

Fu = 65 ksi

Red font indicates user input

PROJECT: STEEL BUILDING DESIGN CASE STUDY

SUBJECT: Girder-to-column flange connection SHEET 119 of 131

Column W10x49

Girder W24x68

a3 a4 Girder Web

d1 t1

A t

a1 H2

C1

a2

Angles Section at A

Design of Bolts and angles:

TRY: 3/4 in. diameter bolts

TRY: 4 rows of bolts and 1/4 in angle thickness (From LRFD table 10-1)

φ Rn = 104 Kips > Ru = 78 Kips OK!

TRY: 2L5x3-1/2x1/4LLBB (Short legs back to back)

g1 = 2 in. min. (LRFD fig. 10-6)

g1 = 2 1/4 in. min. (LRFD table 10-1)

say g1 = 2 1/2 in

Ag = 4.13 Fy = 36 ksi

Fu = 58 ksi

Leh = 1 3/4 (From LRFD table 10-1)

Lev = 1 1/2 (From LRFD table 10-1)

Check supported beam web:

φ Rn = 351 Kips/in (From LRFD table 10-1)

φ Rn = 351 x tw = 145.7 Kips > Ru = 78 Kips OK!

Check supporting column flange:

φ Rn = 702 Kips/in (From LRFD table 10-1)

φ Rn = 702 x tf = 393.12 Kips > Ru = 78 Kips OK!

Red font indicates user input

PROJECT: STEEL BUILDING DESIGN CASE STUDY

SUBJECT: Girder-to-column flange connection SHEET 120 of 131

Connection details:

H2 = 1 3/8 in. max. (LRFD table 7-3a)

C1= 1 1/4 in. min. say C1 = 1 3/8 in. (LRFD table 7-3a)

t= 1/4 in.

t1 = tw / 2 = 0.2075 in. say t1 = 4/16 in

a1 = 3 in.

a2 = 2 in.

a3 = g1 = 2 1/2 in.

a4 = 1 in.

d1 = 6 1/2 in.

If an angle leg is shorter than 4", check yielding, fracture and block shear:

Nominal strength of the angle for yielding of the gross section:

φ Rn = 0.9 x Fy x Ag = 133.8 kips > Ru/2 = 39 kips OK!

Nominal strength of the angle for fracture of the net section:

φ Rn = 0.75 x Fu x Ae = 160.62 kips > Ru/2 = 39 kips OK!

An = Ae = 3.69

Check Block Shear :

Shear areas:

2

Agv = 2.625 in

2

Anv = 1.859 in

Tension areas:

2

Agt = 0.250 in

2

Ant = 0.141 in

Shear rupture design strength φVn: LRFD J4-1

φ(.6*Fu)*Anv = 48.53 kips

Tension rupture design strength φTn: LRFD J4-2

φFu*Ant = 6.1172 kips

The larger fracture term controls: LRFD J4-1 controls

Block shear strength:

φ Rn = 55.28 kips < 54.65 kips

φ Rn = 54.65 kips > 39.00 kips OK!

Red font indicates user input

PROJECT: STEEL BUILDING DESIGN CASE STUDY

SUBJECT: Girder-to-column flange connection SHEET 121 of 131

2 1/2"

1 3/4"

1 1/2"

3"

1' 23.7"

3"

3"

A

1 1/2"

2L 5"x 31/2" x 1/4" x 1' (SLBB)

2 1/2" 1"

4/16"

6 1/2"

1/4"

3" 1 3/8"

1 3/8"

2"

Section at A

Red font indicates user input

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Structure White Paper - Crane Girder - FinalDocument61 pagesStructure White Paper - Crane Girder - Finalclam2014No ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hertz-Halding2022 Book SustainableLightConcreteStructDocument219 pagesHertz-Halding2022 Book SustainableLightConcreteStructclam2014No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- SS 674 2021 Fibre Concrete - Design of Fibre Concrete StructuresDocument48 pagesSS 674 2021 Fibre Concrete - Design of Fibre Concrete Structuresclam2014100% (1)

- SCNZ Case Study 13 - WebDocument4 pagesSCNZ Case Study 13 - Webclam2014No ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Aci 364.9T-03 (11) : Racks in A EpairDocument3 pagesAci 364.9T-03 (11) : Racks in A Epairclam2014No ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- IB - BLSTMB Pro1200 With FPDocument22 pagesIB - BLSTMB Pro1200 With FPclam2014No ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- NZS 4297-2020 Engineering Design of Earth BuildingsDocument63 pagesNZS 4297-2020 Engineering Design of Earth Buildingsclam2014No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Analysis and Design of Noncompact and Slender Concrete-Filled Steel Tube (CFT) Beam-ColumnsDocument20 pagesAnalysis and Design of Noncompact and Slender Concrete-Filled Steel Tube (CFT) Beam-Columnsclam2014No ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Structural Steel Sets The Framework For Massive Airport RedevelopmentDocument4 pagesStructural Steel Sets The Framework For Massive Airport Redevelopmentclam2014No ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Steel: Built To Last: Case Study No 3Document4 pagesSteel: Built To Last: Case Study No 3clam2014No ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Issues On Using Welded Built-Up Box Columns in Steel Special Moment FramesDocument13 pagesIssues On Using Welded Built-Up Box Columns in Steel Special Moment Framesclam2014No ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Waikato University Case Study 5Document4 pagesWaikato University Case Study 5clam2014No ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Case Study No 6 Customhouse QuayDocument4 pagesCase Study No 6 Customhouse Quayclam2014No ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Engineering Journal: Third Quarter 2021 - Volume 58, No. 3Document72 pagesEngineering Journal: Third Quarter 2021 - Volume 58, No. 3clam2014No ratings yet

- Interior Floor Fill Beam Selection - Bay Length 30 FTDocument3 pagesInterior Floor Fill Beam Selection - Bay Length 30 FTclam2014No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Aisc 09 PDFDocument3 pagesAisc 09 PDFclam2014No ratings yet

- Interior Roof GirderDocument5 pagesInterior Roof Girderclam2014No ratings yet

- Lateral Load Flow Calculations - Roof: Pi P (Ki / Sum Ki)Document4 pagesLateral Load Flow Calculations - Roof: Pi P (Ki / Sum Ki)clam2014No ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Project: Steel Building Design Case Study Subject: Gravity Loads (Load Tables) SHEET 7 of 131Document1 pageProject: Steel Building Design Case Study Subject: Gravity Loads (Load Tables) SHEET 7 of 131clam2014No ratings yet

- (Option Ii) Interior Floor Girder Selection Live Load Reduction Check - Bay Width 36 FTDocument2 pages(Option Ii) Interior Floor Girder Selection Live Load Reduction Check - Bay Width 36 FTclam2014No ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Project: Steel Building Design Case Study Subject: Project Plan SHEET 1 of 131Document5 pagesProject: Steel Building Design Case Study Subject: Project Plan SHEET 1 of 131clam2014No ratings yet

- Aisc 05 PDFDocument1 pageAisc 05 PDFclam2014No ratings yet

- 41541-Article Text-221141-2-10-20230605Document14 pages41541-Article Text-221141-2-10-20230605Devy AnggrainiNo ratings yet

- Homework 3 SolutionsDocument44 pagesHomework 3 SolutionsilikebaconinmybuttNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Moody DiagramDocument6 pagesMoody DiagramBelen CabalunaNo ratings yet

- Quantitative Evaluation of Carbonation in Concrete UsingDocument11 pagesQuantitative Evaluation of Carbonation in Concrete UsingJohn YoussefNo ratings yet

- Dme-II Question BankDocument4 pagesDme-II Question BankenggsantuNo ratings yet

- Rule of MixtureDocument16 pagesRule of MixtureSANGHARSH BHAWARNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Level PhysicsDocument157 pagesA Level Physicsvinod_kumarranNo ratings yet

- Introduction To: Nonlinear Cracked Section AnalysisDocument9 pagesIntroduction To: Nonlinear Cracked Section AnalysisMungkorn SattNo ratings yet

- Homework 1 MADocument38 pagesHomework 1 MACarla TolbertNo ratings yet

- Ultrasonic Motors: Department of Electrical&Electronics Engineering Jntua College of Engineering Anantapur (Anantapur)Document27 pagesUltrasonic Motors: Department of Electrical&Electronics Engineering Jntua College of Engineering Anantapur (Anantapur)Shaik Towheed BanuNo ratings yet

- Fracture Mechanics of Concrete SwedenDocument158 pagesFracture Mechanics of Concrete Swedenpaulogud6170No ratings yet

- Stone Masonry Breast Wall - 2.0 MDocument6 pagesStone Masonry Breast Wall - 2.0 Mrahul sumanNo ratings yet

- Introduction To Chemical Engineering Thermodynamics: Prepared by A. R. Caparanga, PHD For Ch126PDocument35 pagesIntroduction To Chemical Engineering Thermodynamics: Prepared by A. R. Caparanga, PHD For Ch126PDOZPandaNo ratings yet

- Assignment MANIFOLD FinalDocument17 pagesAssignment MANIFOLD FinalMohamed SaeedNo ratings yet

- Wittke and Chao - 1967Document8 pagesWittke and Chao - 1967Sachin ZanjeNo ratings yet

- Yoddha Batch (10 - 10 - 2021) - 094037Document7 pagesYoddha Batch (10 - 10 - 2021) - 094037Mayank ShelarNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Stress - Analysis - Report - Optimized - Muhammad - H Adi: Simulation:1Document12 pagesStress - Analysis - Report - Optimized - Muhammad - H Adi: Simulation:1Febrian SyahputraNo ratings yet

- CH 1 - Engineering PhysicsDocument12 pagesCH 1 - Engineering PhysicsHaroonNo ratings yet

- Structural Stability CourseDocument196 pagesStructural Stability CourseBrillVerdeNo ratings yet

- Pump LossesDocument15 pagesPump LossesMuhammad afzal100% (1)

- Manual Roark FormulaDocument5 pagesManual Roark FormulaPeja JusohNo ratings yet

- Plastic Design of Continuous Beams & Portal FramesDocument9 pagesPlastic Design of Continuous Beams & Portal FramesJohan ConradieNo ratings yet

- Com 4Document28 pagesCom 4Lalit RanjanNo ratings yet

- Electrostatic Field 2 Lec3Document7 pagesElectrostatic Field 2 Lec3Sudesh Fernando Vayanga SubasinghaNo ratings yet

- Chapter 3Document15 pagesChapter 3abdu yimerNo ratings yet

- Thermodynamics Chapter 2 Lec1Document8 pagesThermodynamics Chapter 2 Lec1ahmadalsaiahNo ratings yet

- PhysicsDocument2 pagesPhysicsshadaine BlackNo ratings yet

- ETD Model IV QPDocument2 pagesETD Model IV QPtagoreboopathyNo ratings yet

- Topics Covered On Last Class:: Alternating CircuitDocument37 pagesTopics Covered On Last Class:: Alternating CircuitFariha ShahrinNo ratings yet

- OR 64x4.8Document1 pageOR 64x4.8kimNo ratings yet