Professional Documents

Culture Documents

Hoist Universal

Hoist Universal

Uploaded by

Edson Carvalho0 ratings0% found this document useful (0 votes)

98 views37 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

98 views37 pagesHoist Universal

Hoist Universal

Uploaded by

Edson CarvalhoCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 37

Equipment P/N:

98 F275 08498 000

Issue: D

Ground Instruction

Manual

(ORIGINAL)

@

AIRBUS

Ground Instruction Manual

HOIST Ri

FLAP / SLAT / AILERON

P/IN 98 F275 08498 000

Airbus Deutschland GmbH

Department SEMS11

GSE & Tools

Customer Services

AIRBUS Allee 1

28199 Bremen/Germany

Department

GSE-Title:

|” Page: 1 of 37

SEMS11

HOIST R/1 FLAP/SLAT

07.04.2010

Equipment Pin

98 F275 08498 000

Manual

(ORIGINAL)

Ground Instruction

Issue: O

mn

wy

AIRBUS

Acceptance and Signature

vin Date

SEMS11) 02.04 10:

SEMS11) 02.04 1

T Company!) Name

Prepared) AIRBUS,

Bosse

AIRBUS | Pauer

Checked

t

Accepted) AIRBUS. Fokken

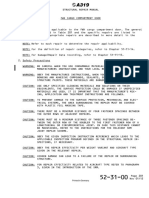

Record of Revision

SEMS17 02.0410, +49 #211836-3608 J Zz

be.

38-5761) 471 Fee q

Issue Date Page effected | Reason for Revision |

A 08.12.05 All First Issue

B 20.01.06 | 1,3.4,6,9,10,32 | Effect. update.

B 29.07.06 16+17/23+23 | _ Insert new Effect.

BB | 29.07.06 [26,27,28,28.30.31| Insert new Effect.

c 02.05.07 “Al | Revision DRW

D_ 07.04.10 All Revised |

Department GSE-Title:

Pane 20897 |

SEMS11 HOIST R/I FLAPISLAT

97.04.2010 |

Equipment PIN:

98 F275 08498 000

Ground Instruction

Manual

Issue: D (ORIGINAL) AIRBUS

List of Effective Pages

Page Issue Rev.-Date

1 D 07.04.2010

2 D 07.04.2010

3 D 07.04.2010

4 D 07.04.2010

5 D (07.04.2010

6 D 07.04.2010

7 D 07.04.2010

8 0 07.04.2010

9 D 07.04.2010

10 D 07.04.2010

11 D 07.04.2010

12 D 07.04.2010

13 D 07.04.2010

14 a) 07.04.2010

15 D 07.04.2010

16 D 07.04.2010

17 D 07.04.2010

78 D 07.04.2010

79 D 07.04.2010

20 D 07.04.2010

21 0 07.04.2010

22 D 07.04.2010

23 D 07.04.2010

24 D 07.04.2010

25 Do 07.04.2040

26 D 07.04.2010

27 D 07.04.2010

28 D 07.04.2010

29 0 07.04.2010

30 D 07.04.2010

31 D 07.04.2010

32 Do 07.04.2010

33 D 07.04.2010

34 D 07.04.2010

35 D 07.04.2010

36 D 07.04.2010

37. D (02.05.2007

Department GSE-Title: Page: 3 of 37

SEMs11 HOIST R/I FLAP/SLAT 07.04.2010

Equipment PIN:

Ground Instruction

Manual

Issue: D (ORIGINAL)

98 F275 08498 000

@

AIRBUS

Table of Contents

1General

LL TERMS AND ABBREVIATIONS.

12 AIRCRAFT MAINTENANCE MANUAL

13 Syste Overview

2Shipping /Transports and Environment.

2.1 PACKING Lis. sn

22 TRANSIT PACKING

23 InammicaTon Laoei,

24 Storact

25 SroRAGE ENVIRONMENT CONDITIONS

2.6 Line MAINTENANCE

Servicing

Calibration

3Technical Data..

3.1 Sreciricarion.

3.2. Ourer DIMENSION...

33. Test Loap Diagram.

installation, Assembly .........

4.1 ASSEMBLY OF THEGSE/ Toor.

Handling of the VARIO WEB

5Operation with the GSE......

5.1 REFERENCE AND SAFETY PRECAUTIONS

5.2___ FUNCTIONAL DESCRIPTION

GSE handling in accordance to the AMM.

Interface GSE €D AIC.

Airoraft System Drawings Fehler! Testmarke nicht definiert

5.24 Removal : Inner Flap 4340-200-300-500-600,

3.24 Removal : Inner Flap A 310, 318, 319, 320, 321.

3.2.5 Removal : Outer Flap 4330 (340-200-300.

Removal : Outer Flap 340-500-600.

Removal : Outer Flap A310, 318, 319, 320, 321.

5.2.7 Removal : Slat !~7 A 330/340. ‘

3.2.7 Removal : Slat 1-5 A 318, 319, 320, 321.

3.2.7 Removal : Slat 1-3 / Krueger Flap/ A 310.

5.2.7 Removal : All Speed Aileron A 310

5.2.8 Installation of Inner Flap A340-200-300-500-600 A 310,318.319,320,321.

5.2.9 Installation of Outer Flap A340-200-300 A310-318-319-320-321.

5.2.10 Installation Outer Flap 4340-500-600.

5.2.11 Installation of Slat 17 A330-200/300 4340-200-300/ 00-600,

Slat 1 ~ 5 A318 / 319/320 /320/ 321.

Slat 1-3, Krueger Flap, 4 310.

5.2.12 Operator Misuse.

5.3 ALTERATIONS TO APPLICATION

6Troubleshooting.

7 illustrated GSE Spare Parts List.

B8inspection Report

13

16

Ww

20

22

4

26

28

30

32

32

32

32

Department GSE-Title:

Page: 4 of 37

‘SEMS11 HOIST R/| FLAP/SLAT

07.04.2010

Equipment PIN:

1 — | TA

98 F275 08498 000 Ground Instruction BD

Manual

Issue: D (ORIGINAL) AIRBUS

1 General

4.4 Terms and Abbreviations

NC Aircraft

A Airbus

IQ Airbus Industrie Quality Instructions

AMM Aircraft Maintenance Manual

‘Appr.lApprox Approximate, Approximately

Dwg Drawing

eg For Example

tc. Etcetera, and so on

Fig, Figs Figure, Figures

9 Gravity Acceleration

cm Ground instruction Manual

GSE Ground Support Equipment

HSB Handbuch Struktur Berechnung (German Stress Manual)

PC lustrated Parts Catalogue

iaw. In accordance with

Iss Issue

max Meximum

min Minimum

NOI Non Destructive Inspection

NA Not Applicable

Prelim Preliminary

ava Quaiitatssicherungsverfahrensanweisungen (Q.A. Procedure Instruction)

Ref. Reference

Ref. To Refer to

Shi Sheet

Spec ‘Specification

TN Technical Note

1

Department GSE-Title: Page: 6 of 87

SEMS11 HOIST R/I FLAP/SLAT ~ 07.04.2010

- E ]

Equipment PIN

98 F275 08498 000 Groune Instruction A

janual

Issue: D (ORIGINAL) AIRBUS

4.2. Aircraft Maintenance Manual

Chapter: 27 — 50 and 27 ~ 80

1.3. System Overview

The GSE "HOIST Ril LR FLAP" is designed for removal installation of the

Inner Flap- AIC 330/ A340 BASIC AIC 340-500/600

AIC 310/ 318/319 / 320/321.

Outer Flap - AIC 330/ A340 BASIC A/C 340-500/600

AIC 310/318 / 319 /320/ 321.

Slat 1 AIC 330/340 Basic 340-500-600

Slat 2-7 AIC 330/340 Basic 340-500-600

Slat 1-3/ Krueger Flap A/C 310

Slat 1-5 AIC 318/319/320/321

All Speed Aileron AIC 310 :

Table of Length

003 max Sling length 5000 mm

004 max Sling length 4000 mm

005 max Sling length 4000 mm

04 |

| Measuring

027 Points

we (LY

013

o12

Department GSE-Title: Page: 6 of 37

SEMS11 HOIST R/I FLAP/SLAT 07.04.2010

Equipment PIN

Ground Instruction

Manual

Issue: D (ORIGINAL)

98 F275 08498 000

yD

AIRBUS

Mr

Protectiv Sleeve

No. on one Side

Oo

Measuring Tape 5 m, Standard Tool

2. Shipping /Transports and Environment

2.1 Packing List

omt :

ry fe)

offo

the other side 98 F275 08498 000

Protractor, Standard Tool

No PIN.

(003 SLING 1_ COMPLETE [98 F275 08408.040 |

(004 SLING 2 COMPLETE _ 98 F275 08498.042

005 [SLING 3 COMPLETE — 98 F275 08498.044

010 LUG ‘98 F275 08498.200

Measuring Tape, length 5m Standard Tool

Protractor Standard Tool

OF PROTECTIV SLEEVE (003) 98 F275 08498.202

on2 PROTECTIV SLEEVE (004) [98 F275 08498.204 |

013 /PROTECTIV SLEEVE (005) _ ‘98 F275 08498.206

O14 PROTECTIV CAP [98 F275 08498.208

022 SWIVEL ADAPTER ~ | Standarc 4

TURNBUCKLE ‘Standard

SPECIAL MASTER LINK (Lifting Eye Standard

Department GSE-Titl

| semsi1 HOIST R/I FLAPISLAT

Page: 7 of 37

07.04.2010

Equipment P/N: MAN

98 F275 08498 000 Ground Instruction BD

anual

'ssue:D (ORIGINAL) AIRBUS

2.2 Transit Packing

= All units must be suitably preserved and packaged for the route and method of trans-

portation, either in the original or in a suitable container. The transit pack is in most

cases the storage pack

- Ifa container is used, adequate cushioning material and bracing must be provided to

secure the units during transit.

2.3 Identification Label

- An identification label must be attached to the units so that itis easily visible both be-

fore and after packing. If necessary an additional identification label must be attached

to the outside of the package

- Each part has its separate part number and identification label.

2.4 Storage

~ Pad comers to prevent puncture of barrier material.

= Pack in approved storage containers.

2.5 Storage Environment Conditions

- Wherever possible retain in their original storage pack until issued for use.

- Do not store near corrosive fluid and gases, or near heat or ozone generating

sources.

- Store ina clean dry ventilated room

- The relative humidity shall not exceed 85%.

- If stacked storage is used, avoid the possibility of damage.

= Position package so that the identification label is visible.

2.6 Line Maintenance

Servicing

NIA

Calibration

Test: see chapter 3.3 (page 10)

Department GSE-Title: Page: 8 of 37

SEMS11 HOIST R/1 FLAP/SLAT 07.04.2010

Equipment PIN: AX

98 F275 08498 000 Ground Instruction AD

love: oneal) AIRBUS

3. Technical Data

3.1 Specification

LOAD: 300 KG /1101,6 Ib

EFFECTIVITY: Inner Flap / Outer Flap / Slat 1 / Slat 2-7 / Krueger Flap /

All Speed Aileron

AIC 330/ A340 BASIC

AIC 340 - 500/ - 600

AC 310/318 / 319 / 320/321.

TEST LOAD: Ref. To Figure 01

3.2. Outer dimension

DIMENSION: CONTAINER

600 x 40x 400 mm appr.

23,6 in x 15,74 in x 15,74 in appr.

TOTAL WEIGHT: 8 kg app. / 17,6 Ib appr.

DWG No.: 98 F275 08498.000

3.3. Test Load Diagram

Acceptance test after manufacturing of Hoist: 450 Kg.

Load test shall be performed once per year: 330 Kg.

CRANE

2000 KG

330 KG

661 Ib

330 KG

661 Ib

330 KG.

661 Ib

Figure 04

Department GSE-Title: Pago: 9 of 37

SEMS11 HOIST R/1 FLAP/SLAT 07.04.2010

Equipment P/N

98 F275 08498 000 Ground Instruction @

Manual

Issue: D (ORIGINAL) AIRBUS

4

44

Installation, Assembly

The GSE is delivered ready for assembly.

Before assembly the parts should be checked refer to packing list.

Assembly of the GSE / Tool

For the removal and/or installation of

Inner Flap- A/C 330/ A340 BASIC and A/C 340 - 500/ - 600°

AIC 310/ 318/ 319/ 320/ 321.

Outer Flap - AC 330/ A340 BASIC and A/C 340 - §00/ - 600

AIC 310/ 318/ 319/ 320/ 321

Slat 1 AIC 330/ A340 Basic and A/C 340-500-600

Slat2-7 AVC 330/ A340 Basic and A/C 340 ~ 500-600

Slatt1-3 AIC 310

Krueger Flap A/C 310

Slati-5 A/C 318/319/320/321

All Speed Aileron A/C 310

various strap length combination are to be adjusted according to the relevant

AJC type - see Chapter 5.2.4

Department GSE-Title: Page: 10 of 37

SEMS11 HOIST R/| FLAP/SLAT 07.04.2010

Equipment PIN:

98 F275 08498 000 Ground Instruction ®D Gi

Manual

tssue: D (ORIGINAL) AIRBUS

Hoist. Fig. 03

For the fine adjustment of the length use turnbuckle pos. 025.

The basic setting before use should be 285 mm/11,22 inch before installing the

025

Figure 03

Department GSE-Title: Page: 11 of 37

‘SEMS11 HOIST R/| FLAP/SLAT 07.04.2010

Equipment P/N:

98 F275 08498 000 Ground Instruction GD

Manual

Issue: D (ORIGINAL) AIRBUS

Handling of the VARIO_WEB :

1. Push lever forward so the friction lock will release

(see Fig. 04 )

2. Adjust lifting strap to length (see Fig. 05 )

3. Push lever to the top (see Fig. 06 )

4. Thread in lifting strap into guide slot (see Fig. 07 )

The lifting strap is ready to use (see Fig. 08 )

— 1 ©.

ww

Figure 04 Figure 05 Figure 06

Figure 07 Figure 08

Department GSE-Title: Page: 12 of 37

‘SEMS11 HOIST R/| FLAPISLAT 07.04.2010

Equipment PIN MAN

98 F275 08498 000 Groune Instruction BW

janual

Issue'0 (ORIGINAL) AIRBUS

5 Operation with the GSE

5.1. Reference and safety precautions.

The Universal Hoist for Inner - Outer Flap, Slat, Krueger Flap & ASA can only

be used in conjunction with a crane min. Load 2000 KG / 4406 Ib

‘The user must be trained in the use of the GSE / Tool.

5.2 Functional description

GSE handling in accordance to the AMM

Any handling procedure with the GSE at A/C must be in accordance with the

AMM Chapter 27 ~ 50 and 27 - 80

Interface GSE €P A/C

Installation / positioning of the GSE to the A/C.

Refer to R/I procedure (chapter 5.2.4, continuous)

5.2.4 Removal : Inner Flap A340-200-300-500-600

= Install lifting eye of hoist into the crane hook.

'

* Adjusting of sling length with a measuring Tape according to

Table of length.

Check Flap extended Position 32° and Installation Angle 14°,

according AMM Task, with a Protractor.

For the fine adjustment the turnbuckle pos 025 and Fig.3 Page 11 is used.

Instructions for handling of the Vario Web ~see chapter 4.1.1- page 12

+ Unscrew protection cap 014 off the hoisting lugs - see Fig. 10

* Screw hoisting lugs 010 into the relevant flap position

Layout of lifting straps and location of hoist points -see Fig. 12 page 15

Department GSE-Title: Page: 13 of 37

SEMS11 HOIST R/I FLAP/SLAT 07.04.2010

Equipment PIN:

98 F275 08498 000

Issue: D

Ground Instruction

Manual

(ORIGINAL)

Or

Dy

AIRBUS

Attention!

Figure 10

Install the lifting lug 010 in full length and turn it less than one turn anti clock-

wise until the bolt has a tangential position to the lifting eye and the swivel

adapter 022 can move freely when under load. ~ see Fig. 11

= After use of hoist protect lifting lug 010 with the protection cap 014.

022

010

Figure 11

Department

GSE-Title:

Page: 14 of 37

SEMS11

HOIST R/I FLAP/SLAT

“Equipment PIN: 7

suraveas 000 Ground Instruction @

'ssue:D oneinat) AIRBUS

Inner Flap A 330 200-300 / A 340 200-300 - 500-600

Lifting Eye

003

INBOARD

‘OUTBOARD

Hoist

Point

inboard

Fwn

Hoist Hoist

Point Point

inboard outboard

AFT

Figure 12

Table of Length

A330 / 340 200 - 300_A 340 500 - 600

003. Sling length 3415 mm

Flap Position 32°

004 Sling length 2330 mm

005. Sling length 1920 mm

For the fine adjustment the turnbuckle pos 025 Page 11 is used,

The basic setting before use should be 285 mm/11,22 inch before installing

Page: 15 of 37,

Department GSE-Title:

‘SEMS11 HOIST R/1 FLAP/SLAT 7 07.04.2010

Equipment PIN: (iP

98 F275 08498 000 Groune Instruction AD

janual

Issue: D (ORIGINAL) AIRBUS

5.2.4 Removal : Inner Flap A 310, 318, 319, 320, 321.

* Install lifting eye of hoist into the crane hook.

* Adjusting of sling length with a measuring Tape according to

Table of length.

Check Flap extended Position 20° and Installation Angle 4°,

according AMM Task, with a Protractor.

For the fine adjustment the turnbuckle pos 02 and Fig.3 Page 11 is used.

Instructions for handling of the Vario Web —see chapter 4.1.1- page 12

= Unscrew protection cap 014 off the hoisting lugs - see Fig. 13

* Screw hoisting lugs 010 into the relevant flap position

Layout of lifting straps and location of hoist points -see Fig. 15 page 17

Attention!

Install the lifting lug 010 in full length and turn it less than one turn anti clock-

wise until the bolt has a tangential position to the lifting eye and the swivel

adapter 022 can move freely when under load. - see Fig.14

After use of hoist protect lifting lug 010 with the protection cap 014.

022

014 :

i 010

Fig.13

Fig. 14

Department GSE-Title: | Page: 16 of 37

SEMS11 HOIST R/1 FLAP/SLAT 07.04.2010

| Equipment P/N: a MAY

98 F275 08498 000 Ground Instruction Dp

janua

sue: (ORIGINAL) l AIRBUS

Inner Flap A 310, 318, 319, 320, 321

Lifting Eye

005

J

a \,_—rrsnine

an

OG

4,0°

Hoa [00a

ton

Inboard SS

a

tot

Spot wi

004

Fig. 15 ms

Hoist Point

Outboard

Table of Length

A310, 318, 319, 320, 321

(003 Sling Length 3350 mm

Flap Position 20°

004 Sling Length 3500 mm.

005 Sling Length 3700 mm

For the fine adjustment the turnbuckle pos 025 Page 11 is used.

The basic setting before use should be 285 mm/11,22 inch before installing

Department GSE-Title: Page: 17 of 37

SEMS11 HOIST R/I FLAPISLAT 07.04.2010

a |

Equipment PIN: 7

98 F275 08498 000 Ground Instruction YY

Manua

Issue: D (ORIGINAL) AIRBUS

5.2.5 Removal : Outer Flap A330 /340-200-300

Install lifting eye of hoist into the crane hook

* adjusting of sling length with a measuring Tape according to

Table of length.

Check Flap extended Position 32° and Installation Angle 4°,

according AMM Task, with a Protractor.

For the fine adjustment a turnbuckle pos 025 and Fig.3 Page 11 is used

Instructions for handling of the Vario Web ~see chapter 4.1.1- page 12

= Unscrew protection cap 014 off the hoisting lugs - see Fig. 16

* Screw hoisting lugs 010 into the relevant flap position

Layout of lifting straps and location of hoist points -see Fig. 18 page 19

Attention!

Install the lifting lug 010 in full length and turn it less than one turn anti clock-

wise until the bolt has a tangential position to the lifting eye and the swivel

adapter 022 can move freely when under load. ~ see Fig. 17

= After use of hoist protect lifting lug 010 with the protection cap 014.

022

'

014

o10

Figure 16 Figure 17

Department GSE-Title: Page: 16 of 37

SEMS11 HOIST R/T FLAP/SLAT 7.042010

Equipment PIN TAN

98 F275 08498 000 Ground Instruction BW

anual

Issue: (ORIGINAL) AIRBUS

Outer Flap A 330/340 200-300

Lifting Eye

005 4 004 003

oureoaR I,

INBOARD

Hoist

Point

OUTBOARD

Point Point

MID INBOARD

Figure 18

Table of Length

003 Sling length 3877mm | Flap Position 32°

004 Sling length 3036 mm

005 Sling length 3413 mm

For the fine adjustment a turnbuckle pos 025 Page11 is used.

The basic setting before use should be 285 mm/11,22 inch before installing

Department

| Page: 19 of 37

dt __

HOIST R/I FLAP/SLAT | 07.04.2010

“SEMS11

Equipment P/N: 7

98 F275 08498 000 Ground Instruction AD

anual

Issue: D (ORIGINAL) AIRBUS

Removal : Outer Flap A340-500-600

+ Install lifting eye of hoist into the crane hook.

+ adjusting of sling length with a measuring Tape according to

Table of length.

Check Flap extended Position 32° and Installation Angle 4°,

according AMM Task, with a Protractor.

For the fine adjustment a turnbuckle pos 025 and Fig.3 Page 11 is used

Instructions for handling of the Vario Web -see chapter 4.1.1- page 12

= Unscrew protection cap 014 off the hoisting lugs - see Fig. 19

= Screw hoisting lugs 010 into the relevant flap position

Layout of lifting straps and location of hoist points -see Fig. 21 page 21

Attention!

Install the lifting Jug 010 in full length and turn it less than one turn anti clock-

wise until the bolt has a tangential position to the lifting eye and the swivel ,

adapter 022 can move freely when under load. - see Fig. 20

= After use of hoist protect lifting lug 010 with the protection cap 014,

022

014

010

Figure 19 Figure 20

Department | GSE-Title: Page: 20 of 37

SEMS11 HOIST R/1 FLAP/SLAT 97.04.2010

EqupmentPin; ~DSS*=~

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Service Bulletin: Goodrich Actuation Systems Sas A Utc Aerospace Systems Company Product Support DepartmentDocument16 pagesService Bulletin: Goodrich Actuation Systems Sas A Utc Aerospace Systems Company Product Support Departmentrobertas negudinasNo ratings yet

- FIXTURE STRUT THSA (GIM - GSE Instruction Manual)Document29 pagesFIXTURE STRUT THSA (GIM - GSE Instruction Manual)Edson Carvalho100% (3)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Jack Tooling 98D07103001Document10 pagesJack Tooling 98D07103001Edson Carvalho100% (1)

- Shell Model Ebook v4Document9 pagesShell Model Ebook v4Edson CarvalhoNo ratings yet

- Printed in GermanyDocument20 pagesPrinted in GermanyEdson CarvalhoNo ratings yet

- Printed in GermanyDocument29 pagesPrinted in GermanyEdson CarvalhoNo ratings yet

- Printed in GermanyDocument46 pagesPrinted in GermanyEdson CarvalhoNo ratings yet

- Printed in GermanyDocument2 pagesPrinted in GermanyEdson CarvalhoNo ratings yet

- Printed in GermanyDocument31 pagesPrinted in GermanyEdson CarvalhoNo ratings yet

- 27-11-18 All Speed Servo CTRL 31055 SeriesDocument190 pages27-11-18 All Speed Servo CTRL 31055 SeriesEdson CarvalhoNo ratings yet

- Printed in GermanyDocument27 pagesPrinted in GermanyEdson CarvalhoNo ratings yet

- 27-31-16 Pitch Servo CTRL 31043 SeriesDocument190 pages27-31-16 Pitch Servo CTRL 31043 SeriesEdson CarvalhoNo ratings yet

- Printed in GermanyDocument2 pagesPrinted in GermanyEdson CarvalhoNo ratings yet

- Nammbva 000005Document42 pagesNammbva 000005Edson CarvalhoNo ratings yet

- Nammbva 000007Document71 pagesNammbva 000007Edson CarvalhoNo ratings yet

- A330 Removal of The Aft Plug AssemblyDocument5 pagesA330 Removal of The Aft Plug AssemblyEdson CarvalhoNo ratings yet

- 27-09-15 Position Pick-Off Unit 9028A0002 SeriesDocument114 pages27-09-15 Position Pick-Off Unit 9028A0002 SeriesEdson CarvalhoNo ratings yet

- Nammdlha 000058Document380 pagesNammdlha 000058Edson CarvalhoNo ratings yet

- TAP - A330 Removal of The Exhaust Nozzle AssemblyDocument7 pagesTAP - A330 Removal of The Exhaust Nozzle AssemblyEdson CarvalhoNo ratings yet

- ON A/C FSN 551-600: Customization Aircraft Types Doctypes Revision Date Title Tail Number - MSN - FSNDocument7 pagesON A/C FSN 551-600: Customization Aircraft Types Doctypes Revision Date Title Tail Number - MSN - FSNEdson CarvalhoNo ratings yet

- Title: Flight Controls - Rudder Hydraulic Actuation - Introduce Roller Bearing On Rod End Rudder ServocontrolDocument248 pagesTitle: Flight Controls - Rudder Hydraulic Actuation - Introduce Roller Bearing On Rod End Rudder ServocontrolEdson CarvalhoNo ratings yet

- Mandatory Mandatory Mandatory: Title: Nacelles/Pylons - Aft Fixed Fairing - Inspection On Pylon Aft Fixed FairingDocument291 pagesMandatory Mandatory Mandatory: Title: Nacelles/Pylons - Aft Fixed Fairing - Inspection On Pylon Aft Fixed FairingEdson CarvalhoNo ratings yet

- A320-27-1247 R0 - Config 001Document85 pagesA320-27-1247 R0 - Config 001Edson Carvalho100% (1)

- Pacific Scientific T60 User ManualDocument14 pagesPacific Scientific T60 User ManualEdson CarvalhoNo ratings yet

- Men S Fitness Body ChallengeDocument194 pagesMen S Fitness Body ChallengeEdson CarvalhoNo ratings yet

- MF 101 Downmagaz - WsDocument132 pagesMF 101 Downmagaz - WsEdson Carvalho100% (2)

- RR Fan Blades Lub Kit PDFDocument4 pagesRR Fan Blades Lub Kit PDFEdson CarvalhoNo ratings yet