Professional Documents

Culture Documents

INTEGRATED Automobile Mechanic

Uploaded by

Saeed AhmedCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

INTEGRATED Automobile Mechanic

Uploaded by

Saeed AhmedCopyright:

Available Formats

A SS E S SM E NT

MAT E RI AL

EVIDENCE

GUIDE

Qualification

Automobile Mechanics

AUTOMOBILE MECHANICS

CS Code:

Level: 2

Credit: 80

Version: 1

CONTENTS 1. Assessment Summary and Record

2. Candidate Assessment

3. Assessor Judgment Guide

4. List of required tools/equipment, material and context of assessment

ASSESSMENT AND Competent Not Yet Competent

ASSESSOR

DETAILS

Assessment Re-Assessment

Assessor’s Name Assessor’s Code

Assessor’s Signature Date

DD MM YYYY

CANDIDATE Candidate’s Name

DETAILS F i r s t N am e L a s t N am e

Father’s Name

Institute Name and District

CNIC/BFORM #

Registration Number issued by

Assessment Body

Gender Male Female Transgender

Candidate's Consent I agree to the time and date of the assessment and am aware of the requirements

of the assessment. I fully understand my rights of appeal.

Candidate’s Signature

ASSESSMENT

You can use this coversheet as an Assessment Results Summary Form. Simply post a photocopy of this completed

RESULTS coversheet to NAVTTC

SUMMARY FORM

NAVTTC OFFICE

1. DATE 2. DATE E NTERE D INTO

ONLY FORM DATABASE:

RECEIVED: DD MM YYYY DD MM YYYY

Integrated_Automobile Mechanics © NAVTTC February 2016 Page 1 of 11

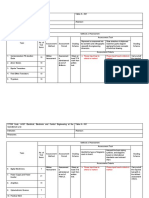

1 ASSESSMENT SUMMARY & RECORD

ACTIVITY METHOD DESIRED OUTCOMES RESULT

OBSERVATION

COMPETENT

COMPETENT

PORTFOLIO

NATURE OF DESIRED OUTCOMES FOR SUCCESSFUL ASSESSMENT OF

WRITTEN

NOT YET

ACTIVITY COMPETENCY STANDARD: AUTOMOBILE MECHANICS

ORAL

Maintain Brake System of the vehicle

Maintain Engine of the vehicle

Practical Skill Maintain fuel system of the vehicle

Demonstration Perform ignition system service of the vehicle

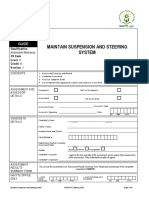

Maintain suspension/steering systems of the vehicle

Maintain drive line systems of the vehicle

Answer all questions your Assessor may have during the

Knowledge

Assessment practical assessment.

Provide a verified evidence of the competency of

performing service & diagnosis of Anti-lock Brake System

(ABS)

Provide verified evidence of the competency of replacing

Other

Requirements

Ignition Switch, Ignition Coil & Battery

Provide verified evidence of the competency of repairing

and maintenance of Steering & Suspension System

Provide verified evidence of the competency of performing

service of Automatic Transmission

Integrated_Automobile Mechanics © NAVTTC February 2016 Page 2 of 11

2 CANDIDATE ASSESSMENT

Candidate's Name………………………………………………..... Father’s Name …………………………………………………………………..

ALL WORK ASSESSED IN THIS COMPETENCY STANDARD MUST BE YOUR OWN WORK.

GUIDANCE TO CANDIDATE

To meet this standard you are required to complete the following tasks within 05 hours timeframe:

Complete the following task:

Perform brake service of the vehicle as per vehicle’s manual

Complete any one task (given by the assessor) from the following tasks.

Perform engine services of the vehicle as per vehicle’s manual

Diagnose the faults of cylinder head and cylinder block components as per vehicle’s manual

Complete the following task:

Diagnose faults of the vehicle’s fuel system and perform its services as per vehicle’s manual

Complete any one task (given by the assessor) from the following tasks.

Service the vehicle’s spark plugs as per vehicle’s manual

Service the vehicle’s distributer as per vehicle’s manual

Complete the following tasks:

Service the vehicle’s emission control system as per vehicle’s manual

Perform services of manual drive line system of the vehicle as per vehicle’s manual

ACTIVITIES CANDIDATE RESPONSE

1. Complete During a practical assessment, under observation by an assessor, I will correctly :

practical task

of Automobile Perform brake service of the vehicle as per vehicle’s manual

Mechanics Diagnose the faults in the brake system through Brake Tester

under Dismantle the disc pads, brake shoes, brake master cylinder and wheel cylinder of the brake system

observation by Replace/Rebuild disc pads, brake shoes, master cylinder and wheel cylinder washer of the brake

an assessor system

Adjust brake shoes of the vehicle with the help of adjuster screw

Perform air bleeding/removing of the brake system

Adjust the parking/hand brake system

Conduct the road test to verify function of the vehicle brake after the brake service

Perform engine services of the vehicle as per vehicle’s manual

Diagnose the faults in the engine for abnormal noise by using Stethoscope, oil leakages and over

heating & water leakages by using Radiator Pressure Tester

Conduct inlet manifold vacuum test by using Vacuum gauge

Adjust the valve clearance of the engine with feeler gauge

Replace Tappet Cover & intake manifold gasket from cylinder head

Clean the spark plug of the ignition system with spark plug cleaner

Re-adjust the Spark Plug Electrode Gap by using feeler gauge

Change the timing oil seals of the engine

Change the radiator coolant

Adjust tension of the radiator fan belt

Replace oil pan gasket of the vehicle

Change oil filter and engine oil of the vehicle

Diagnose the faults of cylinder head and cylinder block components as per vehicle’s manual

Conduct the engine cylinder compression test with compression tester to check the engine

compression

Scan the Electronic Fuel Injection (EFI) system with the help of Universal Diagnostic Scanner (UDS)

Clean defective sensors of engine with de-carbonizing agent (WD40 etc.

Replace the crank shaft position sensor of the engine

Diagnose faults of the vehicle’s fuel system and perform its services as per vehicle’s manual

Diagnose the fuel system with the help of Universal Diagnostic Scanner (UDS)

Integrated_Automobile Mechanics © NAVTTC February 2016 Page 3 of 11

Clean and test the fuel injectors with the help of injector cleaner and tester

Perform the services of Throttle Body, Idle Air Control Valve (IACV) and Throttle Position (TP)

sensor with the help of De-carbonizing Agent (WD-40 etc.)

Replace the fuel filter of the fuel system

Replace the air filter of air cleaner assembly

Clean the oxygen (O2) sensor, Manifold Absolute Pressure (MAP) sensor and intake air temperature

sensor with the help of De-carbonizing Agent (WD-40 etc.)

Replace the Coolant Temperature sensor of the engine

Refresh Fuel System with the help of Universal Diagnostic Scanner (UDS)

Conduct a road test to verify the function of vehicle’s fuel system

Service the vehicle’s spark plugs as per vehicle’s manual

Remove the spark plug wires/leads from the engine

Check the connectivity of spark plug wires/leads with the help of multi meter

Clean the spark plugs with spark plug cleaner

Adjust the spark plugs’ gap with feeler gauge

Test for spark plugs’ sparking with spark plug tester

Refit spark plug wires/leads according to firing order

Service the vehicle’s distributer as per vehicle’s manual

Remove the distributer cap from the distributer

Remove and clean Contact Breaker (CB) point of the distributer

Refit Contact Breaker (CB) point and adjust its gap with feeler gauge

Refit distributer cap and adjust the dwell angle for ignition timing with Ignition Timing Light Gun

Conduct road test to verify the function of ignition system

Service the vehicle’s emission control system as per vehicle’s manual

Remove, clean, test and refit the Positive Crankcase Ventilation (PCV) valve of the engine

Remove, clean and refit the Exhaust Gas Recirculation (EGR) valve of the engine

Remove, clean and refit the oxygen (O2) sensor from the exhaust manifold

Analyse exhaust gas of exhaust system with Exhaust Gas Analyser/CO Tester as per National

Environmental Quality (NEQ) standards

Conduct a road test to verify the function of emission control system

Perform services of manual drive line system of the vehicle as per vehicle’s manual

Check the manual drive line system of the vehicle through road test

Remove the faulty clutch set (clutch plate, pressure plate, clutch release bearing) from the fly wheel

Replace the clutch set (clutch plate, pressure plate, clutch release bearing) and adjust the clutch

system

Replace the leaked differential seal

Grease the universal joints of drive shaft

Replace the damaged gear lever bushes

Change the gear oil and differential oil of the vehicle

Conduct a road test to verify the function of manual drive line system

2. Other Provide a verified evidence of the competency of performing service & diagnosis of Anti-lock Brake

requirements System (ABS)

Provide verified evidence of the competency of replacing Ignition Switch, Ignition Coil & Battery

Provide verified evidence of the competency of repairing and maintenance of Steering & Suspension

System

Provide verified evidence of the competency of performing service of Automatic Transmission

3. Answer any My answers to questions are correct and demonstrate my understanding of the topics and their application.

questions your

assessor may

have during

the practical

assessment

Integrated_Automobile Mechanics © NAVTTC February 2016 Page 4 of 11

3 ASSESSOR JUDGEMENT GUIDE

Candidate’s Name …………………………………………………. Father’s Name.……………………………………………………..

INSTRUCTIONS

This section contains minimum evidence requirements. Oral questioning may be used to clarify

FOR candidate understanding of the topic and its application .

ASSESSOR

ASSESSOR

ACTIVITIES MINIMUM EVIDENCE REQUIRED YES NO

COMMENTS

1. Complete During a practical assessment, under observation by an assessor,

practical tasks of the candidate correctly carried out the following tasks:

Automobile

Mechanics under

observation by an

assessor

Perform brake Diagnosed the faults in the brake system through Brake Tester

service of the vehicle

as per vehicle’s Dismantled the disc pads, brake shoes, brake master cylinder and

manual wheel cylinder of the brake system

Replaced/Rebuilded disc pads, brake shoes, master cylinder and

wheel cylinder washer of the brake system

Adjusted brake shoes of the vehicle with the help of adjuster

screw

Performed air bleeding/removing of the brake system

Adjusted the parking/hand brake system

Conducted the road test to verify function of the vehicle brake

after the brake service

Perform engine Diagnosed the faults in the engine for abnormal noise by using

services of the Stethoscope, oil leakages and over heating & water leakages by

vehicle as per using Radiator Pressure Tester

vehicle’s manual

Conducted inlet manifold vacuum test by using Vacuum gauge

Adjusted the valve clearance of the engine with feeler gauge

Replaced Tappet Cover & intake manifold gasket from cylinder

head

Cleaned the spark plug of the ignition system with spark plug

cleaner

Re-adjusted the Spark Plug Electrode Gap by using feeler gauge

Changed the timing oil seals of the engine

Changed the radiator coolant

Adjusted tension of the radiator fan belt

Replaced oil pan gasket of the vehicle

Changed oil filter and engine oil of the vehicle

Diagnose the faults of Conducted the engine cylinder compression test with compression

cylinder head and tester to check the engine compression

cylinder block Scanned the Electronic Fuel Injection (EFI) system with the help

components as per of Universal Diagnostic Scanner (UDS)

vehicle’s manual Cleaned defective sensors of engine with de-carbonizing agent

(WD40 etc.)

Integrated_Automobile Mechanics © NAVTTC February 2016 Page 5 of 11

Replaced the crank shaft position sensor of the engine

Diagnose faults of the Diagnosed the fuel system with the help of Universal Diagnostic

vehicle’s fuel system Scanner (UDS)

and perform its Cleaned and tested the fuel injectors with the help of injector

services as per cleaner and tester

vehicle’s manual Performed the services of Throttle Body, Idle Air Control Valve

(IACV) and Throttle Position (TP) sensor with the help of De-

carbonizing Agent (WD-40 etc.)

Replaced the fuel filter of the fuel system

Replaced the air filter of air cleaner assembly

Cleaned the oxygen (O2) sensor, Manifold Absolute Pressure

(MAP) sensor and intake air temperature sensor with the help of

De-carbonizing Agent (WD-40 etc.)

Replaced the Coolant Temperature sensor of the engine

Refreshed Fuel System with the help of Universal Diagnostic

Scanner (UDS)

Conducted a road test to verify the function of vehicle’s fuel

system

Service the vehicle’s Removed the spark plug wires/leads from the engine

spark plugs as per

vehicle’s manual Checked the connectivity of spark plug wires/leads with the help of

multi meter

Cleaned the spark plugs with spark plug cleaner

Adjusted the spark plugs’ gap with feeler gauge

Tested for spark plugs’ sparking with spark plug tester

Refitted spark plug wires/leads according to firing order

Service the vehicle’s Removed the distributer cap from the distributer

distributor as per

vehicle’s manual Removed and clean Contact Breaker (CB) point of the distributer

Refitted Contact Breaker (CB) point and adjust its gap with feeler

gauge

Refitted distributer cap and adjust the dwell angle for ignition

timing with Ignition Timing Light Gun

Conducted road test to verify the function of ignition

Service the vehicle’s Removed, cleaned, tested and refitted the Positive Crankcase

emission control Ventilation (PCV) valve of the engine

system as per Removed, cleaned and refitted the Exhaust Gas Recirculation

vehicle’s manual (EGR) valve of the engine

Removed, cleaned and refitted the oxygen (O2) sensor from the

exhaust manifold

Analysed exhaust gas of exhaust system with Exhaust Gas

Analyser/CO Tester as per National Environmental Quality (NEQ)

standards

Conducted a road test to verify the function of emission control

system

Perform services of Checked the manual drive line system of the vehicle through road

manual drive line test

system of the vehicle Removed the faulty clutch set (clutch plate, pressure plate, clutch

as per vehicle’s release bearing) from the fly wheel

manual Replaced the clutch set (clutch plate, pressure plate, clutch

release bearing) and adjust the clutch system

Replaced the leaked differential seal

Greased of Universal Joints of Drive Shaft

Integrated_Automobile Mechanics © NAVTTC February 2016 Page 6 of 11

Replaced the damaged gear lever bushes

Changed the gear oil and differential oil of the vehicle

Conducted a road test to verify the function of manual drive line

system

2. Other Provided a verified evidence of the competency of performing

requirements service & diagnosis of Anti-lock Brake System (ABS)

Provided verified evidence of the competency of replacing Ignition

Switch, Ignition Coil & Battery

Provided verified evidence of the competency of repairing and

maintenance of Steering & Suspension System

Provided verified evidence of the competency of performing

service of Automatic Transmission

Integrated_Automobile Mechanics © NAVTTC February 2016 Page 7 of 11

3. Answer any Candidate’s answers to questions are correct and demonstrate

questions the understanding of the topics and their application.

assessor may have

during the practical Assessor to document below all questions asked and candidate

assessment answers. Use extra sheets if required and attach.

Integrated_Automobile Mechanics © NAVTTC February 2016 Page 8 of 11

LIST OF TOOLS, EQUIPMENT, MATERIAL AND

4 CONTEXT OF ASSESSMENT

This section contains information regarding;

INSTRUCTIONS Context of the assessment

List of required tools and equipment.

List of consumable items required during the service

1. Context of

Assessment This task will be performed in real time/simulated environment.

2. List of tools and equipment required (for five candidates)

S. No Items Quantity

1 Allen key set 05

2 Ball joint opener 05

3 Battery load tester 05

4 Bench Vice 05

5 Brake Tester 05

6 Car Creeper 05

7 Car Lift 05

8 Car Service Creeper 05

9 Circlip plier inside 05

10 Circlip plier out side 05

11 Combination plier 05

12 Compression Gauge 05

13 Exhaust gas analyser 05

14 Feeler gauge 05

15 Fender Cover Set 05

16 Garage Jacks 05

17 Grease Gun 05

18 General tools kit

19 Hammers 05

20 Hydro meter 05

21 Ignition Timing Light Gun 05

22 Injector Cleaner & Tester 05

23 Jack stand 20

24 Magnetic stick 05

25 Mechanical Jack (Scissor type) 05

26 Multi meter 05

27 Nose plier 05

28 Oil Drainer 05

29 Oil Gun 05

30 Oil Pressure Gauge 05

31 Personal Protective Equipment Set (PPEs) 05

32 Plier Set 05

33 Radiator Pressure Tester 05

34 Repair manual 05

35 Safety Stands 20

36 Screw driver Flat & Philip set 05

37 Screw Driver Set 05

Integrated_Automobile Mechanics © NAVTTC February 2016 Page 9 of 11

38 Seat Cover Set 05

38 Socket Set 05

39 Soldering iron 05

40 Spanners Set 05

41 Spark plug cleaner & tester 05

42 SST Kit 05

43 Star key set 05

44 Test lamp 05

45 Torque Wrench 05

46 Universal Diagnostic Scanner (UDS) 05

47 Universal Puller set 05

47 Vacuum Gauge 05

47 Vehicle 05

49 Wheel spanner 05

3. List of consumable items required (for five candidates)

S. No Items Quantity

1 Air Filter 05

2 Automatic Transmission Oil 10 L

3 Big End Bearings Set 05

4 Brake Master Cylinder Repair Kit 05

5 Break Oil 10

6 Break Shoes 05 Set

7 Clutch Plate 05

8 Clutch Release Bearing 05

9 Coolant Temperature Sensor 05

10 Cotton gloves 12

11 Cotton waste 05 Kg

12 De-carbonizing Agent (WD-40 etc.) 05

13 Differential oil 10 L

14 Differential Seal 05

15 Disc Pads 05 Set

16 Electrolyte 05 L

17 Emery Papers 20

18 Engine Oil 20 L

19 Front and back shock absorber mountings 5 set

20 Fuel Filter 05

21 Gear Oil 10 L

22 Grease 01 Kg

23 Injector Seals Set 05

24 Leaf Spring Bushes 5 set

25 Leaked hub seals 5 set

26 Lower and upper suspension arms bushes 5 set

27 Main Bearings Set 05

28 Neutral Switch 05

29 Oil Filter 05

30 Personal Protective Equipment Set (PPEs) 05

31 Petrol for cleaning & testing 20 L

32 Piston Rings Set 05

33 Pressure Plate 05

34 Soldering coil 05 coil

35 Soldering paste 05 packet

36 Sway/stabilizer bar bushes 5 set

Integrated_Automobile Mechanics © NAVTTC February 2016 Page 10 of 11

37 Timing Seals 05

38 Valve Inlet Exhaust Set 05

39 Waste Cotton 05 Kg

40 Wheel Cylinder Washer Set 05

Integrated_Automobile Mechanics © NAVTTC February 2016 Page 11 of 11

You might also like

- Automobile Mechanic-Module 7Document6 pagesAutomobile Mechanic-Module 7hamayunNo ratings yet

- Automobile Mechanic-Module 3Document6 pagesAutomobile Mechanic-Module 3hamayunNo ratings yet

- Automobile Mechanic-Module 4Document6 pagesAutomobile Mechanic-Module 4hamayunNo ratings yet

- Automobile Mechanic-Module 5Document6 pagesAutomobile Mechanic-Module 5hamayunNo ratings yet

- Perform Preventive Maintenance: Evidence GuideDocument6 pagesPerform Preventive Maintenance: Evidence GuidehamayunNo ratings yet

- General Electrician: Evidence GuideDocument10 pagesGeneral Electrician: Evidence GuideHamid UllahNo ratings yet

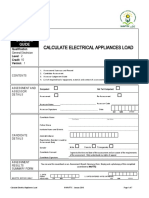

- Calculate Electrical Appliances Load: Evidence GuideDocument7 pagesCalculate Electrical Appliances Load: Evidence GuideHamid UllahNo ratings yet

- Autocad: Evidence GuideDocument9 pagesAutocad: Evidence GuideSALMANNo ratings yet

- Perform Styling Techniques: Evidence GuideDocument7 pagesPerform Styling Techniques: Evidence GuideShahid HanifNo ratings yet

- Manage Information SystemDocument8 pagesManage Information Systemkifayat raufNo ratings yet

- Agriculture Farm Supervisor-Module 1Document6 pagesAgriculture Farm Supervisor-Module 1Virtual BrainsNo ratings yet

- 4-Perform Facials PDFDocument7 pages4-Perform Facials PDFSaif ur RehmanNo ratings yet

- Install Electrical Cables and Wires: Evidence GuideDocument8 pagesInstall Electrical Cables and Wires: Evidence GuideHamid UllahNo ratings yet

- 10-Customise Rendering, Materials and LightsDocument7 pages10-Customise Rendering, Materials and LightsSALMANNo ratings yet

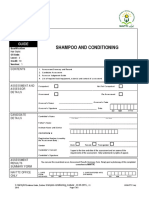

- Shampoo and Conditioning: Evidence GuideDocument5 pagesShampoo and Conditioning: Evidence GuideShahid HanifNo ratings yet

- Modify Solid Faces: Evidence GuideDocument8 pagesModify Solid Faces: Evidence GuideSALMANNo ratings yet

- 9-Navigate Sections and Merge Flat Objects From 3D ModelDocument7 pages9-Navigate Sections and Merge Flat Objects From 3D ModelSALMANNo ratings yet

- 1-Maintain Computer SystemDocument7 pages1-Maintain Computer Systemisrar ahmedNo ratings yet

- Kunstocom India Pvt. LTD.: Format No: Issue No./Date: Qav-Check Sheet Rev - No/Rev. Date: Control Item Check ItemsDocument2 pagesKunstocom India Pvt. LTD.: Format No: Issue No./Date: Qav-Check Sheet Rev - No/Rev. Date: Control Item Check ItemsSandeep VermaNo ratings yet

- Create 3D Interface Drawings: Evidence GuideDocument8 pagesCreate 3D Interface Drawings: Evidence GuideAmeerBrothersNo ratings yet

- Evidence Plan: Competency Standard: Unit of Competency: Ways in Which Evidence Will Be CollectedDocument2 pagesEvidence Plan: Competency Standard: Unit of Competency: Ways in Which Evidence Will Be Collectedhussain DiamlaNo ratings yet

- Evidence Plan: Competency Standard: Unit of Competency: Ways in Which Evidence Will Be CollectedDocument2 pagesEvidence Plan: Competency Standard: Unit of Competency: Ways in Which Evidence Will Be Collectedhussain DiamlaNo ratings yet

- Perform Autocad 2D Fundamentals: Evidence GuideDocument7 pagesPerform Autocad 2D Fundamentals: Evidence GuideEngr Nissar KakarNo ratings yet

- CARSDocument1 pageCARSeunicepucannNo ratings yet

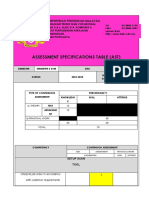

- Assessment Specifications Table (Ast) : Kementerian Pendidikan MalaysiaDocument6 pagesAssessment Specifications Table (Ast) : Kementerian Pendidikan MalaysiaMohd raziffNo ratings yet

- BARDocument2 pagesBARShallimar AlcarionNo ratings yet

- P1-PPsp - TSMDocument7 pagesP1-PPsp - TSMmariah09071964No ratings yet

- Cca PropsDocument8 pagesCca PropsJenni JopiaNo ratings yet

- Sample Rating Sheet With CarsDocument4 pagesSample Rating Sheet With CarsVei Poblete Toledo-Tiongco100% (1)

- SAG - Automotive Servicing NC IDocument3 pagesSAG - Automotive Servicing NC IOne And All Tech SchoolNo ratings yet

- 23 Evaluation Checklist For Accreditation of AC For RatingsDocument17 pages23 Evaluation Checklist For Accreditation of AC For RatingsAura Jane LacuestaNo ratings yet

- Ast Mta 2013 LatestDocument2 pagesAst Mta 2013 LatestFord KatimNo ratings yet

- Vehicle Wheel ServiceDocument12 pagesVehicle Wheel ServiceNadhirah JohaNo ratings yet

- Earth Moving Equipment Safety TestDocument2 pagesEarth Moving Equipment Safety TestSHARAFUDHEEN TKNo ratings yet

- 6 - Testing & Commissioning Data - ItpDocument10 pages6 - Testing & Commissioning Data - ItpzainahmedscribdNo ratings yet

- Rating Sheet FinalDocument7 pagesRating Sheet FinalJazelle FacunNo ratings yet

- Raw Material Inspection Report SummaryDocument1 pageRaw Material Inspection Report SummaryAvinash MulikNo ratings yet

- CARSDocument1 pageCARSJohn Mike DolotNo ratings yet

- Cars MasonryDocument1 pageCars MasonryAbdullah MundasNo ratings yet

- Develop Solids: Evidence GuideDocument7 pagesDevelop Solids: Evidence GuideAmeerBrothersNo ratings yet

- Engine Management SystemDocument15 pagesEngine Management Systemzul khairiNo ratings yet

- STCW A-III/1 Electrical Assessment PlanDocument9 pagesSTCW A-III/1 Electrical Assessment Planneo mialaNo ratings yet

- QCR W 2012Document2 pagesQCR W 2012Madhan KannanNo ratings yet

- Capability Assessment Info SheetDocument4 pagesCapability Assessment Info SheetIsmail SultanNo ratings yet

- 21 - Flow Chart For IQA Rev1Document1 page21 - Flow Chart For IQA Rev1Prasanta ParidaNo ratings yet

- Action Form Mechanic CertificationDocument1 pageAction Form Mechanic CertificationÖmer TAŞNo ratings yet

- Competency Assessment Results Summary (CARS) - TESDA copy-FINALDocument1 pageCompetency Assessment Results Summary (CARS) - TESDA copy-FINALSalbina Enlacinto100% (1)

- QEMS Management Review MeetingDocument3 pagesQEMS Management Review MeetingSusana MonsivaisNo ratings yet

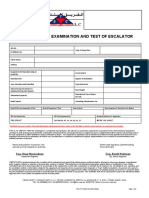

- EscalatorDocument2 pagesEscalatorSHARAFUDHEEN TKNo ratings yet

- CARS RevisedDocument2 pagesCARS RevisedReema Papaki BarahimNo ratings yet

- ESCALATOR-Bk Gulf OnlyDocument3 pagesESCALATOR-Bk Gulf OnlySHARAFUDHEEN TKNo ratings yet

- Competency Assessment Dummmy DocsdocxDocument7 pagesCompetency Assessment Dummmy DocsdocxGale ViernesNo ratings yet

- Etihad Towers Project: Inspection & Test Plan - Cast in Situ Reinforced Concrete WorksDocument8 pagesEtihad Towers Project: Inspection & Test Plan - Cast in Situ Reinforced Concrete WorksjiniNo ratings yet

- 2.7 CarsDocument1 page2.7 CarsMark Anthony AltilleroNo ratings yet

- 10.06.2020 Ims Awareness Training - S-IV-VDocument31 pages10.06.2020 Ims Awareness Training - S-IV-Vyousufali56No ratings yet

- CarsDocument1 pageCarsJDNo ratings yet

- Qms Interaction ChartDocument1 pageQms Interaction Chartpnagarajj0% (1)

- SNI ISO 37001 Certification in Indonesia - Kukuh S Achmad PDFDocument21 pagesSNI ISO 37001 Certification in Indonesia - Kukuh S Achmad PDFdewangga04radenNo ratings yet

- Automotive ServicingDocument24 pagesAutomotive ServicingARIEL STO. TOMASNo ratings yet

- Silicone Heating Cable Type SK Up To 145°CDocument2 pagesSilicone Heating Cable Type SK Up To 145°CSaeed AhmedNo ratings yet

- BOP Application Form A5 Flyer (16th October) Final PagesDocument10 pagesBOP Application Form A5 Flyer (16th October) Final PagesAli Azhar KhanNo ratings yet

- NC - CNC NotesDocument7 pagesNC - CNC NotesAmandeep SinghNo ratings yet

- NC - CNC NotesDocument7 pagesNC - CNC NotesAmandeep SinghNo ratings yet

- Table 2-1 N M KGF M: 2 Inspection Data and Maintenance Period 2.1Document5 pagesTable 2-1 N M KGF M: 2 Inspection Data and Maintenance Period 2.1Gabriel BalcazarNo ratings yet

- Mazda 8 MPV LY3P - Workshop ManualDocument1,923 pagesMazda 8 MPV LY3P - Workshop ManualRoman88% (8)

- Training Book - 950 LoadersDocument248 pagesTraining Book - 950 LoadersSandeep Nikhil100% (3)

- DIXON, J. C. (1996) - Tires, Suspension and HandlingDocument13 pagesDIXON, J. C. (1996) - Tires, Suspension and HandlingAlef GoncalvesNo ratings yet

- Test CDocument14 pagesTest Cmanelisir60% (20)

- Description and Operation: Engine - 2.5L Duratec-ST (VI5) - EngineDocument13 pagesDescription and Operation: Engine - 2.5L Duratec-ST (VI5) - EngineAlejandro BrionesNo ratings yet

- John Deere Valve AdjustmentDocument13 pagesJohn Deere Valve AdjustmentautobritaiNo ratings yet

- Transmission Interchange Section Header Descriptions: Reman Unit Part Number With Integral Oil PumpDocument2 pagesTransmission Interchange Section Header Descriptions: Reman Unit Part Number With Integral Oil PumpPototoNo ratings yet

- 242 - 244 - 245 - 1977 VolvoDocument105 pages242 - 244 - 245 - 1977 VolvokochavNo ratings yet

- Tech Information Basic Weber TuningDocument6 pagesTech Information Basic Weber TuningYacullsNo ratings yet

- Maintenance Manual For Sulzer Diesel Engines Rta76!51!58Document8 pagesMaintenance Manual For Sulzer Diesel Engines Rta76!51!58Tech BastilashipNo ratings yet

- ENG 046 CVVT OCV InspectionDocument5 pagesENG 046 CVVT OCV Inspectionpacosworld100% (1)

- Serstar - The Mobile Flash Butt Welding System: Welding and Destressing As A Continuous ProcessDocument10 pagesSerstar - The Mobile Flash Butt Welding System: Welding and Destressing As A Continuous Processbalaji817150No ratings yet

- ARDOT ROUNDABOUT DESIGN CHECKLISTDocument2 pagesARDOT ROUNDABOUT DESIGN CHECKLISTJames trippNo ratings yet

- Instructions For Parts Books: Note About Country CodesDocument160 pagesInstructions For Parts Books: Note About Country CodesEros Andres Hurtado ZuñigaNo ratings yet

- Despiece Enduro 2t 125 2015 v09r1Document102 pagesDespiece Enduro 2t 125 2015 v09r1Claudiu MorarNo ratings yet

- Report of The Industrial Visit To HondaDocument5 pagesReport of The Industrial Visit To HondaNakul Parameswar0% (1)

- 2011 Audi Q7: Quick Reference GuideDocument16 pages2011 Audi Q7: Quick Reference GuideYewZhiYongNo ratings yet

- Illinois Driving Test Questions and Answers SampleDocument8 pagesIllinois Driving Test Questions and Answers SampleVicky Singh100% (1)

- AFCONS Infrastructure Culvert and Bridge Location DetailsDocument6 pagesAFCONS Infrastructure Culvert and Bridge Location DetailsSANDEEP DANGDANo ratings yet

- Gts 250Document217 pagesGts 250Eduardo M. R. SousaNo ratings yet

- Grade Trimmer AdvantagesDocument32 pagesGrade Trimmer Advantagesxianqianhui100% (1)

- Workshop Manual Audi A6 C6Document198 pagesWorkshop Manual Audi A6 C6Alvaro Abajo100% (1)

- Pontiac Engine Code Guide for 389 and 421 CID EnginesDocument54 pagesPontiac Engine Code Guide for 389 and 421 CID EnginesPericoi100% (1)

- DAEWOO Ultra Novus Fault Codes EngDocument24 pagesDAEWOO Ultra Novus Fault Codes EngAli SoykanNo ratings yet

- Air Traffic Control SystemDocument20 pagesAir Traffic Control SystemTarun singhNo ratings yet

- Implementing a No Private Transport Policy in ManilaDocument1 pageImplementing a No Private Transport Policy in ManilaJeziel ManseguiaoNo ratings yet

- Cayenne - CatalogueDocument81 pagesCayenne - CatalogueAdrian CantaragiuNo ratings yet

- Front Axle: SectionDocument18 pagesFront Axle: SectionAldo LlerenaNo ratings yet

- 706 15 PDFDocument25 pages706 15 PDFHelloNo ratings yet