Professional Documents

Culture Documents

Nitotile Xs

Uploaded by

Vincent JavateCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nitotile Xs

Uploaded by

Vincent JavateCopyright:

Available Formats

Fosroc Nitotile XS constructive solutions

Polymer-modified, one component, high performance,

waterproof tile adhesive

Uses Properties

Nitotile XS is a high quality adhesive for the permanent fixing

Density : 1700 kg/m3

of ceramic wall and floor tiles including porcelain and fully

Tensile adhesion strength

vitrified tiles, ceramic mosaics, quarry tiles, dark natural stone,

(EN 1348 - stoneware tiles)

terrazzo and brick slips. Typical uses include :

28d sc : >1.5 N/mm2

! Wet areas - kitchens and bathrooms 7d sc+21d water : >1.0 N/mm²

14d sc+14d 70°C+1d sc: >2.0 N/mm²

! Swimming pools

Open time by tensile adhesion

! Fixing marble tiles (upto 40kg/m² on vertical) strength (EN 1346-earthenware tiles)

5min : >1.5 N/mm²

! Fixing heavy elements e.g. brick slips, concrete tiles

20min : >1.0N/mm²

! Bridges, underpasses and high rise buildings 30 mins : >0.7 N/mm²

Transverse Deformation

! External claddings

(EN12002)

14 d 23°C/95%RH+14 d sc

Advantages

Deflection at max. force : >3.0 mm

! Formulated to suit Middle East conditions Stress at max. force : >2.5 N/mm²

Deflection at break : >3.0 mm

! Enhanced bond and tensile strengths

Stress at break : >2.3 N/mm²

! Good open time & slip resistance Glazed Impervious Quarry

Tiles Tiles Tiles

! Safe and easy to use

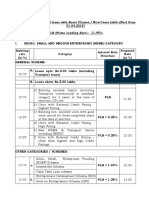

Shear adhesion (ANSI 118.4) (N/mm²)

! Water resistant - suitable for submerged conditions 48h sc : >0.7 - -

7d sc : >2.09 >1.6 >1.2

! Early return to service

7d sc + 7d water : >1.4 >1.05 -

4 weeks sc : >2.4 >1.5 >1.35

Standards compliance

12weeks sc : >2.5 >1.7 >1.3

Nitotile XS conforms to EN 12004, BS 5980 and ANSI 118.4.

The application should be in accordance to BS 5385. Instructions for use

Surface preparation

Description

All surfaces must be sound and thoroughly clean before

Nitotile XS is supplied as a single component pack, which

Nitotile XS is applied. All traces of grease, oil and loose

requires only the on-site addition of clean water to produce a

particles of mortar, old wallpaper, paint etc. must be physically

consistently high performance adhesive, suitable for the

removed.

following substrates:

Surfaces

! Concrete ! Ceramic Tile & Stone

Nitotile XS can be applied directly on concrete, cement

! Cement Plaster ! Brick Masonry

screeds, and cement or lime mortar. Special attention must

! Concrete Masonry ! CementTerrazzo be given to new construction prior to commencing tiling. Tiles

should not be placed on concrete or blockwork until all

! Cement mortar beds ! Ceramic backer board

shrinkage movement has taken place.

Note : Nitotile XS should only be used on gypsum or gypsum

board substrates after priming with Cebond* † or

Nitobond PVA*†.

Nitotile XS

Fosroc Nitotile XS

Mixing Limitations

A slow speed drill fitted with a suitable mixing paddle and - Nitotile XS should not be used when the temperature is

mixing vessel of minimum 30 litre capacity are recommended. below 5oC and falling.

6.25 litres of clean water is required for 25kg bags of - The product should not be exposed to moving water

Nitotile XS. during application.

Pour the recommended volume of clean water into the mixing If any doubt arise concerning temperature or substrate

vessel. With the Fosroc Mixing Paddle MR4 in operation, add conditions, consult your local Fosroc office.

the powder component to the mix and continue mixing for 3

minutes until a uniform and lump-free consistency is Estimating

achieved.

Supply

Application Nitotile XS : 25kg bags

Once mixed, Nitotile XS is typically spread on the substrate to Yield

a uniform thickness of 2-10mm. This is then combed Nitotile XS : 17.9 litres/25kg pack

horizontally.

Place tiles firmly into adhesive bed ensuring good contact Storage

with a twisting motion. Only apply to areas which can be tiled When stored in a dry conditions in the original, unopened

in the adhesive’s open wet time (normally up to 1m2 at a bags, Nitotile XS will have a shelf life of 12 months. If stored

time). at high temperature and / or high humidity conditions the

Joints shelf life will be reduced.

It is recommended that when fixing ceramic tiles, a minimum

spacing of 2mm be left around each tile.

Finishing

Remove excess adhesive with a damp cloth before material

has set.

Cleaning

Nitotile XS should be removed from tools, equipment and

mixers with clean water immediately after use. Cured material

can only be removed mechanically.

Grouting

Grout installation should be after a minimum of 24 hours

curing time at 25°C. Grout with Nitotile XS Grout*† or Nitotile

Grout*†, depending on the floor application. * Denotes the trademark of Fosroc International Limited

†

See separate data sheet

Important note

Fosroc products are guaranteed against defective materials and manufacture and are sold subject to its standard Conditions for

the Supply of Goods and Service. All Fosroc datasheets are updated on a regular basis. It is the user’s responsibility to

obtain the latest version.

Head Office

telephone: (+9714) 2039699 fax: (+9714) 2859649 email: agf@fosroc.com

Al Gurg Fosroc LLC

Regional offices

Post Box 657, Dubai Abu Dhabi, Al Gurg Fosroc telephone: 673 1779 fax: 673 1449 email: abudhabi@fosroc.com

United Arab Emirates Bahrain, YBA Kanoo telephone: 17738200 fax: 17732828 email: bahrain@fosroc.com

Kuwait, Boodai telephone: 4817618 fax: 4832124 email: kuwait@fosroc.com

www.fosroc.com

Oman, Al Amana telephone: 24815080 fax: 24817554 email: oman@fosroc.com

Qatar, Tadmur telephone: 4432365 fax: 4419517 email: qatar@fosroc.com

UAE/0477/05/E

You might also like

- Fosroc Nitotile EN Tile Adhesive Technical Data SheetDocument2 pagesFosroc Nitotile EN Tile Adhesive Technical Data SheetVincent JavateNo ratings yet

- Silver Star: High Polymer Modified, Cementitious, Tile/stone AdhesiveDocument3 pagesSilver Star: High Polymer Modified, Cementitious, Tile/stone AdhesiveGaganNo ratings yet

- Gold Star: High Polymer Modified, Cementitious, Tile/stone AdhesiveDocument3 pagesGold Star: High Polymer Modified, Cementitious, Tile/stone AdhesiveGaganNo ratings yet

- CIKOtile SPDocument2 pagesCIKOtile SPMahmoud OmarNo ratings yet

- Laticrete Hydroban Tds NFDocument6 pagesLaticrete Hydroban Tds NFAbdul Raheem SyedNo ratings yet

- Tile Adhesive Number 1: Typical Properties ApplicationDocument2 pagesTile Adhesive Number 1: Typical Properties ApplicationMedrar TareqNo ratings yet

- LATICRETE 315 Plus TDSDocument4 pagesLATICRETE 315 Plus TDSPRAKASH CHANDRA AHIRNo ratings yet

- Nanocrete FC Data Sheet: Specialist Construction Supplies For Repair, Maintenance, Building & InfrastructureDocument5 pagesNanocrete FC Data Sheet: Specialist Construction Supplies For Repair, Maintenance, Building & InfrastructureVelmurugan BalasubramanianNo ratings yet

- TDS Contite FCW 010 Jul11Document4 pagesTDS Contite FCW 010 Jul11พศิน จันทะสิมNo ratings yet

- Sikatop Seal 107Document4 pagesSikatop Seal 107Solomon AbiyeNo ratings yet

- Conbextra atDocument4 pagesConbextra atsathishbe5No ratings yet

- Roff NEW CONSTRUCTION TILE ADHESIVE NCA TDS DownloadDocument5 pagesRoff NEW CONSTRUCTION TILE ADHESIVE NCA TDS DownloadprakashnethaNo ratings yet

- Renderoc S: Constructive SolutionsDocument4 pagesRenderoc S: Constructive SolutionstalatzahoorNo ratings yet

- Webertai Gres ENG PDFDocument22 pagesWebertai Gres ENG PDFAl-Khreisat HomamNo ratings yet

- Ucrete Ud200 AseanDocument2 pagesUcrete Ud200 AseanDoby YuniardiNo ratings yet

- Izon L : Technical Data Sheet: Izonil Hard - Renovation and Waterproof Plaster (Revision - February 2018)Document4 pagesIzon L : Technical Data Sheet: Izonil Hard - Renovation and Waterproof Plaster (Revision - February 2018)AcingEdogawaNo ratings yet

- Ceramic Tile Fix Technical Data SheetDocument2 pagesCeramic Tile Fix Technical Data SheetThahir Hussain0% (1)

- Laticrete 325 SW AdhesiveDocument4 pagesLaticrete 325 SW AdhesiveAmeya MungaleNo ratings yet

- Webercol FlexDocument3 pagesWebercol FlexTauqeer AhmedNo ratings yet

- Nitoflor SL2050: Constructive SolutionsDocument4 pagesNitoflor SL2050: Constructive SolutionsNishant VasuNo ratings yet

- TEC-030100.2-MET-DoR-002-Fosroc1B-Renderoc HS (High Strenght) (Shrinkage Compensated, Polymer Modified, FibreDocument2 pagesTEC-030100.2-MET-DoR-002-Fosroc1B-Renderoc HS (High Strenght) (Shrinkage Compensated, Polymer Modified, FibreEli MatucadNo ratings yet

- Davco Super TTB 998Document3 pagesDavco Super TTB 998JU SHUANGNo ratings yet

- T03 T04 VITROFIX ADHESIVE VFA TDS DownloadDocument5 pagesT03 T04 VITROFIX ADHESIVE VFA TDS DownloadprakashnethaNo ratings yet

- Fosroc Nitofix: Constructive SolutionsDocument2 pagesFosroc Nitofix: Constructive SolutionsVincent JavateNo ratings yet

- Roff Non Skid Adhesive Nsa Tds DownloadDocument5 pagesRoff Non Skid Adhesive Nsa Tds DownloadChetan MahajanNo ratings yet

- Consol 71 FC: 2-Part Thixotropic Multipurpose Epoxy AdhesiveDocument2 pagesConsol 71 FC: 2-Part Thixotropic Multipurpose Epoxy AdhesiveMuhammad FirdausNo ratings yet

- Sika Top SealDocument2 pagesSika Top SealBilly Joe BreakfastNo ratings yet

- Sika Rapid Repair Mortar PDS - CE - PDFDocument6 pagesSika Rapid Repair Mortar PDS - CE - PDFLouis BirNo ratings yet

- Sika Ceram 205Document5 pagesSika Ceram 205care 7300No ratings yet

- Sika Poxitar MyDocument3 pagesSika Poxitar Myhijur ChenNo ratings yet

- Laticrete 254 TDS NF PDFDocument4 pagesLaticrete 254 TDS NF PDFMohitTripathiNo ratings yet

- 10 - TDS - Emaco S22 NBDocument3 pages10 - TDS - Emaco S22 NBaahtagoNo ratings yet

- Sikaceram 255 LargetileDocument4 pagesSikaceram 255 LargetileanamikakahlatihaiNo ratings yet

- Laticrete 335 Multipurpose Adhesive: Technical Data SheetDocument4 pagesLaticrete 335 Multipurpose Adhesive: Technical Data SheetmukeshNo ratings yet

- Nitocote CM210: Uses Standards ComplianceDocument4 pagesNitocote CM210: Uses Standards ComplianceJoan FosterNo ratings yet

- 12 - TDS - Emaco S42 NTDocument3 pages12 - TDS - Emaco S42 NTaahtagoNo ratings yet

- Nitotile Xs GroutDocument2 pagesNitotile Xs GroutVincent JavateNo ratings yet

- Sikadur - 31: 2-Part Thixotropic Epoxy AdhesiveDocument4 pagesSikadur - 31: 2-Part Thixotropic Epoxy AdhesiveKesto BhaktaNo ratings yet

- Laticrete 307 TDSDocument3 pagesLaticrete 307 TDSAnup DaNo ratings yet

- High polymer modified cementitious tile adhesiveDocument3 pagesHigh polymer modified cementitious tile adhesiveAarish KhanNo ratings yet

- Vitra FixDocument2 pagesVitra FixgoldenmediaNo ratings yet

- White: Smartcare Damp ProofDocument2 pagesWhite: Smartcare Damp ProofPramodh Pramodh K NNo ratings yet

- Sikadur 1 MP - Pds en PDFDocument4 pagesSikadur 1 MP - Pds en PDFandrieysyah2525No ratings yet

- Sika Damp Proofing Slurry Pds CeDocument4 pagesSika Damp Proofing Slurry Pds Cejuli_radNo ratings yet

- Epicon ARG: Technical DatasheetDocument3 pagesEpicon ARG: Technical DatasheetBogdanBNo ratings yet

- RENDEROC SPxtraDocument2 pagesRENDEROC SPxtraIrshad Ali DurraniNo ratings yet

- 2-Part Thixotropic Epoxy Adhesive: Product DescriptionDocument5 pages2-Part Thixotropic Epoxy Adhesive: Product DescriptionMarcos AmorimNo ratings yet

- Sikadur 42 T PDFDocument4 pagesSikadur 42 T PDFFederico.IoriNo ratings yet

- B03 EMIX Putty Product SheetDocument3 pagesB03 EMIX Putty Product SheetAnthony Al LakissNo ratings yet

- TDS Nitoproof Damp Protect India2Document2 pagesTDS Nitoproof Damp Protect India2hitesh315No ratings yet

- TDS Renderoc TG Saudi ArabiaDocument4 pagesTDS Renderoc TG Saudi Arabiaumn_mlkNo ratings yet

- PDS - Sika MonoTop-412 MYDocument4 pagesPDS - Sika MonoTop-412 MYNorlizawati YusofNo ratings yet

- MasterEmaco SBR 2 improves strength and reduces crackingDocument3 pagesMasterEmaco SBR 2 improves strength and reduces crackingRadja NurNo ratings yet

- Pds I 7 BC Gard SBDocument2 pagesPds I 7 BC Gard SBMohamadLutfiNo ratings yet

- Nitokit Surface SealantDocument4 pagesNitokit Surface SealanttalatzahoorNo ratings yet

- US Crete HF - 2020Document2 pagesUS Crete HF - 2020kemdoNo ratings yet

- Fosroc Guncrete E: High Strength, Low Shrinkage, High Build Dry-Spray Applied Repair Mortar Uses Application InstructionsDocument3 pagesFosroc Guncrete E: High Strength, Low Shrinkage, High Build Dry-Spray Applied Repair Mortar Uses Application InstructionsJohnNo ratings yet

- 01 Vetotop CL530 - 141221 JODocument2 pages01 Vetotop CL530 - 141221 JOassala HaddadNo ratings yet

- Weberfix Plus ENGDocument1 pageWeberfix Plus ENGAJ SamsonNo ratings yet

- Fosroc Nitocote EPS Protective CoatingDocument4 pagesFosroc Nitocote EPS Protective CoatingmangjitNo ratings yet

- Barrel GunDocument1 pageBarrel GunVincent JavateNo ratings yet

- Fosroc Colpor 200: Constructive SolutionsDocument4 pagesFosroc Colpor 200: Constructive Solutionsarwin dela cruzNo ratings yet

- Fosroc Bitucell Expansion Joint FillerDocument2 pagesFosroc Bitucell Expansion Joint FillerIna RoseNo ratings yet

- Fosroc Nitocote NT402: Constructive SolutionsDocument4 pagesFosroc Nitocote NT402: Constructive SolutionsVJ QatarNo ratings yet

- Nitocote EP405Document4 pagesNitocote EP405mangjitNo ratings yet

- Fosroc Dekguard S: Constructive SolutionsDocument4 pagesFosroc Dekguard S: Constructive SolutionsshazibNo ratings yet

- Fosroc Nitocote SN502: Constructive SolutionsDocument2 pagesFosroc Nitocote SN502: Constructive SolutionsVJ QatarNo ratings yet

- Nitoseal Debonding Tape AgfDocument1 pageNitoseal Debonding Tape AgfVincent JavateNo ratings yet

- Fosroc Dekguard E2000: (Also Known As Nitocote FBC)Document4 pagesFosroc Dekguard E2000: (Also Known As Nitocote FBC)Tejinder KumarNo ratings yet

- Nitocote PE135 PDFDocument2 pagesNitocote PE135 PDFSuresh BabuNo ratings yet

- Fosroc Nitocote EP410: Constructive SolutionsDocument4 pagesFosroc Nitocote EP410: Constructive SolutionsVJ QatarNo ratings yet

- Fosroc Nitocote HEX: Constructive SolutionsDocument4 pagesFosroc Nitocote HEX: Constructive SolutionsVJ QatarNo ratings yet

- Nitocote Primer SealerDocument2 pagesNitocote Primer SealerVJ QatarNo ratings yet

- Fosroc Nitocote SN522: Non Staining Water RepellentDocument2 pagesFosroc Nitocote SN522: Non Staining Water RepellentDasha DosftNo ratings yet

- Fosroc Nitocote HT120: Constructive SolutionsDocument4 pagesFosroc Nitocote HT120: Constructive SolutionsVincent JavateNo ratings yet

- Fosroc Nitocote ET402: Constructive SolutionsDocument4 pagesFosroc Nitocote ET402: Constructive SolutionsVJ QatarNo ratings yet

- Nitocote CM210Document4 pagesNitocote CM210sivakumar ramaiahNo ratings yet

- Nitocote sr3000Document4 pagesNitocote sr3000VJ QatarNo ratings yet

- Fosroc Nitocote EN901 High Chemical Resistant Protective LiningDocument4 pagesFosroc Nitocote EN901 High Chemical Resistant Protective LiningVincent JavateNo ratings yet

- Fosroc Nitocote NT550: Constructive SolutionsDocument4 pagesFosroc Nitocote NT550: Constructive SolutionsVincent JavateNo ratings yet

- Brush BondDocument4 pagesBrush BondGibbs PerNo ratings yet

- Fosroc Dekguard AC: Constructive SolutionsDocument4 pagesFosroc Dekguard AC: Constructive SolutionsVJ QatarNo ratings yet

- MNVTFRDF 0UDocument4 pagesMNVTFRDF 0UTarek TarekNo ratings yet

- Fosroc Brushbond FLXIII: Constructive SolutionsDocument2 pagesFosroc Brushbond FLXIII: Constructive SolutionsVincent JavateNo ratings yet

- Fosroc Nitocote EP403: Constructive SolutionsDocument4 pagesFosroc Nitocote EP403: Constructive SolutionsVJ QatarNo ratings yet

- Fosroc Dekguard PU: Constructive SolutionsDocument4 pagesFosroc Dekguard PU: Constructive SolutionsVJ QatarNo ratings yet

- Fosroc Dekguard EP302: Water Based, Epoxy Resin Primer For Dekguard PUDocument2 pagesFosroc Dekguard EP302: Water Based, Epoxy Resin Primer For Dekguard PUVJ QatarNo ratings yet

- Fosroc Dekguard Filler: Acrylic, Intercoat Pin Hole FillerDocument2 pagesFosroc Dekguard Filler: Acrylic, Intercoat Pin Hole FillerVincent JavateNo ratings yet

- Galva FroidDocument2 pagesGalva FroidChrill DsilvaNo ratings yet

- Bukidnon's Top Food, Nature SitesDocument3 pagesBukidnon's Top Food, Nature SitesslumbaNo ratings yet

- Housekeeping in The Dental OfficeDocument45 pagesHousekeeping in The Dental OfficeJhaynerzz Padilla AcostaNo ratings yet

- Cause: Lymphatic System Oriental Rat Flea Human Flea Septicemic PlagueDocument3 pagesCause: Lymphatic System Oriental Rat Flea Human Flea Septicemic PlagueMattNo ratings yet

- Interstate Standard: Gost 10444.1-84Document17 pagesInterstate Standard: Gost 10444.1-84giannina cabanillas100% (1)

- Nuclear Radioactivity WorksheetDocument3 pagesNuclear Radioactivity Worksheet14569874No ratings yet

- 32 Diet Recipes - Tamil MagazinesDocument11 pages32 Diet Recipes - Tamil MagazinesPandimadevi Selvakumar0% (1)

- New Flowers - FlowerMedDocument5 pagesNew Flowers - FlowerMedAndré CamargoNo ratings yet

- SAMSUNG LCD Service Manual (Internal) - ES15UDocument81 pagesSAMSUNG LCD Service Manual (Internal) - ES15Umeng798651No ratings yet

- b2 Open Cloze - EpidemicsDocument3 pagesb2 Open Cloze - EpidemicsJose Manuel Morín BarriosNo ratings yet

- Design calculations for 5 ton capacity steel tankDocument26 pagesDesign calculations for 5 ton capacity steel tankhgagselim2012No ratings yet

- English Speaking BasicsDocument52 pagesEnglish Speaking BasicsMukesh Verma100% (1)

- Performance Checklist On Cranial Nerve AssessmentDocument3 pagesPerformance Checklist On Cranial Nerve AssessmentSolsona Natl HS Maananteng100% (1)

- The Abreviated Ajahn Brahm - Concise Instructions For Skillful Meditation PDFDocument8 pagesThe Abreviated Ajahn Brahm - Concise Instructions For Skillful Meditation PDFJean Bessaudou Jan BessNo ratings yet

- Seoul International Invention Fair 2019Document2 pagesSeoul International Invention Fair 2019Mohammad Nuh Al-hudawy SiraitNo ratings yet

- The Importance of Earth Loop ImpedanceDocument4 pagesThe Importance of Earth Loop ImpedanceKarim Amer100% (1)

- School Form 2 Daily Attendance Report of Learners For Senior High School (SF2-SHS)Document2 pagesSchool Form 2 Daily Attendance Report of Learners For Senior High School (SF2-SHS)Charly Mint Atamosa IsraelNo ratings yet

- Leave Policy For EmployeesDocument9 pagesLeave Policy For EmployeesMEGHA PALANDENo ratings yet

- Molykote: 111 CompoundDocument2 pagesMolykote: 111 CompoundEcosuministros ColombiaNo ratings yet

- 310 SRU Thermal Reactor Chemistry and Design SRU Buenos Aires 2018Document27 pages310 SRU Thermal Reactor Chemistry and Design SRU Buenos Aires 2018Nastaran BagheriNo ratings yet

- Appendix 6Document4 pagesAppendix 6Vlad OlariuNo ratings yet

- Benefits and Limitations of GSTDocument7 pagesBenefits and Limitations of GSTGovernment Ramanarayan chellaram collageNo ratings yet

- En - Ineos Bichlor ElectrolyserDocument8 pagesEn - Ineos Bichlor Electrolyserbarun1977No ratings yet

- Tiic Interest RateDocument3 pagesTiic Interest RatePriyaNo ratings yet

- AV32D302 Service ManualDocument37 pagesAV32D302 Service ManualLuis MorenoNo ratings yet

- 7e Lesson PlanDocument6 pages7e Lesson PlanDave Matthew LibiranNo ratings yet

- FAA Instrument Rating Oral Exam PrepDocument8 pagesFAA Instrument Rating Oral Exam Prepvino chandrakumarNo ratings yet

- Theories of AgingDocument6 pagesTheories of AgingBamba FloresNo ratings yet

- Quality Management System: ISO 9001 - 2000 ClausesDocument18 pagesQuality Management System: ISO 9001 - 2000 ClausesRambabuNo ratings yet

- GOVT - Departments - Contact - Details - MF-14-06-2021 UpdatedDocument32 pagesGOVT - Departments - Contact - Details - MF-14-06-2021 Updatedadf_raghuNo ratings yet