Professional Documents

Culture Documents

Instrumentation Project Documentation & Execution Ch.3 Documents To Be Designed Instrument Specification Sheet Instrument Specification Sheet

Uploaded by

VinitaVartak0 ratings0% found this document useful (0 votes)

14 views3 pagesOriginal Title

3.3.Spec sheet

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views3 pagesInstrumentation Project Documentation & Execution Ch.3 Documents To Be Designed Instrument Specification Sheet Instrument Specification Sheet

Uploaded by

VinitaVartakCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

Instrumentation Project Documentation & Execution

Ch.3 Documents to be designed

Instrument Specification Sheet

Instrument Specification Sheet

• Instrument Data Sheet is a document containing specification and information of an

instrument device.

• It specifies general information of instrument such as tag number identification, service

description, location (line number/equipment number), P&ID number or drawing

number reference, process data (if applicable), calibrated range (if applicable), material,

performance details (such as accuracy, linearity – if applicable), hazardous certification

(for electrical device), accessories required, etc.

• The details of information in data sheet may differ among each types of instrument such

as transmitter, switch, gauge, control valves.

References are required

• Piping and Instrumentation Diagram (P&ID)

• Heat and Material Balance (HMB)

• Line List

• Instrument Specification

• Piping Specification

• Calculation

• Vendor Catalog.

1. P&ID: - provides general information such as instrument tag number, service

description, line number/equipment number, P&ID number.

2. Process data-Following process data should be available for selection of

instrument:-

a. Fluid type

b. fluid state (gas/liquid)

c. design pressure & temperature

d. operating pressure & temperature

e. flow rate,

f. density,

g. viscosity,

h. specific gravity,

i. Ratio specific heat (gas), molecular weight (gas).

Prepared By:-Prof.Vinita Vartak 1

Instrumentation Project Documentation & Execution

Ch.3 Documents to be designed

Instrument Specification Sheet

Process Data

• However, the information of process data which is required to be specified in the data

sheet varies depends on the instrument type.

• For example, a pressure gauge data sheet does not require ratio of specific heat.

• By knowing those process data, Instrument engineer may select material of instrument,

calibrated range, body rating, etc.

• Process data can be obtained from process discipline document named “Heat and

Material Balance”.

• Other way, instrument engineer may look to the line list, also issued by process

discipline, to get general process data.

• However, compared to HMB, only limited process data is provided in line list

document.

3. Project Specification

• Company has specification which details minimum requirement for

instrumentation.

• It also provides standard that shall be applied to instrument in order to have uniform

specification for certain instrument throughout the plant.

• This is intended to minimize the spare part and tools, also to give ease of

maintenance.

4. Calculation

• Some instrument need to be calculated to have a proper size.

• This calculation is required prior data sheet preparation.

• Control valve, pressure safety valve, orifice plate, thermowell are some of

instruments which need to be calculated.

5. Vendor catalog

It is recommended to refer vendor catalog during data sheet preparation to ensure that

the device is available on the market.

Skipping this activity could result difficulties in finding the instrument on the market

during procurement phase.

If the instrument is not available on the market, it could change the design, not only the

instrument design but also could revert back up to process design.

Not only re-work, it also could result to project delay.

6. Code and Standard.

Prepared By:-Prof.Vinita Vartak 2

Instrumentation Project Documentation & Execution

Ch.3 Documents to be designed

Instrument Specification Sheet

Last but not least, cross check to the related code and standard is needed although this

issue mostly has been covered in project specification.

The purpose of instrument data sheet

• When the data sheet completed, it is attached to requisition which to be sent to several

vendors.

• Vendors will offer their quotation with various model and manufacturer among the

offers.

• It is an instrument engineer responsibility to evaluate all quotation and determine which

offer is technically acceptable.

• Having been considered its technical and commercial aspects, the instrument is

purchased.

• Following the purchase order, vendor will submit supporting document and drawing.

• Based on vendor data, instrument data sheet may be updated to accommodate details to

make the data sheet “as-built”.

• Finally, data sheet along with its supporting vendor data are stored in library or

document control and will be referred during construction, operation and maintenance.

Prepared By:-Prof.Vinita Vartak 3

You might also like

- Scope of Work For Metering SkidDocument5 pagesScope of Work For Metering SkidmusaveerNo ratings yet

- Guidelines For Vendor Documentation ReviewDocument4 pagesGuidelines For Vendor Documentation ReviewCostin GhenescuNo ratings yet

- Production Engineering: Jig and Tool DesignFrom EverandProduction Engineering: Jig and Tool DesignRating: 4 out of 5 stars4/5 (9)

- Basic Engineering PDFDocument17 pagesBasic Engineering PDFvaradarajck893No ratings yet

- Process DesignDocument2 pagesProcess DesignmuthakaniNo ratings yet

- Fourth Quarter TestDocument5 pagesFourth Quarter TestLorraine Calvez Donio100% (4)

- SNG and LPG Systems Overview - ELY EnergyDocument57 pagesSNG and LPG Systems Overview - ELY EnergyPref181186% (7)

- 2 Lesson Notes Instrument DatasheetDocument5 pages2 Lesson Notes Instrument Datasheetmubanga20000804100% (1)

- Instrumentation Project Documentation & Execution Ch.3 Documents To Be Designed Instrumentation Index Sheet Instrumentation IndexDocument2 pagesInstrumentation Project Documentation & Execution Ch.3 Documents To Be Designed Instrumentation Index Sheet Instrumentation IndexVinitaVartakNo ratings yet

- Instrumentation Work ProcedureDocument10 pagesInstrumentation Work ProcedureAbdelRhman Elfky100% (1)

- Instrument DocumentsDocument14 pagesInstrument DocumentsTrí Nguyễn100% (2)

- Plant DesignDocument53 pagesPlant DesignFaris RazalNo ratings yet

- SECTION III PAC Inst Deliverables PDFDocument22 pagesSECTION III PAC Inst Deliverables PDFRajesh BarkurNo ratings yet

- Piping EngineeringDocument15 pagesPiping EngineeringRANJITHNo ratings yet

- Specification 103 Rev. 8 - Supplier Document RequirementsDocument16 pagesSpecification 103 Rev. 8 - Supplier Document RequirementsTadaya KasaharaNo ratings yet

- Fundamentals of Chemical Engineering Process Equipment DesignDocument25 pagesFundamentals of Chemical Engineering Process Equipment DesignOmar Al-KubasiNo ratings yet

- PD233 Lecture5 DesignDocumentation PDFDocument26 pagesPD233 Lecture5 DesignDocumentation PDFvignesh kumarNo ratings yet

- Process Design Documentation From Ch29 - Mihir - S HandbookDocument14 pagesProcess Design Documentation From Ch29 - Mihir - S HandbookHa LongNo ratings yet

- Integrated Analyzer Systems and Shelters PDFDocument7 pagesIntegrated Analyzer Systems and Shelters PDFwq22030202No ratings yet

- IDocument78 pagesIrathnam.pmNo ratings yet

- Instrumentation Management, Control Valve and Orifice Plate Sizing, Instrumentation DataDocument9 pagesInstrumentation Management, Control Valve and Orifice Plate Sizing, Instrumentation Dataanon_310121872No ratings yet

- Process /project DesignDocument13 pagesProcess /project DesignCc12 22t100% (1)

- DataSheets TipsDocument3 pagesDataSheets TipsChem.Engg100% (1)

- Instrumentation Project Documentation & Execution Ch.3 Documents To Be Designed Piping & Instrumentation Diagram Process Flow DiagramDocument19 pagesInstrumentation Project Documentation & Execution Ch.3 Documents To Be Designed Piping & Instrumentation Diagram Process Flow DiagramVinitaVartakNo ratings yet

- Piping & Instrumentation DiagramDocument15 pagesPiping & Instrumentation Diagramplanet123No ratings yet

- List of Instrumentation Project Engineering DocumentsDocument19 pagesList of Instrumentation Project Engineering DocumentsVraja KisoriNo ratings yet

- EPDE - Lecture No 8Document8 pagesEPDE - Lecture No 8ZaidNo ratings yet

- Flow SheetsDocument23 pagesFlow SheetsAmmar SaeedNo ratings yet

- General Spec - Feed HeaterDocument9 pagesGeneral Spec - Feed HeaterDeepikaNo ratings yet

- Pressure and Temperature ProfileDocument3 pagesPressure and Temperature ProfileFalom BanderNo ratings yet

- Getting The Most Out of Data SheetsDocument3 pagesGetting The Most Out of Data SheetskronafNo ratings yet

- Vendor Drawing Review: Dhulipdi V - V. RamprasadDocument5 pagesVendor Drawing Review: Dhulipdi V - V. RamprasadSalmanNo ratings yet

- Senior Engineer QualificationDocument10 pagesSenior Engineer Qualificationpatrickandreas77No ratings yet

- Chapter 1Document40 pagesChapter 1Hadeer AlbalushiNo ratings yet

- Section III Pac Inst DeliverablesDocument22 pagesSection III Pac Inst DeliverablesLaurence MalanumNo ratings yet

- Datasheet GuidelinesDocument5 pagesDatasheet GuidelinesAbhay BhoirNo ratings yet

- PandID Sheets of A Process PlantDocument36 pagesPandID Sheets of A Process Plantvermaakash22No ratings yet

- Requirements For Pressure Vessel Basic Engineering DesignDocument6 pagesRequirements For Pressure Vessel Basic Engineering DesignLDM Man. e Mont. Ind. EIRELINo ratings yet

- Index of Revisions: Material RequisitionDocument23 pagesIndex of Revisions: Material RequisitionLANKAPALLISURINo ratings yet

- Instrumentation and Control (I&C) DesignDocument7 pagesInstrumentation and Control (I&C) DesignVraja KisoriNo ratings yet

- Development of The Project: - The Key Objectives For A Chemical Engg Plant ProjectDocument39 pagesDevelopment of The Project: - The Key Objectives For A Chemical Engg Plant ProjectDivyamNo ratings yet

- 02 - Annex 2b - Explanations To Form 1Document4 pages02 - Annex 2b - Explanations To Form 1Gabriel MesquitaNo ratings yet

- Supplier Document Requirements SDR GDF PDFDocument14 pagesSupplier Document Requirements SDR GDF PDFRyanNo ratings yet

- C08-016-000J-TS155 - 0 Presion DiferencialDocument11 pagesC08-016-000J-TS155 - 0 Presion DiferencialCristian RománNo ratings yet

- Piping Materials Take-Off & Processing: An OverviewDocument4 pagesPiping Materials Take-Off & Processing: An Overviewkacang meteNo ratings yet

- Unit 4 SpecificationsDocument50 pagesUnit 4 Specificationsgargie20No ratings yet

- hashtag#NCR: (4) All Inspectors Should Understand The ContractDocument6 pageshashtag#NCR: (4) All Inspectors Should Understand The ContractdileepNo ratings yet

- Piping Study Material - RoltaDocument49 pagesPiping Study Material - Roltahummingbird4u92% (12)

- TM - Assignment 9Document3 pagesTM - Assignment 9Ankit BhadesiaNo ratings yet

- Project Engineering Management - Course ContentDocument2 pagesProject Engineering Management - Course ContentWassef MBNo ratings yet

- Process AuxillariesDocument58 pagesProcess AuxillariesHarsh ParmarNo ratings yet

- PLC Interview QuestionsDocument8 pagesPLC Interview QuestionsShiva Prakasam Perneti100% (1)

- Safe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsFrom EverandSafe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsNo ratings yet

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AFrom EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANo ratings yet

- Practical Data Acquisition for Instrumentation and Control SystemsFrom EverandPractical Data Acquisition for Instrumentation and Control SystemsNo ratings yet

- Automatic Instruments and Measuring Systems: Jones' Instrument TechnologyFrom EverandAutomatic Instruments and Measuring Systems: Jones' Instrument TechnologyRating: 5 out of 5 stars5/5 (1)

- Instrumentation Project Documentation & Execution Ch.3 Documents To Be Designed Piping & Instrumentation Diagram Process Flow DiagramDocument19 pagesInstrumentation Project Documentation & Execution Ch.3 Documents To Be Designed Piping & Instrumentation Diagram Process Flow DiagramVinitaVartakNo ratings yet

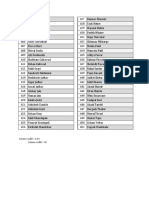

- Column Width 6.43 Column Width 36Document2 pagesColumn Width 6.43 Column Width 36VinitaVartakNo ratings yet

- 3.4.instrument Location PlanDocument20 pages3.4.instrument Location PlanVinitaVartakNo ratings yet

- CH 2Document8 pagesCH 2VinitaVartakNo ratings yet

- DFT ProblemsDocument1 pageDFT ProblemsVinitaVartakNo ratings yet

- Column Width 6.43 Column Width 36Document2 pagesColumn Width 6.43 Column Width 36VinitaVartakNo ratings yet

- # X-Axis Values # Y-Axis Values: Import AsDocument1 page# X-Axis Values # Y-Axis Values: Import AsVinitaVartakNo ratings yet

- Utom Tus 0 0: Vidyavardhini's College of Engineering and TechnologyDocument1 pageUtom Tus 0 0: Vidyavardhini's College of Engineering and TechnologyVinitaVartakNo ratings yet

- 7.traffic Light PDFDocument2 pages7.traffic Light PDFVinitaVartakNo ratings yet

- 1 PDFDocument1 page1 PDFVinitaVartakNo ratings yet

- Unit 2: What Is SCADA?Document7 pagesUnit 2: What Is SCADA?VinitaVartakNo ratings yet

- 7.traffic Light PDFDocument2 pages7.traffic Light PDFVinitaVartakNo ratings yet

- Batch 1: Subject: Industrial Automation (B. E. - Vii Sem) Assignment 1 Date: 4/08/2019Document3 pagesBatch 1: Subject: Industrial Automation (B. E. - Vii Sem) Assignment 1 Date: 4/08/2019VinitaVartakNo ratings yet

- Assignment 1-IA-2019Document1 pageAssignment 1-IA-2019VinitaVartakNo ratings yet

- 1.bioelectric PotentialDocument10 pages1.bioelectric PotentialVinitaVartakNo ratings yet

- Noc18 Ge15 Assignment1Document3 pagesNoc18 Ge15 Assignment1avinas_3marNo ratings yet

- MCQ IpdeDocument12 pagesMCQ IpdeVinitaVartak100% (1)

- You Can Download Suggested Book From: Long GDocument6 pagesYou Can Download Suggested Book From: Long GVinitaVartakNo ratings yet

- Function OutputDocument131 pagesFunction OutputVinitaVartakNo ratings yet

- Noc18 Ge15 Assignment1Document3 pagesNoc18 Ge15 Assignment1avinas_3marNo ratings yet

- Aosong Electronics Co.,LtdDocument10 pagesAosong Electronics Co.,Ltdnagagop930No ratings yet

- BMI - 15 - Imaging TechniquesDocument56 pagesBMI - 15 - Imaging TechniquesVinitaVartakNo ratings yet

- Crystallizers and Their ControlDocument34 pagesCrystallizers and Their ControlVinitaVartakNo ratings yet

- Crystallizers and Their ControlDocument34 pagesCrystallizers and Their ControlVinitaVartakNo ratings yet

- VISA LabviewDocument22 pagesVISA LabviewVinitaVartakNo ratings yet

- Scada ApplicationsDocument8 pagesScada ApplicationsVinitaVartakNo ratings yet

- Study of Gas and Study GuideDocument6 pagesStudy of Gas and Study GuideMarc OdermattNo ratings yet

- Example SheetDocument22 pagesExample SheetBikash Tamu100% (1)

- Revised and Compressed Bme 700oeDocument147 pagesRevised and Compressed Bme 700oeTERALA BHANUPRAKASHNo ratings yet

- Exercise 2 For Solution ThermodynamicsDocument4 pagesExercise 2 For Solution ThermodynamicsShane MillenaNo ratings yet

- Nr-220802-Chemical Engineering Thermodynamics - IDocument8 pagesNr-220802-Chemical Engineering Thermodynamics - ISrinivasa Rao GNo ratings yet

- Vedantu Questions Sorting Materials Into GroupsDocument6 pagesVedantu Questions Sorting Materials Into GroupsSAN AbhinavNo ratings yet

- Boiler OperationDocument17 pagesBoiler OperationhtrbiNo ratings yet

- Deaerator ConstructionDocument23 pagesDeaerator ConstructionSenthil SubramanianNo ratings yet

- IOE Model QuestionsDocument14 pagesIOE Model QuestionsLokendra JoshiNo ratings yet

- Workflow For Integrated Production Modelling of Gas Wells in The Northern Cooper BasinDocument12 pagesWorkflow For Integrated Production Modelling of Gas Wells in The Northern Cooper BasinLawNo ratings yet

- Gay Lussac Combined Avogadro Ideal Gas Law ApplicationDocument28 pagesGay Lussac Combined Avogadro Ideal Gas Law ApplicationAlexandra Venice Ann M. PerezNo ratings yet

- Che101 Exam 2a KeyDocument11 pagesChe101 Exam 2a KeyKartikeNo ratings yet

- Boltzmann ReportDocument7 pagesBoltzmann ReportmurraypurvesNo ratings yet

- Physics I Problems Proposed 2013-2014 INGDocument17 pagesPhysics I Problems Proposed 2013-2014 INGVincent VetterNo ratings yet

- 1869-Heat Considered As A Mode of Motion (Tyndall)Document558 pages1869-Heat Considered As A Mode of Motion (Tyndall)Gleison Elias SilvaNo ratings yet

- ME8391 IQ 03 - by LearnEngineering - inDocument24 pagesME8391 IQ 03 - by LearnEngineering - inelabalajiNo ratings yet

- Physics 28th June Shift-2Document20 pagesPhysics 28th June Shift-2Suman KumariNo ratings yet

- APG-710-H2 Hydrogen Analysis Module: AppliedDocument2 pagesAPG-710-H2 Hydrogen Analysis Module: AppliedCarlos MarquezNo ratings yet

- Statistical Physics (Lectures) 2Document94 pagesStatistical Physics (Lectures) 2Essam Radwan BerikaaNo ratings yet

- Union PDFDocument2 pagesUnion PDFsv32611No ratings yet

- Astm G 125 - 00Document9 pagesAstm G 125 - 00Ivan AlanizNo ratings yet

- Tifr 2015Document20 pagesTifr 2015chanchalNo ratings yet

- Aspen Hydraulics Dynamics ReferenceDocument44 pagesAspen Hydraulics Dynamics ReferenceABULARA2K6100% (1)

- Grade 3 ScienceDocument40 pagesGrade 3 ScienceLovely CarbonelNo ratings yet

- FIITJEE - (JEE-Advanced) : Physics, Chemistry & MathematicsDocument13 pagesFIITJEE - (JEE-Advanced) : Physics, Chemistry & MathematicsHarshit SharmaNo ratings yet

- 18-06-2022 JR - Super60 (Incoming) Jee Mains WTM-04 Q.papeRDocument12 pages18-06-2022 JR - Super60 (Incoming) Jee Mains WTM-04 Q.papeRVishal MNo ratings yet

- R2B-P3-206-02-P-HD-00001 - Rev.1 - Datasheets For GC Analyzer U-21000 - EngDocument6 pagesR2B-P3-206-02-P-HD-00001 - Rev.1 - Datasheets For GC Analyzer U-21000 - EngDiana Paula Echartea MolinaNo ratings yet

- NTPC SyllabusDocument3 pagesNTPC SyllabusVimleshKumarSharma100% (1)