Professional Documents

Culture Documents

1KHW002588AE Commissioning Report ETL600R4 Reichle

1KHW002588AE Commissioning Report ETL600R4 Reichle

Uploaded by

fayssal salvadorCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1KHW002588AE Commissioning Report ETL600R4 Reichle

1KHW002588AE Commissioning Report ETL600R4 Reichle

Uploaded by

fayssal salvadorCopyright:

Available Formats

We reserve all rights in this document and in the information contained therein.

Reproduction,use or disclosure to third parties without express authority is strictly forbidden.

© 2012 ABB

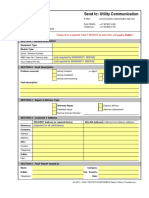

COMMISSIONING REPORT

Powerline Carrier Equipment: Series ETL600R4

Project : …………………………..

ABB Order N° : …………………………..

Station : …………………………..

Link : …………………………..

Equipment N° : …………………………..

Frequency : Tx = …………kHz Rx = …………kHz

Direction : …………………………..

Commissioning Report contains

ETL600 System Test Report Pages C1 to C15

HMI600 Printout of Configuration Pages ................

HMI600 Printout of Status Pages ................

Test ETL600 List of used Test-instruments Pages ................

………………………….. ………………………………… Pages ................

The tuning of the equipment is in accordance with the following instructions:

Programming and Testing of ETL600R4 1KHW002609-EN

Compatibility Requirements for ETL600 1KHW001490-EN

Tuning of ETL600R4 Rx RF Filter P4RX 1KHW002584-EN

Tuning of ETL600R4 Tx RF Filter on E5TH and E5TC 1KHW002585-EN

APLC Channel Equalization for ETL600 1KHW001494-EN

Firmware Download for ETL600R4 1KHW002589-EN

Technical Data ETL600R4 1KHW002590-EN

Rev. ind:

..

Type des. Part no.

No. of p.

Prep. Hans Benninger / PSND 2012-04-15 Doc.kind

Appr. M. Israel / PSND2 2012-05-15 Title Commissioning Report ETL600R4 15+

Resp.dept. PSNEX

Doc. no. Lang. Rev. ind. Page

ABB Switzerland Ltd 1KHW002588 en A C1

FILE: 1KHW002588AE Commissioning Report ETL600R4 Reichle; TEMPLATE: TECHN_DOC_STAND_P.dot R0; SKELETON: ; SAVEDATE: 5/15/2012 11:58:00 AM

Rev. ind.

Commissioning Report ETL600R4 Equipment HE

SAFETY INSTRUCTIONS

Please refer to chapter 2 of ETL600R4 instruction manual 1KHW002582.

Designations and abbreviations used:

Designation Meaning

___________ Measured value

[ ... ] Programmed value

[ ]D Preferred setting (default)

[X ] Test passed or jumper is set

[ ] Not tested or jumper is not set

B5LA Module type

BER Bit Error Ratio

Def. Default value

equ. Equipment

fLo Lower frequency, usually meant as low cut-off frequency

LED Light Emitting Diode found on the front panel

HMI600 User Interface Program for ETL600 running on a PC

N02, N08 Position in rack. Slot number N02, N08

Rx Receiver

Tx Transmitter

PC Personal Computer

(T.02/..1) Connector 1 of terminal block connected to board at rack position N02

Notes:

..............................................................................................................................................................

..............................................................................................................................................................

..............................................................................................................................................................

Sign Commissioning Eng.: Sign Witness Eng.:

Doc. no. Lang. Rev. ind. Page

ABB Switzerland Ltd 1KHW002588 en A C2

Rev. ind.

Commissioning Report ETL600R4 Equipment HE

REVISION

Rev. Page (p.) Description Date

ind. Chapter (c.) Dept./Init.

A c. C.2 Measurement at MCB 2012-05-15 / Be

Notes:

..............................................................................................................................................................

..............................................................................................................................................................

..............................................................................................................................................................

Sign Commissioning Eng.: Sign Witness Eng.:

Doc. no. Lang. Rev. ind. Page

ABB Switzerland Ltd 1KHW002588 en A C3

Rev. ind.

Commissioning Report ETL600R4 Equipment HE

Test Permissible Test

No. Test procedure Test point value Units result

C.1. General

C.1.1 Checking the line of communication

Line attenuation dB [ ]

Return loss Ar dB [ ]

C.1.2 Visual checks

Proper wiring of protective earth P7LH, P7LP, P7LQ PE wired [ ]

Proper wiring of protective earth Cubicle PE wired [ ]

Proper wiring of power supply P7LH, P7LP, P7LQ polarity ok [ ]

If the positive pole (+) of the battery is Cubicle supply terminals [ ]

grounded, place an earth jumper to the

positive pole (+) of the cubicle supply

C.2. Check power supply B5LD Left Right

C.2.1 Battery supply 48V DC MCB -46 to –56 V DC [ ] [ ]D

C.2.2 Ripple on 48V DC MCB <1 V rms [ ] [ ]D

C.2.3 Green LED B5LD front panel Lit [ ] [ ]D

C.3. Upload configuration [ ]

C.4. Change configuration, if necessary [ ]

C.4.1 Reducing output power, if necessary

Determine Ar min = minimal value of Ar as Ar min= dB

measured in C.1.1 _____________

Calculate output power reduction Ared: Ared = dB

No reduction, if Ar min 12 dB: _____________

Ared = max(0, (3 - Ar min / 4 ))

Decrease Max. power PEP by Ared HMI600: [ ]

Configuration / System /

Channel settings /

Max. power (PEP)

Store configuration to flash HMI600: Equipment / [ ]

Store configuration to

FLASH

Notes:

..............................................................................................................................................................

..............................................................................................................................................................

..............................................................................................................................................................

Sign Commissioning Eng.: Sign Witness Eng.:

Doc. no. Lang. Rev. ind. Page

ABB Switzerland Ltd 1KHW002588 en A C4

Rev. ind.

Commissioning Report ETL600R4 Equipment HE

Test Permissible Test

No. Test procedure Test point value Units result

C.5. Transmitter

C.5.1 Adjust Tx RF level

Dialog box Adjust Tx RF level: [ ]

Click Select and then Start

Mark if the Tx level is not [ ]

measured

Measured Tx level is within tolerance RF LINE MONITOR or Permissible [ ]

RF LINE socket at E5TH range indicated

front panel in dialog box

C.5.2 Adjust Tx alarm level

Dialog box: Adjust Tx alarm level

Follow the instructions given in the dialog [ ]

box

Tx ALARM indication: E5TH and - in case of LED(s) to be ON [ ]

ETL600-100 – E5TC

State of HW alarm relay after programmed Pins 2-3 of V9OT cable Closed [ ]

delay.

Turn potentiometer(s) TX-LVL-AL LED(s) to be [ ]

ADJUST on P1LP till TX-LVL-AL LED(s) OFF

go(es) off.

Tx alarm indication E5TH and - in case of LED(s) to be [ ]

ETL600-100 – E5TC OFF

State of HW alarm relay after programmed Pins 2-3 of V9OT cable Open [ ]

delay.

Click OK.

C.6. Receiver

C.6.1 Adjust Rx RF level

Menu: Equipment Commissioning and

maintenance, dialog box: Adjust Rx RF

level

Follow the instructions in the dialog box

Line attenuation Dialog box __________ dB

Increase of receive level (due to parallel Dialog box

PLC links) __________ dB

Adjustment performed [ ]

C.6.2 Connect RF cable and set alarm

thresholds 1

Alarm thresholds set (Menu: Dialog box [ ]

Configuration / System / Alarm settings)

1

If the remote equipment is operational

Notes:

..............................................................................................................................................................

..............................................................................................................................................................

..............................................................................................................................................................

Sign Commissioning Eng.: Sign Witness Eng.:

Doc. no. Lang. Rev. ind. Page

ABB Switzerland Ltd 1KHW002588 en A C5

Rev. ind.

Commissioning Report ETL600R4 Equipment HE

Test Permissible Test

No. Test procedure Test point value Units result

C.6.3 Check link alarms

Link alarm of the local equipment Alarm status of the local No local link [ ]

equipment alarm

Link alarm of the remote equipment No remote link [ ]

alarm

C.6.4 Tune hybrid on E5TH

RF Coaxial cable to be connected.

Dialog box: Tune RF hybrid Dialog box Till minimum is [ ]

Press 'Start measurement' & adjust the read by HMI.

balancing network (Resistance with jumper

R0 … R4 and potentiometer R1101,

inductance with jumper L0 … L17 and

capacitance with jumpers C1 to C17)

Ch 1 Ch 2 Ch 3

C.6.5 SNR pilot Mark if not configured: [ ] [ ] [ ]

Upload status data of local equipment

SNR pilot HMI600 > 15 dB [ ] [ ] [ ]

C.7. Equalization

Ch 1 Ch 2 Ch 3

C.7.1 Measure frequency response Mark if not configured: [ ] [ ] [ ]

In menu Equipment / Commissioning and HMI600 [ ] [ ] [ ]

maintenance / Frequency response /

APLC channel 1, APLC channel 2 or

APLC channel 3

Ch 1 Ch 2 Ch 3

C.7.2 Select Equalizer Mark if not configured: [ ] [ ] [ ]

In menu Equipment / Commissioning and HMI600 [ ] [ ] [ ]

maintenance / Select equalizer / APLC

channel 1, APLC channel 2 or

APLC channel 3

C.8. R1BC, if present Mark if not configured: [ ]

Activate alarms as programmed on R1BC. Corresponding N/C Closed [ ]

contacts on R1BC.

Deactivate alarms as programmed on Corresponding N/C Open [ ]

R1BC. contacts on R1BC.

C.9. Configure Real time Clock (RTC)

C.9.1 Setting real time clock

Menu: Equipment, Commissioning and

maintenance, Eventrecorder, Set clock

Download date/time to RTC Dialog box Actual time and [ ]

date

Notes:

..............................................................................................................................................................

..............................................................................................................................................................

..............................................................................................................................................................

Sign Commissioning Eng.: Sign Witness Eng.:

Doc. no. Lang. Rev. ind. Page

ABB Switzerland Ltd 1KHW002588 en A C6

Rev. ind.

Commissioning Report ETL600R4 Equipment HE

Test Permissible Test

No. Test procedure Test point value Units result

C.9.2 Test external real time clock

synchronization, if available

Menu: Equipment, Commissioning and

maintenance, Eventrecorder, Set clock

Download date/time to RTC Dialog box Wrong time

Upload date/time from RTC Dialog box Correct time [ ]

Test Permissible Test

No. Test procedure Test point value Units result

C.10. NSD600 / G4AI, if present

TPE1 TPE2

C.10.1 NSD600 loop test Mark if not configured: [ ] [ ]

Check Actual transmission

time TLink HMI600 < 2*T0 ms _______ _______

Menu: Equipment,

Commissioning and

maintenance, NSD600 send

loop test

C.10.2 Command transmission

time

TPE1 TPE2

Command A Mark if not configured: [ ] [ ]

Terminal: Refer HMI600

Tx command A (T71/1) – (T71/2) [ ] Mean value

(T…/...) – (T.../…) [ ]

T0 ms ________ ________

Rx command A (T71/9) – (T71/10) [ ]

(T…/...) – (T.../…) [ ]

TPE1 TPE2

Command B Mark if not configured: [ ] [ ]

Terminal: Refer HMI600

Tx command B (T71/3) – (T71/4) [ ] Mean value

(T…/...) – (T.../…) [ ] ms

T0 ________ ________

Rx command B (T71/11) – (T71/12) [ ]

(T…/...) – (T.../…) [ ]

TPE1 TPE2

Command C Mark if not configured: [ ] [ ]

Terminal: Refer HMI600

Tx command C (T71/5) – (T71/6) [ ] Mean value

(T…/...) – (T.../…) [ ] ms

T0 ________ ________

Rx command C (T71/13) – (T71/14) [ ]

(T…/...) – (T.../…) [ ]

Notes:

..............................................................................................................................................................

..............................................................................................................................................................

..............................................................................................................................................................

Sign Commissioning Eng.: Sign Witness Eng.:

Doc. no. Lang. Rev. ind. Page

ABB Switzerland Ltd 1KHW002588 en A C7

Rev. ind.

Commissioning Report ETL600R4 Equipment HE

Test Permissible Test

No. Test procedure Test point value Units result

TPE1 TPE2

Command D Mark if not configured: [ ] [ ]

Terminal: Refer HMI600

Tx command D (T71/7) – (T71/8) [ ] Mean value

(T…/...) – (T.../…) [ ] ms

T0 ________ ________

Rx command D (T71/15) – (T71/16) [ ]

(T…/...) – (T.../…) [ ]

C.10.3 Reset counters Mark if not configured: [ ]

Menu: Equipment, HMI600 All counters = 0 [ ]

Commissioning and

maintenance, Eventrecorder,

Reset counter, OK:

C.11. Testing of O4LE

N02 N08 N14

C.11.1 Service Phone. Mark if not configured: N24 N30 N48

[ ] [ ] [ ]

Pick up the phone and talk. Service phone, at front Own voice is audible N02 N08 N14

panel without feedback or N24 N30 N48

excessive echo [ ] [ ] [ ]

N02 N08 N14

C.11.2 Hot line direct phone Mark if not configured: N24 N30 N48

[ ] [ ] [ ]

Measure voltage at open loop 43 V … 52 V V DC

condition N02/N24: ___________

N08/N30: ___________

N14/N48: ___________

Pick up the phone and talk Direct telephone Own voice is audible N02 N08 N14

without feedback or N24 N30 N48

excessive echo [ ] [ ] [ ]

N02 N08 N14

C.11.3 Remote subscriber Mark if not configured: N24 N30 N48

[ ] [ ] [ ]

Measure voltage at open loop 43 V … 52 V V DC

condition N02/N24: ___________

N08/N30: ___________

N14/N48: ___________

Pick up the phone and talk Suscriber telephone Own voice is audible N02 N08 N14

without feedback or N24 N30 N48

excessive echo [ ] [ ] [ ]

Notes:

..............................................................................................................................................................

..............................................................................................................................................................

..............................................................................................................................................................

Sign Commissioning Eng.: Sign Witness Eng.:

Doc. no. Lang. Rev. ind. Page

ABB Switzerland Ltd 1KHW002588 en A C8

Rev. ind.

Commissioning Report ETL600R4 Equipment HE

Test Permissible Test

No. Test procedure Test point value Units result

N02 N08 N14

C.11.4 Pax 2-wire Mark if not configured: N24 N30 N48

[ ] [ ] [ ]

PAX-BLOCKING normal Measure at terminal 5b-6a is open N02 N08 N14

5b-6a, 6a-6b 6a-6b is closed N24 N30 N48

[ ] [ ] [ ]

PAX-BLOCKING blocked Measure at terminal 5b-6a is closed N02 N08 N14

Interrupt local loop, wait about 5b-6a, 6a-6b 6a-6b is open N24 N30 N48

30 sec. [ ] [ ] [ ]

N02 N08 N14

C.11.5 Pax 4-wire Mark if not configured: N24 N30 N48

[ ] [ ] [ ]

Test E-Wire: Terminal 3a-3b E-Wire must toggle N02 N08 N14

Close and open M-wire at N24 N30 N48

terminal 4a-4b [ ] [ ] [ ]

Measure Output level. Feed into terminal 1a-1b Configured Output dBm N02 N08 N14

Feed 800 Hz with configured Measure at terminal level ±1 dB (600 ) N24 N30 N48

input level of Pax 2a-2b (Def.: -3.5 dBm) [ ] [ ] [ ]

(Default: -3.5 dBm).

(Activate at terminal 4a-4b)

PAX-BLOCKING normal Measure at terminal 5b-6a is open N02 N08 N14

5b-6a, 6a-6b 6a-6b is closed N24 N30 N48

[ ] [ ] [ ]

PAX-BLOCKING blocked Measure at terminal 5b-6a is closed N02 N08 N14

Interrupt local loop, wait about 5b-6a, 6a-6b 6a-6b is open N24 N30 N48

30 sec. [ ] [ ] [ ]

N02 N08 N14

C.11.6 Pax 4/2-wire Mark if not configured: N24 N30 N48

[ ] [ ] [ ]

Test E-Wire: Terminal 3a-3b E-Wire must toggle N02 N08 N14

Close and open M-wire at N24 N30 N48

terminal 4a-4b [ ] [ ] [ ]

Measure Output level at AF1. Feed into terminal 1a-1b Configured Output dBm N02 N08 N14

Feed 800 Hz with configured Measure at terminal level ±1 dB (600 ) N24 N30 N48

input level (Def.: -3.5 dBm). 2a-2b (Def.: -3.5 dBm) [ ] [ ] [ ]

(Activate at terminal 4a-4b)

Measure Output level at Feed into terminal 1a-1b Configured Output dBm N02 N08 N14

PAX2W. Measure at terminal level ±1 dB (600 ) N24 N30 N48

Feed 800 Hz with configured 7a-7b (Def.: -7.0 dBm) [ ] [ ] [ ]

input level (Def.: -3.5 dBm).

(Activate at terminal 4a-4b)

Test Local/Transit: Feed into terminal 1a-1b Configured Output dBm N02 N08 N14

Measure Output level at AF1. Measure at terminal level – 40 dB or (600 ) N24 N30 N48

Feed 800 Hz with configured 7a-7b lower [ ] [ ] [ ]

input level of PAX2W (Def:

-0.0 dBm).

Activate at terminals 5a-4b

and 4a-4b.

Notes:

..............................................................................................................................................................

..............................................................................................................................................................

..............................................................................................................................................................

Sign Commissioning Eng.: Sign Witness Eng.:

Doc. no. Lang. Rev. ind. Page

ABB Switzerland Ltd 1KHW002588 en A C9

Rev. ind.

Commissioning Report ETL600R4 Equipment HE

Test Permissible Test

No. Test procedure Test point value Units result

PAX-BLOCKING normal Measure at terminal 5b-6a is open N02 N08 N14

5b-6a, 6a-6b 6a-6b is closed N24 N30 N48

[ ] [ ] [ ]

PAX-BLOCKING blocked Measure at terminal 5b-6a is closed N02 N08 N14

Interrupt local loop, wait about 5b-6a, 6a-6b 6a-6b is open N24 N30 N48

30 sec. [ ] [ ] [ ]

N02 N08 N14

C.11.7 Transit mode for E&M wire Mark if not configured: N24 N30 N48

[ ] [ ] [ ]

Test E-Wire: Terminal 3a-3b E-Wire must toggle N02 N08 N14

Close and open M-wire at N24 N30 N48

terminal 4a-4b [ ] [ ] [ ]

C.11.8 Testing the teleoperation

ports

N02 N08 N14 N20

C.11.9 Teleoperation AF1, if not Mark if not configured:

N24 N30 N42 N48 N54

used for telephony

[ ] [ ] [ ] [ ] [ ]

Fed input level, [dBm], Expected Output Measured Output level at

@ 800 Hz at AF1-IN level at AF1-OUT AF1-OUT

N02/N24: ___________±1 Feed into terminal 1a-1b N02/N24: ______±1 dBm N02/N24: ___________

Measure at terminal (600 )

N08/N30: ___________±1 N08/N30: ______±1 N08/N30: ___________

2a-2b

N14/N42: ___________±1 N14/N42: ______±1 N14/N42: ___________

Ext. Boost not active.

N20/N48: ___________±1 N20/N48: ______±1 N20/N48: ___________

N54: ___________±1 N54: ______±1 N54: ___________

N02 N08 N14 N20

C.11.10 Teleoperation AF2 Mark if not configured:

N24 N30 N42 N48 N54

[ ] [ ] [ ] [ ] [ ]

Fed input level, [dBm], Expected Output Measured Output level at

@ 800 Hz at AF2-IN of level at AF2-OUT AF2-OUT

remote.

N02/N24: ___________±1 Feed into terminal 9a-9b N02/N24: ______±1 dBm N02/N24: ___________

Measure at terminal (600 )

N08/N30: ___________±1 N08/N30: ______±1 N08/N30: ___________

10a-10b

N14/N42: ___________±1 N14/N42: ______±1 N14/N42: ___________

ext. Boost not active.

N20/N48: ___________±1 N20/N48: ______±1 N20/N48: ___________

N54: ___________±1 N54: ______±1 N54: ___________

Notes:

..............................................................................................................................................................

..............................................................................................................................................................

..............................................................................................................................................................

Sign Commissioning Eng.: Sign Witness Eng.:

Doc. no. Lang. Rev. ind. Page

ABB Switzerland Ltd 1KHW002588 en A C10

Rev. ind.

Commissioning Report ETL600R4 Equipment HE

Test Permissible Test

No. Test procedure Test point value Units result

C.11.11 Teleoperation AF3 Mark if not configured: N02 N08 N14 N20

N24 N30 N42 N48 N54

[ ] [ ] [ ] [ ] [ ]

Fed input level, [dBm], Expected Output Measured Output level at

@ 800 Hz at AF3-IN of level at AF3-OUT AF3-OUT

remote.

N02/N24: ___________±1 Feed into terminal N02/N24: ______±1 dBm N02/N24: ___________

11a-11b (600 )

N08/N30: ___________±1 N08/N30: ______±1 N08/N30: ___________

Measure at terminal

N14/N42: ___________±1 12a-12b N14/N42: ______±1 N14/N42: ___________

N20/N48: ___________±1 ext. Boost not active. N20/N48: ______±1 N20/N48: ___________

N54: ___________±1 N54: ______±1 N54: ___________

N02 N08 N14 N20

C.11.12 Teleoperation AF4 Mark if not configured:

N24 N30 N42 N48 N54

[ ] [ ] [ ] [ ] [ ]

Fed input level, [dBm], Expected Output Measured Output level at

@ 800 Hz at AF4-IN of level at AF4-OUT AF4-OUT

remote.

N02/N24: ___________±1 Feed into terminal N02/N24: ______±1 dBm N02/N24: ___________

13a-13b (600 )

N08/N30: ___________±1 N08/N30: ______±1 N08/N30: ___________

Measure at terminal

N14/N42: ___________±1 14a-14b N14/N42: ______±1 N14/N42: ___________

N20/N48: ___________±1 ext. Boost not active. N20/N48: ______±1 N20/N48: ___________

N54: ___________±1 N54: ______±1 N54: ___________

N02 N08 N14

C.11.13 Teleoperation AF4 used for Mark if not configured: N24 N30 N48

ext. teleprotection [ ] [ ] [ ]

Test EXT-BOOST: Activate at terminal

15a-15b

Fed input level, [dBm], Feed into terminal Expected Output Measured Output level at

@ 800 Hz at AF4-IN 13a-13b level at AF4-OUT AF4-OUT

N02/N24: ___________±1 Measure at terminal N02/N24: ______±1 dBm N02/N24: ___________

14a-14b (600 )

N08/N30: ___________±1 N08/N30: ______±1 N08/N30: ___________

N14/N48: ___________±1 N14/N48: ______±1 N14/N48: ___________

C.12. V.11 ports

C.12.1 V.11 Port 1 Mark if not configured: [ ]

-5

BER test Front plate P4LT/V/X, BER ≤ 10 [ ]

V.11 PORT 1 during ____ sec

C.12.2 V.11 Port 2 Mark if not configured: [ ]

BER test Front plate P4LX, BER ≤ 10-5 [ ]

V.11 PORT 2 during ____ sec

Notes:

..............................................................................................................................................................

..............................................................................................................................................................

..............................................................................................................................................................

Sign Commissioning Eng.: Sign Witness Eng.:

Doc. no. Lang. Rev. ind. Page

ABB Switzerland Ltd 1KHW002588 en A C11

Rev. ind.

Commissioning Report ETL600R4 Equipment HE

Test Permissible Test

No. Test procedure Test point value Units result

C.13. V.24 ports

C.13.1 V.24 Port 1 Mark if not configured: [ ]

BER test Front plate P4LT/V/X, BER ≤ 10-5 [ ]

V.24 PORT 1 during ____ sec

C.13.2 V.24 Port 2 Mark if not configured: [ ]

BER test Front plate P4LT/V/X, BER ≤ 10-5 [ ]

V.24 PORT 2 during ____ sec

C.13.3 V.24 Port 3 Mark if not configured: [ ]

BER test Front plate P4LX, BER ≤ 10-5 [ ]

V.24 PORT 3 during ____ sec

C.13.4 V.24 Port 4 Mark if not configured: [ ]

BER test Front plate P4LX, BER ≤ 10-5 [ ]

V.24 PORT 4 during ____ sec

C.14. Testing of LAN port

C.14.1 LAN Port 1 Mark if not configured: [ ]

Test of throughput Front plate P4LV/X, Throughput

LAN PORT 1 during ______ sec _____ __________________

% errored or missing frames of Front plate P4LV/X, ≤ 0.5% errored or

[ ]D 10’000 LAN PORT 1 missing 128-byte [ ]

frames during

[ ] ……………..

transmitted frames. ___________ sec

C.14.2 LAN Port 2 Mark if not configured: [ ]

Test of throughput Front plate P4LV/X, Throughput

LAN PORT 2 during ______ sec _____ __________________

% errored or missing frames of Front plate P4LV/X, ≤ 0.5% errored or

[ ]D 10’000 LAN PORT 2 missing 128-byte [ ]

frames during

[ ] ……………..

transmitted frames. ___________ sec

C.14.3 LAN Port 3 Mark if not configured: [ ]

Test of throughput Front plate P4LV/X, Throughput

LAN PORT 3 during ______ sec _____ __________________

% errored or missing frames of Front plate P4LV/X, ≤ 0.5% errored or

[ ]D 10’000 LAN PORT 3 missing 128-byte [ ]

frames during

[ ] ……………..

transmitted frames. ___________ sec

Notes:

..............................................................................................................................................................

..............................................................................................................................................................

..............................................................................................................................................................

Sign Commissioning Eng.: Sign Witness Eng.:

Doc. no. Lang. Rev. ind. Page

ABB Switzerland Ltd 1KHW002588 en A C12

Rev. ind.

Commissioning Report ETL600R4 Equipment HE

Test Permissible Test

No. Test procedure Test point value Units result

C.14.4 LAN Port 4 Mark if not configured: [ ]

Test of throughput Front plate P4LV/X, Throughput

LAN PORT 4 during ______ sec _____ __________________

% errored or missing frames of Front plate P4LV/X, ≤ 0.5% errored or

[ ]D 10’000 LAN PORT 4 missing 128-byte [ ]

frames during

[ ] ……………..

transmitted frames. ___________ sec

C.14.5 HMI over LAN

Test of connectivity Front plate P4LU/V/X, Connected [ ]

LAN PORT ____

C.15. Testing of O4CV

C.15.1 Slot positions of O4CV

boards

Record slot positions of O4CV Refer to HMI600

boards configuration view O4CV#1: N_____

O4CV#2: N_____

O4CV#3: N_____

O4CV#4: N_____

C.15.2 Service Phone Mark if not configured: [ ]

Pick up the phone and talk. Service phone, at front Own voice is audible [ ]

panel of O4CV#1 without feedback or

excessive echo

C.15.3 Hot line direct phone Mark if not configured: [ ]

Measure voltage at open loop Terminals 1a-1b, 2a-2b, 40.8 V … 55.2 V O4CV#1: O4CV#2:

condition 3a-3b, 4a-4b of term.bl.2 P1 P2 P3 P4 P1 P2 P3P4

for ports P1, P2, P3, P4 [ ] [ ] [ ] [ ] [ ] [ ] [ ][ ]

O4CV#3: O4CV#4:

P1 P2 P3 P4 P1 P2 P3P4

[ ] [ ] [ ] [ ] [ ] [ ] [ ][ ]

Pick up the phone and talk Direct telephone at Own voice is audible O4CV#1: O4CV#2:

terminals 1a-1b, 2a-2b, without feedback or P1 P2 P3 P4 P1 P2 P3P4

3a-3b, 4a-4b of term.bl.2 excessive echo [ ] [ ] [ ] [ ] [ ] [ ] [ ][ ]

for ports P1, P2, P3, P4

O4CV#3: O4CV#4:

P1 P2 P3 P4 P1 P2 P3P4

[ ] [ ] [ ] [ ] [ ] [ ] [ ][ ]

Notes:

..............................................................................................................................................................

..............................................................................................................................................................

..............................................................................................................................................................

Sign Commissioning Eng.: Sign Witness Eng.:

Doc. no. Lang. Rev. ind. Page

ABB Switzerland Ltd 1KHW002588 en A C13

Rev. ind.

Commissioning Report ETL600R4 Equipment HE

Test Permissible Test

No. Test procedure Test point value Units result

C.15.4 Remote subscriber Mark if not configured: [ ]

Measure voltage at open loop Terminals 1a-1b, 2a-2b, 40.8 V … 55.2 V O4CV#1: O4CV#2:

condition 3a-3b, 4a-4b of term.bl.2 P1 P2 P3 P4 P1 P2 P3P4

for ports P1, P2, P3, P4 [ ] [ ] [ ] [ ] [ ] [ ] [ ][ ]

O4CV#3: O4CV#4:

P1 P2 P3 P4 P1 P2 P3P4

[ ] [ ] [ ] [ ] [ ] [ ] [ ][ ]

Pick up the phone and talk Direct telephone at Own voice is audible O4CV#1: O4CV#2:

terminals 1a-1b, 2a-2b, without feedback or P1 P2 P3 P4 P1 P2 P3P4

3a-3b, 4a-4b of term.bl.2 excessive echo [ ] [ ] [ ] [ ] [ ] [ ] [ ][ ]

for ports P1, P2, P3, P4 O4CV#3: O4CV#4:

P1 P2 P3 P4 P1 P2 P3P4

[ ] [ ] [ ] [ ] [ ] [ ] [ ][ ]

O4CV#1: O4CV#2:

C.15.5 Pax 2-wire Mark if configured: P1 P2 P3 P4 P1 P2 P3P4

[ ] [ ] [ ] [ ] [ ] [ ] [ ][ ]

O4CV#3: O4CV#4:

P1 P2 P3 P4 P1 P2 P3P4

[ ] [ ] [ ] [ ] [ ] [ ] [ ][ ]

C.15.6 Pax 4-wire Mark if not configured: [ ]

Test E-Wire: Terminals 3a-3b, 7a-7b, E-Wire must toggle O4CV#1: O4CV#2:

11a-11b, 15a-15b of P1 P2 P3 P4 P1 P2 P3P4

Close and open M-Wire at

term.bl.1 for ports P1, [ ] [ ] [ ] [ ] [ ] [ ] [ ][ ]

terminals 4a-4b, 8a-8b,

P2, P3, P4 O4CV#3: O4CV#4:

12a-12b, 16a-16b of term.bl.1

for ports P1, P2, P3, P4 P1 P2 P3 P4 P1 P2 P3P4

[ ] [ ] [ ] [ ] [ ] [ ] [ ][ ]

Measure output level. Feed into terminals Configured output dBm O4CV#1: O4CV#2:

Feed 800 Hz with configured

1a-1b, 5a-5b, 9a-9b, level ±5 dB (600 ) P1 P2 P3 P4 P1 P2 P3P4

13a-13b of term.bl.1 for (Def.: -3.5 dBm) [ ] [ ] [ ] [ ] [ ] [ ] [ ][ ]

input level of remote PAX

ports P1, P2, P3, P4

(Def.: -3.5 dBm). O4CV#3: O4CV#4:

Measure at terminals P1 P2 P3 P4 P1 P2 P3P4

(Activate at terminals 4a-4b,

2a-2b, 6a-6b, 10a-10b, [ ] [ ] [ ] [ ] [ ] [ ] [ ][ ]

8a-8b, 12a-12b, 16a-16b of

14a-14b of term.bl.1 for

term.bl.1 for ports P1, P2, P3,

ports P1, P2, P3, P4

P4)

C.16. Manual reset [ ]

C.17. Documentation

If possible, take printout of [ ]

Configuration data for

reference.

Save the 'et6' file on disk with [ ]

Serial No. of ETL coded in

the file name, e.g.

‘HE400327C.et6’.

Notes:

..............................................................................................................................................................

..............................................................................................................................................................

..............................................................................................................................................................

Sign Commissioning Eng.: Sign Witness Eng.:

Doc. no. Lang. Rev. ind. Page

ABB Switzerland Ltd 1KHW002588 en A C14

Rev. ind.

Commissioning Report ETL600R4 Equipment HE

Pending Items List:

Issue Description

YES NO YES NO

Commissioning Approved: Exceptions Noted:

Name PSNP3

of responsible

Signature &

Date

Company ABB Switzerland Ltd Consultant Customer

Doc. no. Lang. Rev. ind. Page

ABB Switzerland Ltd 1KHW002588 en A C15

You might also like

- John Deere 160dlc Repair ManualDocument20 pagesJohn Deere 160dlc Repair Manuallillie100% (63)

- John Deere 750c 850c Crawler Dozer Technical ManualDocument20 pagesJohn Deere 750c 850c Crawler Dozer Technical Manualsantos100% (32)

- Spectrum Power 7 MGMS Application GuideDocument22 pagesSpectrum Power 7 MGMS Application Guidefayssal salvadorNo ratings yet

- SERVOPRO 4000 Series - Service ManualDocument190 pagesSERVOPRO 4000 Series - Service ManualGuillermo Zapata100% (1)

- 2013-04-28 IEC61850 Engineering ManualDocument18 pages2013-04-28 IEC61850 Engineering Manualfayssal salvadorNo ratings yet

- 1KHW002568AE System Test Report ETL600R4Document17 pages1KHW002568AE System Test Report ETL600R4fayssal salvadorNo ratings yet

- 1KHW002569AE System Test Report ETL600R4 ReichleDocument17 pages1KHW002569AE System Test Report ETL600R4 Reichlefayssal salvadorNo ratings yet

- 1khw002585ae Tuning of Etl600r4 TX RF Filter On E5th and E5tcDocument6 pages1khw002585ae Tuning of Etl600r4 TX RF Filter On E5th and E5tcfayssal salvadorNo ratings yet

- PTC Dip5k TS e 001Document20 pagesPTC Dip5k TS e 001jose rochaNo ratings yet

- 1KHW001497SE Anomaly List For ETL600Document8 pages1KHW001497SE Anomaly List For ETL600fayssal salvadorNo ratings yet

- TBN 11551 User Manual UnlockedDocument22 pagesTBN 11551 User Manual UnlockedguanitouNo ratings yet

- 1KHL015946 - EN Instruction Manual ETL500 Rel.3.2Document378 pages1KHL015946 - EN Instruction Manual ETL500 Rel.3.2Denis Leo trindadeNo ratings yet

- Battery Charger Profitec 2000 S 216 V/120 A: Management Documents 81504209.EN0 BFU, enDocument9 pagesBattery Charger Profitec 2000 S 216 V/120 A: Management Documents 81504209.EN0 BFU, endinkoheNo ratings yet

- Battery Charger Profitec 2000 S 216 V/120 A: Management Documents 81504209.EN0 BFU, enDocument9 pagesBattery Charger Profitec 2000 S 216 V/120 A: Management Documents 81504209.EN0 BFU, endinkoheNo ratings yet

- 4000 Series Analysers: Service ManualDocument190 pages4000 Series Analysers: Service ManualFabian MirandaNo ratings yet

- Bulletin 1305 Drives To Powerflex 40 Drives: Migration GuideDocument12 pagesBulletin 1305 Drives To Powerflex 40 Drives: Migration GuideWilliam Alfonso Cañas PratoNo ratings yet

- La 4525Document10 pagesLa 4525richie1479No ratings yet

- Eiki LC-XT3Document110 pagesEiki LC-XT3Dimas Arenas GonzálezNo ratings yet

- General Manual PDFDocument226 pagesGeneral Manual PDFAlexandre Godoi100% (1)

- 1KHW001489-EN Instruction Manual ETL600 Rel.3.2 (Dec 2008, Annex Jan 2010) PDFDocument480 pages1KHW001489-EN Instruction Manual ETL600 Rel.3.2 (Dec 2008, Annex Jan 2010) PDFgam2312No ratings yet

- LNCi N2000 Maintenance Manual ENGV01004408030031Document27 pagesLNCi N2000 Maintenance Manual ENGV01004408030031Ta TuanNo ratings yet

- Xrio Converter Manual Abb Ref615 v1.0 Enu Tu2.22 v1.000Document11 pagesXrio Converter Manual Abb Ref615 v1.0 Enu Tu2.22 v1.000m_dh87129No ratings yet

- OP8681Document17 pagesOP8681Prashant TiwariNo ratings yet

- 03.2114.010.71e TRT800A-OLED OI Rev4.00 210427 WEBDocument56 pages03.2114.010.71e TRT800A-OLED OI Rev4.00 210427 WEBAerotec SvlNo ratings yet

- RES Accepted Relay List - V2.7 - 20.06.2022Document41 pagesRES Accepted Relay List - V2.7 - 20.06.2022Cristina SubirNo ratings yet

- Eda105 4020 LSDocument36 pagesEda105 4020 LSShakey IsPeedoffNo ratings yet

- Test Report Vde-Ar-N 4105Document40 pagesTest Report Vde-Ar-N 4105hmm.hugo7845100% (1)

- Cypress Traveo SeriesDocument308 pagesCypress Traveo SeriesusertestNo ratings yet

- Certification SmaDocument12 pagesCertification Smafadi lamoNo ratings yet

- Flux Vector Drive 0.25 Kw... 2.2 KW: Betriebsanleitung DE Operating InstructionsDocument124 pagesFlux Vector Drive 0.25 Kw... 2.2 KW: Betriebsanleitung DE Operating InstructionsDaniel SitumeangNo ratings yet

- Profile PDR100 Video Disk RecorderDocument84 pagesProfile PDR100 Video Disk RecorderiscrbdiNo ratings yet

- Apollo Elite RSDocument157 pagesApollo Elite RSMarcelo OrtizNo ratings yet

- ITS Report 103807635COL 001 26 March 2019Document145 pagesITS Report 103807635COL 001 26 March 2019technicalconsultationstc03No ratings yet

- ABBOfflineOrderNumberTool Ver 15.41b 758059 ENgDocument75 pagesABBOfflineOrderNumberTool Ver 15.41b 758059 ENgsavijolaNo ratings yet

- Snva 465 ADocument13 pagesSnva 465 Aeneas.baroneNo ratings yet

- 1426-Um001 en 1Document464 pages1426-Um001 en 1Adilon de AssisNo ratings yet

- 13 Opc XML Da Gateway Datalist Cwe f008 181 en r03Document14 pages13 Opc XML Da Gateway Datalist Cwe f008 181 en r03Rana DanialNo ratings yet

- OptiX PTN 3900 Hardware Description - (V100R002C01 04)Document320 pagesOptiX PTN 3900 Hardware Description - (V100R002C01 04)Борис ЧаловскийNo ratings yet

- Fp0 RTD Technicalmanual Acgm0159v13enDocument34 pagesFp0 RTD Technicalmanual Acgm0159v13enRiccardo BottacinNo ratings yet

- Hfe Yamaha Rx-E410 E810 ServiceDocument57 pagesHfe Yamaha Rx-E410 E810 ServiceYoly Rio RamosNo ratings yet

- 1khw002584be Tuning of Etl600r4 RX RF Filter p4rxDocument8 pages1khw002584be Tuning of Etl600r4 RX RF Filter p4rxfayssal salvadorNo ratings yet

- Tl2843 PWM ControllersDocument27 pagesTl2843 PWM ControllersZxdIaminxXzlovewithzxXzyouzxNo ratings yet

- Certificado InternacionalDocument98 pagesCertificado InternacionalAmaury BerteliNo ratings yet

- Simatic Et200s PDFDocument272 pagesSimatic Et200s PDFWalter JosephNo ratings yet

- Catalogo de Partes - Laserjet 1220 LASER MONODocument28 pagesCatalogo de Partes - Laserjet 1220 LASER MONOElton PereiraNo ratings yet

- fp0 A D Converter Unit Technical Manual 0811 PDFDocument42 pagesfp0 A D Converter Unit Technical Manual 0811 PDFHuuThienNo ratings yet

- ABB Offline Order Number Tool Ver. 15.42a 758059 ENhDocument77 pagesABB Offline Order Number Tool Ver. 15.42a 758059 ENhSumith VkNo ratings yet

- LM5175 EVM User's GuideDocument20 pagesLM5175 EVM User's GuideSimone GhirardinNo ratings yet

- Manual RFM 300+Document80 pagesManual RFM 300+saomigasNo ratings yet

- Service Manual /: SupplementDocument29 pagesService Manual /: SupplementsilictronicNo ratings yet

- La 42071Document9 pagesLa 42071Miloud ChouguiNo ratings yet

- ABB Distribution Automation Protection Relay Price List: Enable Content OptionsDocument77 pagesABB Distribution Automation Protection Relay Price List: Enable Content OptionsInsan AzizNo ratings yet

- Safety of Household and Similar Electrical Appliances: Test Report IEC 60335-1 And/or EN 60335-1Document76 pagesSafety of Household and Similar Electrical Appliances: Test Report IEC 60335-1 And/or EN 60335-1Giuseppe FerrariNo ratings yet

- Guide Spec 9395p 675-1100 Kva 400v UpsDocument53 pagesGuide Spec 9395p 675-1100 Kva 400v UpsEduardo VianaNo ratings yet

- 201101048SHA-001 Intertek CE Report For Terminal Block 1Document10 pages201101048SHA-001 Intertek CE Report For Terminal Block 1thegeneral2040No ratings yet

- Power Surse 300w Ice 3pgDocument19 pagesPower Surse 300w Ice 3pgbiotekyNo ratings yet

- KXTG 1100 FXDocument20 pagesKXTG 1100 FXMarius NegreaNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument12 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- Contactores EatonDocument251 pagesContactores EatonJose GuerraNo ratings yet

- 1KHW002582-En Instruction Manual ETL600 Rel.4 (March 2013, Annex Updated June 2013)Document480 pages1KHW002582-En Instruction Manual ETL600 Rel.4 (March 2013, Annex Updated June 2013)fayssal salvadorNo ratings yet

- 6MB Telecontrol System: 6MB552 Compact Remote Terminal UnitDocument12 pages6MB Telecontrol System: 6MB552 Compact Remote Terminal Unitfayssal salvadorNo ratings yet

- 1KHW001497SE Anomaly List For ETL600Document8 pages1KHW001497SE Anomaly List For ETL600fayssal salvadorNo ratings yet

- 1KHW002609AE Programming and Testing of ETL600R4Document27 pages1KHW002609AE Programming and Testing of ETL600R4fayssal salvador100% (1)

- 1khw002584be Tuning of Etl600r4 RX RF Filter p4rxDocument8 pages1khw002584be Tuning of Etl600r4 RX RF Filter p4rxfayssal salvadorNo ratings yet

- 1KHW002589 - E Firmware Download For ETL600R4Document7 pages1KHW002589 - E Firmware Download For ETL600R4fayssal salvadorNo ratings yet

- 1khw002585ae Tuning of Etl600r4 TX RF Filter On E5th and E5tcDocument6 pages1khw002585ae Tuning of Etl600r4 TX RF Filter On E5th and E5tcfayssal salvadorNo ratings yet

- 1KHW001490PE Compatibility Requirements For ETL600Document20 pages1KHW001490PE Compatibility Requirements For ETL600fayssal salvadorNo ratings yet

- 1KHW002569AE System Test Report ETL600R4 ReichleDocument17 pages1KHW002569AE System Test Report ETL600R4 Reichlefayssal salvadorNo ratings yet

- 1KHW002590CE Technical Data ETL600R4Document7 pages1KHW002590CE Technical Data ETL600R4fayssal salvadorNo ratings yet

- 1KHW002586AE Commissioning of ETL600R4Document17 pages1KHW002586AE Commissioning of ETL600R4fayssal salvadorNo ratings yet

- Appendix 00 AK - ACP - Install - ENGDocument132 pagesAppendix 00 AK - ACP - Install - ENGfayssal salvadorNo ratings yet

- Manual Sepam Serie60 enDocument486 pagesManual Sepam Serie60 enfayssal salvadorNo ratings yet

- 1KHW001494FE APLC Channel Equalization For ETL600Document7 pages1KHW001494FE APLC Channel Equalization For ETL600fayssal salvadorNo ratings yet

- 1KHW002568AE System Test Report ETL600R4Document17 pages1KHW002568AE System Test Report ETL600R4fayssal salvadorNo ratings yet

- 1KHM010296KE Repair & Return ProcedureDocument3 pages1KHM010296KE Repair & Return Procedurefayssal salvadorNo ratings yet

- 01 - EA Portfolio - e - IMPORTANTDocument12 pages01 - EA Portfolio - e - IMPORTANTfayssal salvadorNo ratings yet

- 03 Sicam1703-E ImportantDocument25 pages03 Sicam1703-E ImportantSalvador FayssalNo ratings yet

- 04 SICAM1703 Architecture Act ImportantDocument62 pages04 SICAM1703 Architecture Act Importantfayssal salvadorNo ratings yet

- Index Terms LinksDocument18 pagesIndex Terms Linksfayssal salvadorNo ratings yet