Professional Documents

Culture Documents

Pigments and Additives For Powder Coatings: Product Selection Guide

Uploaded by

Ali KesikogluOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pigments and Additives For Powder Coatings: Product Selection Guide

Uploaded by

Ali KesikogluCopyright:

Available Formats

Pigments and

additives for

powder coatings

Product selection guide

PIGM_EDC_3111_e_Beileger_powderCoat.indd 1 18.03.11 15:03

2 Pigments and additives for powder coatings

Product selection guide

Pigment color space: Yellow

Our extensive range of yellow pigments allows for formulations from high-performance to cost-effective

applications and meets the current trend in lead-free formulations. The portfolio consists of quinophthalone,

benzimidazolone, isoindoline and isoindolinone organic pigments for high chroma and tinting strength.

Additionally our inorganic pigments bring to the formulator high opacity, chemical resistance and high

temperature stability. Here we offer the bismuth vanadate range, CICPs and also hybrids.

Temperature stability

Density

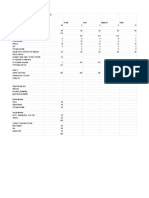

Current name Former name Chemistry Colour Index

(g/cm3) 20 min 10 min 10 min

180 °C 210 °C 240 °C

ΔE* ΔE* ΔE*

recommended products for powder coatings

Paliotol® Yellow L 0962 HD quinophthalone P.Y. 138 2.0 <2 <2 2-4

Sicotan® Yellow L 1010 Ni/Sb/Ti oxide P.Y. 53 4.5 <2 <2 <2

Cromophtal® Yellow L 1061 HD Irgazin® Yellow 2088 benzimidazolone P.Y. 151 1.5 <2 <2 2-4

Sicopal® Yellow L 1120 bismuth vanadate P.Y. 184 5.3 <2 <2 2-4

Paliotan® Yellow L 1145 hybrid - 3.9 <2 2-4 4-6

Paliotol® Yellow L 1155 isoindoline P.Y. 185 1.5 2-4 4-6 >6

Sicopal® Yellow L 1600 bismuth vanadate P.Y. 184 5.8 <2 2-4 4-6

Paliotan® Yellow L 1645 hybrid - 5.7 <2 2-4 4-6

Paliotan® Yellow L 1945 hybrid - 5.0 <2 <2 4-6

Paliotan® Yellow L 2045 hybrid - 3.6 <2 <2 4-6

Irgazin® Yellow L 2060 Irgazin® Yellow 3RLTN isoindolinone P.Y. 110 1.8 <2 <2 <2

Sicotan® Yellow L 2110 Cr/Sb/Ti oxide P.Br. 24 4.3 <2 <2 <2

Paliotol® Yellow L 2146 HD isoindoline P.Y. 139 1.7 <2 <2 2-4

products that find application in powder coatings

Cromophtal® Yellow L 1060 HD Paliotol® Yellow L 1060 HD benzimidazolone P.Y. 151 1.5 <2 <2 2-4

Cromophtal® Yellow L 1084 HD Irgazin® Yellow 2084 benzimidazolone P.Y. 154 1.5 <2 <2 2-4

Sicopal® Yellow L 1100 bismuth vanadate P.Y. 184 5.3 <2 <2 2-4

Paliotol® Yellow L 1820 isoindoline P.Y. 139 1.6 2-4 4-6 >6

Sicotan® Yellow L 1910 Cr/Sb/Ti oxide P.Br. 24 4.4 <2 <2 <2

Paliotol® Yellow L 1970 isoindoline P.Y. 139 1.7 <2 <2 2-4

Sicotan® Yellow L 2010 Cr/Sb/Ti oxide P.Br. 24 4.4 <2 <2 2-4

Paliotol® Yellow L 2140 HD isoindoline P.Y. 139 1.7 <2 <2 2-4

density (g/cm3): determination according to ISO 787-10

temperature stability: assessed as total color difference

ΔE* with reference to 20 minutes 160 °C

PIGM_EDC_3111_e_Beileger_powderCoat.indd 2 18.03.11 15:03

Pigments and additives for powder coatings

Product selection guide 3

Fastness to weathering (2000 h Xenotest®1)

Ease of inorganic organic hybrids Hiding Tinting Amine / amide

dispersion power strength resistance

full shade 1:1 full shade 1:10 full shade 1:3

3 - - 4-5 3 - - low fair fair

2 5 5 - - - - fair low high

3 - - 4-5d 3 - - fair fair low

3 5 5 - - - - high low high

3 - - - - 4-5 4 high fair fair

1 - - - - - - low high low

3 5 5 - - - - high low high

3 - - - - 4-5 4 high fair low

3 - - - - 5 5 high fair low

3 - - - - 4-5 4 high fair low

3 - - 4-5d 4-5 - - low high high

2 5 5 - - - - high low high

3 - - 4-5 3-4 - - fair fair low

2 - - 4-5 3 - - low fair low

2 - - 4-5 4 - - low high fair

3 5 5 - - - - high low high

1 - - - - - - low high low

2 5 5 - - - - high low high

2 - - 4-5 3 - - fair high low

2 5 5 - - - - high low high

3 - - 4-5 3-4 - - fair fair low

ease of dispersion: 1 = very easily dispersible, 2 = easily dispersible, 3 = not easily dispersible

fastness to weathering: is based on 2000 h Xenotest®1; assessment according to the gray scale, ISO 105-A02

PIGM_EDC_3111_e_Beileger_powderCoat.indd 3 18.03.11 15:03

4 Pigments and additives for powder coatings

Product selection guide

Pigment color space: Orange

These multi-purpose pigments find applications across many industries and have been found to have value and

performance in the powder coating market, they consist of DPP pigments and pyrazolone-quinazolone types to

bring enhanced chromaticity. The inorganic Sn/Zn/Ti oxide as a new development brings high opacity coupled

with outstanding durability and heat resistance.

Temperature stability

Density

Current name Former name Chemistry Colour Index

(g/cm3) 20 min 10 min 10 min

180 °C 210 °C 240 °C

ΔE* ΔE* ΔE*

recommended products for powder coatings

Sicopal® Orange L 2430 Sn/Zn/Ti oxide P.O. 82 4.9 <2 <2 <2

pyrazolo-

Paliotol® Orange L 2930 HD P.O. 67 1.8 2-4 4-6 >6

quinazolone

Paliotan® Orange L 2935 hybrid - 2.7 2-4 4-6 >6

products that find application in powder coatings

Irgazin® Orange L 2890 HD Cromophtal® Orange 2G isoindolinone P.O. 61 1.7 <2 <2 2-4

Irgalite® Orange L 2970 Irgalite® Orange MOR dianisidine P.O. 16 1.4 2-4 4-6 >6

diketo-pyrrolo-

Irgazin® Orange L 2990 HD Irgazin® DPP Orange RA1 P.O. 73 1.3 <2 <2 2-4

pyrrole

Irgazin® Orange L 3250 HD Irgazin® Orange 2037 hybrid - 1.6 <2 <2 2-4

1

requires testing if used in combination density (g/cm3): determination according to ISO 787-10

with other DPP pigments temperature stability: assessed as total color difference

ΔE* with reference to 20 minutes 160 °C

PIGM_EDC_3111_e_Beileger_powderCoat.indd 4 18.03.11 15:03

Pigments and additives for powder coatings

Product selection guide 5

Fastness to weathering (2000 h Xenotest®1)

Ease of inorganic organic hybrids Hiding Tinting Amine / amide

dispersion power strength resistance

full shade 1:1 full shade 1:10 full shade 1:3

3 4-5 4-5 - - - - high low high

3 - - 4 2 - - fair fair low

2 - - - - 4 2 high fair low

2 - - 4-5 4 - - low fair low

2 - - 4 2 - - fair high low

2 - - 4-5 4 - - low high low

2 - - - - 4-5 4 fair high low

ease of dispersion: 1 = very easily dispersible, 2 = easily dispersible, 3 = not easily dispersible

fastness to weathering: is based on 2000 h Xenotest®1; assessment according to the gray scale, ISO 105-A02

PIGM_EDC_3111_e_Beileger_powderCoat.indd 5 18.03.11 15:03

6 Pigments and additives for powder coatings

Product selection guide

Pigment color space: Red

These pigment ranges were designed for paint applications and include DPP types for high chromaticity and high tinting

strength, perylene reds for high durability and chemical resistance, quinacridone for outstanding durability and

temperature stability. Hybrid pigments bringing together opacity and mid to high performance with a value approach.

Temperature stability

Density

Current name Former name Chemistry Colour Index

(g/cm3) 20 min 10 min 10 min

180 °C 210 °C 240 °C

ΔE* ΔE* ΔE*

recommended products for powder coatings

diketo-pyrrolo-

Irgazin® Red L 3670 HD Irgazin® Red 2030 P.R. 254 1.7 <2 2-4 2-4

pyrrole

Paliotan® Red L 3745 hybrid - 3.0 <2 <2 <2

Cinquasia® Red L 4100 Cinquasia® Red Y RT-759-D quinacridone P.V. 19 1.5 <2 <2 <2

Paliogen® Red K 4180 perylene P.R. 179 1.5 <2 <2 <2

products that find application in powder coatings

diketo-pyrrolo-

Irgazin® Scarlet L 3550 HD Irgazin® DPP Scarlet EK P.R. 255 1.4 <2 <2 2-4

pyrrole

diketo-pyrrolo-

Irgazin® Red L 3600 HD Irgazin® Red 2031 - 1.4 <2 2-4 2-4

pyrrole

diketo-pyrrolo-

Irgazin® Red L 3660 HD Irgazin® DPP Red BO P.R. 254 1.6 <2 <2 2-4

pyrrole

Irgazin® Red L 3680 HD Irgazin® Red 2029 hybrid - 1.5 <2 <2 2-4

Irgazin® Red L 3685 HD Irgazin® Red 2027 hybrid - 1.6 <2 <2 2-4

Irgazin® DPP Red Ultra diketo-pyrrolo-

Irgazin® Red L 4010 HD P.R. 264 1.4 <2 <2 2-4

Opaque pyrrole

diketo-pyrrolo-

Irgazin® Rubine L 4020 Irgazin® DPP Rubine TRI P.R. 264 1.4 <2 <2 2-4

pyrrole

diketo-pyrrolo-

Irgazin® Rubine L 4025 Irgazin® DPP Rubine TR P.R. 264 1.4 <2 <2 2-4

pyrrole

Pigment color space: Violet and Bordeaux

These pigment ranges were designed for paint applications and include quinacridone and dioxazine types for high chromaticity, durability

and as shading components with organic reds. In addition, because of their high tinting strength, they offer a goodvalue-in-use approach.

Temperature stability

Density

Current name Former name Chemistry Colour Index

(g/cm3) 20 min 10 min 10 min

180 °C 210 °C 240 °C

ΔE* ΔE* ΔE*

recommended products for powder coatings

Cinquasia® Magenta L 4400 Irgazin® Magenta 2012 quinacridone P.R. 282 1.4 <2 <2 2-4

Cinquasia® Violet R

Cinquasia® Violet L 5120 quinacridone P.V. 19 1.5 <2 <2 <2

NRT-201-D

Cromophtal® Violet L 5800 Cromophtal® Violet GT dioxazine P.V. 23 1.8 <2 2-4 2-4

density (g/cm3): determination according to ISO 787-10

temperature stability: assessed as total color difference

ΔE* with reference to 20 minutes 160 °C

PIGM_EDC_3111_e_Beileger_powderCoat.indd 6 18.03.11 15:03

Pigments and additives for powder coatings

Product selection guide 7

Fastness to weathering (2000 h Xenotest®1)

Ease of inorganic organic hybrids Hiding Tinting Amine / amide

dispersion power strength resistance

full shade 1:1 full shade 1:10 full shade 1:3

3 - - 4-5 3-4 - - low high fair

3 - - - - 5 4 high fair high

2 - - 4-5 4-5 - - fair fair fair

2 - - 5 5 - - fair high high

2 - - 4-5 4 - - high high fair

3 - - 4-5 4 - - fair high fair

3 - - 4-5 4 - - fair high fair

3 - - - - 4-5 4 low high low

3 - - - - 4-5 4 low high low

3 - - 4-5 3-4 - - high high fair

2 - - 4-5 4 - - low high fair

2 - - 4-5 4 - - low high fair

Fastness to weathering (2000 h Xenotest®1)

Ease of inorganic organic hybrids Hiding Tinting Amine / amide

dispersion power strength resistance

full shade 1:1 full shade 1:10 full shade 1:3

2 - - 4-5 4-5 - - low high fair

3 - - 4-5 4-5 - - low high high

1 - - 4-5 4 - - low high fair

ease of dispersion: 1 = very easily dispersible, 2 = easily dispersible, 3 = not easily dispersible

fastness to weathering: is based on 2000 h Xenotest®1; assessment according to the gray scale, ISO 105-A02

PIGM_EDC_3111_e_Beileger_powderCoat.indd 7 18.03.11 15:03

8 Pigments and additives for powder coatings

Product selection guide

Pigment color space: Blue and green

These pigment ranges were designed for paint applications and include phthalocyanine blue and green types for

high chromaticity, durability and high tinting strength. Indanthrone blue for unique red shift in solid shades.

Inorganic cobalt blue for high opacity, chemical resistance and temperature stability required for powder coatings

Temperature stability

Density

Current name Former name Chemistry Colour Index

(g/cm3) 20 min 10 min 10 min

180 °C 210 °C 240 °C

ΔE* ΔE* ΔE*

recommended products for powder coatings

Heliogen® Blue L 6700 F ε-phthalocyanine P.B. 15:6 1.7 <2 <2 <2

Heliogen® Blue K 6907 α-phthalocyanine P.B. 15:1 1.6 <2 <2 <2

Heliogen® Blue K 6911 D α-phthalocyanine P.B. 15:1 1.6 <2 <2 <2

Heliogen® Blue K 7090 β-phthalocyanine P.B. 15:3 1.6 <2 <2 <2

Heliogen® Green L 8731 phthalocyanine P.G. 7 2.1 <2 <2 <2

Heliogen® Green K 9360 phthalocyanine P.G. 36 2.1 <2 <2 <2

products that find application in powder coatings

Sicopal® Blue L 6210 cobalt blue P.B. 28 4.0 <2 <2 <2

Paliogen® Blue L 6385 indanthrone P.B. 60 1.8 <2 <2 <2

Heliogen® Blue L 7081 D α-phthalocyanine P.B. 15:2 1.6 <2 <2 <2

Heliogen® Blue L 7085 β-phthalocyanine P.B. 15:3 1.5 <2 <2 <2

Heliogen® Blue L 7087 Irgalite® Blue PG β-phthalocyanine P.B. 15:3 1.6 <2 <2 <2

Heliogen® Green L 8735 phthalocyanine P.G. 7 2.1 <2 <2 <2

Heliogen® Green L 9361 phthalocyanine P.G. 36 2.9 <2 <2 <2

Sicopal® Green K 9610 cobalt green P.G. 50 4.9 <2 <2 <2

Pigment color space: Black

Specialty pigments selected for heat management consisting of perylene and chromium iron oxide types

Temperature stability

Density

Current name Former name Chemistry Colour Index

(g/cm3) 20 min 10 min 10 min

180 °C 210 °C 240 °C

ΔE* ΔE* ΔE*

recommended products for powder coatings

Sicopal® Black L 0095 iron chrome oxide P.Br. 29 5.2 <2 <2 <2

Paliogen® Black L 0086 perylene P.Bl. 32 1.5 <2 2-4 >6

density (g/cm3): determination according to ISO 787-10

temperature stability: assessed as total color difference

ΔE* with reference to 20 minutes 160 °C

PIGM_EDC_3111_e_Beileger_powderCoat.indd 8 18.03.11 15:03

Pigments and additives for powder coatings

Product selection guide 9

Fastness to weathering (2000 h Xenotest®1)

Ease of inorganic organic hybrids Hiding Tinting Amine / amide

dispersion power strength resistance

full shade 1:1 full shade 1:10 full shade 1:3

2 - - 4-5 4-5 - - low high high

3 - - 4-5 4-5 - - low high high

3 - - 4-5 4-5 - - low high high

3 - - 4-5 4-5 - - low high high

3 - - 4-5 4-5 - - low high high

3 - - 4-5 4-5 - - low high high

1 5 5 - - - - high low high

1 - - 4-5 4-5 - - low high high

2 - - 4-5 4-5 - - low high high

2 - - 4-5 4-5 - - low high high

2 - - 4-5 4-5 - - low high high

2 - - 4-5 4-5 - - low high high

2 - - 4-5 4-5 - - low high high

1 5 5 - - - - high low high

Fastness to weathering (2000 h Xenotest®1)

Ease of inorganic organic hybrids Hiding Tinting Amine / amide

dispersion power strength resistance

full shade 1:1 full shade 1:10 full shade 1:3

2 5 5 - - - - high low high

1 - - 4-5 3 - - fair high high

ease of dispersion: 1 = very easily dispersible, 2 = easily dispersible, 3 = not easily dispersible

fastness to weathering: is based on 2000 h Xenotest®1; assessment according to the gray scale, ISO 105-A02

PIGM_EDC_3111_e_Beileger_powderCoat.indd 9 18.03.11 15:03

10 Pigments and additives for powder coatings

Product selection guide

Effect pigments for exterior application

Particle size Particle size

Transparent effects Semi-opaque effects

in μm in μm

Magnapearl® Exterior CFS 3103 2 - 10 Mearlin® Exterior CFS Fine Brass 2323V 4 - 32

Mearlin® Exterior CFS Fine Pearl 1303V 4 - 32 Mearlin® Exterior CFS Super Brass 2323Z 6 - 48

Mearlin® Exterior Fine Pearl 139V 4 - 32 Lumina® Exterior Brass 2323D 10 - 48

Magnapearl® Exterior CFS 1103 8 - 48 Mearlin® Exterior CFS Super Bright Orange 3333Z 6 - 48

Mearlin® Exterior Bright Silver 139Z 6 - 48 Mearlin® Exterior CFS Fine Bronze 2503V 4 - 32

Mearlin® Exterior CFS Bright Silver 1303Z 10 - 48 Mearlin® Exterior CFS Super Bronze 2503Z 6 - 48

Lumina® Exterior Pearl Radiance 1303D 10 - 48 Mearlin® Exterior CFS Micro Copper 3503M 2 - 24

Mearlin® Exterior Bright White 139X 6 - 48 Mearlin® Exterior CFS Fine Copper 3503V 4 - 32

Mearlin® Exterior Sparkle 139P 10 - 110 Mearlin® Exterior CFS Super Copper 3503Z 6 - 48

Mearlin® Exterior CFS Micro Gold 2303M 2 - 10 Lumina® Exterior Copper 3503D 10 - 48

Mearlin® Exterior CFS Fine Gold 2303V 4 - 32 Mearlin® Exterior CFS Micro Russet 4503M 2 - 24

Mearlin® Exterior CFS Super Gold 2303Z 4 - 32 Mearlin® Exterior CFS Fine Russet 4503V 4 - 32

Lumina® Exterior Gold 2303D 10 - 48 Mearlin® Exterior CFS Super Russet 4503Z 4 - 32

Mearlin® Exterior CFS Super Orange 3303Z 6 - 48 Lumina® Exterior Russet 4503D 10 - 48

Mearlin® Exterior CFS Micro Red 4303M 2 - 24 Mearlin® Exterior CFS Blue Russet 6503Z 6 - 48

Mearlin® Exterior CFS Fine Red 4303V 4 - 32 Mearlin® Exterior Blue Green 7289Z 6 - 48

Mearlin® Exterior CFS Super Red 4303Z 6 - 48

Lumina® Exterior Red 4303D 10 - 48

Mearlin® Exterior CFS Micro Violet 5303M 2 - 24

Mearlin® Exterior CFS Fine Violet 5303V 4 - 32

Mearlin® Exterior CFS Super Violet 5303Z 6 - 48

Mearlin® Exterior CFS Micro Blue 6303M 4 - 32

Lumina® Exterior Red Blue 6303D 10 - 48

Lumina® Exterior Aqua Blue 7303D 10 - 48

Lumina® Exterior Turquoise T 303D 10 - 48

Mearlin® Exterior CFS Micro Green 8303M 2 - 24

Mearlin® Exterior CFS Fine Green 8303Z 6 - 48

Lumina® Exterior Green 8303D 10 - 48

Lumina® Royal Exterior Blue EH 402 (6803H) 6 - 48

Glacier™ Exterior Frost White EH 568 (S1303D) 10 - 48

PIGM_EDC_3111_e_Beileger_powderCoat.indd 10 18.03.11 15:03

Pigments and additives for powder coatings

Product selection guide 11

Effect pigments for general applications

Particle size Particle size

Transparent effects Transparent effects

in μm in μm

Magnapearl® 3000 2 - 10 Firemist® Gold 9G230L 52 - 188

Magnapearl® 3100 2 - 10 Firemist® Red 9G430L 52 - 188

Mearlin® Satin White 9130F 2 - 10 Firemist® Violet 9G530L 52 - 188

Magnapearl® 2000 5 - 25 Firemist® Blue 9G630L 52 - 188

Magnapearl® 2100 5 - 25 Firemist® Turquoise 9G730L 52 - 188

Magnapearl® 2300 5 - 25 Firemist® Green 9G830L 52 - 188

Magnapearl® 1000 6 - 48 Firemist® Green 9G830L 25 - 125

Magnapearl® 1100 6 - 48 Firemist® Green 9G830L 25 - 125

Magnapearl® 5000 15 - 95 Lumina® Royal Blue EH 627 (9680H) 6 - 48

Magnapearl® 4000 15 - 150 Glacier™ Frost White EH 682 (9S130D) 10 - 48

Mearlin® Micro Gold 9260M 2 - 10

Particle size

Lumina® Gold 9Y30D 10 - 48 Semi-opaque effects

in μm

Mearlin® Sparkle Gold 9220J 10 - 130 Mearlin® Micro Brass 9262M 2 - 10

Mearlin® Super Orange 9330Z 6 - 48 Mearlin® Super Brass 9232Z 6 - 48

Mearlin® Sparkle Orange 9320J 10 - 130 Lumina® Brass 9232D 10 - 48

Lumina® Red 9R30D 10 - 48 Mearlin® Sparkle Brass 9222J 10 - 10 - 130

Mearlin® Sparkle Red 9420J 10 - 130 Mearlin® Micro Bronze 9250M 2 - 10

Mearlin® Super Violet 9530Z 6 - 48 Mearlin® Super Bronze 9250Z 6 - 48

Mearlin® Micro Blue 9660M 2 - 10 Mearlin® Sparkle Bronze 9250J 10 - 130

Lumina® Red Blue 9830D 10 - 48 Mearlin® Micro Copper 9350M 2 - 10

Lumina® Aqua Blue 9A30D 10 - 48 Mearlin® Super Copper 9350Z 6 - 48

Mearlin® Sparkle Blue 9620J 10 - 130 Lumina® Copper 9350D 10 - 48

Lumina® Turquoise 9T30D 10 - 48 Mearlin® Sparkle Copper 9350J 10 - 130

Mearlin® Micro Green 9860M 2 - 10 Mearlin® Micro Russet 9450M 2 - 10

Lumina® Green 9G30D 10 - 48 Mearlin® Super Russet 9450Z 10 - 48

Mearlin® Sparkle Green 9820J 10 - 130 Mearlin® Super Blue Russet 9650Z 6 - 48

Firemist® Pearl 9G130L 52 - 188 Mearlin® Sparkle Russet 9650J 10 - 130

PIGM_EDC_3111_e_Beileger_powderCoat.indd 11 18.03.11 15:03

12 Pigments and additives for powder coatings

Product selection guide

Additives

Mw Mp Automotive &

Product name CAS Chemistry Physical form

[g/mol] [°C] (1Tg [°C]) Transportation

hindered amine light stabilizer (HALS)

Tinuvin® 111 FDL --- N-alkyl / N-alkyl HALS blend solid 2300 - 4000 60 - 98 1

Tinuvin® 144 63843-89-0 N-alkyl HALS solid 685 148 - 152

Tinuvin® 152 "191743-75-6 N-OR HALS solid 757 72 - 76 1

Tinuvin® 622 SF 65447-77-0 oligomeric N-alkyl HALS solid 3100 - 4000 57 - 61 1

UVA absorbers

2-(2-hydroxyphenyl)-benzotriazole (BTZ)

Tinuvin® 900 70321-86-7 BTZ solid 448 138 - 142

Tinuvin® 928 73936-91-1 BTZ solid 442 109 - 113

2-hydroxyphenyl-s-triazine (HPT)

Tinuvin® 405 137658-79-8 HPT solid 584 73 - 77

Tinuvin® 479 204848-45-3 HPT solid 678 39 - 43 1

antioxidants

Irganox® 1010 6683-19-8 phenol solid 1178 110 - 125

Irganox® 1035 41484-35-9 phenol solid 643 63 - 78

Irganox® 1076 2082-79-3 phenol solid 531 50 - 55

Irganox® 245 36443-68-2 phenol solid 587 76 - 79

Irgafos® 126 26741-53-7 phosphite solid 604 160 - 175

Irgafos® 168 31570-04-4 phosphite solid 647 183 - 186

Irganox® B 900 --- phenol / phospite AO blend solid --- 59 - 61

PIGM_EDC_3111_e_Beileger_powderCoat.indd 12 18.03.11 15:03

Pigments and additives for powder coatings

Product selection guide 13

Industrial Architectural

HALS blend for polyester-based powder coating application with triboelectric charging activity

antioxidant-functionalized basic HALS with additional triboelectric charging activity for powder coatings

non-migrating N-OR HALS for powder coatings based on glycidyl methacrylate (GMA)

low-basic HALS with antioxidant properties for polyester-based powder coatings

medium-performance powder coatings

medium-performance powder coatings

high-performance powder coatings applications based on glycidyl methacrylate (GMA)

highest extinction especially designed for thin or reduced film applications

primary antioxidant for powder coatings

primary antioxidant for powder coatings

primary antioxidant for powder coatings

primary antioxidant for powder coatings

secondary antioxidant for powder coatings

secondary antioxidant for powder coatings

antioxidant blend for powder coatings

PIGM_EDC_3111_e_Beileger_powderCoat.indd 13 18.03.11 15:03

14 Pigments and additives for powder coatings

Product selection guide

UV-VIS absorbance spectra for UV absorbers

1.5 1.5

spectra were recorded with 20 mg/l in toluene, path = 1 cm spectra were recorded with 20 mg/l in toluene, path = 1 cm

1.25 1.25

absorbance / AU

1.0 1.0

absorbance / AU

0.75 0.75

0.5 0.5

0.25 0.25

0 0

290 310 330 350 370 390 410 430 290 310 330 350 370 390 410 430

wavelength / nm wavelength / nm

Tinuvin® 928 Tinuvin® 900

2.5 2.5

spectra were recorded with 20 mg/l in toluene, path = 1 cm spectra were recorded with 20 mg/l in toluene, path = 1 cm

2.0 2.0

absorbance / AU

absorbance / AU

1.5 1.5

1.0 1.0

0.5 0.5

0 0

290 310 330 350 370 390 410 430 290 310 330 350 370 390 410 430

wavelength / nm wavelength / nm

Tinuvin® 479 Tinuvin® 405

PIGM_EDC_3111_e_Beileger_powderCoat.indd 14 18.03.11 15:03

Pigments and additives for powder coatings

Product selection guide 15

PIGM_EDC_3111_e_Beileger_powderCoat.indd 15 18.03.11 15:04

Contact worldwide

Asia North America

BASF East Asia Regional Headquarters Ltd. BASF Corporation

45/F, Jardine House 100 Campus Drive

No. 1 Connaught Place Florham Park, NJ 07932

Central USA

Hong Kong Tel.: +1 800 962-7829

Tel.: +852 2731-0111 Fax: +1 800 971-1123

Fax: +852 2731-5633

Tel.: +1 973 245-7399

Europe Fax: +1 864 332-5080

BASF SE

Pigments South America

E-EDC/FI – J 550 BASF S.A.

67056 Ludwigshafen Av. Faria Lima 3600 – 10° andar

Germany Itaim Bibi – São Paulo – SP

Tel.: +49 621 60-72393 04538-132

Fax: +49 621 60-58320 Brazil

Tel.: +55 11 3043-3637

Eastern Europe, Africa, West Asia Fax: +55 11 3043-2040

BASF SE

Business Management

Dispersions & Pigments

EUM/SD – Europe House

67056 Ludwigshafen

Germany

Tel.: +49 621 60-76429

Fax: +49 621 60-76115

EDC 3111 e

BASF SE

67056 Ludwigshafen

Germany

www.dispersions-pigments.basf.com

The data contained in this publication are based on our current knowledge and experience. In view of the many factors that may affect processing and application of our product, these data do

not relieve processors from carrying out their own investigations and tests; neither do these data imply any guarantee of certain properties, nor the suitability of the product for a specific purpose.

Any descriptions, drawings, photographs, data, proportions, weights, etc. given herein may change without prior information and do not constitute the agreed contractual quality of the product.

The agreed contractual quality of the product results exclusively from the statements made in the product specification. It is the responsibility of the recipient of our product to ensure that any

proprietary rights and existing laws and legislation are observed. When handling these products, advice and information given in the safety data sheet must be complied with. Further, protective

and workplace hygiene measures adequate for handling chemicals must be observed.

® = registered trademark of the BASF Group ®1 = registered trademark of Xenotest Gesellschaft für die Herstellung von Materialprüfgeräten mbH

PIGM_EDC_3111_e_Beileger_powderCoat.indd 16 18.03.11 15:04

You might also like

- Solvent Product List (Metal Complex Solvent Dyes)Document3 pagesSolvent Product List (Metal Complex Solvent Dyes)Camilo DominguezNo ratings yet

- Colors From Around The World1Document2 pagesColors From Around The World1Noviana HussenNo ratings yet

- Pan Pastel Color ChartDocument1 pagePan Pastel Color ChartKath GloverNo ratings yet

- List of ColourDocument13 pagesList of ColourAde KurniawanNo ratings yet

- AAlChem Powder Coatings Line CardDocument8 pagesAAlChem Powder Coatings Line CardChris SmithNo ratings yet

- Manufacturing of Printing Inks With FormulationDocument82 pagesManufacturing of Printing Inks With FormulationI Love MusicNo ratings yet

- BASF - Technical Data BrochureDocument12 pagesBASF - Technical Data BrochureJulia RodriguezNo ratings yet

- Dokumen - Tips - Cappelle Pigments Uv InksDocument2 pagesDokumen - Tips - Cappelle Pigments Uv Inksjw lmNo ratings yet

- Pigment Green 7 & Reactive Blue 21 - ReportDocument245 pagesPigment Green 7 & Reactive Blue 21 - ReportjayshethNo ratings yet

- Clariant Brochure Shade Card Organic Pigments For Plastics Coloration 201710 EN DEDocument13 pagesClariant Brochure Shade Card Organic Pigments For Plastics Coloration 201710 EN DEᎽᎯ ᎡᎯ ᎯᏞᎯᎿᎿᎯᎡNo ratings yet

- Ral CappelleRetLiq PDFDocument349 pagesRal CappelleRetLiq PDFMaria DanciulescuNo ratings yet

- Cultured Marble Coloring TechniquesDocument40 pagesCultured Marble Coloring TechniquesjopiougNo ratings yet

- Brochure Hostatint 500Document4 pagesBrochure Hostatint 500Pablo Mariño MuñizNo ratings yet

- Liquitex Acrylic Gouache BookletDocument24 pagesLiquitex Acrylic Gouache Booklethello belloNo ratings yet

- Welcome: Group No-9 Sy Bba - BDocument26 pagesWelcome: Group No-9 Sy Bba - BAditya ManerikarNo ratings yet

- List of Dyes Colours and Pigments Permitted in CosmeticsDocument5 pagesList of Dyes Colours and Pigments Permitted in Cosmeticsmarkandey guptaNo ratings yet

- Qor Colors Pigment Information 090414Document3 pagesQor Colors Pigment Information 090414Pat ShepardNo ratings yet

- Latex & RubberDocument4 pagesLatex & RubberLựuLiềuLìNo ratings yet

- Arlamol LST DS-295-5 PDFDocument12 pagesArlamol LST DS-295-5 PDFsimmiNo ratings yet

- Coatings Word September 2012Document116 pagesCoatings Word September 2012sami_sakrNo ratings yet

- RAL Colour Chart For PaintDocument4 pagesRAL Colour Chart For PaintAngelo Abara SolivenNo ratings yet

- Pigments For Plastics Product Selection GuideDocument21 pagesPigments For Plastics Product Selection GuideAndrew IMCDNo ratings yet

- TDS - Panax Yellow 3RDocument1 pageTDS - Panax Yellow 3RRio AndriyantoNo ratings yet

- Project 3Document18 pagesProject 3Jay ParekhNo ratings yet

- Liquitex Color Chart Heavy BodyDocument2 pagesLiquitex Color Chart Heavy BodyaleNo ratings yet

- Paper ColorDocument94 pagesPaper Colortrongnhan1479No ratings yet

- Solving Color Challenges in Coatings - Soujanya ColorDocument24 pagesSolving Color Challenges in Coatings - Soujanya ColorBasem MahmoudNo ratings yet

- Catalogo Aditivos AfconaDocument44 pagesCatalogo Aditivos AfconaMaleja HerediaNo ratings yet

- 07 Apr 2018 1600009675JRMYML2PFRBluetronFinal PDFDocument50 pages07 Apr 2018 1600009675JRMYML2PFRBluetronFinal PDFBimo Ary Pujangga PutraNo ratings yet

- Dossier Sccolor WebDocument20 pagesDossier Sccolor WebPatrik NyberghNo ratings yet

- Zinc PhosphateDocument3 pagesZinc PhosphateSandeep BNo ratings yet

- Indigoid & Thioindigoid PigmentsDocument9 pagesIndigoid & Thioindigoid PigmentsShruti100% (1)

- Foreign Formulations On PaintDocument34 pagesForeign Formulations On PaintOluwaseun TaiwoNo ratings yet

- Coatings Word October 2012Document84 pagesCoatings Word October 2012sami_sakrNo ratings yet

- Safety Data Sheet: Dimethylaminopropylamine (DMAPA)Document7 pagesSafety Data Sheet: Dimethylaminopropylamine (DMAPA)harris fikrenNo ratings yet

- Coatings Word April 2015Document52 pagesCoatings Word April 2015sami_sakr100% (1)

- (BASF) Basacid DyesDocument8 pages(BASF) Basacid DyesEugene PaiNo ratings yet

- Arkema - Polymer Selection Guide For Liquid ResinsDocument28 pagesArkema - Polymer Selection Guide For Liquid ResinsYoNo ratings yet

- The Perception of Metallic Stearates As Acid Acceptors Revised PDFDocument53 pagesThe Perception of Metallic Stearates As Acid Acceptors Revised PDF10-priyankaNo ratings yet

- ENG Rws Centerfire-Rifle-Cartridges Brochure 1Document41 pagesENG Rws Centerfire-Rifle-Cartridges Brochure 1vihkr9506No ratings yet

- RAL Descriptive Colour Chart PDFDocument4 pagesRAL Descriptive Colour Chart PDFArun KumarNo ratings yet

- Disparlon GuidelinesDocument6 pagesDisparlon GuidelinesPratik MehtaNo ratings yet

- Pigmente SennelierDocument3 pagesPigmente SennelierJose ValenzuelaNo ratings yet

- Asahi Songwon Colors Limited EIA PDFDocument214 pagesAsahi Songwon Colors Limited EIA PDFjyothiNo ratings yet

- Nike Restricted Substances List (RSL) and Sustainable Chemistry Guidance (SCG)Document65 pagesNike Restricted Substances List (RSL) and Sustainable Chemistry Guidance (SCG)Badrun AhamdNo ratings yet

- CCARD Color CardDocument2 pagesCCARD Color CardJonNo ratings yet

- Chemical Composition of A Fountain Pen InkDocument4 pagesChemical Composition of A Fountain Pen InkmynamecoolNo ratings yet

- Basell PP Homo Rafia Hp456j Mi 3 4Document2 pagesBasell PP Homo Rafia Hp456j Mi 3 4crawn06No ratings yet

- FINAL - FunctionalTrendsInArchCoatingsDocument60 pagesFINAL - FunctionalTrendsInArchCoatingsCHIRE SARAYASI MANUELNo ratings yet

- Shrink Sleeve PVC InksDocument1 pageShrink Sleeve PVC InksPRAVIN A.PANDHARKAMENo ratings yet

- Colorants Portfolio For Sensitive Applications in Plastics EDC1114e 20140725 PDFDocument28 pagesColorants Portfolio For Sensitive Applications in Plastics EDC1114e 20140725 PDFAabraham Samraj PonmaniNo ratings yet

- Poly SurfDocument13 pagesPoly SurfRajNo ratings yet

- ral munsell color 비교Document1 pageral munsell color 비교Muthazhagan Saravanan100% (1)

- Overview On Basic Chemistry of UV-curing TechnologyDocument32 pagesOverview On Basic Chemistry of UV-curing TechnologyEugene PaiNo ratings yet

- Pigment Density of Golden Artist ColorsDocument6 pagesPigment Density of Golden Artist Colors1 2No ratings yet

- SDS-Sunfix Yellow SPR (2020)Document7 pagesSDS-Sunfix Yellow SPR (2020)Waqas AhmedNo ratings yet

- PF1585 Vanilla Cream 6 KGDocument2 pagesPF1585 Vanilla Cream 6 KGSaurabhNo ratings yet

- Tailoring Composite MaterialsDocument23 pagesTailoring Composite MaterialsRama Rifqi100% (1)

- Bengkel SPM 2016 MozacDocument79 pagesBengkel SPM 2016 MozacZULKEFLI BIN MOHD ARIS MoeNo ratings yet

- Class 11 CPT 1 Jee Main Paper 19-05-20Document8 pagesClass 11 CPT 1 Jee Main Paper 19-05-20Rashmi AgrawalNo ratings yet

- Measurement and Prediction of Hydrate-Phase Equilibria For Reservoir FluidsDocument8 pagesMeasurement and Prediction of Hydrate-Phase Equilibria For Reservoir FluidsThevaruban RagunathanNo ratings yet

- Item Bank FIRSTQDocument3 pagesItem Bank FIRSTQRaymond Reyes CuribangNo ratings yet

- Danyal Education: A) ) B) C) D)Document20 pagesDanyal Education: A) ) B) C) D)SONo ratings yet

- Maths IA IntroDocument20 pagesMaths IA Introshakthi aravinthNo ratings yet

- 111l Experiment 6 - Co SynthesisDocument14 pages111l Experiment 6 - Co SynthesisB C Ravi100% (1)

- Solid State Diffusion of MetalsDocument6 pagesSolid State Diffusion of MetalsJatin RaoNo ratings yet

- Grade 5 DLL SCIENCE 5 Q4 Week 9Document6 pagesGrade 5 DLL SCIENCE 5 Q4 Week 9Buena RosarioNo ratings yet

- A Study of Challenges For Fuse Link Protection in The New Generations of Environmentally Friendly VehiclesDocument9 pagesA Study of Challenges For Fuse Link Protection in The New Generations of Environmentally Friendly Vehiclesjk KimNo ratings yet

- Nutrition - BacteriaDocument14 pagesNutrition - BacteriaFuad Hasan Pranto 1921147049No ratings yet

- BTech Engg PhysDocument10 pagesBTech Engg PhysAmith T KiniNo ratings yet

- Rinhs Science 10 Activity 1 Properties of Gas and KMTDocument2 pagesRinhs Science 10 Activity 1 Properties of Gas and KMTRyan BersaminNo ratings yet

- Control of Decarburization of Steel PDFDocument5 pagesControl of Decarburization of Steel PDFBhushan VermaNo ratings yet

- Normality and Molefraction - NumericalsDocument2 pagesNormality and Molefraction - NumericalsSHRAVYA K REDDYNo ratings yet

- Purple Hat App: Multiple Choice QuestionsDocument106 pagesPurple Hat App: Multiple Choice QuestionsSharvesh ChopadeNo ratings yet

- Ekeke Chijioke Bright CVDocument4 pagesEkeke Chijioke Bright CVchijioke ekekeNo ratings yet

- Pollutants (E-Waste) : Chemical Characteristics and Their Potential RisksDocument23 pagesPollutants (E-Waste) : Chemical Characteristics and Their Potential RisksRolly Fallorina SenangeloNo ratings yet

- Separation and Analysis of A Ternary MixtureDocument3 pagesSeparation and Analysis of A Ternary MixtureGregbr62No ratings yet

- 11 - Isomerism in TMCDocument18 pages11 - Isomerism in TMCMohit KambojNo ratings yet

- Chapter 12Document16 pagesChapter 12roxy8marie8chanNo ratings yet

- Ti e Protegol 32-45 Jan 12Document3 pagesTi e Protegol 32-45 Jan 12ruben quedo salazarNo ratings yet

- Post-Second World War: 1945: Alsos MissionDocument1 pagePost-Second World War: 1945: Alsos MissionSkip JonesNo ratings yet

- Ex 1 Aniline PointDocument9 pagesEx 1 Aniline PointSalman Alshammari100% (1)

- Instrument Process Hook-Up DetailsDocument301 pagesInstrument Process Hook-Up DetailsNikki Roberts100% (6)

- واجب شامل للمقررDocument30 pagesواجب شامل للمقررOsama AlkinaneNo ratings yet

- Dual Nature of Matter and Radiation-Notes-Iit-Jee - pdf-65Document7 pagesDual Nature of Matter and Radiation-Notes-Iit-Jee - pdf-65SRITIKANTA RAYNo ratings yet

- Water Treatment Facilities and Process: Group IiiDocument24 pagesWater Treatment Facilities and Process: Group IiiJackie BeltranNo ratings yet

- Quest Forces 1 KeyDocument7 pagesQuest Forces 1 KeyCarlos OrtizNo ratings yet