Professional Documents

Culture Documents

Laticrete 325 SW Adhesive

Uploaded by

Ameya MungaleOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Laticrete 325 SW Adhesive

Uploaded by

Ameya MungaleCopyright:

Available Formats

LATICRETE® 325 SW

Adhesive

High polymer modified adhesive for fixing tiles

and natural stone on interior and exterior floor

& shear walls.

Substrates

Features / Benefits • Concrete & Concrete Masonry

• Mivan / shear walls

• Single component, just add water • VDF / Tremix Concrete

• High strength, polymer modified • Cement Mortar Beds

• Good transfer rate- No hollow sound • Cement Plaster

• Resistance against shrinkage cracks • Ceramic tile, Vitrified Tile and Natural Stone

• Good impact resistance

• Brick Masonry

• Economical & Easy to use • Cement Terrazzo*

• Bonds to various substrates

• Existing Natural Stone*

• Can be used up to a thickness of 15mm

• Complies to EN 12004 for C2T designation * Surface to be cleaned and roughened before

• Meets the requirements of Type 2 T as per IS installation of tiles or stones.

15477: 2019

• Exceeds ANSI A118.4 shear bond strength

requirements.

Application Certifications

Designed for interior floor and wall installations IS 15477: 2019 EN 12004: C2T

and external floor installations of all types of ceramic tile,

Type: 2 T

vitrified tile, precast Cement terrazzo and natural stones

over concrete and a variety of cement-based substrates,

especially on low absorbent cement substrates like

MIVAN/Shear Walls. Can be used up to maximum 15 mm

bed thickness.”

ANSI 118.4 T

MYKL-TDS- L 325 SW Adhesive- Rev00; 10/2021

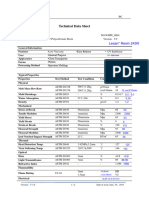

TECHNICAL DATA

The adhesive mortar conforms to ANSI A118.4 T

Performance Properties:

LATICRETE® 325 SW Adhesive mixed with Water EN / ISO Data

Property: Test Requirement Typical Values

Applicable Standards: Method

ANSI A118.4; EN 12004 & ISO 13007; IS15477: 2019 Open Time: EN

0.75 – 0.85

1346 at 20 ≥0.50 N/mm²

N/mm²

ANSI Data minutes

Property : Test Requirement Typical Values Slip Resistance: EN

≤0.50 mm 0.25 - 0.35 mm

method 1308

Open Time (30 Tensile Adhesion Strength

Minutes at 28 Initial: EN 1348 –

≥75 psi (0.50 100 psi – 120 psi ≥1.00 N/mm² 1.35 – 1.45 N/mm²

days): ANSI Clause 8.2

A118.4 Clause – Mpa) (0.68 – 0.82 Mpa) After Water

5.3 Immersion: EN ≥1.00 N/mm² 1.25 – 1.35 N/mm²

1348 - Clause 8.3

Sag: ANSI A118.4- 0.012 – 0.016 Heat Ageing: EN

Clause 6.0 ≤0.02 Inches ≥1.00 N/mm² 1.00 – 1.10 N/mm²

Inches (0.30-0.40 1348 – Clause 8.4

(0.50 mm)

mm) Freeze- Thaw: EN

≥1.00 N/mm² 1.25 – 1.35 N/mm²

Glazed wall tile Shear Strength 1348 – Clause 8.5

7 Days: ANSI 325-350 psi

>300psi The adhesive mortar conforms to EN12004 / ISO 13007

A118.4 – Clause (2.23 Mpa-2.40

(2.07Mpa) as C2T

7.1.2 Mpa)

7 Days Water IS Data

225-250 psi

immersion: ANSI >200psi Property: Test Requirement Typical Values

(1.54 Mpa-1.72

A118.4- Clause (1.38Mpa) method

Mpa)

7.1.3) Tensile Adhesion

Porcelain Mosaic Tile Shear Strength Dry Conditions –

1 Day: ANSI Minimum

>75psi 100 - 150 psi Annex A (Clause 1.35-1.45 N/mm²

A118.4 – Clause 1.00 N/mm²

(0.50Mpa) (0.68 – 1.20 Mpa) 5.1)

7.2.2 Wet Conditions –

7 Days: ANSI Minimum

>200psi 250 - 275 psi Annex A (Clause 1.25-1.35 N/mm²

A118.4 – Clause 1.00 N/mm²

(1.38Mpa) (1.72 – 1.89 Mpa) 5.1)

7.2.3 Shear Adhesion

7 Days Water

immersion: ANSI >150psi 175 - 225 psi Dry Conditions -

A118.4 – Clause (1.03Mpa) (1.21 – 1.55 Mpa) Minimum

(Annex B (Clause 1.30-1.40 N/mm²

7.2.4 1.25 N/mm²

5.2)

28 Days: ANSI Heat Ageing -

>200psi (1. 250 - 300 psi Minimum

A118.4 – Clause Annex B (Clause 1.10-1.15 N/mm²

38Mpa) (1.72 – 2.06 Mpa) 1.00 N/mm²

7.2.5 5.2)

28 Days : Freeze- Wet Conditions -

Thaw cycling. ANSI >175psi 225 - 275 psi Minimum

Annex B (Clause 1.15-1.25 N/mm²

A118.4 – Clause (1.20Mpa) (1.54 – 1.89 Mpa) 1.00 N/mm²

5.2)

7.2.5 Slip resistance -

12 Weeks: ANSI Annex E (Clause ≤ 0.5 mm 0.3-0.4 mm

>200psi 250 - 300 psi

A118.4 – Clause 5.5)

(1.38Mpa) (1.72 – 2.06 Mpa)

7.2.7

Quarry Tile Shear Strength The Adhesive mortar conforms to IS 15477: 2019 - Type

28 Days : ANSI 2 T Adhesive

>150psi 200 - 250 psi

A118.4 – Clause

(1.03Mpa) (1.37 – 1.72 Mpa)

7.3.2

28 Days :Freeze-

Thaw cycling. ANSI >100psi 150 - 200 psi

A118.4 – Clause (0.69Mpa) (1.03 – 1.37 Mpa) Packaging:

7.3.3

50 kg bags

Colour:

Grey

MYKL-TDS- L 325 SW Adhesive- Rev00; 10/2021

*No minimum cure time for concrete slabs when thin-set

Coverage: Per 50 Kg bag when mixed with water:

mortar is mixed with latex additive.

Trowel Bed Thickness Minimum Maximum Expansion joints shall be provided through the tile work

Size Coverage Coverage

6 x 6 mm from all construction or expansion joints in the substrate.

Square 3 mm 137 ft2 150 ft2 Do not cover expansion joints with adhesive set mortar.

Notch

9 x 9 mm Follow ANSI Specification AN-3.8 “Requirements for

Square 4.5 mm 87 ft2 100 ft2

Notch Expansion Joints” or TCA Detail EJ171 “Expansion

12 x 12 Joints”. For tile installation over Cement Backer Board:

mm

Square

6 mm 67 ft2 80 ft2 follow TCA installation details W244.

Notch

NOTES: For tile or stone installations on plywood and

Coverage will vary depending on trowel notch size, type and size of tile

and substrate smoothness and evenness. wood substrates, MYK LATICRETE DWA 215 OR MYK

LATICRETE PUA 212 is recommended. Please refer

Working Properties at 70° F (21° C)

specific product Technical Data Sheet for detailed

LATICRETE®325 SW Adhesive mixed with Water

recommendations.

Open Time 20-25 minutes

For all stone with a back-protection mesh, it is important

Adjustability Time 20-25 minutes

Pot Life 4-5 hours to remove the mesh first and also remove the epoxy layer

Time to Foot Traffic 16 - 24 hours by light grinding to ensure perfect bond with the

Time to heavy Traffic 28 Days adhesive. DO NOT INSTALL TILE / STONE WITHOUT

Specifications subject to change without notification. REMOVING THE PROTECTIVE BACK MESH AND

Results shown are typical but reflect test procedures used. Actual

CLEANING.

field performance will depend on installation methods and site

conditions.

Mixing:

Place clean, potable water into a clean mixing bowl. Add

INSTALLATION

LATICRETE® 325 SW Adhesive powder into the mixing bowl.

Surface Preparation:

Use approximately 13.5L to 15L of water for 50 kg of

All surfaces should be between 40° F(4°C) and 104°

powder.

F(40°C) and structurally sound, clean and free of all dirt,

Mix by hand or with a slow speed mixer to a smooth,

oil, grease, loose peeling paint, laitance, concrete sealers

trowelable consistency. Allow adhesive to slake for 5-10

or curing compounds. Check the surface to be true to minutes. Adjust consistency if necessary. Remix and apply

plumb. All slabs must be plumb and true to within with the proper sized notched trowel.

¼”(6mm) in 10 ft(3m). Rough or uneven concrete Note: Addition of MYK LATICRETE® latex admix*, partially or

surfaces should be made smooth with LATICRETE® completely replacing water would enhance the bond

strength, flexibility of the adhesive mortar.

Screed/Plaster material to provide a wood float (or better)

* Contact MYK LATICRETE technical services for large

finish.

format tile or stone installations on exterior surfaces.

Dry, dusty concrete slabs or masonry should be

dampened, and excess water swept off. Installation may

be made on a damp surface. New concrete slabs shall be

damp cured and 28* days old before application.

MYKL-TDS- L 325 SW Adhesive- Rev00; 10/2021

APPLICATION:

a) Tile/Stone Grouting:

Apply adhesive to the substrate with the flat side of the trowel, Grout installation shall be commenced after a minimum

pressing firmly to work into surface. Comb on additional of 24 hours curing time at 70°F (21° C). Grout with MYK

adhesive with the notched side. Use the proper sized notched LATICRETE® Sanded or Unsanded Grout mixed with MYK

trowel to ensure full bedding of the tile. Spread as much LATICRETE® 1776 Grout Admix Plus.

adhesive as can be covered with tile in 10 minutes. Back butter For maximum stain resistance of Internal spacer joints

large format tiles (> 12”x12”) to provide full bedding and firm applications, use LATAPOXY® SP-100 Stainfree Grout.

support. Place tiles into wet, sticky adhesive and beat in using a For maximum stain resistance of External spacer joints

beating block and rubber mallet to imbed tile and adjust level. applications, use MYK Laticrete Stellar Grout, which can

Check adhesive for complete coverage by periodically removing

accommodate movements and is UV resistant.

a tile and inspecting bedding adhesive transfer onto back of tile.

Use of MYK Laticrete spacers is recommended to provide grout

CUSTOMER CARE

joints between tiles / stones. The joint width shall be as per the

MYK LATICRETE India Pvt Ltd.

recommendation of architect / engineer. Remove the spacers

8-2-703/A, Fourth Floor, Leela Gopal Towers,

when the adhesive is set firm.

Road No-12, Banjara Hills, Hyderabad – 500034

(T.S) Tel: +91-40-6817 3100

If adhesive is skinned over (not sticky), remove and

Customer Care: cc@myklaticrete.com

replace with fresh adhesive.

Website: www.myklaticrete.com

For highly absorbent natural stones which may form a wet

patch when adhesive is used, it is recommended to use

suitable Laticrete Impregnating sealer on all sides.

Laticrete 3642 Latex admix can also be used as a bottom

coat for natural stones to prevent wet patches during

installation. Please refer Technical Data Sheets of product

intended for use for specific instructions of use

NOTE TO THE SPECIFIER AND INSTALLER:

While installing tile/stone on the external walls and floors,

we need to provide the joints by creating spaces between

the tiles/stones and fill them up with MYK LATICRETE®

cement-based grout mixed with MYK Laticrete 1776 grout

admix plus or flexible grout

(In the absence of spacer joints, the surface movements

can push tiles/stones away from the substrate causing de-

bonding of tiles or stones)

The exterior tile / stone installations are provided with

joints (spaces) on the periphery (Peripheral joints) of the

area without allowing the tile / stone to be bound by the

peripheral masonry work or plaster.

HOT & COLD WEATHER TILING:

* Please refer technical document on Hot & Cold weather

tiling

MYKL-TDS- L 325 SW Adhesive- Rev00; 10/2021

You might also like

- Laticrete 335 Multipurpose Adhesive: Technical Data SheetDocument4 pagesLaticrete 335 Multipurpose Adhesive: Technical Data SheetmukeshNo ratings yet

- Laticrete 254 TDS NF PDFDocument4 pagesLaticrete 254 TDS NF PDFMohitTripathiNo ratings yet

- Laticrete 307 TDSDocument3 pagesLaticrete 307 TDSAnup DaNo ratings yet

- LATICRETE 315 Plus TDSDocument4 pagesLATICRETE 315 Plus TDSPRAKASH CHANDRA AHIRNo ratings yet

- Laticrete 290 Premium Floor and Wall Thin-Set Adhesive: Technical Data SheetDocument3 pagesLaticrete 290 Premium Floor and Wall Thin-Set Adhesive: Technical Data SheetMohitTripathiNo ratings yet

- Laticrete Hydroban Tds NFDocument6 pagesLaticrete Hydroban Tds NFAbdul Raheem SyedNo ratings yet

- TDS Laticrete 600 Unsanded Grout NFDocument4 pagesTDS Laticrete 600 Unsanded Grout NFbajrangNo ratings yet

- SP-100 Stain-Free Grout: Technical Data SheetDocument4 pagesSP-100 Stain-Free Grout: Technical Data SheetrohanNo ratings yet

- Gold Star: High Polymer Modified, Cementitious, Tile/stone AdhesiveDocument3 pagesGold Star: High Polymer Modified, Cementitious, Tile/stone AdhesiveGaganNo ratings yet

- Silver Star: High Polymer Modified, Cementitious, Tile/stone AdhesiveDocument3 pagesSilver Star: High Polymer Modified, Cementitious, Tile/stone AdhesiveGaganNo ratings yet

- Nitotile XsDocument2 pagesNitotile XsVincent JavateNo ratings yet

- 3Lpe/3Lpp Coating Guide: Activity Standard Acceptance CriteriaDocument1 page3Lpe/3Lpp Coating Guide: Activity Standard Acceptance CriteriaSandeep PrNo ratings yet

- Laticrete 226 Thick Bed Adhesive: Technical Data SheetDocument3 pagesLaticrete 226 Thick Bed Adhesive: Technical Data SheetYASHICA VAITTIANATHANNo ratings yet

- Renolit Alkorplan 00414 15mm + Lacquer enDocument2 pagesRenolit Alkorplan 00414 15mm + Lacquer enIngénieur CivilNo ratings yet

- Sika Kimia SDN BHD - Pds - Sikabit t130 Mgmy - SgmyDocument3 pagesSika Kimia SDN BHD - Pds - Sikabit t130 Mgmy - Sgmymultifocus sb100% (1)

- Rilsan Fine Powders Physical PropertiesDocument2 pagesRilsan Fine Powders Physical Propertiesธนาชัย เต็งจิรธนาภาNo ratings yet

- HDPE-100 Catalogue PDFDocument9 pagesHDPE-100 Catalogue PDFkumar sandeepNo ratings yet

- Policarbonato Teijin Panlite Ad-5503Document1 pagePolicarbonato Teijin Panlite Ad-5503marioNo ratings yet

- Tds A1105 en 2017pdfpdfDocument2 pagesTds A1105 en 2017pdfpdfagungNo ratings yet

- Sikaceram 125 Easyfix 13Document4 pagesSikaceram 125 Easyfix 13TARGET TRADE LINKSNo ratings yet

- Myk Aac Block Adhesive Technical Data SheetDocument3 pagesMyk Aac Block Adhesive Technical Data SheetAbxNo ratings yet

- NWP Rockwool Filled Roof Panel TDSDocument2 pagesNWP Rockwool Filled Roof Panel TDSRawaa Al-EdreesiNo ratings yet

- Epofine 205 - Finehard 905 - Flex 040 - Acc 061Document4 pagesEpofine 205 - Finehard 905 - Flex 040 - Acc 061Karishma PrabhuNo ratings yet

- SPC Peeling StrengthDocument1 pageSPC Peeling StrengthMd. Main UddinNo ratings yet

- Exalite-10 GB PDFDocument2 pagesExalite-10 GB PDFvijayNo ratings yet

- Lamitex CE Tube Metric DataDocument1 pageLamitex CE Tube Metric Dataabdulloh_99No ratings yet

- VALMEX MEHATOP N - 2018 08 - Samples PDFDocument6 pagesVALMEX MEHATOP N - 2018 08 - Samples PDFRamakrishnan SitaramanNo ratings yet

- Epofine 556 FR/ FInehard 951Document3 pagesEpofine 556 FR/ FInehard 951Karishma Prabhu100% (1)

- Specifying Ceramic Tile With ANSI and ISO StandardsDocument45 pagesSpecifying Ceramic Tile With ANSI and ISO StandardsAlQuon for U100% (1)

- Pds Sika Monotop 4012Document5 pagesPds Sika Monotop 4012arc.medabdelrazekNo ratings yet

- E2SB Series 2.5 2.0 Seam Sealing CrystalDocument1 pageE2SB Series 2.5 2.0 Seam Sealing CrystalMaksimUSNo ratings yet

- Recubrimiento Ext TanqueDocument2 pagesRecubrimiento Ext Tanquehenry307No ratings yet

- Airex T90: The Fire Resistant Structural FoamDocument3 pagesAirex T90: The Fire Resistant Structural FoamJesse Garcia OlmosNo ratings yet

- Acetal Copolymer (POM)Document5 pagesAcetal Copolymer (POM)DiegoTierradentroNo ratings yet

- Ac-700 SpecificationDocument10 pagesAc-700 SpecificationTarek Abuzene100% (1)

- 1035 TD 20 Product Data Sheet ViscopasteDocument2 pages1035 TD 20 Product Data Sheet ViscopasteUrooj IlyasNo ratings yet

- Especificación Membrana GeotextilDocument1 pageEspecificación Membrana GeotextilMiguel RamírezNo ratings yet

- Ceramite T: Bauxite and Silicon Carbide Based Trowellable RefractoryDocument2 pagesCeramite T: Bauxite and Silicon Carbide Based Trowellable RefractorySHRINIVASAN GTKNo ratings yet

- Sikaflex® Pro-3 Purform® - Material SubmittalDocument34 pagesSikaflex® Pro-3 Purform® - Material SubmittalEmad El ShaerNo ratings yet

- TDS Pe 202 SP4808Document2 pagesTDS Pe 202 SP4808Desri AkbarNo ratings yet

- Sikalastic®-1K: Product Data SheetDocument4 pagesSikalastic®-1K: Product Data SheetKhin Sandi KoNo ratings yet

- Morflo 170Document2 pagesMorflo 170baselNo ratings yet

- 550series - HydraustarDocument8 pages550series - HydraustarvijaykumarnNo ratings yet

- Epofine 184-Finehard 907 - Acc 062Document4 pagesEpofine 184-Finehard 907 - Acc 062Karishma PrabhuNo ratings yet

- T Work9000Document2 pagesT Work9000Maike SongNo ratings yet

- Sika Anchorfix-2 NormalDocument7 pagesSika Anchorfix-2 NormalTimoNo ratings yet

- Mds Rheinzink-Artcolor Skygrey 04 2018 de enDocument3 pagesMds Rheinzink-Artcolor Skygrey 04 2018 de encarlosNo ratings yet

- Fiberglass Reinforced Polyester Enclosures: Enclosure ProgramDocument6 pagesFiberglass Reinforced Polyester Enclosures: Enclosure ProgramVBANo ratings yet

- LR-C-VentureClad Catalogue 01Document16 pagesLR-C-VentureClad Catalogue 01himanshu desaiNo ratings yet

- LOCTITEDocument2 pagesLOCTITEHrNo ratings yet

- Nylacast Moly Cast Nylon 6, MoS2 FilledDocument3 pagesNylacast Moly Cast Nylon 6, MoS2 Filledprasad.jppmNo ratings yet

- TP Wanhua Clarnate A1227 Vs Lexan 243RDocument2 pagesTP Wanhua Clarnate A1227 Vs Lexan 243RMitja GorseNo ratings yet

- Technical Specification: LG Hausys Floors (STATICPULSE) : ESD Control TileDocument3 pagesTechnical Specification: LG Hausys Floors (STATICPULSE) : ESD Control TileSakthi VelNo ratings yet

- ShaliProtek PuR 100Document3 pagesShaliProtek PuR 100Rana MahatoNo ratings yet

- NIC HDPE Manhole PDFDocument8 pagesNIC HDPE Manhole PDFreemNo ratings yet

- Loctite 380 Black - Ficha TecnicaDocument3 pagesLoctite 380 Black - Ficha TecnicamonsepackNo ratings yet

- Sika Monotop 4100protectDocument5 pagesSika Monotop 4100protectJanardhana ReddiNo ratings yet

- F F O P L: Epofine - 740 / Finehard - 918 / Accelerator - 062Document4 pagesF F O P L: Epofine - 740 / Finehard - 918 / Accelerator - 062Karishma Prabhu100% (1)

- Webercol FlexDocument3 pagesWebercol FlexTauqeer AhmedNo ratings yet

- 16 - Dining Table - 22.02.2021Document1 page16 - Dining Table - 22.02.2021Ameya MungaleNo ratings yet

- 17 - Dining CHAIRS - 23.02.2021Document1 page17 - Dining CHAIRS - 23.02.2021Ameya MungaleNo ratings yet

- Accelerated Corrosion Test in Mortars of Plastic Consistency With Replacement of Rice Husk Ash and Nano-SioDocument14 pagesAccelerated Corrosion Test in Mortars of Plastic Consistency With Replacement of Rice Husk Ash and Nano-SioAmeya MungaleNo ratings yet

- UTSP - Week 8-Module E-Mode Choice AnalysisDocument96 pagesUTSP - Week 8-Module E-Mode Choice AnalysisAmeya MungaleNo ratings yet

- Mangal Ambika Su Prabhat AmDocument16 pagesMangal Ambika Su Prabhat AmAmeya MungaleNo ratings yet

- Directorate of Technical Education, Maharashtra State: PhoneDocument12 pagesDirectorate of Technical Education, Maharashtra State: PhoneAmeya MungaleNo ratings yet

- .. Shri A.Njaneya Dvadashanama Stotram .. ॥ ौीआंजनेय ादशनामोऽम ्॥Document2 pages.. Shri A.Njaneya Dvadashanama Stotram .. ॥ ौीआंजनेय ादशनामोऽम ्॥Ameya MungaleNo ratings yet

- Checklist BusinessDocument1 pageChecklist BusinessAmeya MungaleNo ratings yet

- Bond Beam - Bond Beam Block vs. Lintel Block - NitterhouseDocument15 pagesBond Beam - Bond Beam Block vs. Lintel Block - NitterhouseRonald SiraitNo ratings yet

- Steel Butt Welding Fittings : All Sizes in MMDocument10 pagesSteel Butt Welding Fittings : All Sizes in MMtisnaNo ratings yet

- Project Title: Proposed Waiting Shed Location: Brgy. Lumbia, Cagayab de Oro City Owner: Lgu-Brgy. Lumbia, CdocDocument2 pagesProject Title: Proposed Waiting Shed Location: Brgy. Lumbia, Cagayab de Oro City Owner: Lgu-Brgy. Lumbia, CdocMac KY100% (1)

- Basement FoundationDocument8 pagesBasement FoundationSayaliNo ratings yet

- Designing With Sips Design ConsiderationsDocument20 pagesDesigning With Sips Design Considerationsgorefest123No ratings yet

- Curtain Walls With Thermal BreakDocument8 pagesCurtain Walls With Thermal Breakrichard machadoNo ratings yet

- House EstimateDocument46 pagesHouse EstimatesheikNo ratings yet

- Horry County Schools Work Orders 2015-2019Document90 pagesHorry County Schools Work Orders 2015-2019WMBF NewsNo ratings yet

- 106 LoadDocument75 pages106 LoadPia Eleanor SantosNo ratings yet

- Application For RenovationDocument1 pageApplication For RenovationAyra ClaorNo ratings yet

- L2 On Ground Concrete Floor Construction PDFDocument36 pagesL2 On Ground Concrete Floor Construction PDFAzeem RahmanNo ratings yet

- Heat Load For Guest Room (N&E)Document1 pageHeat Load For Guest Room (N&E)words4devNo ratings yet

- Long Span StructuresDocument13 pagesLong Span StructuresVinay KatariyaNo ratings yet

- Cooling Load Detail CalculationDocument2 pagesCooling Load Detail Calculationapi-26699613100% (8)

- Mukarba Chowk To Panipat Haryana Section-2 of NH-44 Ravi Infrabuild Project Pvt. LTDDocument1 pageMukarba Chowk To Panipat Haryana Section-2 of NH-44 Ravi Infrabuild Project Pvt. LTDRavi InfraNo ratings yet

- BV Doshi ReportDocument13 pagesBV Doshi ReportNisham LimbuNo ratings yet

- Edward's Stone BrochureDocument14 pagesEdward's Stone BrochureedwardsstoneNo ratings yet

- Foundation Design For Dynamic Equipment Based On ACI 351.3 & ACI 318-19Document5 pagesFoundation Design For Dynamic Equipment Based On ACI 351.3 & ACI 318-19Ridho ZiskaNo ratings yet

- Underground Water Tank Design (Aci 318-08 & 350-01)Document6 pagesUnderground Water Tank Design (Aci 318-08 & 350-01)Franklyn Genove100% (1)

- Chapter 4 StairDocument17 pagesChapter 4 StairRomharsh OliNo ratings yet

- Louis KahnDocument10 pagesLouis KahnSERGIO ALONSO PAREDES CUBANo ratings yet

- Re-Discovery of PalmyraDocument8 pagesRe-Discovery of PalmyratesermetNo ratings yet

- Lecture 3 Rock & Cave ChurchsDocument49 pagesLecture 3 Rock & Cave Churchshiwot tujiNo ratings yet

- Hostel Standard and Safety MeasuresDocument16 pagesHostel Standard and Safety MeasuresSadiya IqbalNo ratings yet

- ASILIMITED Barclays CenterDocument2 pagesASILIMITED Barclays CenterNorman OderNo ratings yet

- Kucna BrosuraDocument35 pagesKucna BrosuramikigruNo ratings yet

- Taj MahalDocument8 pagesTaj MahalSumayya KareemNo ratings yet

- UNDP SZ Environment Doors-Windows ScheduleDocument1 pageUNDP SZ Environment Doors-Windows ScheduleAmiraHenil100% (1)

- Architecture of KeralaDocument30 pagesArchitecture of KeralaAbhinav AggarwalNo ratings yet

- Mix DesignDocument6 pagesMix DesignschaktenNo ratings yet