Professional Documents

Culture Documents

(Painting Works) : Inspection and Test Plan

Uploaded by

rize1159Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

(Painting Works) : Inspection and Test Plan

Uploaded by

rize1159Copyright:

Available Formats

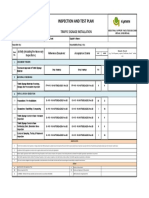

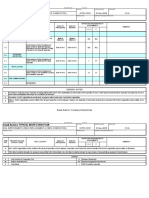

ATTACHMENT 01 - ITP FOR PAINTING WORKS

INSPECTION AND TEST PLAN

[PAINTING WORKS] Page 1 of 2

eni iraq b.v. Rev.No. 01

DISCIPLINE PROJECT / CONTRACT NO. ITP DOC NO. LEGEND

PAINTING / COATING HAMMAR MISHIRIF DGS PROJECT 00251210CBSSJC011 R = Review Point/Document Review M = Monitoring

I = Inspection or Test

ACTIVITY SUB-CONTRACTOR LOCATION W= Witness Point (Inspection)

H = Hold Point

INSPECTION POINT

ITEM ACCEPTANCE REPORT FORM /

ACTIVITY PROCEDURE SAMPLE CONTRACTOR REMARKS

NO. CRITERIA CHECKLIST NUMBER SUB- CONTRACTOR

CONSTRUCTIO COMPANY

CONTRACTOR QC

N

1.0 MATERIAL INSPECTION

Approved supplier, product and

1.1

supplier's test certificates

00251210CJPCOA008 Periodically As per approved paint system SECL-GRAL001 I M R R

Material Receiving Inspection / Physical As per P.O. / Manufacturing

1.2

condition (expiry date, shelf life, etc)

00251210CJPCOA008 Each batch

recommendations

SECL-GRAL005 I W/R W/R W/R

Protected fromsun, rain and

Material Properly Stored / temperature controlled environment

1.3

Safeguarded / Containers integrity

00251210CJPCOA008 All materials

+15° C ~ +25° C

SECL-GRAL005 I W M M

(Ambient Temperature)

Type of quality of abrasive being used / 00251210CJPCOA079 ISO 11127-6

1.4

Batch / Part (i.e. Part A - Part B) 00251210CJPCOA069

Each batch / paint system

≤ 300 ᵤs/CM to 20°C

SECL-GRAL005 I W/R R M

Verification of dry air for blast cleaning

1.5

and spray application

00251210CJPCOA079 Every shift / day ASTM D4285 / Free of oil & moisture SECL-PNT001 I W M M

Preparation of Set of 3 panels to be

1.6 painted along with components / 00251210CJPCOA079 For each paint system Size: 300 x 500 x 5 mm SECL-PNT001 I I/W W W

perform destructive tests.

ISO 8502-6 / ISO 8502-9

1.7 Contaminants and soluble salt test 00251210CJPCOA079 Random / Spot Check ≤ 3µg/cm² for Stainless Steel (A.G) SECL-PNT001 I I/W W M

≤ 5µg/cm² for all others

2.0 PAINTING APPLICATION

For Primer (large areas): SSPC-SP 5

For Primer (minor areas): SSPC-SP 3 SECL-PNT001

2.1 Surface Preparation / Cleanliness 00251210CJPCOA079 Each area / section For bare SECL-PNT002 I I/W W M

metal cleaning: SSPC-SP11 SECL-PNT003

Before each coat: ISO 8502-3

Ambient Temp: >10°C

SECL-PNT001

2.2 Temperature (Ambient / Surface / etc) 00251210CJPCOA079 Random / Spot Check Steel Temp: 3°C > of dew point &

SECL-PNT002

I I/W W/R M

humidity of 85%

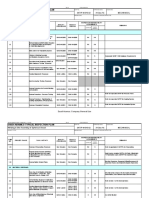

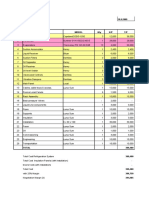

ATTACHMENT 01 - ITP FOR PAINTING WORKS

INSPECTION AND TEST PLAN

[PAINTING WORKS] Page 2 of 2

eni iraq b.v. Rev.No. 01

DISCIPLINE PROJECT / CONTRACT NO. ITP DOC NO. LEGEND

PAINTING / COATING HAMMAR MISHIRIF DGS PROJECT 00251210CBSSJC011 R = Review Point/Document Review M = Monitoring

I = Inspection or Test

ACTIVITY SUB-CONTRACTOR LOCATION W= Witness Point (Inspection)

H = Hold Point

INSPECTION POINT

ITEM ACCEPTANCE REPORT FORM /

ACTIVITY PROCEDURE SAMPLE CONTRACTOR REMARKS

NO. CRITERIA CHECKLIST NUMBER SUB- CONTRACTOR

CONSTRUCTIO COMPANY

CONTRACTOR QC

N

As per approved system

In-Process inspection of Shop Primer SECL-PNT001

2.3

Coat Application

00251210CJPCOA079 Random / Spot Check (DFT 18 ~ 20 microns)

SECL-PNT002

I I/W W/R M

(NDFT < 50%)

Inspection of Primer Coat prior to next

Water pressure (~20 Mpa) SECL-PNT001

2.4 coat (water cleaned by high-pressure 00251210CJPCOA079 Random / Spot Check

Wire Brush Scrubbing (if required) SECL-PNT002

I I/W W M

fresh water)

As per approved system

In-Process inspection of Intermediate SECL-PNT001

2.5

Coat Application (if required)

00251210CJPCOA079 Random / Spot Check (DFT - as per system)

SECL-PNT002

I I/W W M

(NDFT < 50%)

As per approved system

SECL-PNT001

2.6 Inspection of Top Coat Application 00251210CJPCOA079 Random / Spot Check (DFT - as per system)

SECL-PNT002

I I/W W W

(NDFT < 50%)

ASTM D4541 Type III

2.7 Adhesion Test (if required) 00251210CJPCOA079 Random / Spot Check (on test panels) SECL-PNT001 I I/W W/R W

(min 5MPa)

2.8 Holiday Test / Pinhole (if required) 00251210DBQRJA018 Entire completed section As per procedure SECL-PIP015 I I/W W W

Visual (No contamination, cracking

Safety Color Coding and Stenciling for

2.9

Identification

00251210CJPCOA079 Random / Spot Check blistering, damages or obvious SECL-PNT001 I W M M

defects) / As per drawing

Area to shall be less than:

<5% scattered

2.10 Repair / Touch Up Paint 00251210CJPCOA079 Random / Spot Check

<10% localized

SECL-PNT004 I I/W W M

< 1 m2 area

3.0 FINAL INSPECTION / PUNCH LIST

Punch Listing / Walkdown for Final

3.1

Inspection

00251210CJPCOA016 As per procedure As per relevant procedure SECL-PIP005 I I/W W W

You might also like

- Itp For Painting - FDocument5 pagesItp For Painting - FMudabbir HussainNo ratings yet

- Hydraulic crash barriers ITPDocument4 pagesHydraulic crash barriers ITPmoytabura96No ratings yet

- Traffic Signage Installation ITPDocument1 pageTraffic Signage Installation ITPmoytabura96No ratings yet

- Working ITPDocument4 pagesWorking ITPStephen BoodooNo ratings yet

- Inspection and Test Plan - In-Situ Puf Insulation To Valvesflanges Froth PakDocument2 pagesInspection and Test Plan - In-Situ Puf Insulation To Valvesflanges Froth PakDinesh100% (1)

- ITP Heat ExchangerDocument1 pageITP Heat Exchangersarmad009No ratings yet

- RFI For 18.03.2014 Piping, Welding at SESA FabDocument4 pagesRFI For 18.03.2014 Piping, Welding at SESA Fabmuhammedemraan100% (1)

- Inspectable MaterialsDocument2 pagesInspectable MaterialsMohamed RedaNo ratings yet

- Site Inspection Test PlanDocument24 pagesSite Inspection Test Planprabu palaniswamyNo ratings yet

- Tis-Gti-Aosi-Epf-Itp-001 Inspection Test Plan (Itp)Document10 pagesTis-Gti-Aosi-Epf-Itp-001 Inspection Test Plan (Itp)Raka PriaNo ratings yet

- EXternal ITP PDFDocument8 pagesEXternal ITP PDFjaineranaNo ratings yet

- Excavation and Fill Method Statement SummaryDocument12 pagesExcavation and Fill Method Statement Summary한상호No ratings yet

- ExcavationDocument1 pageExcavationkumarakash122392No ratings yet

- SATR-L-2001 Rev 2 - Flange Joint Tightening Inspection ReportDocument12 pagesSATR-L-2001 Rev 2 - Flange Joint Tightening Inspection Reportdeepa narayan100% (1)

- Saudi Aramco Test Report: Welding Rod Oven Calibration/Verification ReportDocument2 pagesSaudi Aramco Test Report: Welding Rod Oven Calibration/Verification ReportJoni Carino Suni100% (1)

- Repair Procedure For Rubber LiningDocument1 pageRepair Procedure For Rubber LiningChuah Cheong JinNo ratings yet

- Itp - 002 - Duct Installation - IfrDocument3 pagesItp - 002 - Duct Installation - IfrMari BelajarNo ratings yet

- NDT Request (Template)Document4 pagesNDT Request (Template)Bethel NdifonNo ratings yet

- EQUIPMENT: Tube Bundle For Shell &tube HX Titile: Inspection Test Plan Item: 6112-E-02Document6 pagesEQUIPMENT: Tube Bundle For Shell &tube HX Titile: Inspection Test Plan Item: 6112-E-02Khalilahmad KhatriNo ratings yet

- HDPE Butt Fusion Weld Inspection and Imaging PDFDocument19 pagesHDPE Butt Fusion Weld Inspection and Imaging PDFelectroscribdNo ratings yet

- DBB BNCPP B M v29 0015 Revb IfaDocument6 pagesDBB BNCPP B M v29 0015 Revb IfaIzzadAfif1990No ratings yet

- Saudi Aramco Typical Inspection Plan: Welding & Site Assembly of Spherical Vessel SATIP-W-010-02 31-Dec-14 MechanicalDocument5 pagesSaudi Aramco Typical Inspection Plan: Welding & Site Assembly of Spherical Vessel SATIP-W-010-02 31-Dec-14 MechanicalpravinNo ratings yet

- 1.13 Inspection & Test PlansDocument1 page1.13 Inspection & Test Plansabimanyubawono100% (2)

- 24.tank Oil Chalk TestDocument3 pages24.tank Oil Chalk TestShubham ShuklaNo ratings yet

- UG PIPING COATINGDocument10 pagesUG PIPING COATINGcloud23No ratings yet

- Project Quality RequirementsDocument8 pagesProject Quality RequirementsSIVANo ratings yet

- Chemical Resistance (LLDPE) PDFDocument24 pagesChemical Resistance (LLDPE) PDFrubyshreeNo ratings yet

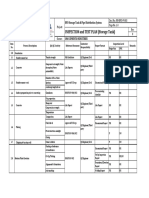

- LPS-01-HTI-ITP-EL-005 - Point WiringDocument5 pagesLPS-01-HTI-ITP-EL-005 - Point WiringJomy JohnyNo ratings yet

- 0610.1 - Shell and Tube Heat ExchangersDocument30 pages0610.1 - Shell and Tube Heat Exchangersvenkatrangan2003No ratings yet

- Tdoc 014 REV.01 - ITP FOR EXCAVATION & COMPACTION (ITP 002)Document1 pageTdoc 014 REV.01 - ITP FOR EXCAVATION & COMPACTION (ITP 002)mNo ratings yet

- Al Wakrah Stadium Tank Inspection and Test PlanDocument19 pagesAl Wakrah Stadium Tank Inspection and Test PlanErin JohnsonNo ratings yet

- Wps Mig PDF FreeDocument3 pagesWps Mig PDF Freehanz bermejoNo ratings yet

- Inspection, Flushing & Testing of Piping-21Document6 pagesInspection, Flushing & Testing of Piping-21Saurabh Kumar VermaNo ratings yet

- MS For Fabrication of Above-Ground Storage TankDocument8 pagesMS For Fabrication of Above-Ground Storage Tankdadz mingiNo ratings yet

- ProcurementDocument6 pagesProcurementDenmark CostanillaNo ratings yet

- ITP For Steel Structure1Document3 pagesITP For Steel Structure1吴兴泊No ratings yet

- INSPECTION & TEST PLAN FOR FLUE GAS AND AIR DUCTSDocument1 pageINSPECTION & TEST PLAN FOR FLUE GAS AND AIR DUCTStreyNo ratings yet

- LV Switch Board 1.1.2 - Test Report For Visual Check Report: ClientDocument1 pageLV Switch Board 1.1.2 - Test Report For Visual Check Report: ClientsameershahzanNo ratings yet

- 8474l-000-Jsd-2310-001-2-Protective CoatingDocument31 pages8474l-000-Jsd-2310-001-2-Protective Coatinglebienthuy100% (1)

- Skid Mounted Unit InstallationDocument2 pagesSkid Mounted Unit Installationric leonisoNo ratings yet

- Inspection & Test Plan for Chilled Water Expansion TanksDocument1 pageInspection & Test Plan for Chilled Water Expansion TanksvictorNo ratings yet

- Quality Assurance PlanDocument6 pagesQuality Assurance Planvkrishnamoorthy100% (2)

- Cold Tap Coating Report 2Document1 pageCold Tap Coating Report 2Jamal BakhtNo ratings yet

- QAF5153 Rev.0 Pre-Mobilization Inspection Checklist - Guidelines - 1Document1 pageQAF5153 Rev.0 Pre-Mobilization Inspection Checklist - Guidelines - 1Mohamed El-SawahNo ratings yet

- Prosedur Penetran TestingDocument11 pagesProsedur Penetran TestingIkhsan DalimuntheNo ratings yet

- MST Gravity Test OwsDocument5 pagesMST Gravity Test OwsJenson T VNo ratings yet

- Method Statement for Pipe Handling and StorageDocument14 pagesMethod Statement for Pipe Handling and StorageShambu S VtkNo ratings yet

- Water Tank Fabrication QAPDocument2 pagesWater Tank Fabrication QAPYOGESHNo ratings yet

- Inspected by QCP Approval 1-APC 1-Employer (APC) 2 - DAR 2 - Engineer (DAR) 3 - Contractor (NEGEMCO) 4 - Vendor 5 - Third PartyDocument6 pagesInspected by QCP Approval 1-APC 1-Employer (APC) 2 - DAR 2 - Engineer (DAR) 3 - Contractor (NEGEMCO) 4 - Vendor 5 - Third PartyAhmad DagamsehNo ratings yet

- Inspection and Test Plan For Piping (PP/FRP Piping)Document2 pagesInspection and Test Plan For Piping (PP/FRP Piping)Anonymous EyK4vt6Y100% (1)

- ITP For Mild Steel Pipe WorksDocument4 pagesITP For Mild Steel Pipe WorksKumar AbhishekNo ratings yet

- Blasting and Painting ProcedureDocument6 pagesBlasting and Painting Procedureanon_994898767No ratings yet

- Pipework Post-Test Checklist (Empty)Document1 pagePipework Post-Test Checklist (Empty)Jorge GarciaNo ratings yet

- ITP For Structural Work-1Document5 pagesITP For Structural Work-1Mohammed MujahidNo ratings yet

- Inspection & Test Plan TankDocument3 pagesInspection & Test Plan TankJOSHUA SULLEGUE100% (1)

- Saudi Aramco Typical Inspection Plan: Soil Improvement (Vibro Replacement & Vibro Compaction) 31-Nov-2018 CivilDocument10 pagesSaudi Aramco Typical Inspection Plan: Soil Improvement (Vibro Replacement & Vibro Compaction) 31-Nov-2018 CivilTariqMalik0% (1)

- Kic Itp M 100 13Document1 pageKic Itp M 100 13irasool261No ratings yet

- SATIP-A-000-01 Rev 7Document1 pageSATIP-A-000-01 Rev 7Zuhaib KhanNo ratings yet

- Satip A 000 01 Rev 7 (Final)Document2 pagesSatip A 000 01 Rev 7 (Final)faisalNo ratings yet

- PM210014-TCC000-FI3-00003 - 00 - IFA - ITP For Static Equipment Installation - Rev 01Document73 pagesPM210014-TCC000-FI3-00003 - 00 - IFA - ITP For Static Equipment Installation - Rev 01problematic NymphNo ratings yet

- Colorado Springs Residential Water Use CalculatorDocument7 pagesColorado Springs Residential Water Use CalculatorNghiaNo ratings yet

- Hydraulic calculation for pumpsDocument22 pagesHydraulic calculation for pumpsrize1159No ratings yet

- Traffic Light - SSR&BDR Audit Form - SSR11Document4 pagesTraffic Light - SSR&BDR Audit Form - SSR11rize1159No ratings yet

- Analytical Methods: Physical Properties of Dairy PowdersDocument17 pagesAnalytical Methods: Physical Properties of Dairy Powdersrize1159No ratings yet

- TONGDocument4 pagesTONGrize1159No ratings yet

- Air Curtain Installation Scorecard - Aug 2012 (FINAL)Document1 pageAir Curtain Installation Scorecard - Aug 2012 (FINAL)rize1159No ratings yet

- GF AD01 Bid Event ScheduleDocument2 pagesGF AD01 Bid Event Schedulerize1159No ratings yet

- Energy TreeDocument1 pageEnergy Treerize1159No ratings yet

- RFP Pricing Document Rev 005 - 15 11 2010Document38 pagesRFP Pricing Document Rev 005 - 15 11 2010rize1159No ratings yet

- GF AD01 Bid Event ScheduleDocument2 pagesGF AD01 Bid Event Schedulerize1159No ratings yet

- Dimensional Inspection ReportDocument2 pagesDimensional Inspection Reportrize1159No ratings yet

- FBR Tax FilingDocument48 pagesFBR Tax FilingMuhammad Waqas Hanif100% (1)

- Field Installation ChecklistDocument7 pagesField Installation Checklistrize1159No ratings yet

- Computer ModelDocument48 pagesComputer ModelMohamed SelimNo ratings yet

- F2-DP-2017-Pasta-Ondrej-priloha-Vypocet Cerpadla Na KavitaciDocument20 pagesF2-DP-2017-Pasta-Ondrej-priloha-Vypocet Cerpadla Na Kavitacirize1159No ratings yet

- Shahi - Tazaj - SAPCO 19.9.2009Document2 pagesShahi - Tazaj - SAPCO 19.9.2009rize1159No ratings yet

- Heat Loss Insulated PipeDocument14 pagesHeat Loss Insulated PipeJonson CaoNo ratings yet

- BHP Tank Fit Up Inspection Report TemplateDocument1 pageBHP Tank Fit Up Inspection Report Templaterize1159No ratings yet

- Tide Load 4 Z05Document30 pagesTide Load 4 Z05NghiaNo ratings yet

- Cooling LoadDocument91 pagesCooling LoadPiyush PandeyNo ratings yet

- Domestic Water Sizing CalculationDocument5 pagesDomestic Water Sizing CalculationNghiaNo ratings yet

- Noniterative Design of Multiple Effect Evaporators Using Excel Add InsDocument10 pagesNoniterative Design of Multiple Effect Evaporators Using Excel Add InsGalang Hanif AbdulahNo ratings yet

- REFREG CHARGE CALCDocument12 pagesREFREG CHARGE CALCKhadija MirajNo ratings yet

- GeavstetraDocument4 pagesGeavstetrarize1159No ratings yet

- Cooling Tower LiquidGas (LG) RatioDocument3 pagesCooling Tower LiquidGas (LG) Ratiorize1159No ratings yet

- Triple Effect EvaporatorDocument6 pagesTriple Effect EvaporatorPrashil Prakash Lakhete100% (4)

- Cacl P 001Document5 pagesCacl P 001rize1159100% (1)

- Avoiding Common Pitfalls in Cooling Tower Pump Intake DesignDocument8 pagesAvoiding Common Pitfalls in Cooling Tower Pump Intake DesignMark ChongNo ratings yet

- Cooling Tower 1 PDFDocument4 pagesCooling Tower 1 PDFrize1159No ratings yet

- Hazardous Area ClassificationDocument100 pagesHazardous Area Classificationcherif yahyaouiNo ratings yet

- Pragmatics: The Study of Its Historical Overview, Meanings, Scope and The Context in Language UseDocument7 pagesPragmatics: The Study of Its Historical Overview, Meanings, Scope and The Context in Language UseIHINOSEN IYOHANo ratings yet

- Human Rights PDFDocument18 pagesHuman Rights PDFRohitNo ratings yet

- 2019 MakeX Courageous Traveler Techinical Guide V1.1Document66 pages2019 MakeX Courageous Traveler Techinical Guide V1.1Yair XolalpaNo ratings yet

- Stat and Prob Q1 M3Document15 pagesStat and Prob Q1 M3Samantha Kyle E. PedrigozaNo ratings yet

- C27 and C32 Generator Set Engines - Troubleshooting - RENR9348-01 - Jan 2007 - CATERPILLARDocument180 pagesC27 and C32 Generator Set Engines - Troubleshooting - RENR9348-01 - Jan 2007 - CATERPILLARpevare85% (27)

- The School and The Community: Prepared By: Sen Xiao Jun Mohana Sundra Segaran Kaviyanayagi PonuduraiDocument26 pagesThe School and The Community: Prepared By: Sen Xiao Jun Mohana Sundra Segaran Kaviyanayagi PonuduraiKaviya SKTDSNo ratings yet

- Modern Tips For The Modern Witch (/)Document5 pagesModern Tips For The Modern Witch (/)Rori sNo ratings yet

- PricelistDocument2,276 pagesPricelistadilcmsNo ratings yet

- Technical ManualDocument32 pagesTechnical ManualIstvan MadacsyNo ratings yet

- METAPHYSICAL POETRY A SummaryDocument3 pagesMETAPHYSICAL POETRY A Summaryrcschoolofenglish1No ratings yet

- Facts About SaturnDocument7 pagesFacts About SaturnGwyn CervantesNo ratings yet

- Is BN 9789526041957Document72 pagesIs BN 9789526041957supriya rakshitNo ratings yet

- Quick Start Guide - QualiPoc AndroidDocument24 pagesQuick Start Guide - QualiPoc AndroidDmitekNo ratings yet

- AR Ageing FinalDocument13 pagesAR Ageing FinalHAbbunoNo ratings yet

- Writing in Bengali - : Past and PresentDocument3 pagesWriting in Bengali - : Past and PresentRanjanNo ratings yet

- Ice Problem Sheet 1Document2 pagesIce Problem Sheet 1Muhammad Hamza AsgharNo ratings yet

- Shark KssDocument2 pagesShark Kssleelee123321No ratings yet

- Schmitt Trigger FinalDocument4 pagesSchmitt Trigger Finalsidd14feb92No ratings yet

- Social Studies Bece Mock 2024Document6 pagesSocial Studies Bece Mock 2024awurikisimonNo ratings yet

- PROBLEM 7 - CDDocument4 pagesPROBLEM 7 - CDRavidya ShripatNo ratings yet

- Danica Seleskovitch-Mariann A Lederer: Interpréter Pour TraduireDocument17 pagesDanica Seleskovitch-Mariann A Lederer: Interpréter Pour TraduireGarima KukrejaNo ratings yet

- 5.talisayon Chapter 3Document12 pages5.talisayon Chapter 3Jinky Marie TuliaoNo ratings yet

- ARP 598, D, 2016, Microscopic SizingDocument17 pagesARP 598, D, 2016, Microscopic SizingRasoul gholinia kiviNo ratings yet

- SARTIKA LESTARI PCR COVID-19 POSITIVEDocument1 pageSARTIKA LESTARI PCR COVID-19 POSITIVEsartika lestariNo ratings yet

- The Power ParadoxDocument27 pagesThe Power ParadoxKieran De PaulNo ratings yet

- .Design and Development of Motorized Multipurpose MachineDocument3 pages.Design and Development of Motorized Multipurpose MachineANKITA MORENo ratings yet

- Ch15 Differential Momentum BalanceDocument20 pagesCh15 Differential Momentum Balance89kkNo ratings yet

- PROPOSED ARFF BUILDINGDocument27 pagesPROPOSED ARFF BUILDINGDale Bryan S DalmacioNo ratings yet

- The Tower Undergraduate Research Journal Volume VI, Issue IDocument92 pagesThe Tower Undergraduate Research Journal Volume VI, Issue IThe Tower Undergraduate Research JournalNo ratings yet