Professional Documents

Culture Documents

ACD II Practical Questions

ACD II Practical Questions

Uploaded by

Sunil AdhikariOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ACD II Practical Questions

ACD II Practical Questions

Uploaded by

Sunil AdhikariCopyright:

Available Formats

AUTOMOBILE COMPONENT DESIGN II (PRACTICAL QUESTIONS)

1. A helical coil compression spring is needed for food service machinery. The load varies from a minimum of

20 N to a maximum of 90 N. The spring rate k is to be 1660 N/m. The outside diameter of the spring cannot

exceed 62 mm. The springmaker has available suitable dies for drawing 2-, 2.3-, 2.6- and 3- diameter wire.

Using a fatigue design factor nf of 1.5, and the Gerber-Zimmerli fatigue-failure criterion, design a suitable

spring.

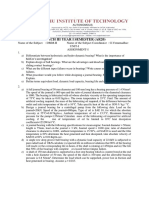

2. A screw clamp similar to the one shown in the figure 1 has a handle with diameter of 10 mm made of cold-

drawn AISI 1006 steel. The overall length is 108 mm, but the force will be applied to the handle at a radius

of 90 mm from the screw centerline. The screw is M20 X 2.5 mm acme thread and 203 mm long, overall.

Distance A is 75 mm. The clamp will accommodate parts up to 150 mm high. [Take E=207 GPa.]

(a) What screw torque will cause the handle to bend permanently?

(b) What clamping force will the answer to part (a) cause if the collar friction is neglected and if the thread

friction is 0.15?

(c) What clamping force will cause the screw to buckle?

(d) Are there any other stresses or possible failures to be checked?

3. The shoes on the brake depicted in the figure 2 subtend a 90° arc on the drum of this external pivoted-shoe

brake. The actuation force P is applied to the lever. The rotation direction of the drum is counterclockwise,

and the coefficient of friction is 0.30.

a) What should the dimension e be?

b) Draw the free-body diagrams of the handle lever and both shoe levers, with forces expressed in

terms of the actuation force P.

c) Does the direction of rotation of the drum affect the braking torque?

d) If a rigid molded non-asbestos lining (coefficient of friction, f = 0.33 and maximum pressure, pmax =

0.7 MPa) is used dry in the brake on a cast iron drum. The shoes are 190 mm wide and subtend a 90°

arc. Find the maximum allowable actuation force and the braking torque.

All dimensions are in mm.

Figure 1 Figure 2

***

You might also like

- MDSP Set 2Document9 pagesMDSP Set 2iaton77100% (2)

- NR 320301 Machine DesignDocument8 pagesNR 320301 Machine DesignSrinivasa Rao GNo ratings yet

- 15A03602 Design of Machine Members - IIDocument2 pages15A03602 Design of Machine Members - IIJagannath CherkuNo ratings yet

- Assignment 01Document2 pagesAssignment 01Ratan Sadanandan O MNo ratings yet

- DMM-2 3 1 Q&aDocument6 pagesDMM-2 3 1 Q&aAnand vinayNo ratings yet

- Design1 SheetsDocument9 pagesDesign1 SheetsYou channelNo ratings yet

- 15ME641Document3 pages15ME641Anmol NairNo ratings yet

- WWW - Manaresults.co - In: Design of Machine Members - IiDocument8 pagesWWW - Manaresults.co - In: Design of Machine Members - IiXyz AbcNo ratings yet

- 12ME5DCDM2Document3 pages12ME5DCDM2Abhyudaya SinghNo ratings yet

- 1830 - Tutorial 4 Clutches and BrakesDocument3 pages1830 - Tutorial 4 Clutches and BrakesJohn RajNo ratings yet

- Dme Model 2Document6 pagesDme Model 2YashwanthI-StyleKuttiNo ratings yet

- BMS College of Engineering, Bangalore-560019: January 2015 Semester End Make Up ExaminationsDocument2 pagesBMS College of Engineering, Bangalore-560019: January 2015 Semester End Make Up ExaminationsAbhyudaya SinghNo ratings yet

- Design of Machine Element-IIDocument53 pagesDesign of Machine Element-IIPramod R Bidve100% (1)

- DME Chapter Three: or (Summer 15)Document7 pagesDME Chapter Three: or (Summer 15)honeyfunnyNo ratings yet

- Btech Auto 5 Sem Design of Machine Components Pau5i101 2020Document2 pagesBtech Auto 5 Sem Design of Machine Components Pau5i101 2020Pagal KutaNo ratings yet

- Tutorial - General Introduction and Spur Gear - 1Document2 pagesTutorial - General Introduction and Spur Gear - 1SR SuryaNo ratings yet

- rr320305 Design of Machine Members IIDocument8 pagesrr320305 Design of Machine Members IISrinivasa Rao GNo ratings yet

- Chp4 2 - BrakesDocument36 pagesChp4 2 - BrakesAzhar BaigNo ratings yet

- MD1 and MD2 Compilation 1Document50 pagesMD1 and MD2 Compilation 1boj VillanuevaNo ratings yet

- Integrated Mechanical Design Jan - 10Document4 pagesIntegrated Mechanical Design Jan - 10SasiKumar PetchiappanNo ratings yet

- MD ConventionalDocument8 pagesMD ConventionalBipin KumarNo ratings yet

- Makalah GTWDocument8 pagesMakalah GTWfaisalNo ratings yet

- Model Question BankDocument4 pagesModel Question BankVinod BalakrishnanNo ratings yet

- Design of Machine Elements: B.E. (Mechanical Engineering / Power Engineering) Fifth Semester (C.B.S.)Document4 pagesDesign of Machine Elements: B.E. (Mechanical Engineering / Power Engineering) Fifth Semester (C.B.S.)Chandani KannakeNo ratings yet

- Tutorial No 4 TorsionDocument7 pagesTutorial No 4 TorsionwaleedkhalillahmedNo ratings yet

- Vance - Antonio LACAYANGA - ASSESSMENT TESTDocument7 pagesVance - Antonio LACAYANGA - ASSESSMENT TESTAyuguNo ratings yet

- Machine Design 1Document2 pagesMachine Design 1Niño Gerard JabagatNo ratings yet

- Design of Machine Members II R5320305 Set 3Document2 pagesDesign of Machine Members II R5320305 Set 3Ravi Kumar KamarthiNo ratings yet

- WWW - Manaresults.co - In: Design of Machine Members - IiDocument2 pagesWWW - Manaresults.co - In: Design of Machine Members - IiXyz AbcNo ratings yet

- RT32033062022Document2 pagesRT32033062022ANJI PRASADNo ratings yet

- Termpaper-Strength Analysis of Screw Jack-Mechanics of SolidsDocument21 pagesTermpaper-Strength Analysis of Screw Jack-Mechanics of SolidsOmkar Kumar JhaNo ratings yet

- Design of Machine Members-II Feb 2022Document3 pagesDesign of Machine Members-II Feb 2022Anand KedhariNo ratings yet

- MD Class Test 1Document5 pagesMD Class Test 1Sambit Das0% (1)

- 07a6ec05 Designofmachinemembers IIDocument11 pages07a6ec05 Designofmachinemembers IIzahid_polyNo ratings yet

- Design of Machine Elements-IiDocument2 pagesDesign of Machine Elements-IiAmal GangadharanNo ratings yet

- ME4001D Assign 1Document3 pagesME4001D Assign 1vivek geddamNo ratings yet

- Design of Machine Members-IDocument8 pagesDesign of Machine Members-IMahesh Babu TalupulaNo ratings yet

- Dme Model Key 2019Document25 pagesDme Model Key 2019Siva RamanNo ratings yet

- 12 Me 5dcdm2Document3 pages12 Me 5dcdm2Abhyudaya SinghNo ratings yet

- Design of Machine Members-I April 2019Document8 pagesDesign of Machine Members-I April 2019Uday NarasimhaNo ratings yet

- Question Paper For MeDocument4 pagesQuestion Paper For MeVishal JhaNo ratings yet

- Virtual Buce 3Document92 pagesVirtual Buce 3Ralph Edward Santiago Moran100% (1)

- DE5302 Strength of Materials 1 S2 2019 - Exam - FINALDocument24 pagesDE5302 Strength of Materials 1 S2 2019 - Exam - FINALGopal KrishanNo ratings yet

- Machine Design/Shop Practice Trivia: Multiple Choice QuestionsDocument6 pagesMachine Design/Shop Practice Trivia: Multiple Choice QuestionsJads CayabyabNo ratings yet

- Day 33Document4 pagesDay 33Marcial Jr. MilitanteNo ratings yet

- Our Official Android App - REJINPAUL NETWORK FromDocument3 pagesOur Official Android App - REJINPAUL NETWORK FromAjay KumarNo ratings yet

- Tutorial Chapter 1Document1 pageTutorial Chapter 1Melvin Shady PereiraNo ratings yet

- AECD QuestionsDocument7 pagesAECD QuestionssbkNo ratings yet

- TIE2208200908 Engineering Design Applications IIDocument4 pagesTIE2208200908 Engineering Design Applications IIPatrick NdlovuNo ratings yet

- WWW - Manaresults.co - In: Design of Machine Members - IiDocument1 pageWWW - Manaresults.co - In: Design of Machine Members - IiXyz AbcNo ratings yet

- A) Find The Total Radial and Axial Forces ActingDocument2 pagesA) Find The Total Radial and Axial Forces ActingARPIT MITTALNo ratings yet

- Power Screw SheetDocument4 pagesPower Screw SheetMohamed GamalNo ratings yet

- 9A14503 Principles of Machine DesignDocument8 pages9A14503 Principles of Machine DesignsivabharathamurthyNo ratings yet

- FRANSCISCO-Sept 2012Document9 pagesFRANSCISCO-Sept 2012Arnz BibosoNo ratings yet

- Clutches Computational LaboratoryDocument1 pageClutches Computational LaboratoryJohn Paul ParoNo ratings yet

- EMM7241-Advanced Machine Design Examination June 2016Document8 pagesEMM7241-Advanced Machine Design Examination June 2016Charles OndiekiNo ratings yet

- Mech-Vi-Design of Machine Elements II (10me62) - Question PaperDocument11 pagesMech-Vi-Design of Machine Elements II (10me62) - Question PaperAnonymous utfuIcnNo ratings yet

- Gujarat Technological UniversityDocument3 pagesGujarat Technological UniversityBhavesh PatelNo ratings yet

- Attendance of Students: SN Name of Student Class Roll No. Exam Roll No. Title of Project/Thesis Digital Signature RemarksDocument2 pagesAttendance of Students: SN Name of Student Class Roll No. Exam Roll No. Title of Project/Thesis Digital Signature RemarksSunil AdhikariNo ratings yet

- Warm Welcome To II (Second) Phase Mid Term DefenseDocument1 pageWarm Welcome To II (Second) Phase Mid Term DefenseSunil AdhikariNo ratings yet

- Pre Final Schedule 1Document4 pagesPre Final Schedule 1Sunil AdhikariNo ratings yet

- Automobile FrameDocument4 pagesAutomobile FrameSunil AdhikariNo ratings yet

- Lec 1Document9 pagesLec 1Sunil AdhikariNo ratings yet

- Governance and LeadershipDocument5 pagesGovernance and LeadershipSunil AdhikariNo ratings yet

- Define Thermodynamic SystemDocument2 pagesDefine Thermodynamic SystemSunil AdhikariNo ratings yet

- A Technical Problem Analysis of Micro Hydro Plant (A Case Study at Pokhari Chauri of Kavre District) Journal: IOE, Pulchowk Campus Vol: 14Document1 pageA Technical Problem Analysis of Micro Hydro Plant (A Case Study at Pokhari Chauri of Kavre District) Journal: IOE, Pulchowk Campus Vol: 14Sunil AdhikariNo ratings yet

- Institute of Engineering: Tribhuvan UniversityDocument3 pagesInstitute of Engineering: Tribhuvan UniversitySunil AdhikariNo ratings yet