Professional Documents

Culture Documents

Lrut Job Preparation Questionnaire Long Range Guided Wave Inspection

Uploaded by

kucing_batamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lrut Job Preparation Questionnaire Long Range Guided Wave Inspection

Uploaded by

kucing_batamCopyright:

Available Formats

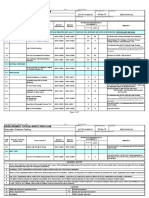

LRUT JOB PREPARATION QUESTIONNAIRE

Long Range Guided Wave Inspection

The purpose of this form is to allow Velosi to assess the application / suitability for Long Range Guided

Wave examination and to allow us to estimate the expected performance and provide precise systematic

reporting. The form will also ensure that the equipment required for the testing is properly selected, and set

up prior to the execution date.

Accurate completion of this form will help make the work on site more efficient and provide better

inspection and markation of the datum, and as such we ask that you answer as many of the questions as

possible in order to gain the most benefit from the process.

We appreciate your response to this questionnaire at least two weeks prior to the projects mobilization to

allow for quotation time and scheduling i.e. Inductions required, Inspection access requirements, etc.

Customer Information:

Client/Company Name

Client Representative Name

Phone No.

E-mail

Report Requirements Prelim report Choose an item.

Final report Choose an item.

Electronic Copies

Choose an item.

Required

Facility Information:

Facility Name

Site Contact Name

Phone No.

E-mail

LRUT JOB PREPARATION QUESTIONNAIRE Page 1 of 4

Item Information:

Plant or Unit #

Line Name and no.

Year Built or Installed

Pipeline Material Choose an item. Other (specify)

Service/ Product

Outside Diameter (O.D.) Choose an item. Other (specify)

Choose an item. Other (specify)

Choose an item. Other (specify)

Choose an item. Other (specify)

Choose an item. Other (specify)

Choose an item. Other (specify)

Design of Pipe Wall

Choose an item. Other (specify)

Thickness Schedule

Is the O.D. / WT constant

Choose an item.

throughout the line?

Temperature during

Choose an item.

Examination

Length (approximate)

Are there other features Weldolet Choose an item.

on the pipe?

Branches Choose an item.

Valves Choose an item.

Others

Frequency of elbows/

bends over proposed

inspection range

Bend/ Elbow Type Choose an item. Other (specify)

Is the Pipe Buried? Choose an item.

If buried, is excavation for

Choose an item.

inspection possible?

Is scaffolding required to

Choose an item.

access the pipes?

Joints Choose an item. Other (specify)

LRUT JOB PREPARATION QUESTIONNAIRE Page 2 of 4

Insulation/Coating Information:

Is the Pipe Insulated? Choose an item.

Coating Type Choose an item. Other (specify)

Coating Condition Choose an item. Other (specify)

Insulation Choose an item. Other (specify)

Can insulation be removed locally in

at least 500mm long sections to Choose an item.

facilitate probe placement?

Wrapped Pipe:

Is the Pipe Wrapped? Choose an item.

Type Choose an item. Other (specify)

Condition Choose an item.

Wall Penetrations:

Are Wall Penetrations present? Choose an item.

Type of Wall Choose an item. Other (specify)

Wall Width/Length (approximate) Choose an item.

Known or Visible Corrosion:

External Corrosion/ Pitting (known)

Choose an item.

(leave blank if unknown)

External corrosion/ Pitting

Choose an item.

Distribution

Internal Corrosion (known)

Choose an item.

(leave blank if unknown)

Internal Corrosion/ Pitting

Choose an item.

Distribution

Pipe Supports:

Basic Configuration Choose an item.

Support Type

Choose an item. Other (specify)

Frequency of Supports

LRUT JOB PREPARATION QUESTIONNAIRE Page 3 of 4

Vibration:

Service Status Choose an item.

Is the line located on pipe racks

Choose an item.

containing vibrating pipes?

Is the line able to be shut down

during the inspection if vibration is Choose an item.

excessive?

Inspection History (not already detailed) : (A brief description of equipment service history/problems that

might assist us in determining defect mechanisms i.e. results from previous examinations,

repairs/alterations performed, notes/comments or lab results from operations etc.)

Purpose of examination: (The suspected deterioration mode; CUI, internal corrosion/erosion etc. and if

there are unique problems.)

Please provide an electronic copy, fax copy, or courier a copy of the Manufacture/Fabrication drawing,

Isometric sketch or As Built drawing of the equipment that contains the following examples: (to scale if

possible)

- Test Areas (hatch test areas if a partial test is required).

- Line Numbers, Meterage, Elevation, Associated Equipment, Orientation, etc.

- Location of Welds, Seams, Nozzles, Reinforcement Plates, Vessel Skirt, etc.

- External Attachments, Deck/Platform levels and Insulation/Stiffing Rings, etc.

- Internal Components, Trays, Downcomers, Clip Attachments, etc.

If you have any questions, concerns, or require assistance in completing the information, please do not

hesitate to contact us at your convenience!

Respectfully,

PT. BILL EMAS SARNO

LRUT JOB PREPARATION QUESTIONNAIRE Page 4 of 4

You might also like

- QP B104-02 NDT Personnel Qualification - Rev, Oct12 - 02Document24 pagesQP B104-02 NDT Personnel Qualification - Rev, Oct12 - 02saenal rapiNo ratings yet

- AcousticEye G3 - User Manual - V6 PDFDocument93 pagesAcousticEye G3 - User Manual - V6 PDFDan-jones TudziNo ratings yet

- 7.4 Eddy Current Testing - 2015R1 - SNS NEWDocument4 pages7.4 Eddy Current Testing - 2015R1 - SNS NEWsaenal rapi100% (1)

- Reviews of ACFMDocument7 pagesReviews of ACFMNILESHNo ratings yet

- Daily Lrut Report: Lrut Instrument Lrut Probe TechniqueDocument1 pageDaily Lrut Report: Lrut Instrument Lrut Probe TechniqueSang Nguyen QuangNo ratings yet

- Topaz64 With FMC TFMDocument19 pagesTopaz64 With FMC TFMJayadevNo ratings yet

- A-4301Document18 pagesA-4301R A BismilNo ratings yet

- Non-Destructive Tube Testing TechniquesDocument22 pagesNon-Destructive Tube Testing TechniquesCepi Sindang KamulanNo ratings yet

- Volvo Trucks Basic Service Manual PDFDocument101 pagesVolvo Trucks Basic Service Manual PDFJorge Armando CortezNo ratings yet

- ACFM Applications1Document12 pagesACFM Applications1naoufel1706No ratings yet

- PAUTDocument2 pagesPAUTAnonymous tBFZZ5UDNo ratings yet

- An Introduction To Long-Range Screening Using Guided WavesDocument8 pagesAn Introduction To Long-Range Screening Using Guided WavesVikas TiwariNo ratings yet

- Dwdi PDFDocument54 pagesDwdi PDFm_seyedNo ratings yet

- Whitepaper NDT Pulsed Eddy Current Whitepaper TUV Rheinland PDFDocument9 pagesWhitepaper NDT Pulsed Eddy Current Whitepaper TUV Rheinland PDFMohammed HassanNo ratings yet

- Ultrasonic Testing Procedure for WeldsDocument19 pagesUltrasonic Testing Procedure for Weldsparag wadekarNo ratings yet

- Electrical Engineering Experience Letter Format and CV ModelDocument15 pagesElectrical Engineering Experience Letter Format and CV ModelprabhumanocNo ratings yet

- VW 52000 enDocument19 pagesVW 52000 enIsabel SierraNo ratings yet

- Plant Integrity BookletDocument79 pagesPlant Integrity Bookletkihal zohirNo ratings yet

- NDT 2019Document32 pagesNDT 2019Muhammad OsamaNo ratings yet

- Inspection, Expediting, Training, Aws Cwi, NDT, Isondt, API, Profile, DashinspectorateDocument22 pagesInspection, Expediting, Training, Aws Cwi, NDT, Isondt, API, Profile, DashinspectoratedashNo ratings yet

- 2 Intro - To - Ultrasonics 03092013 OKDocument43 pages2 Intro - To - Ultrasonics 03092013 OKferyNo ratings yet

- E&I Quality PlanDocument9 pagesE&I Quality PlanJithuRajNo ratings yet

- Dry Van Container Exam Information BulletinDocument12 pagesDry Van Container Exam Information Bulletinsahil josephNo ratings yet

- PSL 30 Log of Pre Cert ExperienceDocument5 pagesPSL 30 Log of Pre Cert Experiencenarutothunderjet216No ratings yet

- Api 577 Q 114Document31 pagesApi 577 Q 114Mohammed YoussefNo ratings yet

- Revetment Wall Design Along Bacao BridgeDocument19 pagesRevetment Wall Design Along Bacao BridgeAngelo MoralNo ratings yet

- GENERAL NAVIGATION & COMMUNICATION EQUIPMENTDocument1 pageGENERAL NAVIGATION & COMMUNICATION EQUIPMENTkucing_batamNo ratings yet

- Asme Questions and Answers Part IIIDocument6 pagesAsme Questions and Answers Part IIIYan FerizalNo ratings yet

- 6-15-0072 Rev 2Document8 pages6-15-0072 Rev 2cynideNo ratings yet

- Hikari Sample InvoiceDocument1 pageHikari Sample Invoicekucing_batamNo ratings yet

- Heat Exchanger Tube Inspection With Olympus Nortec 500 Instrument Rev1Document8 pagesHeat Exchanger Tube Inspection With Olympus Nortec 500 Instrument Rev1luu cong son ndtNo ratings yet

- Guided Wave Presentation NDT Global 1Document41 pagesGuided Wave Presentation NDT Global 1Ahmed LepdaNo ratings yet

- Evaluate Pipes Corrosion Using RadiographyDocument6 pagesEvaluate Pipes Corrosion Using RadiographyMassimo FumarolaNo ratings yet

- Tor For Performance Based Contract-ReviewedDocument36 pagesTor For Performance Based Contract-ReviewedS C JhaNo ratings yet

- Automatic Ultrasonic Course: Issued By: GanzoryDocument58 pagesAutomatic Ultrasonic Course: Issued By: GanzorynaganathanNo ratings yet

- Advanced Inspection Techniques and Best PracticesDocument33 pagesAdvanced Inspection Techniques and Best PracticesriysallNo ratings yet

- Eddy Current Inspection 50 Question Quiz TitleDocument10 pagesEddy Current Inspection 50 Question Quiz TitleDINESH KNo ratings yet

- Catalog Tubing ProbesDocument36 pagesCatalog Tubing ProbesPrasathNo ratings yet

- SupervisionDocument10 pagesSupervisionEESUOLANo ratings yet

- Ship Particular LCT Mac Marine IndonesiaDocument1 pageShip Particular LCT Mac Marine Indonesiakucing_batamNo ratings yet

- PA-CATTM Measures Metal Loss at Pipe Supports Using Phased ArrayDocument12 pagesPA-CATTM Measures Metal Loss at Pipe Supports Using Phased ArrayPetrNo ratings yet

- Automated Robotic InspectionDocument6 pagesAutomated Robotic Inspectionprakush01975225403No ratings yet

- Phased Array Ut PDFDocument32 pagesPhased Array Ut PDFgueridiNo ratings yet

- SED - AUT Brochure Advanced NDTDocument23 pagesSED - AUT Brochure Advanced NDTannmj17No ratings yet

- 11RCFA-CPF2-HP Gas CompBDocument5 pages11RCFA-CPF2-HP Gas CompBJinlong SuNo ratings yet

- Ipc2022-87151 Advanced Non-Destructive Methods For Defect Characterization UnderDocument7 pagesIpc2022-87151 Advanced Non-Destructive Methods For Defect Characterization UnderOswaldo MontenegroNo ratings yet

- Wa0000.Document207 pagesWa0000.Ahmed Shakir100% (1)

- Electrical Works ProceduresDocument13 pagesElectrical Works ProceduresBenadict JoshuaNo ratings yet

- 7.2 Ror Rev#4 IsoDocument31 pages7.2 Ror Rev#4 IsoMohamed Thowfeek100% (1)

- API 570 Section V NDE Requirements for Piping InspectionDocument157 pagesAPI 570 Section V NDE Requirements for Piping InspectionAhmed shabanNo ratings yet

- QM Business Blue Print V4 0Document69 pagesQM Business Blue Print V4 0chameladevi100% (2)

- Introduction To Tofd & Phased Arrays Industrial ApplicationsDocument49 pagesIntroduction To Tofd & Phased Arrays Industrial Applicationschitturi jagadishNo ratings yet

- India Oman Qatar Abudhabi CanadaDocument7 pagesIndia Oman Qatar Abudhabi CanadaMadhusudanNo ratings yet

- Procedure For UtDocument12 pagesProcedure For UtMohammad SyeduzzamanNo ratings yet

- Non Destructive TestingDocument182 pagesNon Destructive TestingAravindNo ratings yet

- Ct02 Ect Extended AsmeDocument1 pageCt02 Ect Extended AsmeVasyaNo ratings yet

- Eddycurrent TestingDocument4 pagesEddycurrent TestingnvemanNo ratings yet

- SafeRad PresentationDocument280 pagesSafeRad PresentationNajib BaharudinNo ratings yet

- Tofd & Pe ReportDocument1 pageTofd & Pe ReportLuong Ho VuNo ratings yet

- Testing Session TOFD EECI - EurosonicDocument47 pagesTesting Session TOFD EECI - EurosonicRupam BaruahNo ratings yet

- RFT for Pipe Defect DetectionDocument1 pageRFT for Pipe Defect DetectionCepi Sindang KamulanNo ratings yet

- Alternating Current Field Measurement ACFMDocument2 pagesAlternating Current Field Measurement ACFMramzi5ben5ahmedNo ratings yet

- M2M GEKKO Specifications Sheet A4Document4 pagesM2M GEKKO Specifications Sheet A4NicholasOtienoNo ratings yet

- 12-Hole Standards InteractiveDocument1 page12-Hole Standards InteractivevikramNo ratings yet

- Advanced NDT Services PDFDocument1 pageAdvanced NDT Services PDFChandrashekhar ThiramdasuNo ratings yet

- Ut Mfd350bDocument3 pagesUt Mfd350bEmily BrockNo ratings yet

- Magnetic Particle Exam GuideDocument18 pagesMagnetic Particle Exam GuidemohamedNo ratings yet

- Advanced MFL Tank Inspection with STARS Defect DiscriminationDocument4 pagesAdvanced MFL Tank Inspection with STARS Defect Discriminationassurendran0% (1)

- Quiz 2 PDFDocument5 pagesQuiz 2 PDFahmedNo ratings yet

- Comparison Between GWT and UT (P5) Rev 0.4Document7 pagesComparison Between GWT and UT (P5) Rev 0.4Asish desaiNo ratings yet

- ASME B31.3-2016 Leak Test RequirementsDocument5 pagesASME B31.3-2016 Leak Test RequirementsGulzar AliNo ratings yet

- Pt. Saferad Servis Indonesia: Ultrasonic Inspection ReportDocument3 pagesPt. Saferad Servis Indonesia: Ultrasonic Inspection Reportkucing_batam0% (1)

- nCoV - Cover Cough Poster Bahasa IndonesiaDocument1 pagenCoV - Cover Cough Poster Bahasa Indonesiakucing_batamNo ratings yet

- Join Our Free Webinar - Advantages of Eddy Current Testing in Oil & Gas IndustryDocument2 pagesJoin Our Free Webinar - Advantages of Eddy Current Testing in Oil & Gas Industrykucing_batamNo ratings yet

- Saferad: 09504/MGN/BTM/P-I/21 Quotation PR 93586Document1 pageSaferad: 09504/MGN/BTM/P-I/21 Quotation PR 93586kucing_batamNo ratings yet

- PT. ILL MAS Arno: Repair 149 Joints With Estimation 266 Sheets (4X10") OnlyDocument2 pagesPT. ILL MAS Arno: Repair 149 Joints With Estimation 266 Sheets (4X10") Onlykucing_batamNo ratings yet

- User inputs for pipe radiography parametersDocument5 pagesUser inputs for pipe radiography parameterskucing_batamNo ratings yet

- Clearance PDFDocument3 pagesClearance PDFkucing_batamNo ratings yet

- 001 VHJHGVKJNDocument1 page001 VHJHGVKJNkucing_batamNo ratings yet

- nCoV - Notice Poster Bahasa IndonesiaDocument1 pagenCoV - Notice Poster Bahasa Indonesiakucing_batamNo ratings yet

- PT. UT Quality Indonesia: Ultrasonic Inspection ReportDocument1 pagePT. UT Quality Indonesia: Ultrasonic Inspection Reportkucing_batamNo ratings yet

- Heavy Cargo Stowage Plan for LCT from Batam to KuchingDocument1 pageHeavy Cargo Stowage Plan for LCT from Batam to Kuchingkucing_batamNo ratings yet

- Training Matrix Schedule EmployeeDocument1 pageTraining Matrix Schedule Employeekucing_batamNo ratings yet

- 143 BES Q NDT 3 19 Castiel HanDocument2 pages143 BES Q NDT 3 19 Castiel Hankucing_batam100% (2)

- Clearance PDFDocument3 pagesClearance PDFkucing_batamNo ratings yet

- Time Sheet-Rent Vacuum PT BESDocument2 pagesTime Sheet-Rent Vacuum PT BESkucing_batamNo ratings yet

- Summary RT SalimDocument6 pagesSummary RT Salimkucing_batamNo ratings yet

- FRM 001 Exp Claim - Cash BondDocument2 pagesFRM 001 Exp Claim - Cash Bondkucing_batamNo ratings yet

- Cargo PLN Karimun To MarundaDocument1 pageCargo PLN Karimun To Marundakucing_batamNo ratings yet

- Summary RT MultiSystemDocument1 pageSummary RT MultiSystemkucing_batamNo ratings yet

- STOWAGE PLAN LCT 1200 - Banjarmasin SerawakDocument2 pagesSTOWAGE PLAN LCT 1200 - Banjarmasin Serawakkucing_batamNo ratings yet

- SP Tug KSD 15Document1 pageSP Tug KSD 15kucing_batam0% (1)

- ROV Packing ListDocument2 pagesROV Packing Listkucing_batam100% (1)

- SDDG FormDocument1 pageSDDG Formkucing_batamNo ratings yet

- Stowage Plan Kuantan - Bintan LCT 350-400Document1 pageStowage Plan Kuantan - Bintan LCT 350-400kucing_batamNo ratings yet

- Mac Marine IndonesiaDocument8 pagesMac Marine Indonesiakucing_batamNo ratings yet

- SP LCT 1000 DWTDocument1 pageSP LCT 1000 DWTkucing_batamNo ratings yet

- Annex AllemandDocument13 pagesAnnex AllemandsobhiNo ratings yet

- Box Culvert Construction Method StatementDocument8 pagesBox Culvert Construction Method StatementTAMILNo ratings yet

- Welding Safety InspectionDocument4 pagesWelding Safety InspectionUnitor ChrisNo ratings yet

- Itop 3-2-045 Small Arms TestingDocument87 pagesItop 3-2-045 Small Arms Testingg c agnihotriNo ratings yet

- 01 SY CRT 0001 0A-General Requirements For Welding and NDT PDFDocument42 pages01 SY CRT 0001 0A-General Requirements For Welding and NDT PDFSanjeev Sahota100% (1)

- RFB Type 4Document5 pagesRFB Type 4Manoj ChitreNo ratings yet

- Cobiax Abz SlimLine Z151307 11 2018 en FinalDocument25 pagesCobiax Abz SlimLine Z151307 11 2018 en Finalkhalil_82423297No ratings yet

- Job Profile Chart & Competency UnitDocument13 pagesJob Profile Chart & Competency UnitMohd FadhliNo ratings yet

- MOL - Central Front End Compression Facility Project: PAGE: 1 of 13 Rev: 0 DATE: 11-Mar-2017Document13 pagesMOL - Central Front End Compression Facility Project: PAGE: 1 of 13 Rev: 0 DATE: 11-Mar-2017eke23No ratings yet

- Saudi Aramco Typical Inspection Plan: Pneumatic Pressure Testing SATIP-A-004-01 MechanicalDocument2 pagesSaudi Aramco Typical Inspection Plan: Pneumatic Pressure Testing SATIP-A-004-01 MechanicalRAMAKRISHNANo ratings yet

- ACS BD Gravimetric Slide Blender A-B Controller SEPT2008Document108 pagesACS BD Gravimetric Slide Blender A-B Controller SEPT2008gregfortkampNo ratings yet

- InspectorDocument3 pagesInspectorTAMRAIZNo ratings yet

- Saudi Aramco Hose Inspection RequirementsDocument2 pagesSaudi Aramco Hose Inspection RequirementsAbu Anas M.SalaheldinNo ratings yet

- Maintaining Grouted AnchorsDocument7 pagesMaintaining Grouted AnchorsRakesh KapoorNo ratings yet

- WWW - Tenders.ongc - Co.in " and The Link For The Same Has Also Been Provided On The Login Page of E-Tender WebsiteDocument4 pagesWWW - Tenders.ongc - Co.in " and The Link For The Same Has Also Been Provided On The Login Page of E-Tender WebsiteRameshchandra SolankiNo ratings yet

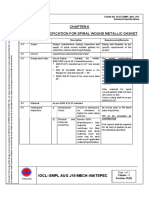

- Chapter-5 Technical Specification For Spiral Wound Metallic GasketDocument3 pagesChapter-5 Technical Specification For Spiral Wound Metallic GasketSomeshNo ratings yet

- Timber Bridge Manual 1 PDFDocument53 pagesTimber Bridge Manual 1 PDFChristeen Sheen EscolaniaNo ratings yet

- ATS Certifications Inc Cert and Scope File 12-08-2018 1544299953Document2 pagesATS Certifications Inc Cert and Scope File 12-08-2018 1544299953Tash BNo ratings yet