Professional Documents

Culture Documents

Mill Test & Inspection Certificate: ACCORDING TO EN 10204: 2004 3.1

Mill Test & Inspection Certificate: ACCORDING TO EN 10204: 2004 3.1

Uploaded by

suria qaqc0 ratings0% found this document useful (0 votes)

77 views1 page1) The document is a mill test and inspection certificate for 17 items made of SA105N steel according to EN 10204:2004 3.1 standards.

2) It lists the items, heat numbers, specifications, inspection results, chemical compositions, mechanical properties, and confirms compliance.

3) The materials were tested and comply with the terms of the order contract.

Original Description:

Original Title

ELBOW, UNION, TEE COUPLING NPT

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1) The document is a mill test and inspection certificate for 17 items made of SA105N steel according to EN 10204:2004 3.1 standards.

2) It lists the items, heat numbers, specifications, inspection results, chemical compositions, mechanical properties, and confirms compliance.

3) The materials were tested and comply with the terms of the order contract.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

77 views1 pageMill Test & Inspection Certificate: ACCORDING TO EN 10204: 2004 3.1

Mill Test & Inspection Certificate: ACCORDING TO EN 10204: 2004 3.1

Uploaded by

suria qaqc1) The document is a mill test and inspection certificate for 17 items made of SA105N steel according to EN 10204:2004 3.1 standards.

2) It lists the items, heat numbers, specifications, inspection results, chemical compositions, mechanical properties, and confirms compliance.

3) The materials were tested and comply with the terms of the order contract.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

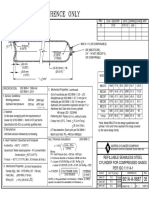

MILL TEST & INSPECTION CERTIFICATE

ACCORDING TO EN 10204 : 2004 3.1

CUSTOMER : SAEED SONS CORPORATION PAGE: 1/1 ORDER NO : 14100002

CERT. NO : MC1411010011 DATE :2019.10.05

CHARGE RAW MATERIAL SPECIFICATION FOR INSPENTION

ITEM

NO HEAT NO. DESCRIPTION QUANTITY MATERIAL FITTING SURFACE DIM.

1 29M27 3535 NPT ELBOW 1/2" 3M SA105N 250

2 29M27 0400 NPT ELBOW 1" 3M SA105N 200 ASTM A105N -09 MSS SP-83 - 2006 GOOD GOOD

3 29M27 0467 NPT TEE 1/2" 3M SA105N 150 ASME SA105N

4 29M27 0333 NPT TEE 3/4" 3M SA105N 100

5 29M27 0333 NPT TEE 1" 3M SA105N 100

6 29M27 3129 TH UNION 1/2" 3M SA105N 100

7 29M27 0333 TH UNION 3/4" 3M SA105N 100

8 29M27 0107 TH UNION 1" 3M SA105N 50

9 29M27 0333 TH UNION 2" 3M SA105N 50

10 29M27 0343 NPT COUPLING 1/2" 3M SA105N 400

11 29M27 0354 NPT COUPLING 3/4" 3M SA105N 450

12 29M27 0363 HEX NIPPLE 1/2" 3M SA 105N 100

13 29M27 0373 HEX PLUG 1/2" 3M SA 105N 300

14 29M27 0383 NPT R/COUPLING 3/4"X1/2" 3M SA105N 50

15 29M27 0393 NPT R/COUPLING 1"X1/2" 3M SA105N 50

16 29M27 3680 NPT R/COUPLING 11/2"X3/4" 3M SA105N 24

17 29M27 3680 NPT R/COUPLING 11/2"X1" 3M SA105N 24

ITEM CHEMICAL COMPOSITION (%)

C Si Mn P S Cu Cr Ni Mo V Cb (Nb) N Al Ti Zr CE

Min HT. CD. - 0.100 0.600 - - - - - - - - - MATERIAL SUPPLIER

Max 0.350 0.350 1.050 0.035 0.040 0.400 0.300 0.400 0.120 0.080 - -

1 3535 0.21 0.26 0.76 0.011 0.005 0.03 0.03 0.01 0.02 0.003

2 0333 0.21 0.26 0.76 0.011 0.005 0.03 0.03 0.01 0.02 0.003

3 0467 0.21 0.26 0.76 0.011 0.005 0.03 0.03 0.01 0.02 0.003

4 0333 0.21 0.26 0.76 0.011 0.005 0.03 0.03 0.01 0.02 0.003

5 0333 0.21 0.26 0.76 0.011 0.005 0.03 0.03 0.01 0.02 0.003

6 3129 0.21 0.26 0.76 0.011 0.005 0.03 0.03 0.01 0.02 0.003

7 0333 0.21 0.26 0.76 0.011 0.005 0.03 0.03 0.01 0.02 0.003

8 0333 0.21 0.26 0.76 0.011 0.005 0.03 0.03 0.01 0.02 0.003

9 0333 0.21 0.26 0.76 0.011 0.005 0.03 0.03 0.01 0.02 0.003

10 0333 0.21 0.26 0.76 0.011 0.005 0.03 0.03 0.01 0.02 0.003

11 0333 0.21 0.26 0.76 0.011 0.005 0.03 0.03 0.01 0.02 0.003

12 0333 0.21 0.26 0.76 0.011 0.005 0.03 0.03 0.01 0.02 0.003

13 0333 0.21 0.26 0.76 0.011 0.005 0.03 0.03 0.01 0.02 0.003

14 0333 0.21 0.26 0.76 0.011 0.005 0.03 0.03 0.01 0.02 0.003

15 0333 0.21 0.26 0.76 0.011 0.005 0.03 0.03 0.01 0.02 0.003

16 3680 0.22 0.21 0.80 0.009 0.006 0.03 0.04 0.03 0.02 0.01

17 3680 0.22 0.21 0.80 0.009 0.006 0.03 0.04 0.03 0.02 0.01

ITEM MECHANICAL PROPERTIES ADDITIONAL TEST / REMARKS

T.S. Y.S. EL. R of A Hardness Charpy Impact HEAT TREATMENT DIMENSION: ASME B16.11

HT. CD. (MPA) (MPA) (%) (%) (HB) (AVG) °F / 0 °C THREADS: ANSI/ASME B1.20.1

Min 485.0 250.0 22.0 30.0 MIN. / AVG. / ( Joule ) CONFORMS TO NACE MR0175/MR0103-2003

Max - - - - 187 1 2 3 AVG. STEEL MAKING PROCESS : ELECTRIC FURNACE

1 3535 520 282 28 52 142-160 NORMALIZIED AT

2 0333 520 282 28 52 142-160 834-927°C、COOL IN

3 0467 520 282 28 52 142-160 STILL AIR

4 0333 520 282 28 52 142-160

5 0333 520 282 28 52 142-160

6 3129 520 282 28 52 142-160

7 0333 520 282 28 52 142-160

8 0333 520 282 28 52 142-160

9 0333 520 282 28 52 142-160

10 0333 520 282 28 52 142-160

11 0333 520 282 28 52 142-160

12 0333 520 282 28 52 142-160

13 0333 520 282 28 52 142-160

14 0333 520 282 28 52 142-160

15 0333 520 282 28 52 142-160

16 3680 541 288 27 57 142-168

17 3680 541 288 27 57 142-168

WE HEREBY CERTIFY, THAT THE MATERIAL DESCRIBED ABOVE HAS BEEN TESTED AND COMPLIES WITH THE TERMS OF

THE ORDER CONTRACT.

You might also like

- 2012 f550 Manual PDFDocument450 pages2012 f550 Manual PDFJuma RefaccionariasNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Taneks Steyr CatalogueDocument50 pagesTaneks Steyr CatalogueeCommerce SAJID Auto100% (1)

- David Abram The Spell of The Sensuous (4 Chap)Document6 pagesDavid Abram The Spell of The Sensuous (4 Chap)kabshiel86% (7)

- Snorkel TB126J PDFDocument234 pagesSnorkel TB126J PDFAnar QasimovNo ratings yet

- Temperature of Mass ConcreteDocument41 pagesTemperature of Mass Concreterahmat amaik0% (1)

- JyothishaPrakaasham MeenaVijayaDocument52 pagesJyothishaPrakaasham MeenaVijayaAnonymous 5mSMeP2j100% (1)

- TM 5-3805-280-24P Part 2 John Deere MDL 230 LCRDocument348 pagesTM 5-3805-280-24P Part 2 John Deere MDL 230 LCRAdvocateNo ratings yet

- Fender LTD Ed Blackwood P90 Telecaster 0175107721 SM REV A 3-21-17Document6 pagesFender LTD Ed Blackwood P90 Telecaster 0175107721 SM REV A 3-21-17Oscar JimenezNo ratings yet

- Catalogo de Pecas Carregadeira Pneus Volvo L120e PDFDocument1,172 pagesCatalogo de Pecas Carregadeira Pneus Volvo L120e PDFPedro Matheus90% (10)

- Cabronita Telecaster Service Manual 017-0148Document5 pagesCabronita Telecaster Service Manual 017-0148rexNo ratings yet

- PDS390S-4B1, Hal 15Document4 pagesPDS390S-4B1, Hal 15AkmalNo ratings yet

- Assistant Director (Environment) BPS-17Document23 pagesAssistant Director (Environment) BPS-17nomanNo ratings yet

- Suria Engineering.: Test Pack For Tt307B PipingDocument16 pagesSuria Engineering.: Test Pack For Tt307B Pipingsuria qaqcNo ratings yet

- Lokotrack LT300HP S N 77462Document733 pagesLokotrack LT300HP S N 77462miguel. montaño100% (1)

- 2.bien Phap Thi Cong Ong GioDocument19 pages2.bien Phap Thi Cong Ong GioQuang Do HoangNo ratings yet

- 9822/0310 F610-30-1 PS TRANSMISSIONS GEARBOX PS750,1:1.364: Marcial MilitanteDocument4 pages9822/0310 F610-30-1 PS TRANSMISSIONS GEARBOX PS750,1:1.364: Marcial MilitanteMarcial Jr. MilitanteNo ratings yet

- Door Seals/Door Gaskets/Bonnet Seals: Number Size DescriptionDocument3 pagesDoor Seals/Door Gaskets/Bonnet Seals: Number Size DescriptionBoyke SaptaNo ratings yet

- Art. No. ISO Body Size Ls ΦD Hs TDocument2 pagesArt. No. ISO Body Size Ls ΦD Hs TSyaifulIslamNo ratings yet

- Seko MSA Data SheetDocument2 pagesSeko MSA Data SheetdadangNo ratings yet

- Subm Motor Accessories Catalog enDocument13 pagesSubm Motor Accessories Catalog enmijael104No ratings yet

- CDS 30Document2 pagesCDS 30MarleyNo ratings yet

- Fineadjust Applicator Specification Sheet Order No. 63900-0100Document5 pagesFineadjust Applicator Specification Sheet Order No. 63900-0100Amine MaaouiNo ratings yet

- Emc Cable Glands 20m3 Datasheet 01 enDocument1 pageEmc Cable Glands 20m3 Datasheet 01 endheerajyadav31No ratings yet

- 9812/7600 F5-2-1 Gearbox, 4WD External Components 449/13160,449/13100Document3 pages9812/7600 F5-2-1 Gearbox, 4WD External Components 449/13160,449/13100heroskNo ratings yet

- Tele American Special 2013Document5 pagesTele American Special 2013suruboNo ratings yet

- Unibraze ER316L PDFDocument1 pageUnibraze ER316L PDFsmpoe017No ratings yet

- Parts Manual m25xpb-m35b-m40b Revision 2 FinalDocument75 pagesParts Manual m25xpb-m35b-m40b Revision 2 FinalJoe SeraphinNo ratings yet

- CDS 32Document2 pagesCDS 32MarleyNo ratings yet

- 1190 HardwareDocument2 pages1190 HardwarejacksonNo ratings yet

- 2.0 Body Work FrameDocument2 pages2.0 Body Work FrameGarcia CruzNo ratings yet

- Aerofoam NBR Tubes Catalogue PDFDocument4 pagesAerofoam NBR Tubes Catalogue PDFAshfak Niyasdeen0% (1)

- Zapp Precision Wire Inc Product CatalogueDocument49 pagesZapp Precision Wire Inc Product CatalogueAyesha AleemNo ratings yet

- Franke Sinfonia Parts Breakdown - 032515Document133 pagesFranke Sinfonia Parts Breakdown - 032515Juan Carlos MunozNo ratings yet

- 9802/9730 F6-10-11 Transmission External Components 2Ws 4Wd 20KPH 449/11140Document2 pages9802/9730 F6-10-11 Transmission External Components 2Ws 4Wd 20KPH 449/11140Javid GuliyevNo ratings yet

- Quotation: Our Ref: SS/Q/631496MHM Your Ref:SWM1020-SW-PIP-PUR-0Document3 pagesQuotation: Our Ref: SS/Q/631496MHM Your Ref:SWM1020-SW-PIP-PUR-0mb.pipingNo ratings yet

- 011-320a SisdDocument5 pages011-320a SisdMichael GrahamNo ratings yet

- Pinnacle Alloys ER2594Document2 pagesPinnacle Alloys ER2594Federico Quintana100% (1)

- Genuine Cummins Parts - FT60765 - 04Document2 pagesGenuine Cummins Parts - FT60765 - 04EPESANo ratings yet

- Sap Code Description Size Qty SR Nos + Marking On ComponentDocument1 pageSap Code Description Size Qty SR Nos + Marking On ComponentSanjay C BhattNo ratings yet

- Circuito Giro 2 BancoDocument2 pagesCircuito Giro 2 BancoManuel felipe PalmaNo ratings yet

- Parts Catalog - Option DetailDocument2 pagesParts Catalog - Option DetailIKNo ratings yet

- Friction Stir Welding of Aluminum MMC: Tracy W. Nelson, Dick LederichDocument22 pagesFriction Stir Welding of Aluminum MMC: Tracy W. Nelson, Dick LederichSanthosh Kumar KodhandapaniNo ratings yet

- Q-After Cooler DONEDocument2 pagesQ-After Cooler DONEIKNo ratings yet

- Fineadjust Applicator Applicator Tooling Specification Order No. 63901-7400Document5 pagesFineadjust Applicator Applicator Tooling Specification Order No. 63901-7400Ernesto VelásquezNo ratings yet

- InertiaDynamics FlangeMtBk310s SpecsheetDocument2 pagesInertiaDynamics FlangeMtBk310s SpecsheetElectromateNo ratings yet

- Parts Catalog - Option DetailDocument1 pageParts Catalog - Option DetailKarthii AjuNo ratings yet

- Sr. No Material Description Part Match Code Current Stock Quantity RequiredDocument4 pagesSr. No Material Description Part Match Code Current Stock Quantity RequiredkuldipsinhNo ratings yet

- Fender Standard Stratocaster HSS 014470XXXX Service Manual REV A 4-27-16Document6 pagesFender Standard Stratocaster HSS 014470XXXX Service Manual REV A 4-27-16Luis FunkNo ratings yet

- Refillable Seamless Steel Cylinder For Compressed Gases PER ISO 11114-1Document1 pageRefillable Seamless Steel Cylinder For Compressed Gases PER ISO 11114-1bkprodhNo ratings yet

- Herion SolenoidDocument8 pagesHerion SolenoidegmbrNo ratings yet

- CDS 31Document2 pagesCDS 31MarleyNo ratings yet

- PB-B1 Surface 400 Basement 80 100Document1 pagePB-B1 Surface 400 Basement 80 100rawda moawadNo ratings yet

- Gambar 33 Cowling 1: Nomor Refere Nomor Part Nama Part KeteranganDocument1 pageGambar 33 Cowling 1: Nomor Refere Nomor Part Nama Part KeteranganHarris Jum'aniandaNo ratings yet

- BodyworkDocument43 pagesBodyworkGarcia CruzNo ratings yet

- Lab TaubaltionDocument4 pagesLab TaubaltionLast NameNo ratings yet

- Manual Tong Typo CDocument3 pagesManual Tong Typo CLeonardo Rachen RodriguezNo ratings yet

- Hec DrawingsDocument58 pagesHec DrawingsGolder ZambranoNo ratings yet

- InertiaDynamics FlangeMtBk310p SpecsheetDocument2 pagesInertiaDynamics FlangeMtBk310p SpecsheetElectromateNo ratings yet

- 9822/0105 L810-1-3 Circuit DieselDocument3 pages9822/0105 L810-1-3 Circuit DieselGervann KempNo ratings yet

- 9802/6220 D1-3-1 Control, Foot Excavator AuxiliaryDocument2 pages9802/6220 D1-3-1 Control, Foot Excavator AuxiliaryGarcia CruzNo ratings yet

- DL Infos Maurer MSM Sliding BearingsDocument14 pagesDL Infos Maurer MSM Sliding BearingsrwaidaabbasNo ratings yet

- Seal Kits: Hydril Ram Type PreventersDocument2 pagesSeal Kits: Hydril Ram Type PreventersBoyke SaptaNo ratings yet

- TDS M30 REV2 Apr14 A4Document2 pagesTDS M30 REV2 Apr14 A4dakidofdaboomNo ratings yet

- Part List Iron Wheel: Kode Part Nama Part Descrition Relation 1 2 3Document3 pagesPart List Iron Wheel: Kode Part Nama Part Descrition Relation 1 2 3Beni hidayatullahNo ratings yet

- SL No:30 Date: 07.10.2020: Process - Planning To Design Version - 1.0Document4 pagesSL No:30 Date: 07.10.2020: Process - Planning To Design Version - 1.0Varunn VelNo ratings yet

- SCTM SCTM-N Brandsma Tyco Electronics Raychem Stress-Control Heatshrink Tubing DatasheetDocument1 pageSCTM SCTM-N Brandsma Tyco Electronics Raychem Stress-Control Heatshrink Tubing DatasheetJavier Silva VidalNo ratings yet

- Daily Inword Gate Pass (D)Document195 pagesDaily Inword Gate Pass (D)suria qaqcNo ratings yet

- Short Description of 10years Professional Journey: Covering LetterDocument1 pageShort Description of 10years Professional Journey: Covering Lettersuria qaqcNo ratings yet

- BOQ PIPING Total DetailDocument16 pagesBOQ PIPING Total Detailsuria qaqcNo ratings yet

- TT-307B Dossier.Document41 pagesTT-307B Dossier.suria qaqcNo ratings yet

- Tle-02 Dossier.Document40 pagesTle-02 Dossier.suria qaqcNo ratings yet

- Suria Engineering.: Test Pack For Tt307B PipingDocument18 pagesSuria Engineering.: Test Pack For Tt307B Pipingsuria qaqcNo ratings yet

- Tle-01 Dossier.Document39 pagesTle-01 Dossier.suria qaqcNo ratings yet

- TT306 Dossier.Document29 pagesTT306 Dossier.suria qaqcNo ratings yet

- GF-304CR Dossier.Document35 pagesGF-304CR Dossier.suria qaqcNo ratings yet

- Ovr Dossier.Document93 pagesOvr Dossier.suria qaqcNo ratings yet

- DSQ Dossier.Document62 pagesDSQ Dossier.suria qaqcNo ratings yet

- Task Instructions (Ti) : Date: Time: Dept: PTW No Location: Emergency No: What Is The Task Today?Document2 pagesTask Instructions (Ti) : Date: Time: Dept: PTW No Location: Emergency No: What Is The Task Today?suria qaqcNo ratings yet

- Sub Station Structure.Document33 pagesSub Station Structure.suria qaqcNo ratings yet

- Weekly HSE ReportDocument1 pageWeekly HSE Reportsuria qaqcNo ratings yet

- E1461 Dossier.Document46 pagesE1461 Dossier.suria qaqcNo ratings yet

- PPEs Issue ListDocument1 pagePPEs Issue Listsuria qaqcNo ratings yet

- Suria Engineering: Tool Box Talk FormDocument1 pageSuria Engineering: Tool Box Talk Formsuria qaqcNo ratings yet

- Bill of Material For Cn2F Dish Heads: Part No. Description Material Thickness-Mm Size-Mm Qty. RemarksDocument1 pageBill of Material For Cn2F Dish Heads: Part No. Description Material Thickness-Mm Size-Mm Qty. Remarkssuria qaqcNo ratings yet

- Suria Engineering Staff List: Doc No: Rev By: DateDocument3 pagesSuria Engineering Staff List: Doc No: Rev By: Datesuria qaqcNo ratings yet

- Safe Work Practices: Doc No: Rev By: DateDocument1 pageSafe Work Practices: Doc No: Rev By: Datesuria qaqcNo ratings yet

- Suria Engineering SR/EPCL/-01/21: Piping Test Package For Tt307B PipingDocument18 pagesSuria Engineering SR/EPCL/-01/21: Piping Test Package For Tt307B Pipingsuria qaqc100% (1)

- QIP TT 307 PIPING WORK - RevisedDocument2 pagesQIP TT 307 PIPING WORK - Revisedsuria qaqcNo ratings yet

- Short Description of 09years Professional Journey: Covering LetterDocument7 pagesShort Description of 09years Professional Journey: Covering Lettersuria qaqcNo ratings yet

- BOQ PIPING Total DetailDocument16 pagesBOQ PIPING Total Detailsuria qaqcNo ratings yet

- AmmaDocument3 pagesAmmaABP SMART CLASSESNo ratings yet

- ConditionalsDocument3 pagesConditionalsCarlos Van Arkel SimónNo ratings yet

- PAS Bhs Inggris XIIDocument5 pagesPAS Bhs Inggris XIIRahmi ZulhidayatiNo ratings yet

- In The Living Room Furniture Prepositions of Place CLT Communicative Language Teaching Resources Fun 89740Document13 pagesIn The Living Room Furniture Prepositions of Place CLT Communicative Language Teaching Resources Fun 89740Алена ТерскаяNo ratings yet

- Hyperglycemia in Pregnant Ladies and Its Outcome Out in The Opd, Labor Ward, Gynecology and Obstetrics, Lady Atichison Hospital, LahoreDocument7 pagesHyperglycemia in Pregnant Ladies and Its Outcome Out in The Opd, Labor Ward, Gynecology and Obstetrics, Lady Atichison Hospital, LahoreiajpsNo ratings yet

- OSHA/AWS/ANSI Shade Selector For WeldingDocument1 pageOSHA/AWS/ANSI Shade Selector For WeldingShabas Lukkumanil HakkimNo ratings yet

- Fimbristylis Littoralis (Lesser Fimbristylis)Document6 pagesFimbristylis Littoralis (Lesser Fimbristylis)MaelstromNo ratings yet

- BF Series Pneumatic Actuator (E-350-08)Document24 pagesBF Series Pneumatic Actuator (E-350-08)JhonNo ratings yet

- 966f Interactivo Esquema ElectricDocument8 pages966f Interactivo Esquema ElectricJavierNo ratings yet

- Wildlife Conservation PrintDocument93 pagesWildlife Conservation PrintNirma yadavNo ratings yet

- Algoritmo IctericiaDocument18 pagesAlgoritmo IctericiaDiego RodriguezNo ratings yet

- Networks Summary ICTDocument7 pagesNetworks Summary ICTTomás BORRASASNo ratings yet

- Entrep Las Second QuarterDocument18 pagesEntrep Las Second QuarterAlodia Carlos PastorizoNo ratings yet

- Desk Sputter Coater - DSR1Document3 pagesDesk Sputter Coater - DSR1mohamadazareshNo ratings yet

- GPM 22Document2 pagesGPM 22Khalid SaddikNo ratings yet

- Iofi Code of Practice 5th RevisionDocument60 pagesIofi Code of Practice 5th RevisionVALERIA HERRERA CHALARCANo ratings yet

- HydraGO-brochure WebDocument2 pagesHydraGO-brochure WebRiego GeomembranaNo ratings yet

- A. B. C. D. A. B. C. D.: Câu 1: Which of The Following Is NOT A Minimal Pair?Document9 pagesA. B. C. D. A. B. C. D.: Câu 1: Which of The Following Is NOT A Minimal Pair?Lan PhongNo ratings yet

- Circular Dichroism of Protein: PC3267 Updated in Jan. 2007Document7 pagesCircular Dichroism of Protein: PC3267 Updated in Jan. 2007Chellam Gayathri SubashNo ratings yet

- Crystallinity and Transition Temperatures in PolymersDocument46 pagesCrystallinity and Transition Temperatures in PolymersghenisNo ratings yet

- ece轮胎文件Document37 pagesece轮胎文件张正No ratings yet

- Schneider Sustainability Deck 05.23.23Document16 pagesSchneider Sustainability Deck 05.23.23SchneiderNo ratings yet

- Daftar Pustaka: Biostratigraphy, Proc - First Int. Conf. Planktonic Micro Fossilles, E.JDocument3 pagesDaftar Pustaka: Biostratigraphy, Proc - First Int. Conf. Planktonic Micro Fossilles, E.JDaniel Indra MarpaungNo ratings yet