Professional Documents

Culture Documents

FIXTURE STRUT THSA (GIM - GSE Instruction Manual)

Uploaded by

Edson CarvalhoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FIXTURE STRUT THSA (GIM - GSE Instruction Manual)

Uploaded by

Edson CarvalhoCopyright:

Available Formats

P/N:

98D27403003002 GSE/Tool User Guide

ORIGINAL VERSION (ENGLISH LANGUAGE)

FIXTURE STRUT THSA

98D27403003002

CE DIRECTIVES ARE NOT

APPLICABLE ON THIS GSE

REACH Compliant

Doc. issue: A FIXTURE STRUT THSA Page 1 of 28

NUMPAGES 16

Released on 06 July 2020

P/N:

98D27403003002 GSE/Tool User Guide

ORIGINAL VERSION (ENGLISH LANGUAGE)

Document Validation

Company Department Date

EXCENT

Made by 16/06/2020

FRANCE

Checked by AIRBUS

Validated by AIRBUS SEMSD

Record of Revisions

Reference of the

Issue Date Affected Page(s) Reason for revision

document used

A 16/06/2020 All

Doc. issue: A FIXTURE STRUT THSA Page 2 of 28

NUMPAGES 16

Released on 06 July 2020

P/N:

98D27403003002 GSE/Tool User Guide

ORIGINAL VERSION (ENGLISH LANGUAGE)

Table of Contents

Document Validation ...............................................................................................2

Record of Revisions ................................................................................................2

1 Prerequisites .....................................................................................................4

1.1 General information .......................................................................................4

1.2 Warning and caution .....................................................................................4

2 GSE/Tool setup .................................................................................................6

2.1 Before use.....................................................................................................6

2.2 Customer checklist ........................................................................................6

2.3 Packing checklist ...........................................................................................7

2.4 Zone of use (aircraft location) ........................................................................8

3 GSE/Tool usage.................................................................................................9

3.1 GSE/Tool description ....................................................................................9

3.2 Personal protective equipment ....................................................................10

3.3 Conditions of use ........................................................................................10

3.4 Assembly procedure....................................................................................11

3.4.1 Hydraulic Assembly ..................................................................................11

3.4.2 Mechanical Assembly ...............................................................................14

3.4.3 Assembly of the 2 recording devices ......................................................17

3.4.4 Tool Utilization ..........................................................................................20

3.5 GSE/Tool usage during maintenance task ..................................................23

3.6 Disassembly procedure ...............................................................................23

3.7 Trouble shooting .........................................................................................23

3.7.1 Trouble shooting with pressure loss .........................................................23

3.7.2 Trouble shooting with pump .....................................................................24

3.7.3 Trouble shooting with standards parts......................................................24

4 Test & Maintenance.........................................................................................25

4.1 Calibration ...................................................................................................25

4.2 Periodical Test ............................................................................................26

5 Handling / Storage ..........................................................................................27

6 End of life.........................................................................................................27

7 Glossary...........................................................................................................28

Doc. issue: A FIXTURE STRUT THSA Page 3 of 28

NUMPAGES 16

Released on 06 July 2020

P/N:

98D27403003002 GSE/Tool User Guide

ORIGINAL VERSION (ENGLISH LANGUAGE)

1 Prerequisites

1.1 General information

All following instructions are only applicable for GSE/Tool P/N 98D27403003002.

This GSE/Tool User Guide must be read in conjunction with the appropriate Aircraft

documentation.

In case of conflicting documents please contact AIRBUS.

Before using or mounting the GSE/Tool, read this GSE/Tool User Guide carefully and

ensure that all content is well understood. Non-compliance with the instructions can

lead to personal injury or material damage and excludes any warranty.

The GSE/Tool is delivered by the manufacturer ready for assembly.

Before GSE/Tool assembly, a visual inspection and crosscheck with tool packing list

(see Chapter 2.3) shall be performed to ensure there are no missing or damaged parts.

During GSE/Tool life cycle, follow the maintenance intervals set out in the maintenance

instructions (see Chapter 4), except where:

- Visual inspection calls for immediate action;

- Unforeseen conditions necessitate more frequent servicing.

1.2 Warning and caution

A. General

The GSE/Tool P/N 98D27403003002 is designed to meet specific conditions of use

and to fulfil a defined function (described into this user guide). Any other use / action

than that given in this user guide will be under users / operators responsibility (except

in case of specific request coming from Airbus).

Doc. issue: A FIXTURE STRUT THSA Page 4 of 28

NUMPAGES 16

Released on 06 July 2020

P/N:

98D27403003002 GSE/Tool User Guide

ORIGINAL VERSION (ENGLISH LANGUAGE)

B. Icons

WARNING

Climbing, standing or riding on this equipment is prohibited

WARNING

Finger pinch point when lowering and aligning

CAUTION

25 kg

C. Safety precautions

Ensure safe working practices when handling the GSE/Tool.

GSE/Tool shall be used only by an authorized and competent person who fully

understands the content of this user guide.

Always follow the procedures described in this user guide and the related Airbus

maintenance tasks.

The user shall ensure that:

The GSE/Tool is only used for the function it has been designed for, as described

in this user guide;

The GSE/Tool is in proper working conditions and that the applicable safety de-

vices are checked for functional reliability;

Required personal protective equipment (PPE) for the GSE/Tool users are avail-

able and being used;

Only qualified personnel is in charge of handling, operating, maintaining and re-

pairing the GSE/Tool;

All attached safety and warning notices will not be removed and are legible.

Before use, the user shall ensure that GSE/Tool is in conformity with local legislation

if used outside of the EU.

Doc. issue: A FIXTURE STRUT THSA Page 5 of 28

NUMPAGES 16

Released on 06 July 2020

P/N:

98D27403003002 GSE/Tool User Guide

ORIGINAL VERSION (ENGLISH LANGUAGE)

2 GSE/Tool setup

2.1 Before use

Before using the equipment, you must, to ensure safe use of the tool and its

efficiency, read these instructions for use and comply with all

recommendations given.

The instructions for use are not a training manual.

These instructions for use must be placed at the disposal of all operators.

Read and keep legible the instructions given on the tool. Do not use the tool if

the markings are not legible.

Before each use, check that the machine is in good condition.

Never use the tool if it is visibly not in good condition.

The tool can be used only by capable, trained and competent operators

Check the validity of the last conformity inspection.

2.2 Customer checklist

Before using the GSE/Tool, be sure that you have:

☐_____a certificate of conformity,

☐_____a GSE User Guide,

Documents

☐_____periodical test results,

☐_____AMM, SB, SRM and/or TSM task relevant to the use of the GSE/Tool.

A manufacturer's plate shall be placed on the GSE/Tool. It must include:

☐_____the name and country of the manufacturer,

On GSE/Tool

☐_____the GSE/Tool part and serial numbers,

☐_____the weight of the GSE/Tool,

☐_____the M.L. of the GSE/Tool,

☐_____the design issue of the GSE/Tool,

Doc. issue: A FIXTURE STRUT THSA Page 6 of 28

NUMPAGES 16

Released on 06 July 2020

P/N:

98D27403003002 GSE/Tool User Guide

ORIGINAL VERSION (ENGLISH LANGUAGE)

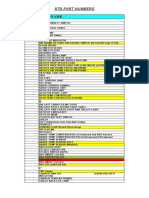

2.3 Packing checklist

062

058

044

042

060

Item Description P/N Quantity

042 RECORDING DEVICE 98D27403003042 1

044 RECORDING DEVICE 2 98D27403003044 1

058 HYDRAULIC ASSY 98D27403003058 1

060 ASSEMBLY PUMP 98D27403003060 1

062 STORAGE 98D27403003062 1

Doc. issue: A FIXTURE STRUT THSA Page 7 of 28

NUMPAGES 16

Released on 06 July 2020

P/N:

98D27403003002 GSE/Tool User Guide

ORIGINAL VERSION (ENGLISH LANGUAGE)

2.4 Zone of use (aircraft location)

All Aircraft except A340-500/600

Doc. issue: A FIXTURE STRUT THSA Page 8 of 28

NUMPAGES 16

Released on 06 July 2020

P/N:

98D27403003002 GSE/Tool User Guide

ORIGINAL VERSION (ENGLISH LANGUAGE)

3 GSE/Tool usage

3.1 GSE/Tool description

FIXTURE STRUT THSA

P/N 98D27403003002

Name of manufacturer

Address

Manufacturer name

Year of construction XXXX

Essential function This tool is used to control damage on THSA

Secondary function N/A

GSE/Tool weight

45 kg

Unit: kg

GSE/Tool dimensions

(Length x Width x Height) 330 x 420 x 1160 mm

Unit: mm

M.L.

850 kg

Unit: kg

Type of energy used by this GSE/Tool Manual

Number of persons required to use this GSE/Tool 2

The tool will be used for a maintenance task in

Working environment

an environment provided for this purpose.

GSE/Tool storage box

P/N 98D27403003062

GSE/Tool storage box dimensions

(Length x Width x Height) 330 x 420 x 1160 mm

Unit: mm

Doc. issue: A FIXTURE STRUT THSA Page 9 of 28

NUMPAGES 16

Released on 06 July 2020

P/N:

98D27403003002 GSE/Tool User Guide

ORIGINAL VERSION (ENGLISH LANGUAGE)

3.2 Personal protective equipment

Note that PPEs to be used for GSE/Tool handling have to be consistent with the

working environment and associated requirements (some of them can be missing in

this chapter).

Mandatory head Mandatory body

protection protection

Mandatory foot Mandatory hand

protection protection

3.3 Conditions of use

Condition Details / Limits

Environment of use Inside …

External power needed? NO …

Operating temperature range -0°C / + 40°C …

Check that the various parts of the tool are in good condition.

Check the validity of the last conformity inspection.

Read the installation instructions given below.

Doc. issue: A FIXTURE STRUT THSA Page 10 of 28

NUMPAGES 16

Released on 06 July 2020

P/N:

98D27403003002 GSE/Tool User Guide

ORIGINAL VERSION (ENGLISH LANGUAGE)

3.4 Assembly procedure

3.4.1 Hydraulic Assembly

Remove from the storage box the following items required:

o ASSEMBLY PUMP (060)

o HYDRAULIC ASSY (058) including:

HYDRAULIC SYSTEM (114)

CLEVIS ASSY (102)

BAR 2 (210)

BAR 3 (212)

Install the hydraulic system (114) on the Aircraft fitting with ball lock pin.

Hydraulic

system (114)

Bush

Ball lock pins

Screw totally the bush of the hydraulic system

OK NOK

Doc. issue: A FIXTURE STRUT THSA Page 11 of 28

NUMPAGES 16

Released on 06 July 2020

P/N:

98D27403003002 GSE/Tool User Guide

ORIGINAL VERSION (ENGLISH LANGUAGE)

Use the correct extension (in accordance with aircraft configuration)

Doc. issue: A FIXTURE STRUT THSA Page 12 of 28

NUMPAGES 16

Released on 06 July 2020

P/N:

98D27403003002 GSE/Tool User Guide

ORIGINAL VERSION (ENGLISH LANGUAGE)

Screw the good extension on the hydraulic system (114)

Extension

Couplers

Hydraulic

system (114)

Connect the hydraulic system (114) to the hydraulic pump (060) with

couplers.

Doc. issue: A FIXTURE STRUT THSA Page 13 of 28

NUMPAGES 16

Released on 06 July 2020

P/N:

98D27403003002 GSE/Tool User Guide

ORIGINAL VERSION (ENGLISH LANGUAGE)

3.4.2 Mechanical Assembly

Next steps consist to connect the tool to the upper fitting of the aircraft. To do that,

it’s necessary to adjust the tool length to be able to connect the ball lock pin to the

upper fitting.

Ball lock pin

Doc. issue: A FIXTURE STRUT THSA Page 14 of 28

NUMPAGES 16

Released on 06 July 2020

P/N:

98D27403003002 GSE/Tool User Guide

ORIGINAL VERSION (ENGLISH LANGUAGE)

1st adjustment: Adjustment with hydraulic system

Open the valves 1 & 2

Put the selector of the manual pump on "compression" or “traction” (See

§3.4.4) and pump to adjust the length of the tool in order to align the green

groove of the extension with the green face of the Hydraulic Assy

Valve 1

Selector

Valve 2

Manual pump

Alignment of the

green groove

Put the selector of the manual pump on "neutral" (See §3.4.4)

Doc. issue: A FIXTURE STRUT THSA Page 15 of 28

NUMPAGES 16

Released on 06 July 2020

P/N:

98D27403003002 GSE/Tool User Guide

ORIGINAL VERSION (ENGLISH LANGUAGE)

2ndadjustment: Adjustment with the knurled bush.

Knurled Bush

Caution:

Adjustment system is used to adjust the length with a simple color control.

The length adjustment is OK if no red marking appear.

If red marking appear, do not use the tool.

NOK

Adjust the length of the tool with the knurled bush until you are able to make

the connection with the fitting and to insert the ball lock pin

Ball lock pin

Doc. issue: A FIXTURE STRUT THSA Page 16 of 28

NUMPAGES 16

Released on 06 July 2020

P/N:

98D27403003002 GSE/Tool User Guide

ORIGINAL VERSION (ENGLISH LANGUAGE)

3.4.3 Assembly of the 2 recording devices

To check the correct operation of the THSA system, the installation of 2

recording devices is necessary

3.4.3.1 Assembly of Tie Bar Comparator

Choose the assembly in accordance with the Aircraft.

98D27403003112 98D27403003110

- -

SA LR

Install the comparator on the comparator system

Comparator

Doc. issue: A FIXTURE STRUT THSA Page 17 of 28

NUMPAGES 16

Released on 06 July 2020

P/N:

98D27403003002 GSE/Tool User Guide

ORIGINAL VERSION (ENGLISH LANGUAGE)

Screw the recording device on the Tie Bar System until the recording device

is stable. Do not compress the spring totally.

Tie bar

Recording devices

Adjust the comparator to 0.

Doc. issue: A FIXTURE STRUT THSA Page 18 of 28

NUMPAGES 16

Released on 06 July 2020

P/N:

98D27403003002 GSE/Tool User Guide

ORIGINAL VERSION (ENGLISH LANGUAGE)

3.4.3.2 Assembly of Ballscrew Comparator

System ballscrew Axis

Positioning of the comparator

To install the system, unscrew both knurled nut to open it (See below),

Axis

Knurled nut + free axis

Once opened, put the system around the ballscrew,

Close the system and clamp it by screwing both knurled nut,

Adjust the comparator.

Doc. issue: A FIXTURE STRUT THSA Page 19 of 28

NUMPAGES 16

Released on 06 July 2020

P/N:

98D27403003002 GSE/Tool User Guide

ORIGINAL VERSION (ENGLISH LANGUAGE)

3.4.4 Tool Utilization

This tool is used to apply a load on the THSA system and to verify that there are no

defects.

Selector Valve 1 Traction Manometer

Traction

Line

-- Neutral

Compression

Line

Valve 2

Compression Manometer

Follow the step below before each utilization (traction or compression):

Valves 1 & 2 opened, action the selector from traction to compression or

inversely and check there is no pressure in the system using manometers.

Traction Compression

Manometer Manometer

Close valves 1 & 2 , and re-open them by half a turn only

Refer to AMM procedure to apply the hydraulic pressure needed to perform

the task.

Note: Manometers can take a few seconds to react

Doc. issue: A FIXTURE STRUT THSA Page 20 of 28

NUMPAGES 16

Released on 06 July 2020

P/N:

98D27403003002 GSE/Tool User Guide

ORIGINAL VERSION (ENGLISH LANGUAGE)

3.4.4.1 Tool Utilization in compression

Selector Valve 1

Compression

Line

Valve 2

Compression Manometer

Note: There is a risk for the safety valve to trigger if this procedure is not respected.

Put the selector of the manual pump on "compression"

To apply the hydraulic pressure needed, press the pump lever slowly about

once each 5 seconds until 120 bars and once each 10 seconds after 120

bars, until the required pressure is reached

Note: If the safety valve is triggered, restart

the hydraulic test from the beginning 3.4.4

Tool Utilization

When you reach the pressure required, close valve 2 (compression valve).

Note: Closing the valve can slightly increase the pressure

Read the displacement value of THSA system on the 2 recording devices

To uncharge the THSA, the pressure has to drop slowly. Change

the selector position from Compression to Traction and open

the valve 2 very slowly

Note: If you have difficulties to apply the pressure needed, refer to 3.7 Trouble

shooting

Doc. issue: A FIXTURE STRUT THSA Page 21 of 28

NUMPAGES 16

Released on 06 July 2020

P/N:

98D27403003002 GSE/Tool User Guide

ORIGINAL VERSION (ENGLISH LANGUAGE)

3.4.4.2 Tool Utilization in traction

Selector Valve 1 Traction Manometer

Traction

Line

Valve 2

Note: There is a risk for the safety valve to trigger if this procedure is not respected.

Put the selector of the manual pump on "traction"

To apply the hydraulic pressure needed, press the pump lever slowly about

once each 5 seconds until 380 bars and once each 10 seconds after 380

bars, until the required pressure is reached

Note: If the safety valve is triggered, restart

the hydraulic test from the beginning 3.4.4

Tool Utilization

When you reach the pressure required, close valve 1 (traction valve).

Note: Closing the valve can slightly increase the pressure

Read the displacement value of THSA system on the 2 recording devices

To uncharge the THSA, the pressure has to drop slowly. Change

the selector position from Traction to Compression and open

the valve 1 very slowly

Note: If you have difficulties to apply the pressure needed, refer to 3.7 Trouble

shooting

Doc. issue: A FIXTURE STRUT THSA Page 22 of 28

NUMPAGES 16

Released on 06 July 2020

P/N:

98D27403003002 GSE/Tool User Guide

ORIGINAL VERSION (ENGLISH LANGUAGE)

3.5 GSE/Tool usage during maintenance task

N/A

3.6 Disassembly procedure

Valves 1 & 2 opened, action the selector from traction to compression or

inversely and check there is no pressure in the system using manometers

Proceed in reverse order of the installation steps.

3.7 Trouble shooting

3.7.1 Trouble shooting with pressure loss

A slight pressure loss can occur during utilization, if not exceed 10 bars in 5 min,

there is no trouble. If exceed, see trouble shooting bellow:

If there is a loss of pressure when using the hydraulic system, this may be caused

by:

The safety valve was triggered because the applied pressure was too strong

In that case, put the selector of the manual pump on “compression”

and “traction” to release the pressure in the system.

Then, test again the system from the beginning 3.4.4 Tool Utilization

Note: For information, the safety valve can be triggered from 443 bars in traction and

from 158 bars in compression

The safety valve is not corectly set (this can happen after several triggers)

Note: Valve setting must be done by an agreemented company

Anyway, setting the valves can be done following procedure in

paragraph 4.1 Calibration

The manometers are not working properly and do not indicate the correct

value

Connect a precise calibrated manometer on the hydraulic tool system

(see procedure in paragraph 4.1 Calibration)

Control the values indicated by each manometers

Change the manometers if necessary

Oil leak in the hydraulic system

Check that there is no oil leakage at the hydraulic connections

Doc. issue: A FIXTURE STRUT THSA Page 23 of 28

NUMPAGES 16

Released on 06 July 2020

P/N:

98D27403003002 GSE/Tool User Guide

ORIGINAL VERSION (ENGLISH LANGUAGE)

3.7.2 Trouble shooting with pump

If you use the pump and the pressure does not increase in the system, it is possible

there is a lack of oil in the pump.

Follow the procedure bellow:

- Warning: Be sure there is no pressure inside the system

- Unscrew “Nut 1” with appropriate Hex Key

- Clean the hydraulic connection at “Nut 1” position

- Fill the pump with mineral hydraulic oil (ref HF95 from ENERPAC or

Equivalent) (the “pipe” is directly connected to the pump)

- Clean the hydraulic connection at “Nut 1” position

- Screw back “Nut 1” by using hydraulic thread sealant / Teflon

- Connect the actuator to the hydraulic Pump

- Bleed the system by folding / unfolding 5 times the actuator.

Nut 1

Pipe

3.7.3 Trouble shooting with standards parts

In case of problems with standard parts (commercial of the shelf) refer to operating

instruction of standard part manufacturer.

In case of any GSE/Tool issues, please contact:

Maintenance Planning &GSE Services

Customer Service

Airbus S.A.S

1 rond point Maurice Bellonte

31707 Blagnac Cedex

France

maint.gsetools@airbus.com

Doc. issue: A FIXTURE STRUT THSA Page 24 of 28

NUMPAGES 16

Released on 06 July 2020

P/N:

98D27403003002 GSE/Tool User Guide

ORIGINAL VERSION (ENGLISH LANGUAGE)

4 Test & Maintenance

4.1 Calibration

As GSE & Tools manufacturer, Airbus recommends calibration tests during tool

life cycle. Those recommendations should include a load test factor and a

periodicity defined here after.

Safety valve Calibration:

Periodicity: 12 months

Procedure:

Connect a precise calibrated manometer on the THSA Hydraulic system

(For the connection, a standard coupler AZ3120 or AZ3140 from Larzep or

equivalent is needed)

Precise Calibrated

Manometer

Male and Female

Standard Coupler

Safety

Valves

THSA

Manometers Hydraulic

system

Remove the protective cap

Unlock the nut with appropriate fork wrench

Doc. issue: A FIXTURE STRUT THSA Page 25 of 28

NUMPAGES 16

Released on 06 July 2020

P/N:

98D27403003002 GSE/Tool User Guide

ORIGINAL VERSION (ENGLISH LANGUAGE)

Set the safety valve with appropriate hex key (closkwise for increase the

pressure limit)

Trigger value of the safety valves:

Traction: 458 bars +/- 3% (6640 psi)

Compression: 164 bars +/- 3% (2378 psi)

Protective cap Nut Do not disassemble

this nut

Hex wrench size 6

Control the trigger value of each safety valve with the calibrated manometer

Note: for safety valve calibration, pump identically as for tool utilization paragraph 3.4.4

Tool Utilization

Once set, tighten the nut and instal the protective cap.

During safety valve calibration, check the correct operation of the manometers

1&2

4.2 Periodical Test

As GSE & Tools manufacturer, Airbus recommends periodical tests during tool life

cycle. Those recommendations should include a load test factor and a periodicity

defined here after.

For hydraulic GSE Tool:

Periodical pressure test has to be performed every year as follow:

- Performed leakage test at operating pressure during 2mn

- The GSE is equiped with 2 safety valves. For both valves, realise calibration (If

needed, follow procedure 3.7.1 Issue with pressure loss to set the safety

valves)

- Manometer check (can be realised during safety valve calibration procedure)

Doc. issue: A FIXTURE STRUT THSA Page 26 of 28

NUMPAGES 16

Released on 06 July 2020

P/N:

98D27403003002 GSE/Tool User Guide

ORIGINAL VERSION (ENGLISH LANGUAGE)

A. Servicing &Maintenance

Servicing and maintenance must be done before each use, with the GSE/Tool

uninstalled and in a rest configuration.

Servicing and maintenance shall consist of:

- Verifying the proper conditions of working of the GSE/Tool.

- Checking periodic tests have been performed

- Checking calibration has been performed

- Cleaning parts

B. Maintenance Schedule

Perfom calibration and periodical test (see §4.1 and §4.2)

C. Specific maintenance

- See calibration and periodical test (see §4.1 and §4.2)

- Grease all threaded areas if needed

- Worn components must be replaced with original parts, not repaired. Parts of

inferior quality could damage the tools and be a risk to safety.

- Clean tool with appropriate cleaning agent

- Follow hydraulic pump & cylinder manuals for their preventive maintenance

actions needed.

5 Handling / Storage

A. Handling

- GSE storage box with stored GSE inside can be handled by hand.

- All items can be handled by hand through one or more people

B. Storage

- Before storing, refer to ‘Packing checklist’ (chapter 2.3) in order to verify the

availability of all items which shall be part of the GSE/Tool P/N 98D27403003002.

6 End of life

WARNING

To be compliant with regulation 2012/19/EC - Do not dispose Electric

and Electronic Equipment waste and collect them separately

Doc. issue: A FIXTURE STRUT THSA Page 27 of 28

NUMPAGES 16

Released on 06 July 2020

P/N:

98D27403003002 GSE/Tool User Guide

ORIGINAL VERSION (ENGLISH LANGUAGE)

7 Glossary

A/C Aircraft

AMM Aircraft Maintenance Manual

E.g. For Example

Fig, Figs Figure, Figures

GSE Ground Support Equipment

Max Maximum

N/A Not Applicable

P/N Partnumber

M.L. Maximum Limit

Doc. issue: A FIXTURE STRUT THSA Page 28 of 28

NUMPAGES 16

Released on 06 July 2020

REFERENCE GIM_90034853

Distribution List

ISSUE A00 DATE 06 Jul 2020

GIM_98D27403003002

Distribution List

MANUAL DISTRIBUTION LIST

-------------------------------------------

wogse@sonovisiongroup.com

-------------------------------------------

maint.gsetools@airbus.com

-------------------------------------------

programs.gsetools@airbus.com

-------------------------------------------

Repair2@hydro.aero

-------------------------------------------

Tooling-Biberach@hydro.aero

-------------------------------------------

Tool.repair@airbus.com

-------------------------------------------

procurement.tools@airbus.com

-------------------------------------------

julio.ortiz@groupedcm.com

-------------------------------------------

contact.airbus@groupe-lpf.com

-------------------------------------------

capra.g@ecagroup.com

-------------------------------------------

gse.technic@ecagroup.com

-------------------------------------------

distribution.gse@airbus.com

-------------------------------------------

gserequest@excent.fr

© AIRBUS S.A.S. 2020. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Released on 06 July 2020

You might also like

- Men S Fitness Body ChallengeDocument194 pagesMen S Fitness Body ChallengeEdson CarvalhoNo ratings yet

- Component Reliability Report - 2021-02Document90 pagesComponent Reliability Report - 2021-02Fred SagreraNo ratings yet

- A330-343 E.O Status Easa FormDocument31 pagesA330-343 E.O Status Easa FormAmr El Kady0% (1)

- Kidde 2015-01-04Document44 pagesKidde 2015-01-04Gerardo Cordova100% (1)

- 5B 711119 R55 Mar19 PDFDocument395 pages5B 711119 R55 Mar19 PDFJivendra Kumar0% (1)

- Binder Cover Sheet: Component Maintenance Manual With Illustrated Parts List AC Outlet Unit (ACOU)Document84 pagesBinder Cover Sheet: Component Maintenance Manual With Illustrated Parts List AC Outlet Unit (ACOU)ali100% (1)

- 21 Air Conditioning CMMDocument81 pages21 Air Conditioning CMMFemi AgbanaNo ratings yet

- Abs 0056Document17 pagesAbs 0056darrow dori100% (1)

- A320-27-1247 R0 - Config 001Document85 pagesA320-27-1247 R0 - Config 001Edson Carvalho100% (1)

- Jack Tooling 98D07103001Document10 pagesJack Tooling 98D07103001Edson Carvalho100% (1)

- Jack Tooling 98D07103001Document10 pagesJack Tooling 98D07103001Edson Carvalho100% (1)

- CFM56 5B SB Rev 72-1083 TSN.00 N 20200728Document7 pagesCFM56 5B SB Rev 72-1083 TSN.00 N 20200728Irfan05100% (1)

- Ignition Cables and Igniter Installation PDFDocument6 pagesIgnition Cables and Igniter Installation PDFMark Evan SalutinNo ratings yet

- CCG A320 Fam 2007Document232 pagesCCG A320 Fam 2007Thomas-Mathias BockNo ratings yet

- Component Capability List: Document Ref.: VTS/MOE/CCL Document Holder: JSC Vostok Technical ServicesDocument40 pagesComponent Capability List: Document Ref.: VTS/MOE/CCL Document Holder: JSC Vostok Technical ServicesVadim RiabovNo ratings yet

- Technical Manual Index: Component Maintenance Manuals August 1, 2019Document91 pagesTechnical Manual Index: Component Maintenance Manuals August 1, 2019chandradeo100% (1)

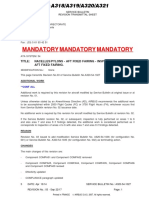

- A318/A319/A320/A321: Service BulletinDocument24 pagesA318/A319/A320/A321: Service BulletinPradeep K sNo ratings yet

- Saft General PDFDocument84 pagesSaft General PDFESAVENo ratings yet

- To: Holders of 4579 (Saft 018550-000) Batteries Subject: CMM Revision No. 8 Dated Mar 15/19 Highlights Chapter/Section and Page Number Description of Change EffectivityDocument71 pagesTo: Holders of 4579 (Saft 018550-000) Batteries Subject: CMM Revision No. 8 Dated Mar 15/19 Highlights Chapter/Section and Page Number Description of Change Effectivitynixon_b_2000100% (1)

- Lpeco Crew Seat CMMDocument174 pagesLpeco Crew Seat CMMvishalsachanameNo ratings yet

- Service Bulletin: Goodrich Actuation Systems Sas A Utc Aerospace Systems Company Product Support DepartmentDocument16 pagesService Bulletin: Goodrich Actuation Systems Sas A Utc Aerospace Systems Company Product Support Departmentrobertas negudinasNo ratings yet

- Manual ELT Artex 570-5001 Rev. HDocument66 pagesManual ELT Artex 570-5001 Rev. Hsebastiandavid9100% (1)

- 285ch - R01 - 27 Jun 2019 - SAFTDocument62 pages285ch - R01 - 27 Jun 2019 - SAFTKirillNo ratings yet

- @A318/A319/A320/A321: Chapter 49 - Airborne Auxiliary PowerDocument31 pages@A318/A319/A320/A321: Chapter 49 - Airborne Auxiliary PowerFabian Andres Soto Lineros (LATAM)No ratings yet

- B737 Ch70 STD PracticesDocument21 pagesB737 Ch70 STD PracticesAhmed Abdoul ZaherNo ratings yet

- A318/A319/A320/A321: Service BulletinDocument213 pagesA318/A319/A320/A321: Service BulletinPradeep K s100% (1)

- Acrt A320 0506 XrefDocument1,754 pagesAcrt A320 0506 XrefhunganhngocNo ratings yet

- Service Newsletter: SubjectDocument5 pagesService Newsletter: SubjectBrsaNo ratings yet

- Title: Engine Fuel and Control - Fadec System - Introduce Ecu Software Standard 5.B.T.F1 On Fadec1+ Hardware On Cfm56-5B EnginesDocument72 pagesTitle: Engine Fuel and Control - Fadec System - Introduce Ecu Software Standard 5.B.T.F1 On Fadec1+ Hardware On Cfm56-5B EnginesVolNo ratings yet

- Cfm56-5B - HP Duct Crack: Engineering SupportDocument3 pagesCfm56-5B - HP Duct Crack: Engineering SupportJivendra Kumar -100% (2)

- Service Letter Atr42: TITLE: Time Limits Document - ATR42-200/-300/-320 - MLG and NLG Additional InformationDocument11 pagesService Letter Atr42: TITLE: Time Limits Document - ATR42-200/-300/-320 - MLG and NLG Additional Informationa_sharafiehNo ratings yet

- 21-61-47 Rev # 6 PACK TEMP CONTROL VALVEDocument88 pages21-61-47 Rev # 6 PACK TEMP CONTROL VALVEAndrew ChegeNo ratings yet

- CMM Index-8 PDFDocument16 pagesCMM Index-8 PDFChandanNo ratings yet

- Title: Flight Controls - Rudder Hydraulic Actuation - Introduce Roller Bearing On Rod End Rudder ServocontrolDocument248 pagesTitle: Flight Controls - Rudder Hydraulic Actuation - Introduce Roller Bearing On Rod End Rudder ServocontrolEdson CarvalhoNo ratings yet

- 35-10-25 Rev.8 PBEDocument83 pages35-10-25 Rev.8 PBEnoureldinkamalNo ratings yet

- M-dlps1003-1 (Treatment - Standard Treatments)Document12 pagesM-dlps1003-1 (Treatment - Standard Treatments)Pradeep K s100% (1)

- General Practices Manual Maintenance Procedures Aircraft Wheel BearingsDocument26 pagesGeneral Practices Manual Maintenance Procedures Aircraft Wheel Bearingskien Duy PhanNo ratings yet

- Ms r05Document364 pagesMs r05LUIS AUGUSTO MINAS SOUZA50% (2)

- SB Index 72 APR-2020 PDFDocument133 pagesSB Index 72 APR-2020 PDFMuhammad Ashraful KabirNo ratings yet

- Fan Lub CFM56-7Document89 pagesFan Lub CFM56-7ANDRA100% (1)

- CT 138167Document46 pagesCT 138167Srand DanNo ratings yet

- Atr Parts ListDocument23 pagesAtr Parts Listasif27No ratings yet

- Cf6cmm PDFDocument85 pagesCf6cmm PDFHaithem BrebishNo ratings yet

- Pinnacle 1022022 SERIES Passenger Seats For Lan Airlines A319 / A320 AircraftDocument360 pagesPinnacle 1022022 SERIES Passenger Seats For Lan Airlines A319 / A320 Aircraftlibrolibro1No ratings yet

- Sales Bulletin: Roduct Iscontinuation OticeDocument3 pagesSales Bulletin: Roduct Iscontinuation OticeVolodymyr PotapovNo ratings yet

- Illustrated Parts CatalogDocument12 pagesIllustrated Parts Catalogbrains26No ratings yet

- 34070ADIRU MixabilityDocument9 pages34070ADIRU MixabilityJános RédeiNo ratings yet

- Amm 32-41-00-210-002Document26 pagesAmm 32-41-00-210-002Andrei NecuţăNo ratings yet

- A318/A319/A320/A321: Service BulletinDocument58 pagesA318/A319/A320/A321: Service BulletinPradeep K sNo ratings yet

- DIEHL CMM 33 51 17 PN 3214 31 Rev 10 10 Oct 2018 PDFDocument92 pagesDIEHL CMM 33 51 17 PN 3214 31 Rev 10 10 Oct 2018 PDFFilip F.No ratings yet

- B/E Aerospace: Component Maintenance Manual Super Diamond Minipod 1070101 SERIESDocument8 pagesB/E Aerospace: Component Maintenance Manual Super Diamond Minipod 1070101 SERIESırmak erolNo ratings yet

- Dowty Prop R352 R410Document8 pagesDowty Prop R352 R410JuanOñateNo ratings yet

- Service Bulletin: Customer Support OperationsDocument4 pagesService Bulletin: Customer Support OperationsPradeep K sNo ratings yet

- Boeing 737 Parts Inventory Ep Tij MX 2Document6 pagesBoeing 737 Parts Inventory Ep Tij MX 2Bobby Robert MaengkomNo ratings yet

- Hydraulic Systems No. 1 or No. 2 - Fill With Hydraulic FluidDocument12 pagesHydraulic Systems No. 1 or No. 2 - Fill With Hydraulic FluidaliNo ratings yet

- TYE Insert Cross Reference ListDocument11 pagesTYE Insert Cross Reference ListJesse KrebsNo ratings yet

- Service Bulletin Atr72: Transmittal Sheet Revision No. 12Document16 pagesService Bulletin Atr72: Transmittal Sheet Revision No. 12Pradeep K sNo ratings yet

- EI-17-272-A322 Rev A ELDS INSTALLATION SB PDFDocument50 pagesEI-17-272-A322 Rev A ELDS INSTALLATION SB PDFAbhishek Roy100% (1)

- PART 8 - Fly Etc CCDocument206 pagesPART 8 - Fly Etc CCkemoam birhanuNo ratings yet

- CAO - IRI Part - MDocument102 pagesCAO - IRI Part - MDariush ShNo ratings yet

- Curtiss-Wright Controls Integrated Sensing (Cage Code: 03972)Document6 pagesCurtiss-Wright Controls Integrated Sensing (Cage Code: 03972)Huda LestraNo ratings yet

- HT1000 GNSS Pilot Guide HandbookDocument363 pagesHT1000 GNSS Pilot Guide Handbookifal ahmadNo ratings yet

- Fill Unit - Nitrogen 98F29103500000: GSE/Tool User GuideDocument18 pagesFill Unit - Nitrogen 98F29103500000: GSE/Tool User GuideJivendra KumarNo ratings yet

- Cali 01Document19 pagesCali 01sam tariqNo ratings yet

- Cube 30 Touch User Manual Rev. 2.1 en 05.2022Document79 pagesCube 30 Touch User Manual Rev. 2.1 en 05.2022kahlilNo ratings yet

- Printed in GermanyDocument20 pagesPrinted in GermanyEdson CarvalhoNo ratings yet

- Printed in GermanyDocument46 pagesPrinted in GermanyEdson CarvalhoNo ratings yet

- Printed in GermanyDocument29 pagesPrinted in GermanyEdson CarvalhoNo ratings yet

- Nammdlha 000058Document380 pagesNammdlha 000058Edson CarvalhoNo ratings yet

- 27-11-18 All Speed Servo CTRL 31055 SeriesDocument190 pages27-11-18 All Speed Servo CTRL 31055 SeriesEdson CarvalhoNo ratings yet

- Printed in GermanyDocument31 pagesPrinted in GermanyEdson CarvalhoNo ratings yet

- 27-31-16 Pitch Servo CTRL 31043 SeriesDocument190 pages27-31-16 Pitch Servo CTRL 31043 SeriesEdson CarvalhoNo ratings yet

- ON A/C FSN 551-600: Customization Aircraft Types Doctypes Revision Date Title Tail Number - MSN - FSNDocument7 pagesON A/C FSN 551-600: Customization Aircraft Types Doctypes Revision Date Title Tail Number - MSN - FSNEdson CarvalhoNo ratings yet

- Nammbva 000007Document71 pagesNammbva 000007Edson CarvalhoNo ratings yet

- TAP - A330 Removal of The Exhaust Nozzle AssemblyDocument7 pagesTAP - A330 Removal of The Exhaust Nozzle AssemblyEdson CarvalhoNo ratings yet

- A330 Removal of The Aft Plug AssemblyDocument5 pagesA330 Removal of The Aft Plug AssemblyEdson CarvalhoNo ratings yet

- Nammbva 000005Document42 pagesNammbva 000005Edson CarvalhoNo ratings yet

- Mandatory Mandatory Mandatory: Title: Nacelles/Pylons - Aft Fixed Fairing - Inspection On Pylon Aft Fixed FairingDocument291 pagesMandatory Mandatory Mandatory: Title: Nacelles/Pylons - Aft Fixed Fairing - Inspection On Pylon Aft Fixed FairingEdson CarvalhoNo ratings yet

- Pacific Scientific T60 User ManualDocument14 pagesPacific Scientific T60 User ManualEdson CarvalhoNo ratings yet

- MF 101 Downmagaz - WsDocument132 pagesMF 101 Downmagaz - WsEdson Carvalho100% (2)

- Shell Model Ebook v4Document9 pagesShell Model Ebook v4Edson CarvalhoNo ratings yet