0% found this document useful (0 votes)

559 views34 pagesChapter 2 - P - ID

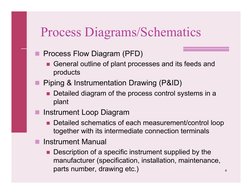

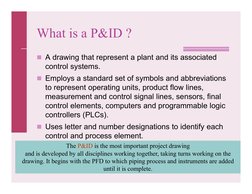

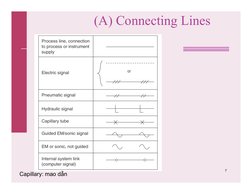

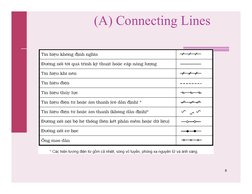

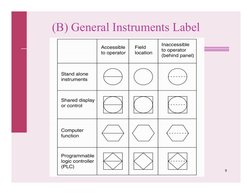

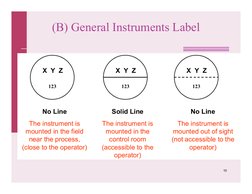

The document discusses process control systems and piping and instrumentation drawings (P&IDs). It describes the objectives of understanding common symbols and abbreviations in P&IDs and being able to describe a system's operation from a P&ID. The contents then explain what a P&ID is and covers topics like connecting lines, tag numbers, process elements, and final control elements. Examples are provided to illustrate P&ID diagrams and describing a plant's operation based on its diagram.

Uploaded by

Huy Nguyen LuongCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

559 views34 pagesChapter 2 - P - ID

The document discusses process control systems and piping and instrumentation drawings (P&IDs). It describes the objectives of understanding common symbols and abbreviations in P&IDs and being able to describe a system's operation from a P&ID. The contents then explain what a P&ID is and covers topics like connecting lines, tag numbers, process elements, and final control elements. Examples are provided to illustrate P&ID diagrams and describing a plant's operation based on its diagram.

Uploaded by

Huy Nguyen LuongCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd