Professional Documents

Culture Documents

Test Pack Format

Test Pack Format

Uploaded by

miteshCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Test Pack Format

Test Pack Format

Uploaded by

miteshCopyright:

Available Formats

Test Pack Format

- Pressure test report for Piping

- Marked-up PID

- Blind check list

- Welding History Report and Welding Joint Marked ISO Drawing

- NDE Report

- PWHT and Hardness test Report

- Post – Test Punch List (contractor + Client)

- Copies of reinforcing pad pressure test certificates (If necessary).

Test packs will include the latest available revision of each isometric covering the

scope of the test.

a. Test limits, and highlight line to be tested.

b. Size (thickness') and location of all test blinds and including those required at

instrument connections e.g. orifice flanges.

c. Identify location for the connection of the fill and drainage points for the

system.

d. Vent points

e. Drain points

f. Location and range of pressure gauges to be used. Minimum (2) Calibrate

gauges enquired, one located at an accessible low point of the test and one

gauge located at the highest points on the test manifold.

g. Any other special requirements such as chloride content if applicable

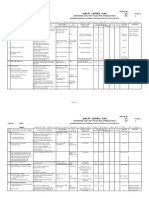

CONTENTS OF HYDROSTATIC

TEST PACKAGES

Cover sheet Pressurize As- Built File

Description of Line Test

Safety Check Sheet

Pipe Work Pre test

Check list

Hydrostatic Test Report

Monitoring During Testing

Data Sheet

Turn over Dossier

Welding Travel

Check Sheet

Heat Treatment

Check Sheet

Hardness Testing Report

Blow, Flush & Chemical

Cleaning Check List

Flushing & Cleaning

Check List

Punch List Check Sheet

NDT Reports

You might also like

- Storage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFDocument1 pageStorage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFJaco CalitzNo ratings yet

- 010 - ITP For Hydro TestDocument5 pages010 - ITP For Hydro TestSam Jose0% (2)

- 201485-25000-QP-01-B Inspection Test Plan (ITP) For FRP Tank R0Document1 page201485-25000-QP-01-B Inspection Test Plan (ITP) For FRP Tank R0muchamad yasin100% (1)

- Piping Field Inspection Checklist DikonversiDocument3 pagesPiping Field Inspection Checklist DikonversiJo Francesc100% (2)

- Method Statement of Gate ValvesDocument8 pagesMethod Statement of Gate ValvesRamalingam PrabhakaranNo ratings yet

- Inspection Checklist: Pipes and Fittings Material Receiving PipingDocument2 pagesInspection Checklist: Pipes and Fittings Material Receiving PipingSardarFaisalHameed100% (2)

- Offer Letter McDermott Onshore - Nitin Kumar PatelDocument3 pagesOffer Letter McDermott Onshore - Nitin Kumar PatelmiteshNo ratings yet

- Hydrostatic Test Report FormDocument1 pageHydrostatic Test Report FormCipta AdikaryaNo ratings yet

- Inspection and Test Plan For HDPE PipingDocument1 pageInspection and Test Plan For HDPE Pipingkadir tanzania100% (2)

- Dimensional Inspection ReportDocument2 pagesDimensional Inspection Reportshabbir626No ratings yet

- Inspection and Test Plan For Piping (PP/FRP Piping)Document2 pagesInspection and Test Plan For Piping (PP/FRP Piping)Anonymous EyK4vt6Y100% (1)

- Dimensional Inspection ReportDocument2 pagesDimensional Inspection Reportrize1159No ratings yet

- Hydrostatic Test Report Form - 201211201035009705 PDFDocument1 pageHydrostatic Test Report Form - 201211201035009705 PDFมินคุง เอโอซี100% (2)

- Inspection Test Plan For Pipeline JobsDocument6 pagesInspection Test Plan For Pipeline Jobsمحمد أزها نو الدينNo ratings yet

- Inspection and Test Plan For Shell and Tube Heat ExchangerDocument6 pagesInspection and Test Plan For Shell and Tube Heat ExchangertomychalilNo ratings yet

- ITP - Erection of Static EquipmentDocument4 pagesITP - Erection of Static Equipmentbhct1987No ratings yet

- Itp For InsulationDocument14 pagesItp For InsulationHytham El-NoubyNo ratings yet

- Visual Inspection Checklist For Piping Systems: Connected Mechanical Equipment, Instrumentation, and Pipe Support SystemsDocument2 pagesVisual Inspection Checklist For Piping Systems: Connected Mechanical Equipment, Instrumentation, and Pipe Support SystemsrajuajiNo ratings yet

- ITP For Storage TankDocument6 pagesITP For Storage TankAhmed Ben HmidaNo ratings yet

- Water Tank ItpDocument5 pagesWater Tank ItpHgagselim SelimNo ratings yet

- 24 Pressure Testing Report - FormatDocument1 page24 Pressure Testing Report - FormatRrgs Bandara100% (1)

- ITP SampleDocument6 pagesITP SampleMat RidhanNo ratings yet

- Bolt Tightening ReportDocument1 pageBolt Tightening ReportMahfudRido'iRonggomaniaNo ratings yet

- SAIC-L-2017 Piping Sys Internal Cleanliness Verif PDFDocument4 pagesSAIC-L-2017 Piping Sys Internal Cleanliness Verif PDFAnonymous S9qBDVkyNo ratings yet

- Inspection report-GRVE BlankDocument2 pagesInspection report-GRVE BlankJoseph Perez100% (1)

- ITP For Hydraulic BarrierDocument4 pagesITP For Hydraulic Barriermoytabura96No ratings yet

- Flange Management Register PDFDocument1 pageFlange Management Register PDFsudeesh kumar100% (1)

- Fit Up Report Format-1Document1 pageFit Up Report Format-1BalkishanDyavanapellyNo ratings yet

- Itp For Installation of Pressurization UnitDocument1 pageItp For Installation of Pressurization UnitvictorNo ratings yet

- Wps & Pqr-013 (Ss Gtaw-Smaw TGS)Document17 pagesWps & Pqr-013 (Ss Gtaw-Smaw TGS)Atuk SafizNo ratings yet

- Inspection & Test Plan (ITP) For Simple Package EquipmentDocument2 pagesInspection & Test Plan (ITP) For Simple Package Equipmentxajo50% (2)

- 04 Weld Joint NumberingDocument3 pages04 Weld Joint NumberingAkhilesh KumarNo ratings yet

- Flange Installation ProceduresDocument3 pagesFlange Installation Proceduresgplese0100% (1)

- 5 - Tank Itp - Inspection & Test Plan For TanksDocument9 pages5 - Tank Itp - Inspection & Test Plan For Tanksmandi100% (1)

- Sadara MFC Inspection Checklist: Copper Pipe Installation SMIC-S-4050 PlumbingDocument1 pageSadara MFC Inspection Checklist: Copper Pipe Installation SMIC-S-4050 PlumbingSiddiqui Abdul KhaliqNo ratings yet

- 0.hydro Test Package Index - 1Document13 pages0.hydro Test Package Index - 1VISHNUPRASAD ARAKKAL MOHANDASNo ratings yet

- Storage Tank Shell Banding Quality Control and Inspection Report FormDocument1 pageStorage Tank Shell Banding Quality Control and Inspection Report FormAlif Rahmat FebriantoNo ratings yet

- SA04C2-T-MET-AAG-00037 Hydrotest Method StatementDocument25 pagesSA04C2-T-MET-AAG-00037 Hydrotest Method StatementABAID ULLAH100% (2)

- Weld Visual Report Rev.0Document1 pageWeld Visual Report Rev.0John TerryNo ratings yet

- 0901b80380959cc7 PDFDocument2 pages0901b80380959cc7 PDFikan100% (1)

- Inspection Report-Hdpec BlankDocument2 pagesInspection Report-Hdpec BlankJoseph Perez100% (1)

- Sample ItpDocument4 pagesSample ItpWijayanto BekasiNo ratings yet

- Itp Concrete CoatingDocument4 pagesItp Concrete Coatingkaml100% (1)

- Piping Fabrication Installation QCP On SiteDocument1 pagePiping Fabrication Installation QCP On SiteTarun PatelNo ratings yet

- Blowers Fans Supply Verification ITPDocument7 pagesBlowers Fans Supply Verification ITPgauravamberkarNo ratings yet

- Bolted Flanged Joints New Methods Practices ProceedingsDocument2 pagesBolted Flanged Joints New Methods Practices ProceedingsMladen ČorokaloNo ratings yet

- Pipeline Pressure Test Flow Chart PDFDocument1 pagePipeline Pressure Test Flow Chart PDFKing王No ratings yet

- F07-Visual Inspection Report NEWDocument1 pageF07-Visual Inspection Report NEWmohd as shahiddin jafriNo ratings yet

- Letter For Testing of PQRDocument1 pageLetter For Testing of PQRPA PROJECTS PVT LTDNo ratings yet

- Itp For Carbon Steel PipeDocument9 pagesItp For Carbon Steel PipehamedpdmsNo ratings yet

- Pressurized Air Shock BlowingDocument3 pagesPressurized Air Shock BlowingEmir PayNo ratings yet

- Sanitary Check ListDocument36 pagesSanitary Check ListankurNo ratings yet

- ITP For Electric HeatersDocument5 pagesITP For Electric Heatersakram husseinNo ratings yet

- Pqr-152 - Run SheetDocument38 pagesPqr-152 - Run SheetMAT-LIONNo ratings yet

- Chemical Resistance (LLDPE) PDFDocument24 pagesChemical Resistance (LLDPE) PDFrubyshreeNo ratings yet

- SAIC-LT-2007 LeaK Testing-Vacuum BoxDocument3 pagesSAIC-LT-2007 LeaK Testing-Vacuum BoxKirubhakarPooranamNo ratings yet

- BPV IX-16-3 QW-283 - ButteringDocument1 pageBPV IX-16-3 QW-283 - ButteringyutweldingNo ratings yet

- 2014 10 14 Pipework SpecificationDocument110 pages2014 10 14 Pipework SpecificationmionomeNo ratings yet

- Piping, Hydro QC List-InterviewDocument3 pagesPiping, Hydro QC List-InterviewAnonymous 4e7GNjzGW100% (2)

- Lines Piping - Gross Air Leak TestDocument1 pageLines Piping - Gross Air Leak TestHashemAliHashemNo ratings yet

- Sample QAPDocument3 pagesSample QAPsniperiNo ratings yet

- Na GR 02 Sep 2016 NewDocument8 pagesNa GR 02 Sep 2016 NewmiteshNo ratings yet

- Split Type Room Air Conditioner Operation ManualDocument8 pagesSplit Type Room Air Conditioner Operation ManualmiteshNo ratings yet

- Background Story Pipeline Construction en 1Document22 pagesBackground Story Pipeline Construction en 1miteshNo ratings yet

- API 571 SummaryDocument17 pagesAPI 571 Summarymitesh100% (2)

- Haier Controller HBS01 ManualDocument2 pagesHaier Controller HBS01 ManualmiteshNo ratings yet

- Boiler SafetyDocument23 pagesBoiler SafetymiteshNo ratings yet

- SPEC CHECK Checklist-LanglaDocument7 pagesSPEC CHECK Checklist-LanglamiteshNo ratings yet

- The Process of Fatigue Analysis On Fixed Metal Offshore PlatformsDocument7 pagesThe Process of Fatigue Analysis On Fixed Metal Offshore PlatformsmiteshNo ratings yet

- PID A Specs: 'S Ttention To & SPEC-CheckDocument1 pagePID A Specs: 'S Ttention To & SPEC-CheckmiteshNo ratings yet

- Heat Treatment Furnaces and AtmospheresDocument12 pagesHeat Treatment Furnaces and AtmospheresmiteshNo ratings yet

- Support DetailsDocument1 pageSupport DetailsmiteshNo ratings yet

- Heat Treatment and Related Processes: AnnealingDocument24 pagesHeat Treatment and Related Processes: AnnealingmiteshNo ratings yet

- Cab o SilDocument8 pagesCab o SilmiteshNo ratings yet

- Qa-Rkm-Techdoc-Ht-A6 - PreheatDocument3 pagesQa-Rkm-Techdoc-Ht-A6 - PreheatmiteshNo ratings yet

- QW-451 Procedure Qualification Thickness Limits and Test SpecimensDocument2 pagesQW-451 Procedure Qualification Thickness Limits and Test SpecimensmiteshNo ratings yet

- CCGT BookDocument14 pagesCCGT BookmiteshNo ratings yet