Professional Documents

Culture Documents

Duralprep A.C.: Bonding Agent and Anti-Corrosion Coating

Uploaded by

aandueza_1Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Duralprep A.C.: Bonding Agent and Anti-Corrosion Coating

Uploaded by

aandueza_1Copyright:

Available Formats

The Euclid Chemical Company

DURALPREP A.C.

Bonding Agents and Adhesives

Bonding Agent and Anti-Corrosion Coating

Description

DURALPREP A.C. is a three-component bonding agent and anti-corrosion coating for reinforcing steel. It is a pre-

proportioned kit that contains a water-based epoxy, combined with portland cement that can be used as a bonding

agent for placing fresh concrete and repair mortars to existing concrete substrates. DURALPREP A.C. contains a

corrosion inhibitor which protects reinforcement when used as an anti-corrosion coating for steel. DURALPREP A.C.

has a long open time, is non-flammable, VOC compliant, and does not form a water vapor barrier after cure.

Primary Applications

• Bonding agent for fresh concrete to existing concrete • Exterior or interior

• Vertical & overhead concrete repairs • On grade or above grade applications

• Anti-corrosion coating for steel reinforcement

Features/Benefits

• Long open time • Non-flammable

• Contains a corrosion inhibitor • Does not form a vapor barrier

• Ease of application (brush/spray)

Technical Information

The following are typical values obtained under laboratory conditions. Expect reasonable variation under field conditions.

Property Result

1 gal:1 gal:36 lbs

Mix Ratio (A:B:C)

(3.8 L:3.8 L:16 kg)

Contact Time Up to 24 hours depending on temperature

DURALPREP A.C.

Pot Life (2 gal (7.6 L) unit), minutes 35 to 40

3 days: 2,900 (20.0)

Compressive Strength, psi (MPa)

7 days: 4,100 (28.3)

ASTM C109

28 days: 4,500 (31.0)

Flexural Strength, psi (MPa)

28 days: > 1,280 (8.8)

ASTM C348

Shore D Hardness

90 to 95

ASTM D2240

Bond Strength, psi (MPa) 7 days (w/ 1 hr open time): 2,480 (17.1)

ASTM C882 7 days (w/ 24 hr open time): 2,700 (18.6)

Split Tensile Strength, psi (MPa)

28 days: > 600 (4.1)

ASTM C496

Water Vapor Transmission

0.16 grains/hr•ft2

ASTM E96

Master Format #:

Appearance/Color Concrete Gray

03 05 00

Packaging

DURALPREP A.C. is packaged in 3.75 gal (14.2 L) kits and in cases of 1 gal (3.8 L) units (2 units per case).

Shelf Life

2 years in original, unopened package

Coverage

One 3.75 gal (14.2 L) kit of DURALPREP A.C. will cover approximately 250 ft² (23.2 m²), per coat.

One 1 gal (3.8L) unit will cover approximately 65 ft² (6.0 m²), per coat.

Note: Coverage rates are approximate. Actual coverage depends on temperature, texture, and substrate porosity.

19215 Redwood Road • Cleveland, OH 44110

www.euclidchemical.com

800-321-7628 t • 216-531-9596 f

Directions for Use

Surface Preparation: The surface must be structurally sound, clean and free of grease, oil, curing compounds,

soil, dust and other contaminants. Surface laitance must be removed. Concrete surfaces must be roughened

and made absorptive, preferably by mechanical means, and then thoroughly cleaned of all dust and debris. If

the surface was prepared by chemical means (acid etching), a water/baking soda or water/ammonia mixture,

followed by a clean water rinse, must be used for cleaning, in order to neutralize the substrate. The substrate

should be saturated, surface-dry (SSD) prior to application, with no standing water/puddles. Following surface

preparation, the strength of the surface can be tested if quantitative results are required by project specifications.

An elcometer or similar tensile pull tester may be used in accordance with ASTM D4541, and the tensile pull-off

strength should be at least 250 psi (1.7 MPa).

When coating steel, all contamination should be removed and the steel surface prepared to a “near white” finish

(SSPC SP10) using clean, dry blasting media.

Mixing: Mix DURALPREP A.C. using a low-speed drill and a mixing paddle. Pre-mix Part A and Part B separately

for approximately 1 minute each. Combine all of Part A with all of Part B, then mix thoroughly for 30 to 45

seconds. After the 30 to 45 seconds have elapsed, gradually add all of Part C (powder) into the mixed epoxy,

then mix thoroughly for 3 minutes. Scrape the bottom and sides of the containers at least once during mixing.

Do not scrape bottom or sides of the container once mixing operations have ceased; doing so may result in

unmixed resin or hardener being applied to the substrate. Unmixed resin or hardener will not cure properly. Do

not aerate the material during mixing. To keep aeration to a minimum, the recommended mixing paddles are

#P1 or #P2 as found in ICRI Guideline 320.5R-2014.

Application: Bonding agent: Apply one coat, between 20 and 27 mils thick, of DURALPREP A.C. to the SSD

surface using a stiff bristle brush, or spray with a hopper gun at a rate of 60 to 80 ft2/gal (1.5 to 2.0 m2/L). Allow to

fully dry (approximately 1 hour) before placing concrete or repair mortars. DURALPREP A.C. has an open time from

1 to 24 hours at 75°F (24°C). Anti-corrosion coating: Coat the exposed reinforcing steel, making sure to coat the

underside portion of the steel as well. Apply two coats, at 20 mils thick each, of DURALPREP A.C. to the properly

prepared steel using a stiff bristle brush, or spray with a hopper gun at a rate of 80 ft2/gal (2.0 m2/L). Allow 3 to 6

hours between applications. Place subsequent concrete or repair mortars within the open time of the second coat of

DURALPREP A.C. (1 to 24 hours at 75°F (24°C)).

Note: If the applied DURALPREP A.C. exceeds its open time (see times in “Precautions/Limitations” below) before

the subsequent application of concrete or repair mortar, lightly sand the existing DURALPREP A.C., wipe the surface

clean, and apply a fresh coat of DURALPREP A.C. to the area.

Clean-Up

Clean tools and application equipment immediately with water. Clean spills or drips with water while still wet.

Hardened DURALPREP A.C. will require mechanical abrasion for removal.

Precautions/Limitations

• Store DURALPREP A.C. indoors, protected from moisture, at temperatures between 65°F and 80°F (18°C and

27°C)

• Surface and ambient temperature during applications should be between 45°F and 90°F (7°C and 32°C)

• Material temperatures should be at least 45°F (7°C) and rising

• Working time and cure time will decrease as the temperature increases, and will increase as the temperature

decreases

• Do not use DURALPREP A.C. as a surface bonding agent for horizontal toppings less than 3.5 inches (8.9 cm)

thick

• Do not thin DURALPREP A.C.

• DURALPREP A.C. is not to be used as a finished/aesthetic coating

• Do not mix DURALPREP A.C. for longer than 3 minutes

• Protect applied DURALPREP A.C. from wind and excessive heat. These conditions will shorten open time.

• Maximum open times: 12 hours at 90°F (32°C), 24 hours at 75°F (24°C), 30 hours at 45°F (7°C)

• In all cases, consult the product Safety Data Sheet before use

Rev. 05.19

WARRANTY: The Euclid Chemical Company (“Euclid”) solely and expressly warrants that its products shall be free from defects in materials and workmanship for one (1) year from the date of purchase. Unless authorized

in writing by an officer of Euclid, no other representations or statements made by Euclid or its representatives, in writing or orally, shall alter this warranty. EUCLID MAKES NO WARRANTIES, IMPLIED OR OTHERWISE,

AS TO THE MERCHANTABILITY OR FITNESS FOR ORDINARY OR PARTICULAR PURPOSES OF ITS PRODUCTS AND EXCLUDES THE SAME. If any Euclid product fails to conform with this warranty, Euclid will replace the

product at no cost to Buyer. Replacement of any product shall be the sole and exclusive remedy available and buyer shall have no claim for incidental or consequential damages. Any warranty claim must be made within

one (1) year from the date of the claimed breach. Euclid does not authorize anyone on its behalf to make any written or oral statements which in any way alter Euclid’s installation information or instructions in its product

literature or on its packaging labels. Any installation of Euclid products which fails to conform with such installation information or instructions shall void this warranty. Product demonstrations, if any, are done for illustrative

purposes only and do not constitute a warranty or warranty alteration of any kind. Buyer shall be solely responsible for determining the suitability of Euclid’s products for the Buyer’s intended purposes.

You might also like

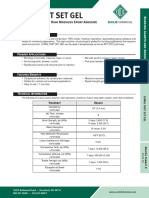

- Dural Fast Epoxy Gel EuclidDocument3 pagesDural Fast Epoxy Gel Euclidpayaso1973No ratings yet

- Technical Data: Plastic Steel Putty (A)Document4 pagesTechnical Data: Plastic Steel Putty (A)francisNo ratings yet

- Chersterton Arc 982 PDFDocument2 pagesChersterton Arc 982 PDFMohamed NouzerNo ratings yet

- Plastic Steel Putty A v3Document2 pagesPlastic Steel Putty A v3feri.ferdianto02No ratings yet

- Coroflake 24Document2 pagesCoroflake 24ChristianNo ratings yet

- Nukote Har: DescriptionDocument4 pagesNukote Har: DescriptionMarco Dos Santos NevesNo ratings yet

- Sikatop 123 Plus: Polymer-Modified, Cementitious, Non-Sag Mortar, Plus Migrating Corrosion InhibitorDocument2 pagesSikatop 123 Plus: Polymer-Modified, Cementitious, Non-Sag Mortar, Plus Migrating Corrosion InhibitorMarkNo ratings yet

- Sika Repair Grout 223Document2 pagesSika Repair Grout 223Bill MurrayNo ratings yet

- Datasheet Chockfast RedDocument2 pagesDatasheet Chockfast RedAlexander0% (1)

- Sikadur®-42 Grout Pak LE: Pre-Proportioned, Precision Epoxy Grouting SystemDocument2 pagesSikadur®-42 Grout Pak LE: Pre-Proportioned, Precision Epoxy Grouting Systemraunak upadhyayaNo ratings yet

- High Performance Backing Compound: Technical Data SheetDocument2 pagesHigh Performance Backing Compound: Technical Data SheetNiku SamarthNo ratings yet

- Quakebond J300Sr: The Infrastructure InnovatorsDocument2 pagesQuakebond J300Sr: The Infrastructure Innovatorskhoirul ramadhanNo ratings yet

- Sikatoparmatec110epocem Pds PDFDocument2 pagesSikatoparmatec110epocem Pds PDFRio CahyantoNo ratings yet

- Koroglass 1000Document3 pagesKoroglass 1000Sandeep gangulyNo ratings yet

- E-Bond T526 Technical Data Sheet-1Document5 pagesE-Bond T526 Technical Data Sheet-1fatemeh.ahmadkhaniNo ratings yet

- Sikadur 42 Gorut Palk LE - CaDocument2 pagesSikadur 42 Gorut Palk LE - Carobert benavidesNo ratings yet

- Corr BondDocument2 pagesCorr BondShahzad Aslam ShahbazNo ratings yet

- Ceramic Repair Paste TDSDocument3 pagesCeramic Repair Paste TDSAzril DahariNo ratings yet

- SikaAnchorFix3001 PdsDocument4 pagesSikaAnchorFix3001 PdssaulolmNo ratings yet

- Description Packaging Product Data SheetDocument2 pagesDescription Packaging Product Data SheetRonald Fernandez ManubuluNo ratings yet

- Jazeera Floor Coating 400Document3 pagesJazeera Floor Coating 400Ahmad BougeisNo ratings yet

- SikaGrout212HP Pds PDFDocument3 pagesSikaGrout212HP Pds PDFraunak upadhyayaNo ratings yet

- Ceramic Repair Putty: Technical Data SheetDocument2 pagesCeramic Repair Putty: Technical Data SheetNiku SamarthNo ratings yet

- Acrylic Elastomeric Paint Technical DataDocument3 pagesAcrylic Elastomeric Paint Technical DataAhmad BougeisNo ratings yet

- Technical Data: Plastic Steel 5-Minute Putty (SF)Document4 pagesTechnical Data: Plastic Steel 5-Minute Putty (SF)Hoàng DũngNo ratings yet

- NS Grout PDFDocument2 pagesNS Grout PDFRenjithNo ratings yet

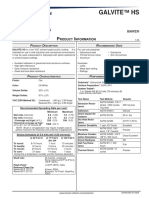

- Protective & Marine Coatings: Galvite™ HsDocument4 pagesProtective & Marine Coatings: Galvite™ HsAna CabreraNo ratings yet

- ADMIX Epoflex SRDocument2 pagesADMIX Epoflex SRbeto pagoadaNo ratings yet

- Technical Data Sheet: DescriptionDocument4 pagesTechnical Data Sheet: Descriptionerode els erodeNo ratings yet

- Structural Concrete: Product DescriptionDocument2 pagesStructural Concrete: Product DescriptionAram HovsepianNo ratings yet

- Duraplate 8200Document4 pagesDuraplate 8200Carlos VillacrizNo ratings yet

- Megamix: Description CoverageDocument4 pagesMegamix: Description CoverageSolomon AhimbisibweNo ratings yet

- SikaAnchorFix2Arctic PdsDocument4 pagesSikaAnchorFix2Arctic PdsDragoș SturzoiuNo ratings yet

- Pds CPD D30 SikaGrout 300 PT UsDocument2 pagesPds CPD D30 SikaGrout 300 PT UsJonathan FelixNo ratings yet

- Devcon Plastic Steel Putty ADocument3 pagesDevcon Plastic Steel Putty AAZLAN ABDULLAINo ratings yet

- ALUBOND SpecificationsDocument2 pagesALUBOND SpecificationssoosanantonyNo ratings yet

- Spec Guide NonshrinkprecgroutDocument4 pagesSpec Guide NonshrinkprecgroutNOEL PLEÑOSNo ratings yet

- PS 14 Anchor Bolt TolerancesDocument4 pagesPS 14 Anchor Bolt TolerancesjebrijaNo ratings yet

- Bronze Putty: Technical Data SheetDocument2 pagesBronze Putty: Technical Data SheetSharad ShahNo ratings yet

- Protective DTM Acrylic Primer/Finish Product DescriptionDocument4 pagesProtective DTM Acrylic Primer/Finish Product DescriptionVernon Jiménez FonsecaNo ratings yet

- Ripstar 121: SpecificationDocument3 pagesRipstar 121: SpecificationAnkita Baban GavadeNo ratings yet

- Technical Data Sheet: DescriptionDocument3 pagesTechnical Data Sheet: Descriptionerode els erodeNo ratings yet

- New 1000 CSDocument2 pagesNew 1000 CSSantiago MonteroNo ratings yet

- Especificaciones Pintura Macropoxi NavalDocument4 pagesEspecificaciones Pintura Macropoxi NavalVicenteRojasLeonNo ratings yet

- Carboguard 890 PDSDocument2 pagesCarboguard 890 PDSLinnie McleodNo ratings yet

- Product: Chocking & Anchor Bolt Setting CompoundDocument2 pagesProduct: Chocking & Anchor Bolt Setting CompoundFajri AnnamlaNo ratings yet

- QuakeBond-220TC-PDS-0120 (Renforcement Des Hea Avec de La Resine)Document2 pagesQuakeBond-220TC-PDS-0120 (Renforcement Des Hea Avec de La Resine)Amel RNo ratings yet

- Five Star Rapid Epoxy GroutDocument2 pagesFive Star Rapid Epoxy GroutJohnprasannaNo ratings yet

- Nukote XT Plus TdsDocument4 pagesNukote XT Plus TdsAnsar AliNo ratings yet

- DTM Bonding Primer: Protective & Marine CoatingsDocument4 pagesDTM Bonding Primer: Protective & Marine CoatingsAna CabreraNo ratings yet

- Titanium Putty HPDocument2 pagesTitanium Putty HPDivyanshu GuptaNo ratings yet

- Protective & Marine Coatings: Polysiloxane 1KDocument4 pagesProtective & Marine Coatings: Polysiloxane 1KAna CabreraNo ratings yet

- Nukote STDocument4 pagesNukote STMarco Dos Santos NevesNo ratings yet

- 3M2216Document8 pages3M2216pat_kunal1601No ratings yet

- Dow Corning AllGuard Silicone Elastomeric CoatingDocument4 pagesDow Corning AllGuard Silicone Elastomeric Coatinggpax42No ratings yet

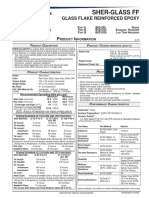

- Sherglass FFDocument4 pagesSherglass FFJhose BonillaNo ratings yet

- CLADLINER TDS October 2017Document2 pagesCLADLINER TDS October 2017LuisSantiagoNo ratings yet

- Pro Mastic Ste 87Document4 pagesPro Mastic Ste 87ahmedyahea181No ratings yet

- Urethane Coating 165 PWDocument2 pagesUrethane Coating 165 PWANIBALLOPEZVEGANo ratings yet

- XLF60 Owners Manual 1Document78 pagesXLF60 Owners Manual 1aandueza_1No ratings yet

- Fender Systems Ver3 - 9Document5 pagesFender Systems Ver3 - 9aandueza_1No ratings yet

- TLE2015 05TekmarineCatalogueR001cDocument18 pagesTLE2015 05TekmarineCatalogueR001caandueza_1No ratings yet

- Fender Systems Ver3 - 9Document5 pagesFender Systems Ver3 - 9aandueza_1No ratings yet

- AG 18420 Penguard Pro GF Euk GBDocument12 pagesAG 18420 Penguard Pro GF Euk GBaandueza_1No ratings yet

- 5 1Document12 pages5 1mahakNo ratings yet

- Product Manual enDocument122 pagesProduct Manual enadacostNo ratings yet

- TLE2015 05TekmarineCatalogueR001cDocument18 pagesTLE2015 05TekmarineCatalogueR001caandueza_1No ratings yet

- XLF60 Service Manual 1Document18 pagesXLF60 Service Manual 1aandueza_1No ratings yet

- SAP2000 Pipe Rack Modeling GuideDocument92 pagesSAP2000 Pipe Rack Modeling Guideagvelazquez100% (9)

- Drafts - Concrete - Nov 24, 2021Document8 pagesDrafts - Concrete - Nov 24, 2021aandueza_1No ratings yet

- Matias Bedroom: Designed by Maiya Rojas - Dec 1, 2021 Made For AndresDocument4 pagesMatias Bedroom: Designed by Maiya Rojas - Dec 1, 2021 Made For Andresaandueza_1No ratings yet

- 68 PNCQ ODocument1 page68 PNCQ Oaandueza_1No ratings yet

- Ku 6 y NPXDocument1 pageKu 6 y NPXaandueza_1No ratings yet

- 190924-N-BI924-9813 USNS GillilandDocument1 page190924-N-BI924-9813 USNS Gillilandaandueza_1No ratings yet

- QVF by 9 JDocument1 pageQVF by 9 Jaandueza_1No ratings yet

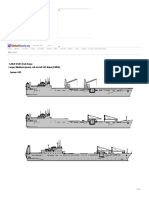

- USNS Bob Hope Class in BremertonDocument1 pageUSNS Bob Hope Class in Bremertonaandueza_1No ratings yet

- Pandas PDFDocument3,071 pagesPandas PDFJoemon JoseNo ratings yet

- ABS RECORD, The Online Database For ABS Vessel Records, Lists All Vessels and Offshore Installations in Class With ABS, Including Class NotationsDocument3 pagesABS RECORD, The Online Database For ABS Vessel Records, Lists All Vessels and Offshore Installations in Class With ABS, Including Class Notationsaandueza_1No ratings yet

- Newapps HughesDocument16 pagesNewapps Hughesaandueza_1No ratings yet

- TAKR-300 USNS Bob HopeDocument2 pagesTAKR-300 USNS Bob Hopeaandueza_1No ratings yet

- GD-APS FutureWaves Oceans2016Document9 pagesGD-APS FutureWaves Oceans2016aandueza_1No ratings yet

- HILTI PROFIS Anchor Design GuideDocument362 pagesHILTI PROFIS Anchor Design Guidearun_angshu100% (2)

- NWSA Slide Deck For USNS Bob HopeDocument5 pagesNWSA Slide Deck For USNS Bob HopeWestSeattleBlogNo ratings yet

- Evaluate The Cylindrical Rubber Fender Response Under Dynamic LoadDocument5 pagesEvaluate The Cylindrical Rubber Fender Response Under Dynamic Loadaandueza_1No ratings yet

- Beginners Python Cheat Sheet PCC All PDFDocument26 pagesBeginners Python Cheat Sheet PCC All PDFName100% (1)

- Wheel Loader: Engine (Tier 4) Engine (Tier 2)Document28 pagesWheel Loader: Engine (Tier 4) Engine (Tier 2)Chenna VijayNo ratings yet

- Fender Design Test GuidelineDocument135 pagesFender Design Test GuidelineAleksa CavicNo ratings yet

- Beginners Python Cheat Sheet PCC All PDFDocument26 pagesBeginners Python Cheat Sheet PCC All PDFName100% (1)

- Pandas PDFDocument3,071 pagesPandas PDFJoemon JoseNo ratings yet

- Seismic Design of Steel Structures: Updates of Eurocode 8Document107 pagesSeismic Design of Steel Structures: Updates of Eurocode 8antonio111aNo ratings yet

- European Business in China Position Paper 2017 2018 (English Version)Document408 pagesEuropean Business in China Position Paper 2017 2018 (English Version)Prasanth RajuNo ratings yet

- L Williams ResumeDocument2 pagesL Williams Resumeapi-555629186No ratings yet

- Software Client Linux 21 01Document81 pagesSoftware Client Linux 21 01BronskyNo ratings yet

- Project Report On AdidasDocument33 pagesProject Report On Adidassanyam73% (37)

- Appliance Saver Prevents OverheatingDocument2 pagesAppliance Saver Prevents OverheatingphilipNo ratings yet

- Banu Maaruf of The LevantDocument6 pagesBanu Maaruf of The LevantMotiwala AbbasNo ratings yet

- Simulia Abaqus Standard DatasheetDocument3 pagesSimulia Abaqus Standard Datasheetuser923019231831No ratings yet

- Project Report Software and Web Development Company: WWW - Dparksolutions.inDocument12 pagesProject Report Software and Web Development Company: WWW - Dparksolutions.inRavi Kiran Rajbhure100% (1)

- Dyna 2000 LiteDocument2 pagesDyna 2000 LiteRNKNo ratings yet

- Earth Life Science Module 9 Second Quarter 1Document25 pagesEarth Life Science Module 9 Second Quarter 1Milo CatNo ratings yet

- Lateral capacity of pile in clayDocument10 pagesLateral capacity of pile in clayGeetha MaNo ratings yet

- Time Table Semester II 2019-2020Document18 pagesTime Table Semester II 2019-2020Shiv Kumar MeenaNo ratings yet

- An Overview of The FUPLA 2 Tools: Project DatabaseDocument2 pagesAn Overview of The FUPLA 2 Tools: Project DatabaseJulio Cesar Rojas SaavedraNo ratings yet

- Political Engineering and Party Politics in Conflict-Prone SocietiesDocument18 pagesPolitical Engineering and Party Politics in Conflict-Prone SocietiesNashiba Dida-AgunNo ratings yet

- Power Team PE55 ManualDocument13 pagesPower Team PE55 ManualTitanplyNo ratings yet

- SolarBright MaxBreeze Solar Roof Fan Brochure Web 1022Document4 pagesSolarBright MaxBreeze Solar Roof Fan Brochure Web 1022kewiso7811No ratings yet

- Presepsi Khalayak Terhadap Program Acara Televise Reality Show "Jika Aku Menjadi" Di Trans TVDocument128 pagesPresepsi Khalayak Terhadap Program Acara Televise Reality Show "Jika Aku Menjadi" Di Trans TVAngga DianNo ratings yet

- 8.4 Example: Swiss Market Index (SMI) : 188 8 Models of VolatilityDocument3 pages8.4 Example: Swiss Market Index (SMI) : 188 8 Models of VolatilityNickesh ShahNo ratings yet

- HHG4M - Lifespan Development Textbook Lesson 2Document95 pagesHHG4M - Lifespan Development Textbook Lesson 2Lubomira SucheckiNo ratings yet

- History and Development of the Foodservice IndustryDocument23 pagesHistory and Development of the Foodservice IndustryMaria Athenna MallariNo ratings yet

- TNTCL Cost Data 2021 22Document95 pagesTNTCL Cost Data 2021 22Akd DeshmukhNo ratings yet

- Eagle Test ReportDocument25 pagesEagle Test ReportMuhammad FahadNo ratings yet

- Indonesia Banks Bank Mandiri Trading Buy on Strong 9M21 EarningsDocument8 pagesIndonesia Banks Bank Mandiri Trading Buy on Strong 9M21 EarningsdkdehackerNo ratings yet

- Serv7107 V05N01 TXT7Document32 pagesServ7107 V05N01 TXT7azry_alqadry100% (6)

- GastrectomyDocument19 pagesGastrectomyCyrus GarciaNo ratings yet

- Second Quarterly Examination Math 9Document2 pagesSecond Quarterly Examination Math 9Mark Kiven Martinez94% (16)

- True False Survey FinalDocument2 pagesTrue False Survey Finalwayan_agustianaNo ratings yet

- Mind Map On The History of Science, Technology and SocietyDocument1 pageMind Map On The History of Science, Technology and SocietyJohn Michael Vincent CarreonNo ratings yet

- MATHEMATICAL ECONOMICSDocument54 pagesMATHEMATICAL ECONOMICSCities Normah0% (1)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- A Place of My Own: The Architecture of DaydreamsFrom EverandA Place of My Own: The Architecture of DaydreamsRating: 4 out of 5 stars4/5 (241)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionFrom EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionRating: 4.5 out of 5 stars4.5/5 (2)

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Civil Engineer's Handbook of Professional PracticeFrom EverandCivil Engineer's Handbook of Professional PracticeRating: 4.5 out of 5 stars4.5/5 (2)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- Building Construction Technology: A Useful Guide - Part 1From EverandBuilding Construction Technology: A Useful Guide - Part 1Rating: 4 out of 5 stars4/5 (3)

- Building Construction Technology: A Useful Guide - Part 2From EverandBuilding Construction Technology: A Useful Guide - Part 2Rating: 5 out of 5 stars5/5 (1)

- An Architect's Guide to Construction: Tales from the Trenches Book 1From EverandAn Architect's Guide to Construction: Tales from the Trenches Book 1No ratings yet

- The Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsFrom EverandThe Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsRating: 4.5 out of 5 stars4.5/5 (6)

- Welding for Beginners in Fabrication: The Essentials of the Welding CraftFrom EverandWelding for Beginners in Fabrication: The Essentials of the Welding CraftRating: 5 out of 5 stars5/5 (5)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- Nir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryFrom EverandNir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryRating: 4 out of 5 stars4/5 (5)

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseFrom EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseRating: 5 out of 5 stars5/5 (3)

- Practical Troubleshooting of Electrical Equipment and Control CircuitsFrom EverandPractical Troubleshooting of Electrical Equipment and Control CircuitsRating: 4 out of 5 stars4/5 (5)

- The User's Journey: Storymapping Products That People LoveFrom EverandThe User's Journey: Storymapping Products That People LoveRating: 3.5 out of 5 stars3.5/5 (8)

- Engineering Critical Assessment (ECA) for Offshore Pipeline SystemsFrom EverandEngineering Critical Assessment (ECA) for Offshore Pipeline SystemsNo ratings yet

- 507 Mechanical Movements: Mechanisms and DevicesFrom Everand507 Mechanical Movements: Mechanisms and DevicesRating: 4 out of 5 stars4/5 (28)