Professional Documents

Culture Documents

Fuel system with EDC MS6 and unit injector PDE function description

Uploaded by

Musharraf KhanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fuel system with EDC MS6 and unit injector PDE function description

Uploaded by

Musharraf KhanCopyright:

Available Formats

03:04-02

Issue 3 en

Fuel system with unit injector PDE

and EDC MS6

Function description

cardiagn.com

EDC

EDC

115 762

ã Scania CV AB 2002, Sweden

1 710 249

Contents

Contents

Important .................................................................................. 3

General .................................................................................. 4

Fuel path ................................................................... 5

Fuel quantity and injection timing............................ 7

Components in the fuel system Feed pump ................................................................ 8

Hand pump ............................................................... 8

Location diagrams .................................................... 9

Control unit cooler.................................................. 10

Fuel manifold ......................................................... 10

Overflow valve ....................................................... 10

Unit injector............................................................ 11

Fuel filter ................................................................ 17

EDC

cardiagn.com

General ................................................................... 18

Components on the engine ..................................... 21

Components in the driver area................................ 37

Type of regulator .................................................... 48

Warning system ...................................................... 49

Interaction with other systems................................ 53

2 ã Scania CV AB 2002, Sweden 03:04-02

Important

Important

The safety precautions and warnings in the work

description must be read thoroughly before any

work is carried out.

Using only the function description as a basis

for the work is not permitted.

cardiagn.com

03:04-02 ã Scania CV AB 2002, Sweden 3

General

General

A fuel system with EDC, Electronic Diesel

Control, and unit injectors PDE, Pumpe- Düse-

Einheit, consists – besides the fuel lines and a

fuel tank – of the following parts.

1 A feed pump

2 A hand pump

3 An electronic control unit and a control unit 7

cooler

4 A fuel filter

3

5 One or two fuel manifolds. 6 cylinder

engines have one fuel manifold, 8 cylinder 6

cardiagn.com

engines have two. 5

4 2

6 An overflow valve 1

7 One unit injector, of type PDE, per cylinder

115 849

The fuel system also includes an electronic

control system. The control system consists of –

besides the control unit – the unit injector 11 and 12 litre engines

solenoid valves, sensors and other control units,

among other things. More information about the

electronic control system can be found in the

section EDC.

7

5

4

6

115 959

2 1

16 litre engine

4 ã Scania CV AB 2002, Sweden 03:04-02

Fuel path

Fuel path

The feed pump 1 draws in fuel from the fuel

tank and presses it through the control unit 7

cooler 3, the fuel filter 4 and into the fuel 5

6 3

manifold 5, 16 litre engines have two fuel

manifolds. 2

4

A hand pump 2 is located on the feed pump. The

hand pump is used when bleeding the fuel 1

system.

The fuel manifold is fitted with an overflow

valve 6. The overflow valve controls the fuel

pressure at all times. When the pressure is too

116 246

high, the overflow valve opens so that the

surplus fuel drains back to the fuel tank.

11 and 12 litre engines. References in the text

The fuel manifold distributes the fuel to the unit refer to the numbers in the illustration.

injectors for each cylinder head. The EDC

cardiagn.com

control unit controls when the unit injectors are

to inject the fuel into the cylinders.

If the O-rings on the unit injectors are faulty, 4 5 7

fuel will leak from the overflow holes 7 and the 3

overflow channels 7. There is an overflow hole 5

in the fuel manifold at each cylinder. In addition,

16 litre engines have overflow channels that

drain any fuel leakage away from the overflow

holes and the top of the engine. 6

2 116 245

16 litre engine. References in the text refer to the

numbers in the illustration.

03:04-02 ã Scania CV AB 2002, Sweden 5

Fuel path

Skeleton diagram of the fuel

system

11 and 12 litre engines 16 litre engine

1 2 A 3 4 5 1 2 A 3 4 D 5

B B

A A

E

116 253

116 252 C 6 D

C 6 E D

A Check valve

1 Feed pump B Gear pump (feed pump)

2 Hand pump C Safety valve

cardiagn.com

3 EDC control unit D Overflow valve

4 Fuel filter E Drain union

5 Cylinders

6 Fuel tank

6 ã Scania CV AB 2002, Sweden 03:04-02

Fuel quantity and injection timing

Fuel quantity and injection

timing

Each unit injector consists of a pump element,

a solenoid valve and a nozzle. In this way, it is

possible to control the fuel injection for each

individual cylinder.

EDC, Electronic Diesel Control, is the

electronic system that controls both how much

fuel each unit injector should inject into the

cylinder and also when the unit injector should

inject the fuel. This control of the injection

means that we can optimise the combustion,

which in turn leads to cleaner exhaust gases

and lower fuel consumption. The EDC system

described in this booklet is designated MS6.

The control unit is the brain of the EDC

cardiagn.com

system. The control unit processes the

information both from the sensors and the

components that are part of the EDC system

and also from the control units in other

systems. When the control unit has processed

the information, it then transmits signals to the

unit injectors. The signals control the injection

of the fuel.

The EDC system makes possible such

functions as cruise control, hand throttle, speed

limiter, smoke limiter and a special cold start

programme.

03:04-02 ã Scania CV AB 2002, Sweden 7

Feed pump, Hand pump

Components in the fuel system

Feed pump

The feed pump is of the gear pump type. On 11

and 12 litre engines, the feed pump is positioned

on the rear end of the air compressor and is

driven by the crankshaft of the compressor. On

16 litre engines, the feed pump is positioned on

the front of the engine and is driven via the left-

hand camshaft.

Its capacity is adjusted to deliver the right

pressure and flow rate to all unit injectors.

The hole drilled in the flange of the feed pump is

used to indicate leaks.

cardiagn.com

107 413

Location of feed pump on 11 and 12 litre engines

Hand pump

The hand pump is positioned on the rear end of

the feed pump and is used for bleeding the fuel

system. On buses, the hand pump is positioned

so that it is easily accessible through the rear

engine compartment door.

115 782

Location of feed pump on 16 litre engine

8 ã Scania CV AB 2002, Sweden 03:04-02

Location diagrams

Location diagrams

11 and 12 litre engines

cardiagn.com

1 Fuel manifold

2 Control unit cooler

3 Overflow valve

16 litre engine

1

2

1

3

115 936

1 Fuel manifolds

2 Control unit cooler

3 Overflow valve

03:04-02 ã Scania CV AB 2002, Sweden 9

Control unit cooler, Fuel manifold, Overflow valve

Control unit cooler

The control unit is cooled using fuel that passes

through the control unit cooler. The control unit

cooler is positioned between the engine and the

control unit and mounted on vibration

insulators. This is to reduce the amount of

vibration to which the control unit is exposed.

The vibration insulators also insulate the

control unit electrically from the engine.

cardiagn.com

Fuel manifold

The fuel manifold distributes the fuel into the

unit injectors for each cylinder head. The fuel

manifold is fastened with banjo screws that are

connected to the overflow line. In this way, it is

possible to see if there are any leaks from the

O-rings on the unit injectors.

Overflow valve

The overflow valve is positioned in the end of

the fuel manifold.

The overflow valve controls the supply

pressure in the fuel system.

10 ã Scania CV AB 2002, Sweden 03:04-02

Unit injector

Unit injector

General

There is one unit injector for each cylinder. The

unit injector is positioned in the centre of the

cylinder head between the four valves.

The unit injector is a pump element forming a

single unit with the injector nozzle. It is driven

by the engine camshaft. The drive is transferred

from the camshaft via a roller tappet, pushrod

and rocker arm to the unit injector.

cardiagn.com

1 Pump section

2 Injector section

3 Valve housing

The unit injector consists of three main parts.

• Pump section, containing cylinder and

plunger, corresponding to the pump element

in an injection pump.

• Injector section, with nozzle sleeve, nozzle

needle and spring.

• Valve housing, with an electromagnetically

controlled fuel valve.

The lower part of the unit injector is fitted in a

steel sleeve with copper washer resting against

the bottom of the cylinder head, similar to an

ordinary injector.

The upper part of the unit injector, with

compression spring and valve housing, is

located above the cylinder head.

Injection timing and the amount of fuel to be

injected are determined by the control unit. The

control unit controls the electromagnetic fuel

valve in the unit injector valve housing.

The opening duration of the injector (injector

timing) determines the amount of fuel that is

injected into the cylinder.

03:04-02 ã Scania CV AB 2002, Sweden 11

Unit injector

Leak indication

An overflow channel runs from the unit injector A

to the banjo screw in the fuel manifold. If oil

leaks from the overflow channel the upper

O-ring A is damaged. If fuel leaks from the

overflow channel, the central O-ring B is

B

damaged.

The lower O-ring C is fitted for extra safety as a

seal against coolant.

115 919

cardiagn.com

12 ã Scania CV AB 2002, Sweden 03:04-02

Unit injector

Filling phase

During the filling phase, pump plunger 2 moves

up to its highest position.

The highest point of the cam on the camshaft

has passed and the roller tappet is moving

towards the camshaft's base circle.

Fuel valve 1 is in the open position and fuel can

flow into the barrel from fuel duct 3.

Filling continues until the pump plunger reaches

its highest position.

cardiagn.com

1 Fuel valve

2 Pump plunger

3 Fuel duct, inlet and outlet

03:04-02 ã Scania CV AB 2002, Sweden 13

Unit injector

Spill phase

The spill phase begins when the camshaft has

moved on to the position in which the cam on

the camshaft starts to press pump plunger 2

down by means of the roller tappet, pushrod and

rocker arm.

The fuel can now flow through fuel valve 1,

through the hole in the unit injector and out

through fuel duct 3.

The spill phase continues as long as fuel valve 1

remains open.

cardiagn.com

1 Fuel valve

2 Pump plunger

3 Fuel duct, inlet and outlet

14 ã Scania CV AB 2002, Sweden 03:04-02

Unit injector

Injection phase

The injection phase begins when fuel valve 1

closes. The fuel valve closes when voltage is

applied to the solenoid valve. The cam on the

camshaft continues to press pump plunger 2

down by means of the rocker arm and injection

takes place since the passage through the fuel

valve is closed.

The injection phase continues as long as fuel

valve 1 remains closed.

cardiagn.com

1 Fuel valve

2 Pump plunger

3 Fuel duct, inlet and outlet

03:04-02 ã Scania CV AB 2002, Sweden 15

Unit injector

Pressure reduction phase

Injection stops when fuel valve 1 opens and the

pressure in the unit injector drops below the

nozzle's opening pressure.

The fuel flows through the open fuel valve 1, the

hole in the unit injector and out through fuel

duct 3.

It is the closed or open position of the fuel valve

which determines when injection should begin

and end.

The length of time the fuel valve remains closed

determines the amount of fuel that is injected

during each pump stroke.

cardiagn.com

1 Fuel valve

2 Pump plunger

3 Fuel duct, inlet and outlet

16 ã Scania CV AB 2002, Sweden 03:04-02

Fuel filter

Fuel filter

There are two types of fuel filter.

11 and 12 litre engines have a filter that consists

of a metal container with spiral wound paper

inserts. This cannot be dismantled but must be

replaced as an assembly.

The 16 litre engine has a filter assembly

containing a filter element. The filter element is

secured to the lid and when the filter is removed,

the filter housing drains automatically.

cardiagn.com

107 415

115 941

C

116 323

A B

Fuel filter for 16 litre engine

A = Outlet

B = Drain channel

C = Inlet, from control unit cooler

03:04-02 ã Scania CV AB 2002, Sweden 17

General

EDC

General

On the following page you can see which

components and systems the EDC control unit

communicates with.

If the vehicle is equipped with a coordinator

then the EDC control unit communicates with

the following components via the coordinator.

Otherwise, the components are directly

connected to the EDC control unit.

• Accelerator pedal sensor

• Brake pedal switches

cardiagn.com

• Clutch pedal switch

115 913

• Control for the cruise control

• Tachograph

• Warning lamp for EDC

• Diagnostics switch with lamp

• Body builder switch, C271, for activation

of special functions

If the vehicle has a coordinator, the lamp in the

switch should come on for a few seconds when

the power is activated using the starter key.

18 ã Scania CV AB 2002, Sweden 03:04-02

General

Communication within the different EDC systems

System not equipped with coordinator

1 2 3 4

A

EDC

B

cardiagn.com

ABS/TC

EBS

RETARDER PC

DIAGNOS

OPTICRUISE

5 6 7 8 9 10

11 12 13 14 15 16 17 18

ON

ACC

RES

RET

EDC

OFF

115 785

1 Engine speed sensors, Quantity 2 10 Diagnostic socket for the PC

2 Charge air pressure and temperature 11 Accelerator pedal sensor

sensor 12 Brake pedal switches

3 Coolant temperature sensor 13 Clutch pedal switch

4 Unit injector solenoid valves, one per 14 Control for the cruise control

cylinder

15 Tachograph (vehicle speed)

5 Supply relay

16 Warning lamp for EDC (truck)

6 Control unit for ABS/TC, EBS

17 Warning lamp for EDC (bus)

7 Control unit for the retarder

18 Diagnostics switch with lamp

8 Exhaust brake

9 Control unit for Opticruise

03:04-02 ã Scania CV AB 2002, Sweden 19

General

System with coordinator

1 2 3 4 6

5

EDC A

EDC

ON

ACC

RES

RET

OFF

COO

12

B

4

0 7

15

10 20

80 100

5 25

cardiagn.com

40 120

r/min x 100

0 30

ABS/TC

EBS

RETARDER PC

DIAGNOS

OPTICRUISE

115 488

7 8 9 10 11

Communication with components in the driver area goes via the coordinator (COO).

1 Engine speed sensors, Quantity 2 7 Supply relay

2 Charge air pressure and temperature 8 Control unit for ABS/TC, EBS

sensor 9 Control unit for the retarder

3 Coolant temperature sensor 10 Control unit for Opticruise

4 Oil pressure sensor 11 Diagnostic socket for the PC

5 Fan solenoid valve 12 Coordinator that connects the EDC control

6 Unit injector solenoid valves, one per unit to the components in the driver area.

cylinder

20 ã Scania CV AB 2002, Sweden 03:04-02

Components on the engine

Components on the engine

Component locations on 11 and 12 litre engines

6 1

2

3

4

cardiagn.com

5

115 855

1 Unit injector solenoid valves

2 Coolant temperature sensor

3 Auxiliary engine speed sensor on camshaft

gear

4 Main engine speed sensor on flywheel

5 EDC control unit

6 Charge air pressure and temperature

sensor

A – connection between engine components

and EDC control unit

B – connection between other components and

EDC control unit

03:04-02 ã Scania CV AB 2002, Sweden 21

Components on the engine

Component locations on a 16-litre engine

A

5 B 7

115 856

3 2

cardiagn.com

1 Unit injector solenoid valves, one per

cylinder

2 Oil pressure sensor

3 Coolant temperature sensor

4 Fan solenoid valve

5 Charge air pressure and temperature

sensor

6 EDC control unit

7 Auxiliary engine speed sensor on camshaft

gear

8 Main engine speed sensor on flywheel

A – connection between engine components

and EDC control unit

B – connection between other components and

EDC control unit

22 ã Scania CV AB 2002, Sweden 03:04-02

Components on the engine

Engine speed sensors T74 and T75

The EDC system contains two engine speed

sensors: main engine speed sensor T74 and

auxiliary engine speed sensor T75. The sensors

are inductive.

If the sensors begin to show different values

when the engine is already running, the control

unit will work only from the value from the

116 744

main engine speed sensor – for safety reasons,

the engine torque will then be limited.

If the control unit does not receive a signal from

one of the sensors, the engine torque will be

limited. If the signal returns, the engine will

operate normally again.

If the control unit receives no signal from either

sensor, the engine will not start; if the engine is

cardiagn.com

running, it will be switched off.

On the following two pages is a more detailed

description of both sensors.

03:04-02 ã Scania CV AB 2002, Sweden 23

Components on the engine

Main engine speed sensor T74 (flywheel)

Around the edge of the flywheel are 58 holes

(refer to illustration). The main engine speed

sensor senses the holes when the flywheel rotates

and sends impulses from each hole to the EDC

control unit. In this way, the control unit can

calculate the position and speed of the engine.

The space between two of the holes is greater

than the space between the other holes. When

116 392

the control unit senses that the sensor has passed

this larger space, it then knows that the flywheel

is at TDC. In this position, either cylinder 1 or 6 Flywheel. The detail shows some of the holes

is in the firing position. that are sensed by the main engine speed sensor.

If the auxiliary engine speed sensor is faulty at

start up, the control unit needs to find out when

cylinder 1 is in the firing position. It does this by

attempting to inject fuel into cylinder 1 as soon

cardiagn.com

as the flywheel is at TDC. When the control unit

notes that the engine speed increases, it realizes

that it was cylinder 1 that fired.

The control unit senses the voltage from the

main engine speed sensor between pins A1 and

A13.

If the control unit detects a fault, fault code 12 is

116 111

generated.

Note: The sensor is sensitive to polarity reversal Location of main engine speed sensor on 11 and

and the pins must be connected as indicated 12 litre engines

below.

Pin A1 – signal voltage

Pin A13 – earth

115 862

Location of main engine speed sensor on 16 litre

engine

24 ã Scania CV AB 2002, Sweden 03:04-02

Components on the engine

Auxiliary engine speed sensor T75

(camshaft gear)

The auxiliary engine speed sensor senses the 1 8

raised portions on the camshaft gear – indicated

in the illustration. In this way, the EDC control 7

unit knows which cylinder is in the firing 5 3

position.

4

The camshaft gear is attached to the camshaft 6

and they rotate at the same speed. In this way, 2

116 393

the control unit can also calculate the engine

speed.

Camshaft gear on 16 litre engine. The numbers

The control unit senses the voltage from the indicate the raised portions where the auxiliary

sensor between pins A2 and A14. engine speed sensor senses the firing position of

each cylinder.

If the control unit detects a fault, fault code 13 is

generated.

Note: The sensor is sensitive to polarity reversal

cardiagn.com

and the pins must be connected as indicated

below.

Pin A2 – signal voltage

Pin A14 – earth

116 112

Location of auxiliary engine speed sensor on 11

and 12 litre engines

116 026

Location of auxiliary engine speed sensor on

16 litre engine

03:04-02 ã Scania CV AB 2002, Sweden 25

Components on the engine

Charge air pressure and

temperature sensor, T47

The sensors for charge air pressure and

temperature are integrated into one single

component. Both sensors are described in more

detail on the next page.

107 456

cardiagn.com

116 113

Location of sensor on 11 and 12 litre engines

116 114

Location of sensor on 16 litre engine

26 ã Scania CV AB 2002, Sweden 03:04-02

Components on the engine

Charge air pressure sensor

The charge air pressure sensor detects the The engine will then react more slowly than

absolute pressure in the intake manifold, i.e. normal when actuating the throttle in cold

the atmospheric pressure plus the positive weather, as the EDC control unit thinks that the

pressure provided by the turbocharger. air is warmer than it really is.

The EDC control unit uses the signal from the

sensor to limit the fuel quantity when the

charge air pressure is under a certain level. The

lower the pressure, the less fuel the control unit

allows to go out to the unit injectors. In this

way black smoke is avoided.

The sensor receives a supply voltage of +5 V

from the EDC control unit pin A23 and is

earthed through pin A17.

The control unit pin A12 receives a signal

voltage from the sensor. The signal voltage is

cardiagn.com

directly proportional to the charge air pressure.

High pressure gives high voltage and vice

versa.

If there is a fault with the signal, the control

unit operates after a preset pressure value –

while at the same time generating fault

code 16.

As a safety precaution, the engine torque is

then limited.

Charge air temperature sensor

The charge air temperature sensor detects the

temperature in the intake manifold. The EDC

control unit uses the signal from the sensor to

finely adjust the fuel quantity so that black

smoke is not produced. The warmer the charge

air, the less fuel the control unit allows to go

out to the unit injectors.

The sensor is of the NTC type, which means

that its resistance is temperature dependent. If

the temperature increases, the resistance in the

sensor drops.

The sensor is earthed via pin A17. The control

unit senses the voltage level across pins A17

and A21.

If the voltage is outside a given range, the

control unit operates after a preset temperature

value– while at the same time generating fault

code 15.

03:04-02 ã Scania CV AB 2002, Sweden 27

Components on the engine

Coolant temperature sensor T33

The coolant temperature sensor sends a signal to

the EDC control unit which controls the fuel

quantity when the engine is started. It also

influences the EDC control unit so that it

controls the engine idling speed and maximum

106132

engine speed when the engine is cold and the

engine power when it is too warm.

If the EDC control unit receives a signal from

the coolant temperature sensor that the engine is

cold when attempting to start (cold start), the

following will occur. If the engine does not start

within 2 seconds, the fuel quantity injected will

successively increase until the engine starts.

Directly after a cold start, the engine speed is

limited to 1000 rpm in order to protect the

engine - the engine idling speed is raised to

cardiagn.com

600 rpm.

116 115

The length of time engine speed limitation is

engaged varies depending on the coolant

temperature:

Location of coolant temperature sensor on 11

and 12 litre engines

Below +10°C 30 seconds

Above +20°C 3 seconds

The engine idling speed returns to normal when

the coolant has reached 20 - 60°C

(the temperature limit differs between engine

types).

116 116

Location of coolant temperature sensor on 16

litre engine

28 ã Scania CV AB 2002, Sweden 03:04-02

Components on the engine

On certain engines – e.g. the 16 litre engine –

the engine power is limited when the coolant

temperature exceeds 103°C. Refer to diagram.

o

The engine power is limited to prevent the /o

engine from overheating.

100

The sensor is earthed via pin A5. The EDC

control unit detects the voltage level between

pins A5 and A22.

If the voltage is outside a given range, the

control unit operates after a preset temperature

value – while at the same time generating fault o

C

code 14.

116 642

103 107

The engine will then have poorer cold start

characteristics, the engine idling speed is raised

to 600 rpm and it cannot be adjusted.

cardiagn.com

03:04-02 ã Scania CV AB 2002, Sweden 29

Components on the engine

Oil pressure sensor T5

The oil pressure sensor senses the absolute

pressure of the engine oil, i.e. atmospheric

pressure plus the positive pressure from the oil

pump.

Engines with coordinator

Location of oil pressure sensor on 11 and 12

• Oil pressure sensor T5 is directly connected litre engines

to the EDC control unit. The EDC control

unit does not use this value but simply sends

it on to the coordinator.

cardiagn.com

The sensor receives a supply voltage of +5 V

from the control unit pin A8 and is earthed

through pin A6.

The sensor sends a signal voltage to control unit

pin A9.

If the signal voltage is outside a given range, the

control unit sends a preset pressure value to the

coordinator – while at the same time generating

fault code 18.

116 173

Location of oil pressure sensor on 16 litre

engine

30 ã Scania CV AB 2002, Sweden 03:04-02

Components on the engine

Fan solenoid valve V56

The fan is mechanically driven by the crankshaft

via the outer belt transmission. It is either

mechanically or electrically controlled.

We know that on a mechanically controlled fan,

it is a bimetallic spring that controls the slip in

the viscous coupling of the fan.

On an electrically controlled fan, the bimetallic

spring is replaced by a solenoid valve. The EDC

control unit controls the solenoid valve using a

116 174

PWM signal of +24 V (more detailed

information on PWM signals can be found in the

section PWM signals). In this way, the control Location of solenoid valve on 16 litre engine

unit can control the speed of the fan.

cardiagn.com

One of the advantages with an electrically

controlled fan is that the idling speed of the fan

is lower than with a mechanically controlled fan.

In this way, fuel consumption will be less.

Another advantage is that the electrically If the control unit cannot control the solenoid

controlled fan can be more precisely controlled valve correctly, then fault code 39 is generated.

than the mechanically controlled fan. During

retarder braking, the retarder control unit can

request, for example, the EDC control unit to

increase the fan speed to maximum. In this way,

the cooling capacity is increased and the driver

can brake longer with the retarder before it starts

to deregulate due to the temperature being too

high.

If the solenoid valve does not receive a signal

from the control unit then the fan is fully

engaged and follows the engine speed. This is

done to ensure that the engine is cooled even if

there is a fault with fan control.

The control unit processes the signals from the

following components – before it decides how it

should control the fan:

• Coolant temperature sensor

• Charge air temperature sensor

• Retarder control unit

• Engine speed sensors

The solenoid valve is earthed at control unit pin

A16 and it receives the PWM signal from pin A10.

03:04-02 ã Scania CV AB 2002, Sweden 31

Components on the engine

EDC control unit E12

Location of EDC control unit

The EDC control unit is attached to a control

unit cooler on the engine. The fuel flowing

through the control unit cooler cools the control

unit.

The control unit is attached to the engine with

vibration insulators to protect the control unit.

The vibration insulators also insulate the control

unit electrically from the engine.

116 117

It is important to ensure that the control unit

casing is not earthed to the engine. The control

unit may only be earthed to the chassis via the Location of EDC control unit on 11 and 12 litre

cab and chassis wiring. Inside the control unit is engines

an interference suppressor that requires perfect

cardiagn.com

earthing in order to function correctly.

116 118

Location of EDC control unit on 16 litre engine

32 ã Scania CV AB 2002, Sweden 03:04-02

Components on the engine

Function of the EDC control unit EDC control unit, integrated

atmospheric pressure sensor

The EDC control unit collects information and

then processes it into signals which control the Some EDC control units have an integrated

solenoid valves on the unit injectors. atmospheric pressure sensor.

We know that the electrical system of the When the control unit senses that the

vehicle has a system voltage of +24 V and is atmospheric pressure is low – i.e. at high

earthed via the chassis. altitude – the control unit will then limit the

maximum amount of injected fuel. It does this

The control unit converts the system voltage to to protect the turbocharger from overrevving.

a lower voltage of approximately 5 V, which it

then supplies to the sensors, etc. These sensors The control unit interprets the voltage from the

are always earthed through the control unit. sensor according to the following.

The control unit can be configured using • 0,2–2.36 V = 0.6 bar

Scania Programmer. For example, a maximum

speed can be set up. • 2,37–4.74 V = 0.6–1.2 bar

Every time the control unit is configured, the If the voltage is outside the above voltage

date and VCI identification number are stored ranges, the control unit operates according to a

cardiagn.com

in the memory of the control unit. This is the preset pressure value – while at the same time

equivalent of security sealing. generating fault code 29.

03:04-02 ã Scania CV AB 2002, Sweden 33

Components on the engine

EDC control unit, connections

The EDC control unit is connected to the other

EDC systems in the vehicle via the two 35-pin

connectors A and B. See illustration.

12

35

23

34

11

22

33

10

21

32

9

20

The connector A is connected to the engine

31

8

19

A

30

7

18

29

6

17

28

5

components.

16

27

4

15

26

3

14

25

2

13

24

1

The connector B is connected to the other EDC

24

1

13

components in the vehicle. In vehicles

25

2

14

26

3

15

27

4

16

28

5

equipped with a coordinator, the control unit

17

B

29

6

18

30

7

19

31

8

20

communicates with the components in the

32

9

21

10

33

22

11

34

23

35

12

driver area via the coordinator. Communication

with the coordinator is through CAN

106 138

communication via pins B11and B12.

How the pins are connected is shown below.

A1 Input signal from the main engine A21 Input signal from the charge air

cardiagn.com

speed sensor. temperature sensor. The control unit

A2 Input signal from the auxiliary engine senses the voltage level across

speed sensor. pins A21 and A17.

A3 Not used. A22 Input signal from the coolant

temperature sensor. The control unit

A4 Not used. senses the voltage level across

A5 Earth for coolant temperature sensor. pins A22 and A5.

A6 Earth for oil pressure sensor. A23 Supply voltage +5 V to the charge air

A7 Not used. pressure sensor.

A8 Supply voltage +5 V to the oil pressure A24 Supply voltage to the solenoid valves

sensor. in the following cylinders.

A9 Input signal from the oil pressure 6 cylinder engine: 1, 2 and 3.

sensor. 8 cylinder engine: 1, 4, 6 and 7.

A10 Supply voltage +24 V to the fan A25 Supply voltage to the solenoid valves

solenoid valve. in the following cylinders.

A11 Not used. 6 cylinder engine: 4, 5 and 6.

A12 Input signal from the charge air 8 cylinder engine: 2, 3, 5 and 8.

pressure sensor. A26 Earthing of the solenoid valves in the

A13 Earth for main engine speed sensor. following cylinders.

A14 Earth for auxiliary engine speed 6 cylinder engine: 3.

sensor. 8 cylinder engine: 5.

A15 Not used. A27 Earthing of the solenoid valves in the

A16 Earth for fan solenoid valve. following cylinders.

A17 Earth for charge air pressure sensor. 6 cylinder engine: 2.

A18 Not used. 8 cylinder engine: 2.

A19 Not used. A28 Earthing of the solenoid valves in the

A20 Not used. following cylinders.

6 cylinder engine: 1.

8 cylinder engine: 3.

34 ã Scania CV AB 2002, Sweden 03:04-02

Components on the engine

A29 Used only on 8 cylinder engines. B13 Diagnostic cable K.

Earthing of the solenoid valve in B14 Not used.

cylinder 8. B15 Input signal +24 V from the starter

A30 Not used. lock (when the key is in the drive

A31 Not used. position).

A32 Used only on 8 cylinder engines. B16 Supply voltage +5 V to the

potentiometer in the accelerator pedal

Earthing of the solenoid valve in sensor.

cylinder 7.

B17 Input signal from the throttle actuation

A33 Earthing of the solenoid valves in the switch. If the pin is earthed, the control

following cylinders. unit interprets the accelerator pedal as

6 cylinder engine: 4. being depressed.

8 cylinder engine: 6. B18 Not used.

A34 Earthing of the solenoid valves in the B19 Input signal for the Torque limiter 2

following cylinders. function. Earthed pin gives the Torque

6 cylinder engine: 6. limiter 2 function (the pin B28 must

not be earthed). If pin B28 is grounded

8 cylinder engine: 4.

cardiagn.com

at the same time, the Torque limiter 3

A35 Earthing of the solenoid valves in the function is activated instead.

following cylinders. B20 Input signal from the clutch pedal

6 cylinder engine: 5. switch. If the pin is earthed, the control

8 cylinder engine: 1. unit interprets the clutch pedal as being

depressed.

B1 Earth connection for the control unit to B21 Input signal for the Limited hand

chassis. throttle function. Earthed pin gives the

B2 Earth connection for the control unit to Limited hand throttle function (the pin

chassis. B32 must not be earthed). If pin B32 is

earthed at the same time, the Fixed

B3 Supply voltage +24 V from the supply engine speed function is engaged

relay to the control unit. instead.

B4 Supply voltage +24 V from the supply B22 Input signal for the Emergency stop

relay to the control unit. function. The function is activated

B5 Not used (output signal for engine when the pin is earthed.

speed). B23 Input signal from the potentiometer in

B6 Earthing input signal from the the accelerator pedal sensor. The pin

diagnostics switch. Earthing output receives a signal voltage of 0.25–

signal for activation of the diagnostic 4.00 V, depending on how far the

and warning lamps. accelerator pedal is depressed.

B7 PWM signal. Output signal for throttle B24 Not used.

actuation. B25 Earthing of the control for the cruise

B8 Input signal from the control for the control.

cruise control. The control unit senses B26 Input signal from brake pedal switch 1.

the voltage level across pins B8 and If the earthing connection is broken,

B25. the control unit interprets the brake

B9 Not used. pedal as being depressed.

B10 Not used. B27 Output signal for activation of the

B11 CAN communication, L lead supply relay. The pin earths the relay.

B12 CAN communication, H lead

03:04-02 ã Scania CV AB 2002, Sweden 35

Components on the engine

B28 Input signal for the Torque limiter 1

function. Earthed pin gives the Torque

limiter 1 function (the pin B19 must

not be earthed). If pin B19 is earthed at

the same time, the Torque limiter 3

function is activated instead.

B29 Speed signal from tachograph output

D3.

B30 Not used.

B31 Input signal from brake pedal switch 2.

If the pin is earthed, the control unit

interprets the brake pedal as being

depressed.

B32 Input signal for the Raised idling speed

function. Earthed pin activates the

Raised idling speed function (the pin

B21 must not be earthed). If pin B21 is

earthed at the same time, the Fixed

cardiagn.com

engine speed function is activated

instead.

B33 Input signal for cruise control

disengagement. +24 V applied to the

pin disengages the cruise control.

B34 Input signal for the Speed limiter 2

function. +24 V applied to the pin

engages the Speed limiter 2 function.

B35 Earthing of the potentiometer in the

accelerator pedal sensor.

36 ã Scania CV AB 2002, Sweden 03:04-02

Components in the driver area

Components in the driver

area

If the vehicle is equipped with a coordinator,

refer to the function description of the Component locations, bus

coordinator to read about the components in the

driver area. The supply relay is an exception;

10

this is always controlled by the EDC control

unit.

In the EDC section General, there is a

description of how to check if the vehicle is 9

equipped with a coordinator.

Component locations, truck 8

4 5 6 7 8 9 7

cardiagn.com

6

116 328

5 4 3 2 1

1 Diagnostics switch with lamp

2 Control for the cruise control

3 Clutch pedal switch

106 122

3 2 1

4 Brake pedal switches

1 Accelerator pedal sensor 5 Accelerator pedal sensor

2 Brake pedal switches 6 Warning lamp for EDC

3 Clutch pedal switch 7 Tachograph (vehicle speed)

4 Control for the cruise control 8 Switch for temporary raising of the engine

speed (engine speed function Fixed engine

5 Tachograph (vehicle speed)

speed)

6 Diagnostics switch with lamp

9 Diagnostic socket for the PC

7 Warning lamp for EDC

10 Supply relay

8 Supply relay

9 Diagnostic socket for the PC

03:04-02 ã Scania CV AB 2002, Sweden 37

Components in the driver area

Supply relay R34

The supply relay acts as the main switch for the

EDC system. The EDC control unit is supplied

with voltage by the supply relay. The control RP14 RP15 RP16 RP17 RP18 RP19 RP20 RP21 RP22 RP23

unit controls the relay itself and this gives it

control over the system. If the relay releases, the RP7 RP8 RP9 RP10 RP11 RP12 RP13

engine will stop.

RP1 RP2 RP3 RP4 RP5 RP6

When the starter voltage is turned on using the

starter key, voltage is applied to the control unit 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33

116 341

pin B15 with the battery voltage of +24 V. The

control unit then earths pin B27, the supply

relay is activated and the control unit is supplied Location of supply relay in central electric unit.

with +24 V on pins B3 and B4. The central electric unit is the same in both

trucks and buses.

cardiagn.com

116 342

Location of supply relay and central electric

unit, truck. The location of the central electric

unit varies in buses.

38 ã Scania CV AB 2002, Sweden 03:04-02

Components in the driver area

Accelerator pedal sensor – B25,

B26 and D35

Note: If the vehicle is equipped with a Accelerator pedal and accelerator pedal

coordinator, the component is associated to the sensor, truck

coordinator. The EDC control unit will then only

receive a CAN message about the status of the

component.

The accelerator pedal sensor consists of the

following three components.

• A potentiometer.

• A throttle actuation switch

• A kick-down switch

cardiagn.com

1 Accelerator pedal sensor

Accelerator pedal and accelerator pedal

sensor, bus

116 357

1 Accelerator pedal sensor

03:04-02 ã Scania CV AB 2002, Sweden 39

Components in the driver area

The potentiometer informs the EDC control

unit of the accelerator pedal position. The

potentiometer receives a supply voltage of

approx. +5 V from control unit pin B16 and is

then earthed via pin B35. The sensor supplies a

signal voltage to control unit pin B23. The

voltage is directly dependent on how much the

accelerator pedal is depressed. At 2.7 V, the

control unit interprets the voltage as a request

for full throttle. Voltages above 2.7 V do not

result in higher engine power.

The throttle actuation switch informs the

control unit pin B17 if the accelerator pedal is

fully released or depressed. When the pedal is

fully released, the throttle actuation switch is

open. The control unit interprets this as a

request for idling speed. The throttle actuation

switch closes when the pedal is pressed down

and earths pin B17 on the control unit.

cardiagn.com

The kick-down switch is activated when the

accelerator pedal is pressed from full throttle to

the kick-down position. However, the EDC

system does not utilise the signal from the

kick-down switch. The signal can be used by

other systems however – for example

Opticruise.

40 ã Scania CV AB 2002, Sweden 03:04-02

Components in the driver area

Control for the cruise control S51

Note: If the vehicle is equipped with a

coordinator, the component is associated to the

coordinator. The EDC control unit will then

only receive a CAN message about the status

of the component.

Using the control for the cruise control system,

the EDC control unit is informed of the speed

the vehicle is required to hold. The control unit

receives continuous information on vehicle

speed from the tachograph.

03_0767

The control for cruise control is also used when

adjusting idling speed or using the functions

for the control of engine speed.

cardiagn.com

The control for cruise control has the following

five functions.

• ON

• OFF

• ACC (accelerate, the speed of the vehicle

increases)

• RET (retard, the speed of the vehicle

decreases)

• RES (resume, the vehicle returns to the

previously selected speed)

03:04-02 ã Scania CV AB 2002, Sweden 41

Components in the driver area

There are only two cables between the control U

and the control unit. The cables are connected (volt)

to the control unit pins B8 and B25. Each

function gives a certain voltage level (refer to

graph) which the control unit senses across the 5

pins.

The voltage levels are created when the 4 OFF

resistance in the circuit changes depending on

which function is engaged. ON

3

The control receives a supply voltage of

RET

approximately +5 V from control unit pin B8

and is then earthed via pin B25. 2

RES

1

ACC

107 426

0

cardiagn.com

Different voltage levels of cruise control

functions

42 ã Scania CV AB 2002, Sweden 03:04-02

Components in the driver area

Brake pedal switches B1 and B34

Note: If the vehicle is equipped with a

coordinator, the components are associated to Pedals, truck

the coordinator. The EDC control unit will then

only receive a CAN message about the status

of the component.

Two brake pedal switches sense when the brake

pedal is depressed. The switches are connected

so that one opens and the other closes when the

pedal is depressed. They switch at the same 1

time when the pedal is lightly pressed, i.e. at 2

the start of pedal travel.

The switch that opens when the pedal is

depressed is called brake pedal switch 1 and

the switch that closes is called brake pedal

cardiagn.com

switch 2.

Brake pedal switch 1 is connected between the

116 249

EDC control unit pin B26 and chassis earth.

When the brake pedal is pressed down, the

ground connection to pin B26 is broken.

1 Brake pedal switch 1

Brake pedal switch 2 is connected between 2 Brake pedal switch 2

control unit pin B31and chassis earth. When

the pedal is depressed, pin B31 is earthed.

Brake pedal and service brake valve, bus

1

116 385

1 Service brake valve containing brake pedal

switches 1 and 2

03:04-02 ã Scania CV AB 2002, Sweden 43

Components in the driver area

Clutch pedal switch B32

Note: If the vehicle is equipped with a Pedals, truck

coordinator, the component is associated to the

coordinator. The EDC control unit will then

only receive a CAN message about the status

of the component.

The clutch pedal switch senses when the clutch

pedal is depressed. 1

The switch is connected between the EDC

control unit pin B20 and chassis earth. When

the pedal is depressed, the switch closes and

earths pin B20.

cardiagn.com

116 250

1 Clutch pedal switch. The clutch pedal and

its switch look the same in buses.

44 ã Scania CV AB 2002, Sweden 03:04-02

Components in the driver area

Tachograph O4

Note: If the vehicle is equipped with a

coordinator, the component is associated to the

coordinator. The EDC control unit will then only

receive a CAN message about the status of the

component.

The tachograph gives the EDC control unit

information about vehicle speed. Vehicle speed

sensing is a prerequisite for certain functions

such as cruise control, speed limiter and engine

speed control.

17 0121

If the control unit does not receive a signal from

the tachograph, it will then operate according to

the preset speed 15 km/h.

The speed signal is applied to control unit

cardiagn.com

pin B29.

03:04-02 ã Scania CV AB 2002, Sweden 45

Components in the driver area

Warning lamp for EDC, W27

Note: If the vehicle is equipped with a

coordinator, the component is associated to the

coordinator. The EDC control unit will then 1 2 EDC

only receive a CAN message about the status

106 448

of the component.

Warning lamp for EDC (truck)

The EDC warning lamp comes on for a few

seconds when the starter voltage is switched on

with the starter key and also when the engine is

switched off.

STOP

When starter voltage is switched on, the s

warning lamp comes on for a few seconds to

check that it is intact. 15

1 2 10 20

When the engine is switched off, the warning 1/2 80 100

0 1 40 120 5 25

lamp comes on while the EDC control unit

cardiagn.com

carries out a functional check of the EDC 0

r/min x 100

30

system. When the check is completed, the 0

6

12 0

6

12

supply relay releases and the warning lamp 1 2

113 178

goes out. Sometimes, the warning lamp may

flash as part of the functional check; this is not

a fault. Warning lamp for EDC (bus)

When the engine is running, the warning lamp

should normally be off. If there is a fault in the

EDC system, the warning lamp comes on.

The warning lamp receives the voltage +24 V

from the supply relay and is earthed via control

unit pin B6.

46 ã Scania CV AB 2002, Sweden 03:04-02

Components in the driver area

Diagnostics switch with lamp, S52

Note: If the vehicle is equipped with a

coordinator, the component is associated to the

coordinator. The EDC control unit will then only

receive a CAN message about the status of the

component.

Using the diagnostics switch, it is possible to

extract fault codes that may be stored in the

EDC control unit memory. The fault codes are

flashed out by the lamp. This switch is also used

to clear fault codes.

The switch is connected between control unit

EDC

pin B6 and chassis earth. The switch, which is

cardiagn.com

spring-loaded, closes when pressed.

ED C

The diagnostics lamp receives +24 V from the ETC

116 532

supply relay and is earthed via control unit pin

B6.

When the switch is pressed, it earths the lamp. Two types of diagnostics switch, truck

More about the diagnostics switch, e.g. how to

interpret the flash codes, can be found in the

section Warning system.

The diagnostics lamp is connected in parallel

with the EDC warning lamp and therefore, both

lamps are always on at the same time.

116 533

Diagnostics switch, bus

03:04-02 ã Scania CV AB 2002, Sweden 47

Type of regulator

Type of regulator

There are two different types of governor: RQ

and RQV. When choosing governor type it must

be decided how the EDC control unit should

interpret the signals or messages from the

accelerator pedal. Below is an explanation of the

difference between RQ and RQV.

• RQV = the throttle pedal requests a certain

engine speed. RQV is used in most vehicles

and is also preset in control units that are

ordered as parts.

• RQ = the throttle pedal requests a certain

torque. RQ is used in buses equipped with

automatic gearbox. If a new control unit is

ordered, it must be reprogrammed to RQ.

The governor type can be programmed into the

cardiagn.com

control unit using Scania Programmer.

48 ã Scania CV AB 2002, Sweden 03:04-02

Warning system

Warning system

If a fault occurs in the EDC system, one or more General

of the following measures will be carried out by

the EDC control unit, depending on what the

fault is.

1 2 EDC

• The warning lamp for EDC comes on. It

106 448

will often go out on its own when the fault

ceases. Sometimes, however, it may be Warning lamp for EDC (truck)

necessary to switch the starter voltage off

and on to get the lamp to go out.

• Functions like cruise control and hand

throttle are disengaged.

STOP

• Torque is limited. s

cardiagn.com

15

• The defective unit injector (cylinder) is 1 2 10 20

turned off.

1/2 80 100

0 1 40 120 5 25

• When idling, the engine runs at a slightly

r/min x 100

higher engine speed than normal. 0 30

6 6

0 12 0 12

• The engine is switched off. 1 2

113 178

The control unit carries out the above measures

in order to prevent the fault causing expensive Warning lamp for EDC (bus)

damage and at worst leading to uncontrolled

throttle actuation.

If the engine is not turned off, the vehicle can

often be driven to a workshop. It should be

remembered, however, that the system has less

than normal safety margins, especially if engine

output is reduced.

03:04-02 ã Scania CV AB 2002, Sweden 49

Warning system

Shutdown test

Every time the engine is switched off, the EDC

control unit carries out a special test of the

EDC system. While this shutdown test is

running, the warning lamp is lit. When the

check is complete, the following occurs: the

supply relay releases, the lamp goes out and

there is no power to the control unit.

If the control unit discovers a fault during the

shutdown test, the warning lamp will come on

the next time the engine is started, even if the

fault is no longer present. The control unit must

carry out a fault-free shutdown test before the

warning lamp goes out.

cardiagn.com

50 ã Scania CV AB 2002, Sweden 03:04-02

Warning system

Fault codes

When the control unit discovers a fault, or

something which it interprets as abnormal, it

generates a fault code. The warning system can

generate approximately 30 different fault

codes.

Arrangement of flashing codes

The fault codes are flashed out by the

cardiagn.com

diagnostics lamp and are arranged in a certain

way. The long flashes – of 1 second – that

come first represent units of ten. The short

flashes – of 0.3 seconds – that follow represent

units of one.

The example on the right signifies fault

106 157

code 25.

A single very long flash of 4 seconds indicates

106 158

that no fault codes are stored in the memory.

03:04-02 ã Scania CV AB 2002, Sweden 51

Warning system

Fault code memory Limp-home mode

The EDC control unit memory has sufficient If the potentiometer in the accelerator pedal

space to store all the fault codes. sensor is faulty, fault code 25 is generated. The

vehicle can, however, be driven to the nearest

The fault codes are stored in two different places workshop in limp-home mode. Limp-home

in the control unit. Erasing with the diagnostic mode is activated by releasing the accelerator

switch erases the fault codes that are flashed on pedal once so that the EDC control unit is aware

the diagnostic lamp. that the throttle actuation switch works.

However, the fault codes will remain stored in When the accelerator pedal is then depressed the

another memory that can only be accessed using throttle actuation switch is closed. The closed

Scania Diagnos. Scania Diagnos can be used to throttle actuation switch gives a throttle

see how many times each fault has occurred; actuation equal to half of full throttle.

this information can be valuable with a loose

connection for example. Scania Diagnos is used When the accelerator pedal is released, the

to erase both fault code memories at the same engine will run at idling speed.

time.

cardiagn.com

52 ã Scania CV AB 2002, Sweden 03:04-02

Interaction with other systems

Interaction with other

systems

ABS/TC and EBS Exhaust brake

The ABS/TC system influences the EDC The exhaust brake influences the EDC system,

system and vice versa. but not vice versa.

The ABS/TC control unit continuously senses When the exhaust brake is activated, a message

if one of the driving wheels is spinning. TC is sent to the EDC control unit, which then

engine control is activated when the driving deactivates the cruise control.

wheels spin and the throttle actuation is then

reduced, irrespective of the accelerator pedal If the exhaust brake is activated using the brake

position, until the driving wheels cease to spin. pedal, the throttle actuation is reduced to idling

speed.

The EDC control unit continuously sends

information on the accelerator pedal position to

the ABS/TC control unit. Retarder

cardiagn.com

The EBS and ABS/TC control units The retarder influences the EDC system and

communicate with the EDC control unit in the vice versa.

same way.

When the retarder is activated, a message is

sent to the EDC control unit, which then

Opticruise deactivates the cruise control.

Opticruise influences the EDC system and vice If the accelerator pedal is depressed while the

versa. retarder is activated, the retarder will

immediately be de-activated and the vehicle

The Opticruise control unit continuously will respond to the accelerator pedal.

receives information from the EDC control unit

about data such as engine speed or accelerator When the retarder is active, it can request a

pedal position. certain speed for the electrically controlled fan.

During gear changing, the Opticruise control

unit takes over control of the EDC system and

controls throttle actuation.

03:04-02 ã Scania CV AB 2002, Sweden 53

Interaction with other systems

PWM signals

Note: A PWM signal cannot be measured – in a

reliable way – using a normal multimeter.

Instead, use the fault codes to locate the cause of

any possible malfunctions.

cardiagn.com

PWM means that a signal is Pulse Width U

Modulated. The pulse width may, for example,

become greater when the throttle actuation

increases.

The PWM signal is a square wave with a 10%

T

constant frequency (T). The voltage level (U) is

106 159

100%

also constant; the variable is the activation time

– calculated as a percentage – of each cycle (the PWM signal at idling speed.

cycle is shown as 100% in the illustrations).

The PWM signal transmits very accurate

information. U

T

90%

106 160

100%

PWM signal at full throttle.

54 ã Scania CV AB 2002, Sweden 03:04-02

Interaction with other systems

CAN communication

Note: Bodywork builders and coachbuilders The control unit receives all the CAN messages

must not connect their own systems to the CAN – that are sent through the communication

network without the approval of Scania. If any circuit – in a special memory. This memory may

other equipment other than the factory fitted be compared to a number of radio receivers that

equipment is connected, safety and reliability are all on but set to different radio stations to

can be affected. listen to several radio programmes

simultaneously. In this way, the control unit

Note: It is not possible to measure or check always knows what is going on.

CAN messages with a multimeter either. Use the

fault codes to locate the cause of any possible

malfunctions.

CAN is an abbreviation of Controller Area

Network. CAN communication is used to reduce

the number of cables in the vehicle and at the

same time increase reliability. The

communication circuit consists of two cables,

CAN H (High) and CAN L (Low).

cardiagn.com

OPTICRUISE

COO ABS/TC EDC EBS

116 757

Several different systems are connected to these

two cables and in this way form a network.

CAN communication is used for example

between EDC, ABS/TC, EBS, the retarder,

Opticruise and the coordinator.

In simple terms, CAN communication is rather

like radio. The data messages that travel along a

CAN cable can be compared to radio waves that

travel through the air.

When listening to the radio, the receiver is set so

that one radio station is heard at one time. Only

one station is heard, even though many other

radio stations are transmitting simultaneously.

A control unit does approximately the same with

the messages that travel through a CAN cable. It

listens, for example, for information from the

EDC control unit concerning the coolant

temperature, receives this value and uses it in its

calculations.

03:04-02 ã Scania CV AB 2002, Sweden 55

You might also like

- Sistema de Combustible Con Inyector Bomba Pde y Edc s6 PDFDocument48 pagesSistema de Combustible Con Inyector Bomba Pde y Edc s6 PDFRuanWheeling100% (1)

- Work Description 9 Litre Engine With 5 CylindersDocument123 pagesWork Description 9 Litre Engine With 5 CylindersCharlie RebañoNo ratings yet

- Scania P, G, R, T Series Workshop Manual - Removing The RetarderDocument6 pagesScania P, G, R, T Series Workshop Manual - Removing The RetarderEdinson Ulloa100% (1)

- Wartungsanweisungen Für Gruppe 1-3 P-, G-, R - Und T-SerieDocument173 pagesWartungsanweisungen Für Gruppe 1-3 P-, G-, R - Und T-SerieWeber BennyNo ratings yet

- 19-20 Central Gear 1Document80 pages19-20 Central Gear 1Mamat salto100% (1)

- Oil CoolerDocument3 pagesOil CoolerCahyo Utomo100% (1)

- Clutch Controol p360Document15 pagesClutch Controol p360andi maryantoNo ratings yet

- DAF LF Gearboxes and Clutch Service ManualDocument254 pagesDAF LF Gearboxes and Clutch Service ManualNEBOJSANo ratings yet

- Scania Engines For 2011 - 178653Document6 pagesScania Engines For 2011 - 178653Volvo TruckNo ratings yet

- Scania P, G, R, T Series Workshop Manual - Draining AxlesDocument7 pagesScania P, G, R, T Series Workshop Manual - Draining AxlesBambang Mulyanto100% (1)

- LT-11a Gesamt EngDocument77 pagesLT-11a Gesamt EngPetar Nikolaev100% (3)

- TGX Air CompressorDocument52 pagesTGX Air CompressorChristian Mac Lean100% (1)

- Auxiliary Heater Operation Unit CTT D1LC and D1LCC: Issue 1Document35 pagesAuxiliary Heater Operation Unit CTT D1LC and D1LCC: Issue 1Dusan Masle100% (1)

- Turbo CompoundDocument8 pagesTurbo CompoundJack PranNo ratings yet

- Clutch Compressor Service Manual For VolvoDocument36 pagesClutch Compressor Service Manual For Volvox100% (2)

- Scania dc12 Cylinder Head TestDocument6 pagesScania dc12 Cylinder Head TestaliNo ratings yet

- Scania: DifferentialDocument4 pagesScania: DifferentialLuisTurpoNo ratings yet

- Volvo D16 Engine Family: Volvo Trucks. Driving ProgressDocument6 pagesVolvo D16 Engine Family: Volvo Trucks. Driving ProgressinduramNo ratings yet

- enDocument30 pagesenRegistr RegistrNo ratings yet

- Electric Installation ManualDocument47 pagesElectric Installation ManualAbuhurairah MunshiNo ratings yet

- Scania+Opticruise+transmission+troubleshooting PDFDocument84 pagesScania+Opticruise+transmission+troubleshooting PDFMikwile Julias KephaNo ratings yet

- Product Data Sheet ServotwinDocument2 pagesProduct Data Sheet Servotwinurl295100% (1)

- Close Crankcase Ventilation CCVDocument24 pagesClose Crankcase Ventilation CCVPetrus Kanisius Wiratno100% (2)

- Adjustable Parameters - EngineDocument33 pagesAdjustable Parameters - EnginescaniaNo ratings yet

- 8.edc 17 9 Aug 2016Document34 pages8.edc 17 9 Aug 2016iqbal husseinNo ratings yet

- Spare Parts Catalog: 16 S 151 IT Material Number: 1315.041.719 Current Date: 29.10.2013Document94 pagesSpare Parts Catalog: 16 S 151 IT Material Number: 1315.041.719 Current Date: 29.10.2013Муслим КадралиевNo ratings yet

- Pnumatic BrakeDocument19 pagesPnumatic BrakeClovis100% (1)

- Iveco StralisDocument1 pageIveco Stralisdejanflojd100% (2)

- Breake System DiagramsDocument36 pagesBreake System DiagramsAnd Dron100% (1)

- Automatic transmission system for coachesDocument2 pagesAutomatic transmission system for coachesGoudjil100% (1)

- P11X24EN Scania Opticruise and Retarder Tcm40 280864Document6 pagesP11X24EN Scania Opticruise and Retarder Tcm40 280864Ionut LefterNo ratings yet

- Hub Reduction Gear RH 835Document60 pagesHub Reduction Gear RH 835Syarifuddin Rahman100% (1)

- Atc Fault Code List PDFDocument10 pagesAtc Fault Code List PDFPutra PuguhNo ratings yet

- Air Suspention Work DescriptionDocument52 pagesAir Suspention Work DescriptionHari100% (1)

- Meritor Service Caliper ELSA1 and ELSA2 - MM1129Document90 pagesMeritor Service Caliper ELSA1 and ELSA2 - MM1129LUKASNo ratings yet

- Electrical System Issue 7Document38 pagesElectrical System Issue 7Charl Pietersen100% (1)

- Cooling T4FDocument19 pagesCooling T4FDragan100% (1)

- Wheel Brake Component For Drum-Work Desc - 10.02-06Document48 pagesWheel Brake Component For Drum-Work Desc - 10.02-06Novie RizkyNo ratings yet

- Magnum Dxi13 Engine Torque Settings PDFDocument67 pagesMagnum Dxi13 Engine Torque Settings PDFbuchniyNo ratings yet

- Fuel Injection PDFDocument11 pagesFuel Injection PDFscaniaNo ratings yet

- SCR System Issue 1Document24 pagesSCR System Issue 1Teddy KhantNo ratings yet

- Retrofitting Alarm and Theft Protection, VPS: Issue 1Document36 pagesRetrofitting Alarm and Theft Protection, VPS: Issue 1ruanNo ratings yet

- Injector NozleDocument25 pagesInjector NozleHariNo ratings yet

- Cutting The Cylinder Head Gasket Grooves On A Planed Sealing SurfaceDocument8 pagesCutting The Cylinder Head Gasket Grooves On A Planed Sealing SurfaceruanNo ratings yet

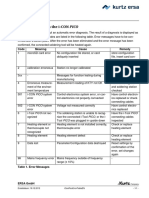

- Error Messages in The i-CON PICODocument1 pageError Messages in The i-CON PICOIvana Ika StankovicNo ratings yet

- Engine Data D12 PDFDocument20 pagesEngine Data D12 PDFClaudesson Nascimento Rodrigues100% (1)

- Field Service Tips: Fault tracing on D6B enginesDocument3 pagesField Service Tips: Fault tracing on D6B enginesyazeed naibanNo ratings yet

- EAS-3 Epa mx13Document2 pagesEAS-3 Epa mx13Robles JmrNo ratings yet

- Wartungsanweisungen Für Gruppe 7-9 P-, G-, R - Und T-SerieDocument24 pagesWartungsanweisungen Für Gruppe 7-9 P-, G-, R - Und T-SerieWeber BennyNo ratings yet

- Engine Oil Pressure Fault DiagnosisDocument9 pagesEngine Oil Pressure Fault DiagnosisIzz BaharNo ratings yet

- Scania: Pumpe Za Vodu I Ulje Water & Oil PumpsDocument4 pagesScania: Pumpe Za Vodu I Ulje Water & Oil PumpsJasminM dooNo ratings yet

- Daf Ix Custom Par Pmci2Document12 pagesDaf Ix Custom Par Pmci2Mircea GilcaNo ratings yet

- P Dmci (D965) : Ower Supply and Earth of Electronic UnitDocument136 pagesP Dmci (D965) : Ower Supply and Earth of Electronic UnitBranko Andric100% (1)

- Industrial and Genset Engines Issue 9Document47 pagesIndustrial and Genset Engines Issue 9ramon hidalgoNo ratings yet

- Technical Note - Diagnostics: I - Subject: Engine Oil Circuit Diagnostics HelpDocument7 pagesTechnical Note - Diagnostics: I - Subject: Engine Oil Circuit Diagnostics Helpsdr saviNo ratings yet

- CALIBRACIONDocument65 pagesCALIBRACIONNuñez JesusNo ratings yet

- Scania Ralentizador 100507 PDFDocument39 pagesScania Ralentizador 100507 PDFGermainCampillayNo ratings yet

- Scania dt12 02 470 Euro 3 Engine Emission Measurements For Vti and Cost 346 PDFDocument48 pagesScania dt12 02 470 Euro 3 Engine Emission Measurements For Vti and Cost 346 PDFsusundegiNo ratings yet

- Zulfiqar Engineering Works Quotation 13-07-2020555Document1 pageZulfiqar Engineering Works Quotation 13-07-2020555Musharraf KhanNo ratings yet

- "Guard Touch" Control Panel: Main FeaturesDocument1 page"Guard Touch" Control Panel: Main FeaturesWaqar AhmedNo ratings yet

- Opticruise: Description of Operation and Work DescriptionDocument84 pagesOpticruise: Description of Operation and Work DescriptionMusharraf KhanNo ratings yet

- Fuel System With Unit Injector PDE and EDC MS6: Issue 3Document55 pagesFuel System With Unit Injector PDE and EDC MS6: Issue 3Musharraf KhanNo ratings yet

- Scania HPI Injection System and Edc S6Document70 pagesScania HPI Injection System and Edc S6Musharraf Khan83% (6)

- EDC MS5 For Injection PumpDocument64 pagesEDC MS5 For Injection PumpMusharraf KhanNo ratings yet

- Special Functions: Issue 1Document24 pagesSpecial Functions: Issue 1Musharraf KhanNo ratings yet

- Fuel System With Unit Injector PDE and EDC MS6: Issue 2Document60 pagesFuel System With Unit Injector PDE and EDC MS6: Issue 2Musharraf KhanNo ratings yet

- Wiring Diagram Handbook: For LHD and RHD TrucksDocument96 pagesWiring Diagram Handbook: For LHD and RHD TrucksMusharraf KhanNo ratings yet

- EDC MS5 In-Line Injection Pump: Issue 2Document57 pagesEDC MS5 In-Line Injection Pump: Issue 2Musharraf KhanNo ratings yet

- 2013Document102 pages2013ctorres_505746100% (1)

- PM Loan SchemeDocument9 pagesPM Loan SchemeKaleem WebCornerNo ratings yet

- Terberg Operation ManualDocument43 pagesTerberg Operation Manualahsa86% (7)

- EDC MS5 For Injection Pump: Issue 3Document17 pagesEDC MS5 For Injection Pump: Issue 3Musharraf KhanNo ratings yet

- Application FormDocument3 pagesApplication Formsunnykhan bwnNo ratings yet

- "Guard Touch" Control Panel: Main FeaturesDocument1 page"Guard Touch" Control Panel: Main FeaturesWaqar AhmedNo ratings yet

- DSE7310 MKII DSE7320 MKII Configuration Suite PC Software ManualDocument168 pagesDSE7310 MKII DSE7320 MKII Configuration Suite PC Software ManualCarlos Petul100% (1)

- Zulfiqar Engineering Works Quotation 13-07-2020555Document1 pageZulfiqar Engineering Works Quotation 13-07-2020555Musharraf KhanNo ratings yet

- FM, FH 4x2, BSYS-EBS A509018 - B246868Document9 pagesFM, FH 4x2, BSYS-EBS A509018 - B246868Евгений Аксёнов100% (2)

- WSM 0000591 01Document87 pagesWSM 0000591 01David MurrayNo ratings yet

- Fault Codes: STO U AndriivDocument23 pagesFault Codes: STO U AndriivAtochkavNo ratings yet

- CPC Module 2 Session 2Document73 pagesCPC Module 2 Session 2Tigg CNo ratings yet

- ECE-TRANS-WP29-GRRF-62-inf09a1e ISO 11992Document30 pagesECE-TRANS-WP29-GRRF-62-inf09a1e ISO 11992PawluchNo ratings yet

- AutotronicsDocument5 pagesAutotronicsshintoNo ratings yet

- MAN TGA Wiring Diagrams (032 062) PDFDocument31 pagesMAN TGA Wiring Diagrams (032 062) PDFAbdelhak Ezzahrioui100% (5)

- Full Power For Start-Stop and All Consumer Units in The Car - S5 EFB and S6 AGM From BoschDocument12 pagesFull Power For Start-Stop and All Consumer Units in The Car - S5 EFB and S6 AGM From BoschdekaNo ratings yet

- Application Software ListDocument514 pagesApplication Software Listyoppp1100% (1)

- Ebs (Epb) - Electronically Controlled Braking System: Description of System and FunctionsDocument36 pagesEbs (Epb) - Electronically Controlled Braking System: Description of System and Functionsoskar oskarNo ratings yet

- Man TGX Fuse Box DiagramDocument7 pagesMan TGX Fuse Box DiagramIB Eldin0% (1)

- Ebs System PDFDocument5 pagesEbs System PDFBipulBrahmaNo ratings yet

- WSM 0000410 01Document64 pagesWSM 0000410 01Viktor Sebastian Morales CabreraNo ratings yet

- Ivtm - Tire Pressure Monitoring For Commercial Vehicles: System DescriptionDocument48 pagesIvtm - Tire Pressure Monitoring For Commercial Vehicles: System DescriptionElmin SkuljNo ratings yet

- Wabco Ebs D PDFDocument8 pagesWabco Ebs D PDFarminNo ratings yet

- Truck 5 0.0.0: IDC5 Softwar e UpdateDocument64 pagesTruck 5 0.0.0: IDC5 Softwar e UpdatescaniaNo ratings yet

- 4200133-Polaris 2008 Sportsman 700-800 Service ManualDocument378 pages4200133-Polaris 2008 Sportsman 700-800 Service ManualRyan Marrs100% (3)

- Wiring Diagram Renault C PDFDocument724 pagesWiring Diagram Renault C PDFHAMDANE HAMDANE0% (1)

- Apm VolvoDocument23 pagesApm VolvoAlexandru Nicola100% (9)

- Volvo Service Manual Trucks MID128Document172 pagesVolvo Service Manual Trucks MID128Dan Birkenhead96% (91)

- Circuitos Freno - KNORRDocument352 pagesCircuitos Freno - KNORRPaulo Jorge Oliveira100% (6)

- EBS Wiring Diagrams for 3-Axle TrucksDocument56 pagesEBS Wiring Diagrams for 3-Axle TrucksMyk VoroshchukNo ratings yet

- 1939 1708 Data Link Fault TracingDocument16 pages1939 1708 Data Link Fault TracingAyoub Ayoub100% (1)

- Initial Quick Test LogDocument6 pagesInitial Quick Test LogDedi RahmatNo ratings yet

- Renault Midlum D- Range D 18 Technical SpecificationsDocument5 pagesRenault Midlum D- Range D 18 Technical SpecificationsAliNo ratings yet

- Scania CatalogDocument54 pagesScania Catalogkhaledshekh133No ratings yet

- How Can Convert My Petrol Car To Electric CarDocument5 pagesHow Can Convert My Petrol Car To Electric CarAdekunle AdewoleNo ratings yet

- 2014 08 01 Techinfo Conecto enDocument16 pages2014 08 01 Techinfo Conecto enGfggftNo ratings yet

- Knorr BrakeDocument116 pagesKnorr BrakesengottaiyanNo ratings yet

- Wiring Diagram EBSDocument9 pagesWiring Diagram EBSnikolayNo ratings yet

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerFrom EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerRating: 4.5 out of 5 stars4.5/5 (53)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestFrom EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestRating: 4 out of 5 stars4/5 (28)

- The Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesFrom EverandThe Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesRating: 5 out of 5 stars5/5 (1)

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionFrom EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionRating: 4.5 out of 5 stars4.5/5 (543)

- Why We Drive: Toward a Philosophy of the Open RoadFrom EverandWhy We Drive: Toward a Philosophy of the Open RoadRating: 4.5 out of 5 stars4.5/5 (21)

- CDL Study Guide 2024-2025: Exam Prep Book With 425+ Questions and Explained Answers to Pass the Commercial Driver’s License Exam on Your First Try, With the Most Complete and Up-To-Date Practice Tests [Complete Version]From EverandCDL Study Guide 2024-2025: Exam Prep Book With 425+ Questions and Explained Answers to Pass the Commercial Driver’s License Exam on Your First Try, With the Most Complete and Up-To-Date Practice Tests [Complete Version]Rating: 5 out of 5 stars5/5 (2)

- The RVer's Bible (Revised and Updated): Everything You Need to Know About Choosing, Using, and Enjoying Your RVFrom EverandThe RVer's Bible (Revised and Updated): Everything You Need to Know About Choosing, Using, and Enjoying Your RVRating: 5 out of 5 stars5/5 (2)

- OBD-I and OBD-II: A Complete Guide to Diagnosis, Repair, and Emissions ComplianceFrom EverandOBD-I and OBD-II: A Complete Guide to Diagnosis, Repair, and Emissions ComplianceNo ratings yet