Professional Documents

Culture Documents

Inspection & Test Plan for Simple Package Equipment

Uploaded by

xajoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inspection & Test Plan for Simple Package Equipment

Uploaded by

xajoCopyright:

Available Formats

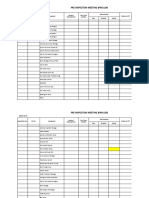

Inspection & Test Plan (ITP) for Simple Package Equipment

NO SEQUENCE ACTIVITY DOCS ACC CRITERIA VERIFICATION

VENDOR PIC Name sign Date CTR CPY 3RD PARTY

1 Construction prepare

1.1 Receiving of drawings NA Manufacturing work order Drawing

list

1.2 Verify of drawings NA

1.3 Approval of ITP Check on availability of approved ITP Inspection & Test Plan Inspection & Test Plan

1.4 Technical clarifications Construct Drawings and Technical clarifications records

specification

1.5 Welding Procedures Qualification Record (WPQR) Check WPQR PQR API PQR reports

EN 15614-1

1.6 Approval of weld procedures specification (WPS) Check on availability of approved WPS Welding procedure ASME sect IX WPS

EN 15614-1

ASME section IX

1.7 Welders Performance Qualification (WPQ) Witness welder qualification Welder Approval Certificate EN 9606-1 Approval Certificates

2 Material inspection & acceptance

2.1 Check Material compliance Material specification Piping class & Drawing EN 10204 Acceptance certificate

3 prefabrication

EN 17637 Construct Dwg and

3.1 Visual checks, dimensions and welds Inspection Record and welding record

specification

Operator qualification level III

3.2 NDE inspection (dye Penetrant test) Procedure of penetrant testing examination ASME V article 6 & VIII div 1 Dye Penetrant test record

acc to ASME I, III, V & IX

Page 1 B12146 ITP ABB Filtration skid

NO SEQUENCE ACTIVITY DOCS ACC CRITERIA VERIFICATION

VENDOR PIC Name sign Date CTR CPY 3RD PARTY

4 Delivery of Equipment from sub-suppliers

Piping class

4.1 Control at delivery (filters, intruments, steel Check compliance Drawing Compliance Under SAP

structure ...) Paint specification

Purchase Order descript.

5 Erection and equipment assembly

Dimensional check of equipment and piping Equipment layout dwg, P&ID Constructure Dwg. and

5.1 Check layout of Equipment & Piping against drawings Final check report

locations and isometric drawings specification

Pressure test procedure and

5.2 Carry out pressure and leak test (Air test) Witness test P&ID No leak detection Pressure test report

5.3 Paint inspection Paint color, thickness, adhesion Painting procedure Final check report

6 Piping cleaning check

Construct drawing and the

6.1 Piping internal cleaning check Pipe cleaning procedure Continuous supervision

spec

7 Final Inspection & control - FAT

7.1 Factory acceptance test Check final quality when all work is done FAT procedure Compliance FAT report

8 Punch List Killing

8.1 Punch List Killing Solve punch list reserves Punch List Solve the reserves Inspection report

9 QA/QC Dossier

Include in the project final

9.1 All reports during fabrication Dossier compilation

documentation

10 Delivery

10.1 Packing readiness Prepare for packing Packing list Logistic service check and Inform planning dept of readiness for

acceptance packing

Check case content before closing

10.2 Packing order Check case markings Packing list Logistic service check and Inform planning dept of readiness for

Check case fabrication Packing specifications acceptance transport

Page 2 B12146 ITP ABB Filtration skid

You might also like

- PBI-ITP-QA-0001 Inspection and Test Plan Rev.0Document7 pagesPBI-ITP-QA-0001 Inspection and Test Plan Rev.0Tadaya KasaharaNo ratings yet

- Hydraulic crash barriers ITPDocument4 pagesHydraulic crash barriers ITPmoytabura96No ratings yet

- Contractor Quality Control Plan For Rotary Equipment InstallationDocument4 pagesContractor Quality Control Plan For Rotary Equipment InstallationJoel SnowNo ratings yet

- Inspection & Test Plan for Chilled Water Expansion TanksDocument1 pageInspection & Test Plan for Chilled Water Expansion TanksvictorNo ratings yet

- SATR-L-2001 Rev 2 - Flange Joint Tightening Inspection ReportDocument12 pagesSATR-L-2001 Rev 2 - Flange Joint Tightening Inspection Reportdeepa narayan100% (1)

- Pressure Vessel Inspection and Test Plan ChecklistDocument4 pagesPressure Vessel Inspection and Test Plan ChecklistkorbelNo ratings yet

- Inspection and Test Plan For Piping (PP/FRP Piping)Document2 pagesInspection and Test Plan For Piping (PP/FRP Piping)Anonymous EyK4vt6Y100% (1)

- Sample - Template - Itp For Piping Fabrication and InstallationDocument2 pagesSample - Template - Itp For Piping Fabrication and Installationmohd as shahiddin jafriNo ratings yet

- Iqwq-ce1092-Qpqac-00-0001 - 0 -Quality Control Procedure for Civil 土建质量控制程序Document37 pagesIqwq-ce1092-Qpqac-00-0001 - 0 -Quality Control Procedure for Civil 土建质量控制程序Ali MajeedNo ratings yet

- Contractor Quality Control Plan For Fix or Stationery Equipment Installation Inspection and Test Plan For Fix or Stationery Equipment InstallationDocument5 pagesContractor Quality Control Plan For Fix or Stationery Equipment Installation Inspection and Test Plan For Fix or Stationery Equipment InstallationSergey KichenkoNo ratings yet

- Inspection and Test Plan For Above Ground FRP Piping Fabrication & Erection at FieldDocument3 pagesInspection and Test Plan For Above Ground FRP Piping Fabrication & Erection at FieldGohel100% (1)

- Test Pack Format: Contents of Hydrostatic Test PackagesDocument2 pagesTest Pack Format: Contents of Hydrostatic Test PackagesmiteshNo ratings yet

- ITP - 004 - Static Equipment - IFRDocument3 pagesITP - 004 - Static Equipment - IFRMari BelajarNo ratings yet

- Sample Forms WPS PQRDocument22 pagesSample Forms WPS PQRGMNo ratings yet

- 2539-00-ITP-012 - 0 - ITP For Plastic Piping PDFDocument17 pages2539-00-ITP-012 - 0 - ITP For Plastic Piping PDFdang2172014100% (1)

- Hydrotest ProcedureDocument6 pagesHydrotest Procedurebagusu_6No ratings yet

- Qap HPCLDocument13 pagesQap HPCLdarshan100% (1)

- Inspection & Test Plan For Equipment Erection (Static) : ITP NO.:-9560/SITE/QAC/029/ITP-15Document4 pagesInspection & Test Plan For Equipment Erection (Static) : ITP NO.:-9560/SITE/QAC/029/ITP-15Shubham ShuklaNo ratings yet

- PP1-2M90-1043-007 - B - Inspection Test Procedure - CODE BDocument11 pagesPP1-2M90-1043-007 - B - Inspection Test Procedure - CODE Bfreeman11072000No ratings yet

- Inspection Test Plan Fuel Gas Conditioning SkidDocument19 pagesInspection Test Plan Fuel Gas Conditioning SkidDin AizuNo ratings yet

- Chemical Resistance (LLDPE) PDFDocument24 pagesChemical Resistance (LLDPE) PDFrubyshreeNo ratings yet

- Control Valves Installation ChecklistDocument2 pagesControl Valves Installation Checklistabdelkader benabdallahNo ratings yet

- Fit Up ReportDocument41 pagesFit Up ReportFendik NewbieNo ratings yet

- Storage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFDocument1 pageStorage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFRadhakrishna VachaNo ratings yet

- Inspection, Flushing & Testing of Piping-21Document6 pagesInspection, Flushing & Testing of Piping-21Saurabh Kumar VermaNo ratings yet

- ITP - (Pressure Testing Piping) PDFDocument3 pagesITP - (Pressure Testing Piping) PDFSUNNY BOSS100% (1)

- Jacobs: Equipment Inspection Code: ADocument2 pagesJacobs: Equipment Inspection Code: ASigit BintanNo ratings yet

- Hydrotest Procedure For HVAC PKG#2 (Incl. Fire Fighting) WorkDocument8 pagesHydrotest Procedure For HVAC PKG#2 (Incl. Fire Fighting) WorkCipta Adikarya100% (1)

- (Painting Works) : Inspection and Test PlanDocument2 pages(Painting Works) : Inspection and Test Planrize1159No ratings yet

- EFCO Maschinenbau India Private Limited: Job Card - Isolation ValveDocument2 pagesEFCO Maschinenbau India Private Limited: Job Card - Isolation ValveDebasis Pattnaik DebaNo ratings yet

- WPS Pipe 08'' SHD 40 SMAW REV02Document2 pagesWPS Pipe 08'' SHD 40 SMAW REV02Amine MaalejNo ratings yet

- FGD Project at 2X 525 MW MPL: Document Title: FQP For General Structural Works of FGDDocument10 pagesFGD Project at 2X 525 MW MPL: Document Title: FQP For General Structural Works of FGDBhanu Pratap Choudhury100% (1)

- ITP For Process PipingDocument4 pagesITP For Process PipingSebastian RajeshNo ratings yet

- 1.13 Inspection & Test PlansDocument1 page1.13 Inspection & Test Plansabimanyubawono100% (2)

- Inspection Release NoteDocument1 pageInspection Release NoteNur WijiantoNo ratings yet

- 04 Weld Joint NumberingDocument3 pages04 Weld Joint NumberingAkhilesh KumarNo ratings yet

- MS For Fabrication of Above-Ground Storage TankDocument8 pagesMS For Fabrication of Above-Ground Storage Tankdadz mingiNo ratings yet

- Inspection and Test Plan For Process PipingDocument4 pagesInspection and Test Plan For Process PipingRobin GuNo ratings yet

- Sample ItpDocument4 pagesSample ItpWijayanto BekasiNo ratings yet

- Company Logo Added to QAP DocumentDocument4 pagesCompany Logo Added to QAP Documentmanoj thakkar100% (1)

- Welding Report For PipingDocument1 pageWelding Report For PipingRifki HasyaNo ratings yet

- Itp PipingDocument18 pagesItp PipingBayu Reza Fauzi100% (1)

- Daily Welding Progress ReportDocument1 pageDaily Welding Progress ReportManoj KumarNo ratings yet

- Quality Control Manual GuideDocument99 pagesQuality Control Manual Guidedoyenofcastle100% (4)

- GRE Pipes Inspection Test PlanDocument6 pagesGRE Pipes Inspection Test PlanMat RidhanNo ratings yet

- Technical Bid Evaluation SheetDocument3 pagesTechnical Bid Evaluation SheetPer Bagus HandokoNo ratings yet

- NCT-SCN-000-E06-00002: Site Query on NDT Personnel QualificationDocument1 pageNCT-SCN-000-E06-00002: Site Query on NDT Personnel QualificationCharles KingNo ratings yet

- Fabrication Procedure for Rolling Shell PlatesDocument10 pagesFabrication Procedure for Rolling Shell PlatesMuhammad Yunus NurdinNo ratings yet

- FInal QAP HDPE WeldingDocument2 pagesFInal QAP HDPE Weldingkannagi198No ratings yet

- ITP-SV-M-FAN-CENTRIFUGAL&AXIALDocument7 pagesITP-SV-M-FAN-CENTRIFUGAL&AXIALgauravamberkarNo ratings yet

- 004 - Method of Statement of BendingDocument9 pages004 - Method of Statement of Bendingahmed08839494100% (1)

- Scaffold ChecklistDocument5 pagesScaffold ChecklistMohamed GhariebNo ratings yet

- LOG-563-03 Receiving Inspection Checklist Rev.1Document1 pageLOG-563-03 Receiving Inspection Checklist Rev.1Emy SumartiniNo ratings yet

- Precision Storage Vessels PVT LTD: Pressure Test ReportDocument2 pagesPrecision Storage Vessels PVT LTD: Pressure Test ReportSenthil Kumaran100% (1)

- Iso9001 AsmeDocument2 pagesIso9001 AsmeAnonymous wKvJXBJ2iNo ratings yet

- Factory Acceptance Test & SAT Site Acceptance TestDocument3 pagesFactory Acceptance Test & SAT Site Acceptance TestMohamedNo ratings yet

- Technical Requisition SummaryDocument48 pagesTechnical Requisition Summarykunal shahNo ratings yet

- Itp For Piping Fabrication and InstallationDocument10 pagesItp For Piping Fabrication and InstallationwidiNo ratings yet

- 4.1i Inspection &test PlanDocument8 pages4.1i Inspection &test PlanISAACNo ratings yet

- Scan 27 Sep 2020 (3)Document2 pagesScan 27 Sep 2020 (3)SURAJ PRSADNo ratings yet

- Pre Inspection Meeting LogDocument8 pagesPre Inspection Meeting LogxajoNo ratings yet

- PJ Punch List TrackingDocument10 pagesPJ Punch List TrackingxajoNo ratings yet

- Positive Material Identification Control SheetDocument1 pagePositive Material Identification Control SheetxajoNo ratings yet

- Fat and Inspection MonitoringDocument15 pagesFat and Inspection MonitoringxajoNo ratings yet

- Pre Inspection Meeting LogDocument8 pagesPre Inspection Meeting LogxajoNo ratings yet

- Flowchart of Piping InspectionDocument1 pageFlowchart of Piping InspectionxajoNo ratings yet

- Status Inspection SampleDocument5 pagesStatus Inspection SamplexajoNo ratings yet

- PWHT Equipment and ToolsDocument3 pagesPWHT Equipment and ToolsxajoNo ratings yet

- Daily Welding Report FormDocument1 pageDaily Welding Report FormxajoNo ratings yet

- File12992 0 m10Document2 pagesFile12992 0 m10mikecostantiniNo ratings yet

- Istilah Istilah CoatingDocument63 pagesIstilah Istilah CoatingxajoNo ratings yet

- Examination Exercise Welding InspectorDocument1 pageExamination Exercise Welding InspectorxajoNo ratings yet

- Techalloy 625: Conformances Key FeaturesDocument2 pagesTechalloy 625: Conformances Key FeaturesJulian AdaraqueNo ratings yet

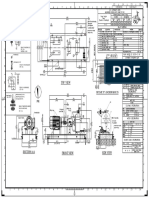

- Sample Pump Skid DWG 1Document1 pageSample Pump Skid DWG 1xajoNo ratings yet

- A New Frontier, Offshore Natural Gas Liquefaction - DR Chen Hwa Chiu (Chevron)Document20 pagesA New Frontier, Offshore Natural Gas Liquefaction - DR Chen Hwa Chiu (Chevron)xajoNo ratings yet

- Sample - Base Frame - Test Report 23Document2 pagesSample - Base Frame - Test Report 23xajoNo ratings yet

- Porsche Boxster Versus Factory Five 818Document8 pagesPorsche Boxster Versus Factory Five 818SteveNo ratings yet

- A Study On Renewable Energy Resources in IndiaDocument39 pagesA Study On Renewable Energy Resources in IndiaDevendra SharmaNo ratings yet

- The Cactus and the SnowsDocument22 pagesThe Cactus and the SnowsCrisNo ratings yet

- Impex Kitchen Appliances PDFDocument4 pagesImpex Kitchen Appliances PDFqwqw11No ratings yet

- Rotating Sharp Shooting Multi Target Mechanism Improves Military AimDocument13 pagesRotating Sharp Shooting Multi Target Mechanism Improves Military AimVishal GNo ratings yet

- MSDS 442 BulkDocument2 pagesMSDS 442 BulkEliasNo ratings yet

- Rational Use of AntibioticsDocument35 pagesRational Use of AntibioticsRahul SharmaNo ratings yet

- Blackmer Pump Parts ListDocument2 pagesBlackmer Pump Parts ListFelipe Ignacio PaillavilNo ratings yet

- Biologic License ApplicationDocument16 pagesBiologic License ApplicationJean Sandra PintoNo ratings yet

- 60d068822a861e19f4179ec9 - 11. Consensus - Local Cerberus - CompressedDocument1 page60d068822a861e19f4179ec9 - 11. Consensus - Local Cerberus - Compressedhombre pocilgaNo ratings yet

- Algebra 1 FINAL EXAM REVIEW 2Document2 pagesAlgebra 1 FINAL EXAM REVIEW 2Makala DarwoodNo ratings yet

- Practical 7 - Angiosperms Marking Guide Exercise 1: Class DicotyledonsDocument3 pagesPractical 7 - Angiosperms Marking Guide Exercise 1: Class DicotyledonsDitiro Maletsanake50% (2)

- KND 3200 eDocument0 pagesKND 3200 eGianna FrolaNo ratings yet

- Juxtaposition and Non Motion Varese BridDocument13 pagesJuxtaposition and Non Motion Varese BridIvan Eiji Yamauchi SimurraNo ratings yet

- Seal Pores & ImperfectionsDocument1 pageSeal Pores & ImperfectionsP176414 Mohammad MazanNo ratings yet

- Zooniverse Book 2022Document28 pagesZooniverse Book 2022Dr Pankaj DhussaNo ratings yet

- Mechanical Design of Turine EginesDocument51 pagesMechanical Design of Turine EginessriniNo ratings yet

- Shangqiu Jinpeng Industrial Co., LTD.: Widely Used Waste Rubber Pyrolysis Equipment (XY-7)Document2 pagesShangqiu Jinpeng Industrial Co., LTD.: Widely Used Waste Rubber Pyrolysis Equipment (XY-7)Salma FarooqNo ratings yet

- Bernard BTB MIG GunsDocument8 pagesBernard BTB MIG GunsEdwin Mauricio Gallego OsorioNo ratings yet

- ES vs SIGINT: Understanding the DifferencesDocument9 pagesES vs SIGINT: Understanding the DifferencesYasir ShigileeniNo ratings yet

- Tugas Bahasa Inggris-1Document8 pagesTugas Bahasa Inggris-1Nur KomariyahNo ratings yet

- B+G+2 Boq - (367-625)Document116 pagesB+G+2 Boq - (367-625)Amy Fitzpatrick100% (3)

- HSB Julian Reyes 4ab 1Document3 pagesHSB Julian Reyes 4ab 1Kéññy RèqüēñåNo ratings yet

- Preventive Maintenance Service Concept For SPACOM Product FamilyDocument27 pagesPreventive Maintenance Service Concept For SPACOM Product FamilyMiguel MarquesNo ratings yet

- Engineering Services for Abadan Petrochemical Plant VCM Unloading Station Piping DesignDocument28 pagesEngineering Services for Abadan Petrochemical Plant VCM Unloading Station Piping DesignMehdi NouriNo ratings yet

- Melese Hotel ST ReportDocument74 pagesMelese Hotel ST ReportKidist MollaNo ratings yet

- LP PG Conversion To Thar CoalDocument3 pagesLP PG Conversion To Thar CoalRaja Zeeshan100% (1)

- CH 2.2: Separable Equations: X F DX DyDocument9 pagesCH 2.2: Separable Equations: X F DX DyPFENo ratings yet

- Roland Berger Hot Trends InconstructionDocument24 pagesRoland Berger Hot Trends InconstructionJavier ContrerasNo ratings yet

- Bronchiolitis A Practical Approach For The General RadiologistDocument42 pagesBronchiolitis A Practical Approach For The General RadiologistTara NareswariNo ratings yet