Professional Documents

Culture Documents

Biodiversity & Endangered Species

Uploaded by

Syed IrtazaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Biodiversity & Endangered Species

Uploaded by

Syed IrtazaCopyright:

Available Formats

sity & End

er

Journal of

an

al o odiv

gere Spe

f Bi

ISSN: 2332-2543

d Biodiversity & Endangered Species Gaur, J Biodivers Endanger Species 2015, 3:1

DOI: 10.4172/2332-2543.1000147

rn

ci

es

Jou

Review Article Open Access

Study of Reduced Formation Damage due to Oil Well Drilling Mud by Barite

and Gas Oil Additives

Kapil Gaur*

Department of Biotechnology, Deenbandhu Choturam University of Science and Technology, Murthal, Sonepat, India

*Corresponding author: Kapil Gaur, Department of Biotechnology, Deenbandhu Choturam University of Science and Technology, Murthal, Sonepat, India, Tel:

8376837633; E-mail: djgaur007@gmail.com

Received date: February 24, 2015; Accepted date: February 26, 2015; Published date: March 06, 2015

Copyright: © 2014 Gaur K. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use,

distribution, and reproduction in any medium, provided the original author and source are credited.

Abstract

This analysis presents study of the impact of drilling muds on the oil reservoir rocks specifications, and also the

interactions between the clay minerals existing within the formation with the drilling muds. For minimization and

interference of formation harm ensuing from drilling muds, and formation minerals, drilling muds were ready in such

some way that they give the muds that are used according to the daily mud report of the South Company. These

muds are H2O mud, Ferrochrome Lignosulfonate (FcLs).

About a hundred core plugs were ready from seven wells and for 3 fields of the Zubair formation from depths of

over (3000) meters. The core plugs were cut in size to regarding one in. (2.54 centimeters) diameter and 3

centimeters length. They were cleansed, dried, and so subjected to petrophysical tests that were (porosity,

porousness, saturation, and pore size distribution by the capillary pressure), X-ray diffraction, and also the

petrographical analyses. The results of the experimental work showed that the clay minerals in formation increase

the formation harm, and reduce the oil permeability. Additionally, the results showed that the treatments of drilling

muds might cut back formation impairment. This was accomplished through create bridging system with completely

different barytes additions seventy, 140, 200, 280 lb/bbl to H2O mud. This bridging system creates an efficient

waterproofing of impervious filter cake, thereby inhibiting continual losses of little solids and dust filtrate into the

formation. Finally, relationships for various oil permeability's are obtained for predicting harm in oil permeability's as

a result of completely different drilling muds.

Keywords: Oil; Lubricant; Barite; Mud; Fuel mud into the formation doesn't typically occur, as a result of the mud

solids area unit filtered out onto the wall of the opening, forming a

Introduction cake of comparatively low porosity through that solely filtrate will

pass. This analysis deals with the impact of mud filtrates and dirt

Drilling operations perpetually expose a formation to drilling fluids, particles on formation permeability and formation minerals. A rise in

which can impair its productive capability. This reduction in water saturation within the zone straightaway around the wellbore

productivity is termed formation harm. There are several vital main would cause loss of oil porosity. However, in such a system, much of

functions of drilling muds in oiler drilling engineering however the this water is also removed by boring, that happens in clean pay sand. If

disadvantage of victimization drilling fluids is expounded to formation filtration happens into unclean sands (sands that contain clay

harm. The choice of appropriate mud kind for a given reservoir could minerals), the clay swelling or different mechanisms may cause losses

also be essential. Most investigations proved the consequences of in oil porosity, that can’t be overcame by boring.

drilling muds on rock permeableness and formation harm owing to

the choice of unsuitable mud. This may be owing to the interactions The two principle factors, which govern the magnitude of

between the lubricant filtrate with the formation minerals in the productivity impairment caused by mud, are as follows:-

producing horizons, and also the penetration of drilling mud particles 1. The depth of invasion of its filtrate into the reservoir.

into the formation that cause pore plugging of the porous media. The

harm caused by filtrate penetration depends on the effectiveness of 2. The amount of damage (permeability loss) that it causes.

fluid loss control. The filtrate penetration could vary from few inches

to many feet. Harm quantitative relation (permeability once harm Literature Survey

divided by the initial unmarred porosity) for permeability of oil could

Nowak, et al. [1] studied the impact of binary compound solutions;

vary from 0.3 to 1.0 looking on the sort of filtrate and kind of core

field-drilling mud filtrates, and mud particles on effective oil

material. Therefore, it's necessary to pick the correct lubricant, which

porousness of productive sand cores that were identified to be water

have the simplest major functions for drilling operations, and

sensitive. The tests indicated that the filtrates from muds of low salt

minimize formation harm. So as to forestall formation fluids from

content caused low recovery percentages of the first oil permeability.

coming into the borehole, the hydrostatic pressure of the mud column

ought to be bigger than the formation pore pressure. Consequently, Bertness [2] conferred laboratory and field knowledge to assist

mud tends to invade the porous formations. When the distinction within the analysis of water damage to grease sands and to propose

between hydrostatic pressure and pore pressure is high huge loss of attainable clarification for the kinds harm to grease sands which are

J Biodivers Endanger Species Volume 3 • Issue 1 • 1000147

ISSN:2332-2543 JBES, an open access journal

Citation: Gaur K (2015) Study of Reduced Formation Damage due to Oil Well Drilling Mud by Barite and Gas Oil Additives. J Biodivers Endanger

Species 3: 147. doi:10.4172/2332-2543.1000147

Page 2 of 2

discovered. The reservoir water permeability of unclean sands is controlling the formation damage were to keep the pH of all injection

severely reduced if the sands are exposed to water. fluids in a buffered to control the filtrate to near zero in such sensitive

formation.

Abrams, [3] studied the possibility to minimize solids invasion and

formation damage by adding bridging material to the muds. This Warren, et al. [9] used air particles for minimizing formation

bridging material was chosen by matching its size to the formation impairment in drilling fluid system. Air particles were used as the

rock pore sizes. The core face was drilled a (0.25) inch diameter hole, bridging particles to remedial formation damage. This treatment was

following mud exposure and removal, and then measured original applied in higher-pressure wells and give low-density muds.

permeability as a function of depth of the hole for comparison. The

rapid restoration of the original permeability with a perforation depth Discussions

of only (0.11) inch to 90 percent of the original permeability for both

exposures indicates the shallow depth of impairment. The experiments Several experiments are done to research the foremost dominant

indicated that muds containing bridging material that meets the one- factors of formation harm by drilling muds. Completely different mud

third rule for bridging, impair rock to depth less than one inch. treatments are accustomed to examine the possibility of reducing its

damaging result.

Muecke, [4] focused his study on determining the effects of three

types of analyses on sandstone samples, Scanning Electron Microscope

(SEM) examinations to determine particle size and shape, sieve Conclusions

analyses to determine the amounts of various sizes of particles present, X-ray diffraction analyses for core samples at pay zones indicated

and X-Ray Diffraction (XRD) to determine mineralogical content. A clean fine grained arenaceous rock with traces of clay minerals (very

micro-model of porous media was used to simulate the porous matrix low or pure zones (100 %) quartz), this gave low injury in these

present in sandstone formations. intervals when exposed to drilling muds and will not suffer any

Sanner, et al. [5] conducted core study of five different rock types to swelling because of the alternative intervals. Some of the pay zone

investigate the return permeability and changes in irreducible water intervals containing differing kinds and percentages of clay minerals

saturation (Swi), when exposed to filtrate from oil-based and water- like Illite and Montmorillonite, suffers swelling and spalling once

based drilling mud by Hassler cell. Results indicated that the oil-based exposed to drilling muds that cause formation injury. All the muds,

filtrate contains sufficient oil wetting surfactants and emulsifiers to that were used, have the flexibility to break the petrophysical

reverse the wet-ability of rock surfaces from water wet to oil wet. The properties of formation, however some additives to mud might scale

oil wet rock surface in the low permeability matrix, reduced the back petrophysical properties. Fuel oil addition would generally cause

effective oil permeability drastically. In the high permeability matrix, reduction in mud filtrate as a result of the formation of rubberized

reduced the irreducible water saturation, resulting in an increase in the mud cake on the face of the paper or on the face of core samples.

effective oil permeability.

References

Ismail, et al. [6] investigated the effect of solids concentration and

filter media on fluid loss and permeability recovery of cores depending 1. Nowak TJ, Krueger RF (1951) The Effect of Mud Filtrates and Mud

on some consideration before Glenn [7] and Abrams (3) related to use Particles upon the Permeabilities of Cores Drill. Prod Prac: 164-181.

bridging material. KCl-polymer muds of different barite concentration 2. Bertness TA (1953) Observation of water damage to oil productivity

and different types of core were used to perform the tests. Filtration Drill. Prod Prac: 287-299.

tests showed that fluid loss increased as solids concentration in the 3. Abrams A (1977) Mud Design to Minimize Rock Impairment due to

mud increased. Increasing the solids concentration in the mud appears Particle Invasion. JPT: 586-592.

to improve permeability recovery when the cores were back flushed. 4. Muecke TW (1979) Formation Fines and Factors Controlling Their

Movement in Porous Media. JPT: 144-150.

However, high spurt loss and poor permeability recovery were

observed if muds containing polymer materials were used without the 5. Sanner DO, Azar JJ (1994) Alteration of Reservoir Rock Wettability and

Its Flow Properties Caused by Oil-Based and Water-Based Drilling Muds.

addition of solid particles. SPE: 171-180.

Hayadavoudi, et al. [8] made a study to control formation damage 6. Ismail AR, Peden JM (1994) The Effect of Solids Concentration and

caused by kaolinite clay minerals. Most, if not all, laboratory analysts, Formation Characteristics on Formation Damage and Permeability

upon observing Kaolinite mineral in the pore space of the sidewall or Recovery. SPE: 203-212.

conventional cores, conclude that the main cause of possible 7. Glenn EE, Slusser ML (1975) Factors Affecting Well Productivity- II.

Drilling Fluid Particle Invasion into Porous Media. Trans AIME 210:

formation damage (decrease in permeability) could be attributed to

132-139.

the migration of fines within the pores. Petrophysical analysis showed

8. Hayatdavoudi A, Ghalambor A (1996) Controlling Formation Damage

that within this short period of contact time between the rock and Caused by Kaolinite Clay Minerals. Society of Petroleum Engineers,

fluid at pH approximately 10-12, the permeability of cores decreased Louisiana.

considerably. Both field and laboratory coring and/or drilling any sand 9. Warren B, King K, Browne G, Mann C (2001) Preventing Formation

with a high Kaolinite content (greater than 5%), the best conditions for Impairment with a MicronAire Drilling Fluid System. AADE :1-10.

J Biodivers Endanger Species Volume 3 • Issue 1 • 1000147

ISSN:2332-2543 JBES, an open access journal

You might also like

- Eco-efficient Rendering Mortars: Use of Recycled MaterialsFrom EverandEco-efficient Rendering Mortars: Use of Recycled MaterialsNo ratings yet

- SPE/IADC 139534 Preliminary Test Results of Nano-Based Drilling Fluids For Oil and Gas Field ApplicationDocument9 pagesSPE/IADC 139534 Preliminary Test Results of Nano-Based Drilling Fluids For Oil and Gas Field ApplicationmuhammadNo ratings yet

- A Study On The Role of Pre-Gelatinized Starch PGSDocument11 pagesA Study On The Role of Pre-Gelatinized Starch PGSizzybjNo ratings yet

- The Influence of XC Polymer-On Drilling Fluid Filtercake Properties and Formation DamageDocument10 pagesThe Influence of XC Polymer-On Drilling Fluid Filtercake Properties and Formation Damageمنتظر محمد عليNo ratings yet

- Broni BediakoandAmorin2019Document7 pagesBroni BediakoandAmorin2019febrianricky001No ratings yet

- SPE-183743-MS Maintaining Injectivity of Disposal Wells: From Water Quality To Formation PermeabilityDocument19 pagesSPE-183743-MS Maintaining Injectivity of Disposal Wells: From Water Quality To Formation PermeabilityAminNo ratings yet

- Sedaghatzadeh 2016Document17 pagesSedaghatzadeh 2016mustafasavci900No ratings yet

- Effect of Perlite Particles On Thefiltration PropertiesDocument10 pagesEffect of Perlite Particles On Thefiltration PropertiessedaNo ratings yet

- Effect of Perlite Particles On Thefiltration PropertiesDocument10 pagesEffect of Perlite Particles On Thefiltration PropertiessedaNo ratings yet

- SPE-184308-MS Effects of Mud Filtrate Invasion On Well Log MeasurementsDocument12 pagesSPE-184308-MS Effects of Mud Filtrate Invasion On Well Log MeasurementsCamiloAndresGuerreroNo ratings yet

- SPE 78560 Applied Carbonate Stimulation - An Engineering ApproachDocument16 pagesSPE 78560 Applied Carbonate Stimulation - An Engineering ApproachBolsec14No ratings yet

- Stabilization of Black Cotton Soil Using Fly AshDocument9 pagesStabilization of Black Cotton Soil Using Fly AshIJRASETPublicationsNo ratings yet

- 930-Article Text-3544-2-10-20141231Document7 pages930-Article Text-3544-2-10-20141231Teerasak YaowaratNo ratings yet

- Drilling Fluid Losses Circulation Investigation Mechanism and Solution in Basra Oil FieldDocument26 pagesDrilling Fluid Losses Circulation Investigation Mechanism and Solution in Basra Oil Fieldعاشق الليلNo ratings yet

- Geomechanics For HF Productivity Suarez Rivera 2013Document10 pagesGeomechanics For HF Productivity Suarez Rivera 2013ahmed el faramawyNo ratings yet

- Underground Mine Water Ingress Mitigation ProgramsDocument5 pagesUnderground Mine Water Ingress Mitigation ProgramsThamsanqa AsromNo ratings yet

- Effects of Partial Replacement of Cement With Marble Dust Powder On Properties of ConcreteDocument9 pagesEffects of Partial Replacement of Cement With Marble Dust Powder On Properties of ConcreteAnkush ThakurNo ratings yet

- Clay Minerals Damage Quantification in Sandstone Rocks Using Core Flooding and NMRDocument11 pagesClay Minerals Damage Quantification in Sandstone Rocks Using Core Flooding and NMRmohamedNo ratings yet

- IJCERDJournalDocument8 pagesIJCERDJournalAlamgir kabirNo ratings yet

- NDDFDocument10 pagesNDDFDil Dhadakne DoNo ratings yet

- Nanoparticulas en Lodos de PerforaciónDocument4 pagesNanoparticulas en Lodos de PerforaciónWilliam CárdenasNo ratings yet

- EFFECT OF MOISTURE VARIATION ON SAND CASTINGDocument10 pagesEFFECT OF MOISTURE VARIATION ON SAND CASTINGADITYA RAHMANNo ratings yet

- Determination of Effect Bentonite and Additives On Drilling FluidsDocument8 pagesDetermination of Effect Bentonite and Additives On Drilling Fluidshau dinhNo ratings yet

- 1 s2.0 S1110062115300672 MainDocument6 pages1 s2.0 S1110062115300672 MainHytham RiadNo ratings yet

- Associative Polymers For Invasion Control in Water - and Oil-Based MudsDocument15 pagesAssociative Polymers For Invasion Control in Water - and Oil-Based MudsAry RachmanNo ratings yet

- Experimental Study On Partial Replacement of Fine Aggregate With Quarry Dust and Saw DustDocument13 pagesExperimental Study On Partial Replacement of Fine Aggregate With Quarry Dust and Saw DustPerarasan MNo ratings yet

- IJCERDJournalDocument8 pagesIJCERDJournalRitesh BomdyalNo ratings yet

- Construction Materials Durability StudyDocument13 pagesConstruction Materials Durability StudysalahNo ratings yet

- A Review On Need of Manufactured Sand in Concrete As A Replacement of River SandDocument4 pagesA Review On Need of Manufactured Sand in Concrete As A Replacement of River SandGanesh SuryawashiNo ratings yet

- Microstructure As A Critical Factor of Cement Mortars' Behavior: The Effect of Aggregates' PropertiesDocument11 pagesMicrostructure As A Critical Factor of Cement Mortars' Behavior: The Effect of Aggregates' PropertiesKhang LaiNo ratings yet

- Well Completion, Well Intervention/ Stimulation, and WorkoverDocument15 pagesWell Completion, Well Intervention/ Stimulation, and WorkoverKhairi OmarNo ratings yet

- Stabilization of Soil Using Fly AshDocument6 pagesStabilization of Soil Using Fly AshIJRASETPublicationsNo ratings yet

- A Review of The Current Options For TheDocument17 pagesA Review of The Current Options For TheRuvindran VasuNo ratings yet

- Partial Replacement of River Sand With Quarry Rock DustDocument8 pagesPartial Replacement of River Sand With Quarry Rock DustDharma banothuNo ratings yet

- Journal of Petroleum Science and Engineering: C. Vipulanandan, A. MohammedDocument13 pagesJournal of Petroleum Science and Engineering: C. Vipulanandan, A. MohammedAl-Shargabi MohaNo ratings yet

- 2745-Article Text-5065-1-10-20210723 (UTILIZATION OF STONE DUST FOR STABILIZATION OF BLACK COTTON SOIL)Document6 pages2745-Article Text-5065-1-10-20210723 (UTILIZATION OF STONE DUST FOR STABILIZATION OF BLACK COTTON SOIL)Amanulla KhanNo ratings yet

- Final 22Document36 pagesFinal 22Ashish SharmaNo ratings yet

- 28IJAERS 11202024 Effectof PDFDocument10 pages28IJAERS 11202024 Effectof PDFIJAERS JOURNALNo ratings yet

- Journal of Rock Mechanics and Geotechnical Engineering: Araz Salimnezhad, Hossein Soltani-Jigheh, Ali Abolhasani SoorkiDocument19 pagesJournal of Rock Mechanics and Geotechnical Engineering: Araz Salimnezhad, Hossein Soltani-Jigheh, Ali Abolhasani SoorkiXronia YiorgosNo ratings yet

- Formation Damage Causes and SolutionsDocument24 pagesFormation Damage Causes and SolutionsDinesh KanesanNo ratings yet

- Dokumen - Tips - Iadcspe 133724 Effect of Permeability Impairment by Iadcspe 133724 EffectDocument15 pagesDokumen - Tips - Iadcspe 133724 Effect of Permeability Impairment by Iadcspe 133724 EffectJes MorNo ratings yet

- Studying The Effects of Leaching On Treated Gypsum-Rich SoilDocument12 pagesStudying The Effects of Leaching On Treated Gypsum-Rich SoilImad Habeeb ObeadNo ratings yet

- Materials Selection for Seawater Intake ScreensDocument9 pagesMaterials Selection for Seawater Intake ScreensRyan KohpaeiNo ratings yet

- 1.1 General: Study of Suitability of Manufactured Sand (M-Sand) As Fine Aggregate in ConcreteDocument62 pages1.1 General: Study of Suitability of Manufactured Sand (M-Sand) As Fine Aggregate in Concretebits computersNo ratings yet

- The Influence of Chloride Contents in Sands On Reinforcement CorrosionDocument8 pagesThe Influence of Chloride Contents in Sands On Reinforcement CorrosionPrashant DevdaNo ratings yet

- Question: Is Coring Always Necessarily Performed Before Well Logging?Document6 pagesQuestion: Is Coring Always Necessarily Performed Before Well Logging?Maisam AbbasNo ratings yet

- Replacement of River Sand With Proportions of Sea SandDocument8 pagesReplacement of River Sand With Proportions of Sea SandDharma banothuNo ratings yet

- Stabilization of Problematic Soil Using Pond Ash and Mosaic DustDocument3 pagesStabilization of Problematic Soil Using Pond Ash and Mosaic DustIJORATNo ratings yet

- AADE 17 NTCE 094 EzeakachaDocument9 pagesAADE 17 NTCE 094 EzeakachaNamam Muhammad SalihNo ratings yet

- Effectof Particle Sizeof BentoniteDocument16 pagesEffectof Particle Sizeof BentoniteHuynh Minh Quan B2014431No ratings yet

- The Formulation of Water Based Drilling Fluid From Local MaterialsDocument5 pagesThe Formulation of Water Based Drilling Fluid From Local MaterialsAl Hafiz Ibn HamzahNo ratings yet

- Drilling Engineering Lecture on Functions and Properties of Drilling FluidsDocument17 pagesDrilling Engineering Lecture on Functions and Properties of Drilling FluidskwesimarkNo ratings yet

- Simulation of Sand Production Prediction PDFDocument10 pagesSimulation of Sand Production Prediction PDFAnonymous SEEyca1bRQNo ratings yet

- Chapter - 1 1.1 GeneralDocument37 pagesChapter - 1 1.1 GeneralAshish SharmaNo ratings yet

- Henrique - Kawabata Et Al. 2021 Petrological AssessmentDocument14 pagesHenrique - Kawabata Et Al. 2021 Petrological AssessmentHenrique GoncalvesNo ratings yet

- J Jngse 2017 04 004Document8 pagesJ Jngse 2017 04 004Muhammad Hanif AbsharNo ratings yet

- Bekelcha Edited orDocument20 pagesBekelcha Edited orBeeka GMNo ratings yet

- Experimental Setup For Evaluating Rock Volume AlterationDocument18 pagesExperimental Setup For Evaluating Rock Volume AlterationManuel LealNo ratings yet

- STABILIZING EXPANSIVE SOILDocument10 pagesSTABILIZING EXPANSIVE SOILkaushal yadavNo ratings yet

- Payment Plan-OsDocument1 pagePayment Plan-OsSyed IrtazaNo ratings yet

- New Payment Schedule For FGEDocument2 pagesNew Payment Schedule For FGESyed IrtazaNo ratings yet

- Drilling Cost and Drilling RateDocument41 pagesDrilling Cost and Drilling RateZurdokMov100% (2)

- Final ReportDocument60 pagesFinal ReportYounas OkzNo ratings yet

- Sindh Building Control Authority: Stamp Paper)Document5 pagesSindh Building Control Authority: Stamp Paper)Syed IrtazaNo ratings yet

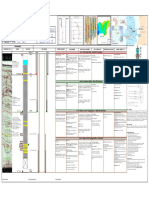

- Banda East Well Montage 28sept08 A4 SizeDocument1 pageBanda East Well Montage 28sept08 A4 SizeSyed IrtazaNo ratings yet

- 3 CasingSelectionDocument15 pages3 CasingSelectioncodigocarnetNo ratings yet

- Well Design - PE 413: Chapter 1: Fracture PressureDocument44 pagesWell Design - PE 413: Chapter 1: Fracture PressureWeny AstutiNo ratings yet

- Quick Kill Calculations Example. (For Revision Purposes)Document2 pagesQuick Kill Calculations Example. (For Revision Purposes)Syed IrtazaNo ratings yet

- Casing DesignDocument95 pagesCasing DesignAnand RamamurthyNo ratings yet

- Feedback Form British Canadian International EducationDocument1 pageFeedback Form British Canadian International EducationSyed IrtazaNo ratings yet

- DPT1 - 01 - Rig Sizing and SelectionDocument65 pagesDPT1 - 01 - Rig Sizing and SelectionBrahim Letaief100% (5)

- Casing String Notes v0Document15 pagesCasing String Notes v0Syed IrtazaNo ratings yet

- Lloyds Drilling in Extreme EnvironmentsDocument44 pagesLloyds Drilling in Extreme EnvironmentsSyed IrtazaNo ratings yet

- Facilities Of: 5Th Avenue ApartmentsDocument2 pagesFacilities Of: 5Th Avenue ApartmentsSyed IrtazaNo ratings yet

- Well Design - PE 413: Chapter 1: Fracture PressureDocument44 pagesWell Design - PE 413: Chapter 1: Fracture PressureWeny AstutiNo ratings yet

- The Great Muslim Scientist and Philosopher Imam Jafar Ibn Mohammed As-Sadiq (As) - Imam Jaffer-As-Sadiq (As) - XKPDocument42 pagesThe Great Muslim Scientist and Philosopher Imam Jafar Ibn Mohammed As-Sadiq (As) - Imam Jaffer-As-Sadiq (As) - XKPIslamicMobilityNo ratings yet

- Guide To The Pallet Specification Sheet: Pallet Design System PDSDocument6 pagesGuide To The Pallet Specification Sheet: Pallet Design System PDSirtaza324197No ratings yet

- Drawings All - 2017-06-23Document118 pagesDrawings All - 2017-06-23Syed IrtazaNo ratings yet

- Wellheads Xmas Trees ValvesDocument29 pagesWellheads Xmas Trees ValvesAbdul Hameed OmarNo ratings yet

- IWCF Equipmet PDFDocument203 pagesIWCF Equipmet PDFzahir100% (9)

- Induction Program - Dr. Asif Jan MuhammadDocument1 pageInduction Program - Dr. Asif Jan MuhammadSyed IrtazaNo ratings yet

- Analysis of Factor Effects in Drilling Operations.?Document13 pagesAnalysis of Factor Effects in Drilling Operations.?Syed IrtazaNo ratings yet

- Pallete InstructionsDocument1 pagePallete InstructionsSyed IrtazaNo ratings yet

- Datasheet Comparison: Pipe FeaturesDocument2 pagesDatasheet Comparison: Pipe FeaturesSyed IrtazaNo ratings yet

- Date Palm ResearchDocument5 pagesDate Palm ResearchSyed IrtazaNo ratings yet

- Catalogue 2018: Six-Arm CaliperDocument2 pagesCatalogue 2018: Six-Arm CaliperSyed IrtazaNo ratings yet

- Premium Connection Catalogue EnglishDocument112 pagesPremium Connection Catalogue EnglishRameez AnwarNo ratings yet

- Surge and swab pressure calculationsDocument2 pagesSurge and swab pressure calculationsSyed IrtazaNo ratings yet

- Soil Classification and PropertiesDocument127 pagesSoil Classification and PropertiesAdewunmi AdurayemiNo ratings yet

- Eclipse 100Document43 pagesEclipse 100zemabderNo ratings yet

- Matrix Acidizing Design and ApplicationsDocument73 pagesMatrix Acidizing Design and ApplicationsNguyễnTrường100% (1)

- Kamran Aziz, Aamir Rasheed, Arshad Hussain Palekar, Rehan Hanif, S. Sohaib Zulfiqar, and M. Zeeshan BaigDocument24 pagesKamran Aziz, Aamir Rasheed, Arshad Hussain Palekar, Rehan Hanif, S. Sohaib Zulfiqar, and M. Zeeshan BaigKesempurnaan ZeindroNo ratings yet

- Present Status of Bangladesh Gas Fields and Future DevelopmentDocument8 pagesPresent Status of Bangladesh Gas Fields and Future DevelopmentABDULLAH MD. ZOBAYER 1602090No ratings yet

- Chapter 10 Relative PermeabilityDocument27 pagesChapter 10 Relative PermeabilityAndrew Guo100% (1)

- Using Wireline Formation TesterDocument2 pagesUsing Wireline Formation TesterbelahmeursNo ratings yet

- Permeability cut-off: Should low-K facies be ignored in reservoir modelingDocument7 pagesPermeability cut-off: Should low-K facies be ignored in reservoir modelingMinh NguyễnNo ratings yet

- AcidizingDocument34 pagesAcidizingAnonymous aIuHKoKZjNo ratings yet

- DRAINAGE OPTIMIZATIONDocument16 pagesDRAINAGE OPTIMIZATIONAlbanNo ratings yet

- CE504Document4 pagesCE504Mohasin KamalNo ratings yet

- Polimer SurfaktanDocument16 pagesPolimer Surfaktanpermata ulfaNo ratings yet

- 2007 SPE 107142 MS PCHightJamiolahmadyEtal PDFDocument10 pages2007 SPE 107142 MS PCHightJamiolahmadyEtal PDFcristinaNo ratings yet

- Coupling Hydrodynamics and Geophysics With COMSOLDocument6 pagesCoupling Hydrodynamics and Geophysics With COMSOLNILNo ratings yet

- Constant Head Permeability TestDocument12 pagesConstant Head Permeability Testanis098No ratings yet

- PSST (T-2) Day 1 Training Student ManualDocument151 pagesPSST (T-2) Day 1 Training Student ManualjakeNo ratings yet

- Dictionary of Petroleum Exploration, Drilling & Production 2nd Ed (2014)Document777 pagesDictionary of Petroleum Exploration, Drilling & Production 2nd Ed (2014)Olvin HernandezNo ratings yet

- Field Application of After-Closure Analysis of Fracture Calibration TestsDocument12 pagesField Application of After-Closure Analysis of Fracture Calibration TestsRamanamurthy PalliNo ratings yet

- 101-116 BergerDocument16 pages101-116 BergerBalaji GuruNo ratings yet

- Thermal and Hydraulic Properties of RockDocument11 pagesThermal and Hydraulic Properties of RockaliNo ratings yet

- Fracture Modeling PetrelDocument23 pagesFracture Modeling PetrelAnonymous 4hvWNxu9VNo ratings yet

- Professor Abbas Firoozabadi's Major Contributions to Petroleum EngineeringDocument24 pagesProfessor Abbas Firoozabadi's Major Contributions to Petroleum EngineeringjuanNo ratings yet

- Field Sampling Procedure ManualDocument574 pagesField Sampling Procedure Manualpetrus01idNo ratings yet

- Pet Geo 1Document5 pagesPet Geo 1api-347509160No ratings yet

- Online Course - Petrosoftware: Basic Information Course ObjectivesDocument27 pagesOnline Course - Petrosoftware: Basic Information Course ObjectiveskhalifasaadNo ratings yet

- WAC and PorosityDocument11 pagesWAC and PorosityvempadareddyNo ratings yet

- Lesson 7 Construction Dewatering and Ground FreezingDocument17 pagesLesson 7 Construction Dewatering and Ground FreezingRsjBugtongNo ratings yet

- 5 - Formation DamageDocument39 pages5 - Formation DamageRaed fouadNo ratings yet

- PETSOC-2003-181-P - Using Decline Curves To Forecast Waterflooded Reservoris - Fundamentals and Field CasesDocument25 pagesPETSOC-2003-181-P - Using Decline Curves To Forecast Waterflooded Reservoris - Fundamentals and Field CasesFranck IparraguirreNo ratings yet

- SPE 77949 Determination of Fracture Orientation by Multi-Well Interference TestingDocument11 pagesSPE 77949 Determination of Fracture Orientation by Multi-Well Interference Testingleonelz6aNo ratings yet