Professional Documents

Culture Documents

Automatic Mechanical Self Lowering Light Bulb 1

Automatic Mechanical Self Lowering Light Bulb 1

Uploaded by

api-484218441Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Automatic Mechanical Self Lowering Light Bulb 1

Automatic Mechanical Self Lowering Light Bulb 1

Uploaded by

api-484218441Copyright:

Available Formats

Automatic Mechanical Self-Lowering Light Bulb

Lily Chappell & Maya Chappell

Introduction Materials Conclusion

The use of electricity is something that is common in people's daily lives, and with the use of lights Materials This engineering project was created to make changing light bulbs an easier task. In the end, the project

people can get around safer whether it is in their home or outside. For many people, the use of light bulbs in was overall successful because it mechanically lowers and raises a light bulb. The frame was the first thing

life is necessary ;however, when a light bulb goes out it can become a struggle for older people or people with

● Light Bulb ● Extension cord

built, which was made from plywood and screws. Holes for the lights, switches, and wires were added in with

high ceilings to change their light bulb. If people cannot renew their old light bulbs it may become a hazard ● Screwdriver ● Drill Motor the use of a drill. Next, a breaker box and wires were added to give the project an external power source. Next,

and lead to an injury. In a study done on elderly people living alone, “38% of patients falls took place when ● Screws ● Long Drill bit the lights were put in place and wired to a light switch, and then the switch was wired to the breaker box.

there is a visual deficit”(Asiri, 2018); therefore, with the use a mechanical self-lowing light bulb people will be ● Drill and drill bit ● Thin metal cordage Wires were secured with electrical tape, and the lights were tested. After a few attempts, the light did

less at risk of getting injured due to the lack of visibility. People will be able to exchange old light bulbs with work. The first motor used to lift the lights was a bathroom fan motor, the attempt was unsuccessful because

new ones easier than ever before without worrying if they could get injured while changing the light or

● 1 4x4 ft plywood ● Breaker box

the fan was unable to reverse direction, and the fan motor was too weak causing nothing to lift. The second

walking around a dark areas. ● 4 2x4 ft plywood ● 2 single breakers attempt included an electric hand drill motor, this motor was able to raise and lower the lights. Then it needed

● 6 2”x4” 4ft wood ● 1 double breaker to be mounted, one problem was that the wires from the motor to the control handle of the drill were too short

● 4 2”x4” 2ft wood ● String so, it needed to be wired with longer wires and secured. After that, the drill was mounted a foot from the top of

Objective ● Black wire ● Electrical tape

the frame. It wasn’t high enough, so the drill was raised another foot, and supports were added. When tested

the lights did lower and raised but with some trouble. More supports were added, so the motor was no longer

● Red wire ● Metal brackets as loose. The hand drill motor was tested several times to make sure all the supports were sturdy. The motor

The objective of this engendering project was to create an automatic self-lowering light bulb mechanism

● 2 Light switches successfully raised and lowered the lights and did support the weight of the lights; however, the project has

that makes it easier and safer for all people to replace old light bulbs.

● Light bulb much room for improvement.

Methodology

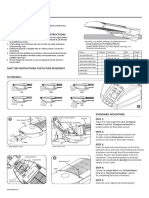

Part 1 6. Next take apart the drill from its handle so the wires

1. Screw together the six 2”x4” 4ft wood and 4 2”x4” connecting it to the control handel are exposed.

2ft wood to create a rectangular frame. 7. Carefully remove the wires from their place and add

2. Screw on the four 2x4 ft plywood to the sides of the longer ones.

wooden frame. 8. Use electrical tape to secure wires in place.

3. Screw on the one 4x4 ft plywood to the back and 9. Place the drill motor atop the mount, high enough it

the frame. will be able to pull the string with ease.

4. Screw on the one 2x4 ft plywood to the top of the 10.Screw in supports using wood and metal cordage.

Figure 1. Picture of the frame being constructed frame 11.Then attach the drill motor to the lights using string.

Figure 4. A picture of the completed project Figure 5. A picture of the wiring of the breaker box

5. Use the drill to drill the 2 holes needed to install the 12.Drill a hole on the right inner wall for the control

recessed lights into the top of the constructed frame. handel wires to go.

6. Attach the recessed light to the celling of the frame. 13.Reattach the wires to the handle that’s now on the Next Step

7. Add clamps at the height of them fully lowered so inside.

they don’t go any farther down. 14.Connect the handle wires to a switch so the power

Part 2 supply can be controlled. Due to time constraints this project still has room for improvements, and if this project is going to

1. Use the red and black wires to connect the light 15.Connect wires from the switch to double breaker so continue, there would be many adjustments that could take place. The first step would be to replace to handle

switch and the recessed light. it can be supplied with power. of the drill, which is currently acting as the way to control the drill. It needs to be replaced with a light switch

2. Attach the breaker box on the outside of the frame. 16.Check to make sure all wires are in place and secure and a dimming switch. The control switches would allow the project to look as if it could be in a real home

3. Add a plug to the breaker box so it can be powered. and add electrical tape for safety before adding

4. Wire the plug into a single breaker so it can be power. and would be more convenient. Another adjustment that should occur would be to smooth the track of the

plugged into a bigger power source. lowering and raising the light bulbs. After that, the next step might be to find a strong motor that would work

5. Then wire the switch to a single breaker in the better than the drill did. With a real motor instead of a drill, the project would be more sophisticated. The new

breaker box so it can supply it with power. motor would be sturdier when lifting the lights, unlike the dismantled drill.

Figure 2. Diagram of the final project

Test Trials and Adjustments

A: A wooden frame that holds the drill motor.

B: Screws that sick out slightly to make the string go up so the lights stay on track. # of test Observations Adjustments Date

C: Wire cordage that acts as support.

D: String that is tied to the lights and is used to pull the lights up.

Citations

E: A hole drilled into the wood that the light’s wires go though. 1 The metal cordage used to pull up the lights Changed the wire to yellow string then taped up the drill bit and put a 11/24/20

F: Wires from the motor of the drill to the control handle. would break or get tangled around the drill medium plastic spool on it to collect the yellow string as needed.

bit.

G: Wiring that connects the light switch to the motor and the breaker box which allows the drill motor and the Davis, R. G., McCunn, L. J., Wilkerson, A., & Safranek, S. (2020). Nurses’ Satisfaction With Patient Room

2 The motor was able to pull up the lights, but Since the motor was not high enough the supports already standing had to 11/24/20

control handle to get power. the motor was too low to the top of the frame be taken down. The motor was raised above the frame anther 1ft but is Lighting Conditions: A Study of Nurses in Four Hospitals With Differences in the Environment of

H: A block of wood that puts the handle off the wall so that a person can fit their hand around the handle. and it started to roll the electric wires for the standing at a total of 2ft, so it was tall enough to raise the lights. Care. Health Environments Research & Design Journal (HERD) (Sage Publications, Ltd.), 13(3), 110.

I: The control handle controls the speed and has a reverse switch that allows the lights to move up and down. lights. https://doi-org.proxygsu-scob.galileo.usg.edu/10.1177/1937586719890940

J: A light switch that allows the drill motor and the control handle to get power. 4 The drill was able to pull the lights up, but Add screws on both sides of the supports to make the string go up in a

the lights got caught on surrounding wood straighter position. 11/24/20

K: The light switch that turns on the lights. and when they reached the top they were very Ng, S. S. M., Liu, T.-W., Kwong, P. W. H., Choy, H.-M., Fong, T. Y. K., Lee, J. Y. C., Tan, Y.-L., Tong,

L: The wiring that connects the light switch to the breaker box. crooked. G. Y. H., Wong, C. C. Y., Lai, C. Y. Y., & Tse, M. M. Y. (2020). Psychometric testing of the Fall

M: The breaker box. Risks for Older People in the Community screening tool (FROP-Com screen) for community-dwelling

N: Clamps to keep the light from lowing too far down. 5 The drill wasn’t stably in place, so it wiggled Added wooden supports on both sides of drill to prevent it from moving 11/24/20 people with stroke. PLoS ONE, 15(5), 1–9. https://doi-org.proxygsu-

O: Wiring that connects the lights to the breaker box. while bringing up the lights. left and right. scob.galileo.usg.edu/10.1371/journal.pone.023304

P: Wiring that connect the motor, its control handle, and switches to the breaker box which gives everything

power. 6 The support of the drill leaned forward as the Screws were drilled halfway in on the back, in front, and sides of the 11/24/20 Shirer, D. L. (2019). Electrical Circuits. Salem Press Encyclopedia of Science.

lights were pulled up. supports then screws were drilled in on the far sides of the top, right infront

Q: Light bulbs. of the supports on the frame and on the back of the frame. Then metal

R: The drill motor and the plastic spool attached to the drill bit. cordage was wrapped around the screws on both the supports and frame.

When screwed in the wires tightened preventing the wooden support from

moving forward.

Figure 3. Observation and adjustments data table

You might also like

- Wahl Clippers Instructions PDFDocument2 pagesWahl Clippers Instructions PDFmukadeNo ratings yet

- Land Telegraph LinesDocument26 pagesLand Telegraph LinesAlex WarHorseNo ratings yet

- Maintaining Johnson 1974-1992Document64 pagesMaintaining Johnson 1974-1992fokaiboi67% (3)

- Tag-2-GbDocument2 pagesTag-2-Gbmanual imbNo ratings yet

- Amazing Remote Control Cardboard Tank: Project On EsmDocument3 pagesAmazing Remote Control Cardboard Tank: Project On Esmraymond baliteNo ratings yet

- Guitar WiringDocument21 pagesGuitar WiringLazyfingers61100% (4)

- Capítulo 1Document22 pagesCapítulo 1Leonardo MuñozNo ratings yet

- Build A Power Supply For Your Guitar Pedals: InstructablesDocument19 pagesBuild A Power Supply For Your Guitar Pedals: InstructablesNebojsaKocicNo ratings yet

- Making A Faraday Flashlight: Executive Summary: This ProjectDocument4 pagesMaking A Faraday Flashlight: Executive Summary: This ProjectNp Crush9No ratings yet

- Making A Faraday Flashlight: Executive Summary: This ProjectDocument4 pagesMaking A Faraday Flashlight: Executive Summary: This ProjectNp Crush9No ratings yet

- Ultra-Simple Electric Generator: William BeatyDocument14 pagesUltra-Simple Electric Generator: William Beaty50raj5060190% (1)

- Rly SW Catalog PDFDocument241 pagesRly SW Catalog PDFSamHdzNo ratings yet

- 626 e 3 CCB 56164Document2 pages626 e 3 CCB 56164MohamedHussein MohamedHusseinNo ratings yet

- ActivityDescription ElectroMagnet BuzzerDocument3 pagesActivityDescription ElectroMagnet BuzzermagrinraphaelNo ratings yet

- ToolsDocument4 pagesToolsCarlos SalamancaNo ratings yet

- Generator Aur ColoidalDocument16 pagesGenerator Aur ColoidalAnonymous 4aChpF1hZNo ratings yet

- How To Replace Electric ShowerDocument9 pagesHow To Replace Electric ShowerBob KowalskiNo ratings yet

- Procedure Text, JuanDocument6 pagesProcedure Text, Juanggwpgamerz25No ratings yet

- Diy Homopolar Generator: A. Background of The StudyDocument3 pagesDiy Homopolar Generator: A. Background of The StudyJohn Bricks NakilaNo ratings yet

- Faros Led Alto PerformanceDocument2 pagesFaros Led Alto PerformanceRAUL PEREZ NEGREIROSNo ratings yet

- Project On Electromagnetic Induction For Class 12th PhysicsDocument14 pagesProject On Electromagnetic Induction For Class 12th Physicsanish.raoNo ratings yet

- Electron Diffraction TubeDocument4 pagesElectron Diffraction TubeIch Habe KopfschmerzenNo ratings yet

- Survivor 2018Document3 pagesSurvivor 2018safetyandtrust22No ratings yet

- Me Sci 10 q2 0901 SGDocument24 pagesMe Sci 10 q2 0901 SGIcia VillegasNo ratings yet

- JHS Electrical 9 Module 1 PDFDocument15 pagesJHS Electrical 9 Module 1 PDFMark Xyriel BartolomeNo ratings yet

- El18 Lightbars070618Document27 pagesEl18 Lightbars070618Reubz FishingNo ratings yet

- The Torch Project Wiktor ChmielDocument8 pagesThe Torch Project Wiktor Chmielwchmiel2012No ratings yet

- Manual Wizard v4 C2 Pro Nichia-ML-full Rev 00-0003Document33 pagesManual Wizard v4 C2 Pro Nichia-ML-full Rev 00-0003xzgyqiosdzjqahjonbNo ratings yet

- Engineering Practice Lab Manual Electrical and ElectronicsDocument55 pagesEngineering Practice Lab Manual Electrical and ElectronicsThanix SubramanianNo ratings yet

- SMD & Extraction ToolsDocument1 pageSMD & Extraction ToolsUblida TiseNo ratings yet

- Lesson 1: Module in Tle 10 Eim First Quarter - Week 2Document2 pagesLesson 1: Module in Tle 10 Eim First Quarter - Week 2Maria Christina ManzanoNo ratings yet

- Ee8261 - Engineering Practices Laboratory: Syllabus Group B (Electrical & Electronics) A.Electrical Engineering PracticeDocument24 pagesEe8261 - Engineering Practices Laboratory: Syllabus Group B (Electrical & Electronics) A.Electrical Engineering PracticeSenthil IlangovanNo ratings yet

- Catalog Appleton Exgjh Exlk Flexible Couplings en Us 190428Document3 pagesCatalog Appleton Exgjh Exlk Flexible Couplings en Us 190428Fredy Eloy Quispe CruzNo ratings yet

- DIY Heng LampDocument9 pagesDIY Heng LampLahssen HadjaiNo ratings yet

- Script Translated To EnglishDocument4 pagesScript Translated To EnglishShakira BilaNo ratings yet

- WireWrapTools Eng ManDocument2 pagesWireWrapTools Eng Man1realestabassNo ratings yet

- Make Your Own High Voltage ElectromagnetsDocument15 pagesMake Your Own High Voltage Electromagnetsapi-3715567100% (22)

- Electromagnet ActivityDocument3 pagesElectromagnet ActivitySab DicoNo ratings yet

- PORTABLE Mag Loop For 40m-10m - G8ODEDocument4 pagesPORTABLE Mag Loop For 40m-10m - G8ODEAnonymous XoW23y58ONo ratings yet

- 01 Week TLE 8 - EIM ModuleDocument10 pages01 Week TLE 8 - EIM ModuleRenato Reyes Jr.No ratings yet

- Technology and Livelihood Education: Quarter 3 - Module 1 - Week 1Document14 pagesTechnology and Livelihood Education: Quarter 3 - Module 1 - Week 1SITTIE ASIA MINALANG100% (1)

- Electricity and Currents Phet LabDocument5 pagesElectricity and Currents Phet LabEthicalRobin455No ratings yet

- Shop SuppliesDocument102 pagesShop SuppliesHuron Industrial SupplyNo ratings yet

- One On One OffDocument14 pagesOne On One OffKimberly JuriNo ratings yet

- Nichrome Wire Power Supply DesignDocument4 pagesNichrome Wire Power Supply DesignxiaoboshiNo ratings yet

- Reverse EngineeringDocument22 pagesReverse Engineeringapi-297309213No ratings yet

- Kenko Powerband QrsDocument2 pagesKenko Powerband QrsIohanNo ratings yet

- H65 Material List For Quotation. Electrical PDFDocument1 pageH65 Material List For Quotation. Electrical PDFRick.B.KNo ratings yet

- Product RedesignDocument28 pagesProduct RedesignLAKSHMI C.ANo ratings yet

- Build Your Own: Hydroelectric GeneratorDocument9 pagesBuild Your Own: Hydroelectric GeneratorAnkit SawantNo ratings yet

- Introduction To: CircuitsDocument12 pagesIntroduction To: Circuitsexia breakNo ratings yet

- 01 Week TLE 8 - EIM ModuleDocument10 pages01 Week TLE 8 - EIM ModuleRenato Reyes Jr.No ratings yet

- Harrison Williams Trifold Board 2023-2024Document1 pageHarrison Williams Trifold Board 2023-2024api-564260034No ratings yet

- Digital Patterns: Designed by Steve GoodDocument43 pagesDigital Patterns: Designed by Steve Goodrichardppz124No ratings yet

- Fun Experiments with Electricity: Mini Robots, Micro Lightning Strikes, and MoreFrom EverandFun Experiments with Electricity: Mini Robots, Micro Lightning Strikes, and MoreRating: 5 out of 5 stars5/5 (1)

- Haywired: Pointless (Yet Awesome) Projects for the Electronically InclinedFrom EverandHaywired: Pointless (Yet Awesome) Projects for the Electronically InclinedRating: 3.5 out of 5 stars3.5/5 (3)

- Electromagnetic Clutches and Couplings: International Series of Monographs on Electronics and InstrumentationFrom EverandElectromagnetic Clutches and Couplings: International Series of Monographs on Electronics and InstrumentationRating: 4 out of 5 stars4/5 (1)

- Apa Paper Shell L Chappell FinalDocument23 pagesApa Paper Shell L Chappell Finalapi-484218441No ratings yet

- Presentation15 1Document5 pagesPresentation15 1api-484218441No ratings yet

- The Nature of Tennessee Williams Kate Chopin 1Document4 pagesThe Nature of Tennessee Williams Kate Chopin 1api-484218441No ratings yet

- 2022 Research PaperDocument5 pages2022 Research Paperapi-484218441No ratings yet

- Action PlanDocument9 pagesAction Planapi-484218441No ratings yet

- OralDocument21 pagesOralapi-484218441No ratings yet

- Environmental Health Community Profile: Lily Chappell, Neel Jahan, Aarav PatelDocument26 pagesEnvironmental Health Community Profile: Lily Chappell, Neel Jahan, Aarav Patelapi-484218441No ratings yet

- Researchplanprojectsummaryforform 1 AlilycDocument4 pagesResearchplanprojectsummaryforform 1 Alilycapi-484218441No ratings yet

- Stem Hhs Virtual Enrichment TripDocument2 pagesStem Hhs Virtual Enrichment Tripapi-484218441No ratings yet

- Cable Tray Lay Out 1Document1 pageCable Tray Lay Out 1ferdinandz_010No ratings yet

- 220 ElectricalDocument17 pages220 ElectricalAyman EsaNo ratings yet

- Astm 492 - 95Document2 pagesAstm 492 - 95Alvaro HernandezNo ratings yet

- Casar Technical DocumentationDocument31 pagesCasar Technical DocumentationmarketakisioannisNo ratings yet

- Electrical Design Construction of Skate ParkDocument5 pagesElectrical Design Construction of Skate ParkJorge Dela PeñaNo ratings yet

- 1 and 1 Hour Fire Rated MBMA Roof SystemsDocument7 pages1 and 1 Hour Fire Rated MBMA Roof SystemsPrakash BharatiNo ratings yet

- BOQ - Site WiseDocument44 pagesBOQ - Site WiseShahed HussainNo ratings yet

- Wire RopesDocument66 pagesWire RopesPinto CarlosNo ratings yet

- Summative Test EIM - G9 1Document2 pagesSummative Test EIM - G9 1Roniel BalverdeNo ratings yet

- Chapter 20: HealthDocument42 pagesChapter 20: HealthMajid KarimiNo ratings yet

- Anna University First Year Practical Question Paper GE 6163 Set2 - 2013 RegulationGE 6163Document2 pagesAnna University First Year Practical Question Paper GE 6163 Set2 - 2013 RegulationGE 6163heavendewNo ratings yet

- NYSYDocument5 pagesNYSYRinda_RaynaNo ratings yet

- Leader Telecommunication PDFDocument38 pagesLeader Telecommunication PDFZeckrey JikurunNo ratings yet

- Dogging Cpccldg3001 SampleDocument12 pagesDogging Cpccldg3001 SampleRuchi GuptaNo ratings yet

- Production Orale en Interaction: Student A Student BDocument2 pagesProduction Orale en Interaction: Student A Student Ble monde créative d'aliNo ratings yet

- Rittal Catalogue 34 02Document249 pagesRittal Catalogue 34 02okylimNo ratings yet

- Astm A82 1979Document6 pagesAstm A82 1979yoki_triwahyudiNo ratings yet

- Red Panda Digital Enrichment System ManualDocument22 pagesRed Panda Digital Enrichment System ManualAndrew QuitmeyerNo ratings yet

- Dry Type Arc Welding MachineDocument11 pagesDry Type Arc Welding MachineIsaac Honny Jnr100% (1)

- Gis 38-202Document15 pagesGis 38-202Arash SotoudehNo ratings yet

- Squid Jigging - FAODocument13 pagesSquid Jigging - FAOsjdarkman1930No ratings yet

- MP Vidyut Vitaran Nd08adb Vol2 11feb11Document342 pagesMP Vidyut Vitaran Nd08adb Vol2 11feb11Krishna ChandavarNo ratings yet

- Cu Wire BondingDocument6 pagesCu Wire BondingbalapmuruganNo ratings yet

- Rapid Shutdown Product Manual BCG.00884.0AP revACDocument36 pagesRapid Shutdown Product Manual BCG.00884.0AP revACmarkmarkchanchan0902No ratings yet

- LS MCB & RCD CatalogDocument56 pagesLS MCB & RCD Catalogkmleongmy100% (1)

- Underground Electrical Cable Bury DepthsDocument2 pagesUnderground Electrical Cable Bury DepthsTesfahun GirmaNo ratings yet

- Quarter 1 Week 1: Electrical Installation and Maintenance (EIM) Grade 10Document14 pagesQuarter 1 Week 1: Electrical Installation and Maintenance (EIM) Grade 10Jhobhel Christopher Galivo100% (1)

- Make Your Own VGA Cord of CAT5 CableDocument8 pagesMake Your Own VGA Cord of CAT5 CableAatish BijuNo ratings yet