Professional Documents

Culture Documents

This Way To CE Marking: Standards

Uploaded by

MarcoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

This Way To CE Marking: Standards

Uploaded by

MarcoCopyright:

Available Formats

Standards

This way to CE Marking

The BCSA outlines the measures which must be undertaken to fulfill the requirements of BS

EN 1090-1, that allows companies to CE Mark its structural steelwork.

The new European standard for the CE Marking Execution Class

of structural steelwork, BS EN 1090-1, is expected Specification of an Execution Class (EXC) for

to come into force in May next year. Once in steel structures is a new concept within the steel

place steelwork contractors in all European Union construction industry. In BS EN 1090-2 these

member states will be able to CE Mark their range from EXC1 to EXC4, and the strictness of

fabricated steelwork. requirements increases correspondingly from 1 to 4.

While CE Marking will not be enforced The choice of EXC is a design issue where each

immediately in the UK and the Republic of Ireland class is based on the criticality of a structure in

(ROI), it is likely to become a legal mandatory terms of its service conditions and the consequence

requirement in 2012. To support steelwork of its failure. However, while the designer is

contractors and ensure that they are fully prepared, responsible for determining the required EXC, to

BCSA has produced a series of guidance notes enable CE Marking of its fabricated steelwork, a

and a comprehensive publication outlining the steelwork contractor must declare and demonstrate

requirements for CE Marking. its capability to produce a structure that will

All of the BCSA’s guidance is aimed at providing conform to a specified EXC.

steelwork contractors with practical advice on the The importance of a steelwork contractor

routes to achieving a certified Factory Production declaring the correct EXC for its range of fabricated

Control system by which they can declare steelwork cannot be overstated since this not

conformity with the requirements of BS EN 1090-1, only impacts on the systems and competency

and, as a consequence, CE Mark structural of personnel used to implement and control its

steelwork produced in their factories. manufacturing operations but also the work to be

tendered for in the future. A steelwork contractor

Factory Production Control system declaring conformance to a particular EXC can

BS EN 1090-1 defines the manufacturing controls undertake work in a lower class but not to a higher

required to ensure that structural steel components class.

meet a range of clearly set-out technical

requirements relevant to the manufacture of steel Responsible Welding Coordinator

components. In particular, it requires a steelwork The term Responsible Welding Coordinator (RWC)

contractor to implement and maintain a ‘certified’ is used to identify the person who is competent

Factory Production Control (FPC) system. to control and supervise a steelwork contractor’s

An FPC system for structural steelwork is similar welding activities. A steelwork contractor should

to a BS EN ISO 9001 Quality Management System nominate at least one RWC with the technical

(QMS), with the exception that incorporated within knowledge and experience appropriate for the

it the steelwork contractor is required to have a range of fabricated steelwork being manufactured.

documented Welding Quality Management System BS EN 1090-2 sets out the technical knowledge

(WQMS). A nominated a person responsible for requirements for the RWC based on the steelwork

all welding activities - a Responsible Welding contractor’s declared EXC, the welding processes

Coordinator (RWC) - is also required. and materials used. It makes reference to the

International Standard for Welding Cordination

Welding Quality Management System (BS EN ISO 14731) which specifies three categories

To satisfy the manufacturing controls of BS EN of technical knowledge ie: Comprehensive,

1090-1, a steelwork contractor is also required to Specific and Basic, and links these respectively to

demonstrate that its steelwork meets the technical International Welding Engineer (IWE), International

requirements of BS EN 1090-2, the fabrication Welding Technologist (IWT) and International

standard for CE Marking. Welding Specialist (IWS).

This requires the steelwork contractor to BCSA has recognised the difficulty in finding

implement and maintain a documented Welding formally qualified IWS, IWT or IWE personnel,

Quality Management System (WQMS) in particularly for those steelwork contractors

accordance with the relevant part of BS EN ISO working solely on buildings. The BCSA is offering

3834. The relevant part, and consequently the its members an alternative RWC training and

stringency of requirements, is determined by the assessment route for their direct employees. Using

Execution Class (EXC) declared by the steelwork a direct employee as the RWC is the preferred

contractor for its fabricated steelwork. option, however, this may not always be possible

24 NSC September 2009

Standards

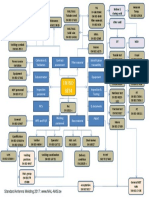

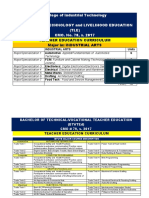

Routes to CE Marking Certification for Steelwork Contractors

START

Already have

Already have certified ISO 3834

certified ISO 9001 YES (WQMS) and YES ALL STRUCTURES ROUTE THEN ALL STRUCTURES ROUTE

(QMS)? employ IWE/IWT as

RWC?

ALL STRUCTURES ROUTE

Apply to SCCS to

carry out certification

NO NO assessment of

THEN ALL STRUCTURES ROUTE Factory Production

Develop written Control system

Develop written

Factory Employ or (includes WQMS and

welding Apply to SCCS for RWC assessments) –

Production THEN subcontract YES management Pre-audit if NO See Note 1

Control system IWE/IWT as RWC? control certified ISO 9001

procedures procedures

BUILDINGS ONLY

THEN

ROUTE

ONLY ROUTE

IF ‘NO’ THEN

BUILDINGS

GENERAL NOTE

Before embarking on the route

THEN

THEN

THEN

to CE Marking it is essential that

steelwork contractors become

familiar with BS EN 1090-1 and

BS EN 1090-2. Award of

Employ Welding

Notes referred to in flow-chart

BCSA factory certificates

Inspector level 3.1

assessment of for CE

1. If your certified ISO 9001 or 3.2 or Identify Only available to BCSA Members

is with SCCS then the FPC RWC’s application Marking

skilled employee

certification assessment is in lieu

as RWC (Buildings Route only) of WQMS (includes

of one SCCS ISO 9001 FPC and

surveillance visit Welding

THEN

2. If your certified ISO 9001 is with Certificates)

THEN

SCCS then the FPC surveillance

visit in lieu of one SCCS ISO

THEN

THEN

9001 surveillance visit

Welding

Develop written

Inspector/skilled

LEGEND Request and welding

employee to 6 month period to Annual surveillance of Factory

Orange route – complete BCSA THEN THEN management THEN

attend BCSA implement WQMS Production Control system.

All structures (EXC 3 and/or 4) review form control

course and pass See Note 2

Blue route – procedures

assessment

Buildings only (EXC 2)

DEFINITIONS

QMS Quality Management System

WQMS Welding Quality Management System

FPC Factory Production Control System

IWE International Welding Engineer Further information on CE Marking can be found in

IWT International Welding Technologist

BCSA’s ‘Guide to the CE Marking of Structural Steelwork’, Pub No. 46/08

RWC Responsible Welding Coordinator

and BCSA recommends that where subcontractor assessment by the Steel Construction Certification

personnel are engaged they should hold the Scheme (SCCS),” says Dr David Moore BCSA

appropriate IWE, IWT or IWS qualification. Director of Engineering. “This tests the candidate’s

knowledge gleaned from the course and

BCSA Members’ Training competency at work.”

and Assessment Route

The BCSA training and assessment route is aimed The Steel Construction Certification Scheme

at providing skilled and experienced personnel The Steel Construction Certification Scheme (SCCS)

with the technical knowledge required to undertake is the certification body specifically for companies

the role of the RWC. This route is limited to BCSA engaged in design, manufacture and erection of

members and their direct employees only; it is structural steelwork and its associated products and

aimed at those steelwork contractors working services. The scheme’s objective is to secure high

primarily in the Buildings sector wishing to declare standards of excellence and quality of processes

CE Marking conformance to Execution Class 2. and associated construction procedures and

The route requires the steelwork contractor to practices through independent certification.

propose an employee who it considers suitable to SCCS is a UKAS accredited notified body for the

fulfil the RWC role. The candidate is then required assessment of factory production control systems,

to complete and submit an authenticated CV to the ie: those required for CE Marking of structural

BCSA for review, attend and successfully complete steelwork.

the BCSA RWC training course which last two days. For those BCSA members who currently have

“The candidate then returns to the workplace their BS EN ISO 9001 QMS certification with SCCS,

to develop and implement an appropriate WQMS SCCS is proposing to substitute a QMS surveillance

and following a six month implementation period visit with an FPC visit. SCCS is also exploring how

we would then carry out a factory assessment best to alternate surveillance visits to minimise

of both the RWC and WQMS to demonstrate costs, while maintaining the effectiveness and

RWC competency and readiness for a FPC pre- accreditation of both systems.

NSC September 2009 25

You might also like

- En 1090Document1 pageEn 1090Anonymous pgQIReuNo ratings yet

- Steel Construction UKCA Marking v3Document20 pagesSteel Construction UKCA Marking v3ioancNo ratings yet

- Cen Iso 17844 - 2004 PDFDocument80 pagesCen Iso 17844 - 2004 PDFANNo ratings yet

- PDFDocument15 pagesPDFkumarkk1969No ratings yet

- QT2109958 - ITP For 1T-1201 Buffer Water Tank Itp PDFDocument3 pagesQT2109958 - ITP For 1T-1201 Buffer Water Tank Itp PDFGanesh EswaranNo ratings yet

- Iso 17640 2017 en PDFDocument11 pagesIso 17640 2017 en PDFTanveer Ahmed Quadri100% (1)

- CE Marking Requirements for Structural Steel PlatesDocument4 pagesCE Marking Requirements for Structural Steel PlatesSebastián Araya MoraNo ratings yet

- Poster DIN EN 1090-1 ENG Final PDFDocument1 pagePoster DIN EN 1090-1 ENG Final PDFlth770310No ratings yet

- BS en 1090-2:2008+a1:2011Document1 pageBS en 1090-2:2008+a1:2011234ahmed50% (2)

- Equivalences Certified Welder According ASME EN ISO 14732 - 2013 - GleDocument1 pageEquivalences Certified Welder According ASME EN ISO 14732 - 2013 - Gleer_wenNo ratings yet

- Atex Part 36Document189 pagesAtex Part 36CRISTIAN SILVIU IANUCNo ratings yet

- Section IiiDocument163 pagesSection Iiiprabhu100% (1)

- Conformity Assessment For The Execution of Steel & Aluminium StructuresDocument14 pagesConformity Assessment For The Execution of Steel & Aluminium StructuresJevgenijsKolupajevsNo ratings yet

- Pressure Equipment - : Part 4: Establishment of Technical Delivery Conditions For Metallic MaterialsDocument48 pagesPressure Equipment - : Part 4: Establishment of Technical Delivery Conditions For Metallic MaterialsAhmed Hussien50% (2)

- WPS standard welding processes and LORCH welding techniquesDocument1 pageWPS standard welding processes and LORCH welding techniquesAnilNo ratings yet

- BS en Iso 14731-2019Document20 pagesBS en Iso 14731-2019Hüseyin BuğdaycıNo ratings yet

- BS EN ISO 26304-2009 焊接消耗品.高强度钢埋弧焊用线状和管状芯电极及焊条熔剂化合物.分类 PDFDocument28 pagesBS EN ISO 26304-2009 焊接消耗品.高强度钢埋弧焊用线状和管状芯电极及焊条熔剂化合物.分类 PDFShyam ParsanaNo ratings yet

- BS en 14399-9-2018 - (2019-07-15 - 10-31-27 Am)Document32 pagesBS en 14399-9-2018 - (2019-07-15 - 10-31-27 Am)DEEPAK SHARMANo ratings yet

- Iso 21809 2 2007 en FR PDFDocument11 pagesIso 21809 2 2007 en FR PDFmsaremiNo ratings yet

- PD CENTR 16332-2012 Non-Destructive TestingDocument21 pagesPD CENTR 16332-2012 Non-Destructive TestingWHWENNo ratings yet

- EN 1090 Compliance for Structural SteelDocument42 pagesEN 1090 Compliance for Structural Steelbharani dharanNo ratings yet

- European Standard EN 288-1: 1992 + A1: 1997 Has The Status of A DIN StandardDocument9 pagesEuropean Standard EN 288-1: 1992 + A1: 1997 Has The Status of A DIN StandardSanjay C BhattNo ratings yet

- Marine Cable Product CatalogDocument214 pagesMarine Cable Product CatalogJose Luius100% (1)

- BS en 00287-6-2010Document26 pagesBS en 00287-6-2010Shan Sandaruwan AbeywardeneNo ratings yet

- BS en 19-2002 - Industrial Valves. Marking of Metallic ValvesDocument14 pagesBS en 19-2002 - Industrial Valves. Marking of Metallic Valvesnikolicjelena100% (1)

- BS En-12952-2-2021Document46 pagesBS En-12952-2-2021TANK INSPECTNo ratings yet

- 0526 16 2004 07 en - enDocument6 pages0526 16 2004 07 en - envtsusr fvNo ratings yet

- Aluminium en AW 6082Document3 pagesAluminium en AW 6082doshi78No ratings yet

- BS en 1708-3-12Document22 pagesBS en 1708-3-12gaso99No ratings yet

- Guia Iso 14731Document7 pagesGuia Iso 14731englopesNo ratings yet

- BS en 1011-5-2003Document14 pagesBS en 1011-5-2003pham khietNo ratings yet

- Clarification On CE Marking With EN 1090-1 PDFDocument5 pagesClarification On CE Marking With EN 1090-1 PDFAMGConsultadoriaNo ratings yet

- Overzicht en Iso 3834 Editie 2017 - Engels PDFDocument1 pageOverzicht en Iso 3834 Editie 2017 - Engels PDFrohit mathankerNo ratings yet

- Repair Dvs Supplement PDFDocument6 pagesRepair Dvs Supplement PDFGnana MoorthyNo ratings yet

- BS en 1335-3-2009Document30 pagesBS en 1335-3-2009Adel A. Abdelaziz100% (1)

- ISO 1579-1 (Part Only)Document5 pagesISO 1579-1 (Part Only)sn200709100% (1)

- En 12451 1999Document24 pagesEn 12451 1999victoraghiNo ratings yet

- 25CrMo4Document1 page25CrMo4Hans GoetheNo ratings yet

- File - 4houldcroft Weldability Test of Aluminium Alloy EN AW 6082 T6 7 - Part - 254-1Document8 pagesFile - 4houldcroft Weldability Test of Aluminium Alloy EN AW 6082 T6 7 - Part - 254-1Corey DodsonNo ratings yet

- Best practice – initial type testing and subcontractorsDocument32 pagesBest practice – initial type testing and subcontractorsfenasikerimNo ratings yet

- BS en Iso 13918 2018Document11 pagesBS en Iso 13918 2018MAHESHNo ratings yet

- Pre-Load: Bolt Assemblies HR BS EN 14399-3:2015Document5 pagesPre-Load: Bolt Assemblies HR BS EN 14399-3:2015erharsinghNo ratings yet

- ISO 15510 - Part 1Document5 pagesISO 15510 - Part 1Zdenko MahacekNo ratings yet

- Cen TR 13480-7 (2002) (E)Document6 pagesCen TR 13480-7 (2002) (E)g9g9No ratings yet

- En Iso 15609Document2 pagesEn Iso 15609Wazir Shah KazmiNo ratings yet

- Cen TR 14633 (E)Document9 pagesCen TR 14633 (E)consssNo ratings yet

- Iso 15614-13Document24 pagesIso 15614-13Marija IvanovskaNo ratings yet

- Iso 3452-5 - 2008Document12 pagesIso 3452-5 - 2008jesonelite100% (1)

- PI Tectyl-506 TE031-01Document2 pagesPI Tectyl-506 TE031-01nicusebpNo ratings yet

- Steel fabrications CE certification essential qualityDocument2 pagesSteel fabrications CE certification essential qualitylafssNo ratings yet

- Steel Fabrications With CE Certification - An Essential QualityDocument2 pagesSteel Fabrications With CE Certification - An Essential QualitylafssNo ratings yet

- KCS 14 31 20 용접Document47 pagesKCS 14 31 20 용접yoonchankim0911No ratings yet

- Welding Requirements For The CE MarkDocument2 pagesWelding Requirements For The CE MarkAekJayNo ratings yet

- Masonry Support Systems and LintelsDocument40 pagesMasonry Support Systems and LintelsakajsiNo ratings yet

- 6 Welding Procedure Qualification & Welder Qualification PDFDocument15 pages6 Welding Procedure Qualification & Welder Qualification PDFParminder Singh100% (2)

- Bs130 CSPG Guidelines 24062021 PDFDocument38 pagesBs130 CSPG Guidelines 24062021 PDFRamesh GuptaNo ratings yet

- Hot Dip Galvanizing To EN ISO 1461 and CDocument12 pagesHot Dip Galvanizing To EN ISO 1461 and CAhmedRamadanNo ratings yet

- Inspection of Fixed Steel Offshore Structures During Fabrication and Installation - GuidelinesDocument9 pagesInspection of Fixed Steel Offshore Structures During Fabrication and Installation - GuidelinesShanmugam SailappanNo ratings yet

- H1006400MKF51 Sa12qt 01Document4 pagesH1006400MKF51 Sa12qt 01MarcoNo ratings yet

- H 623500meu71 Sa00pb 01 - CDocument9 pagesH 623500meu71 Sa00pb 01 - CMarcoNo ratings yet

- Plexiglas model specifications sheetDocument1 pagePlexiglas model specifications sheetMarcoNo ratings yet

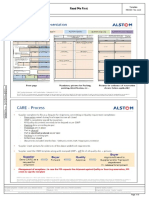

- Chute de Gavet: Commun Aux Groupes Quality Working Plan Runner TipDocument5 pagesChute de Gavet: Commun Aux Groupes Quality Working Plan Runner TipMarcoNo ratings yet

- HS FNT02 00000080aec - DDocument4 pagesHS FNT02 00000080aec - DMarcoNo ratings yet

- HS Cal01 000000000ecDocument4 pagesHS Cal01 000000000ecMarcoNo ratings yet

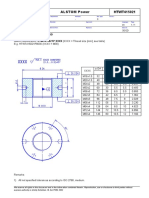

- ALSTOM Power NB00129: 1 GeneralDocument1 pageALSTOM Power NB00129: 1 GeneralMarcoNo ratings yet

- P8AHEM4100Document9 pagesP8AHEM4100MarcoNo ratings yet

- HGGD223001 A en 001Document1 pageHGGD223001 A en 001MarcoNo ratings yet

- P8AHEM4800Document14 pagesP8AHEM4800MarcoNo ratings yet

- HTWT415575 A en 01Document1 pageHTWT415575 A en 01MarcoNo ratings yet

- ALSTOM Power ZN 00110Document6 pagesALSTOM Power ZN 00110MarcoNo ratings yet

- HTWT415073 DDocument3 pagesHTWT415073 DMarcoNo ratings yet

- HTWT417350 BDocument2 pagesHTWT417350 BMarcoNo ratings yet

- HTWT415575 A en 01Document1 pageHTWT415575 A en 01MarcoNo ratings yet

- HTWT415021P0036Document1 pageHTWT415021P0036MarcoNo ratings yet

- HS FSW01 00000088aec - CDocument5 pagesHS FSW01 00000088aec - CMarcoNo ratings yet

- Washer D37 specificationsDocument1 pageWasher D37 specificationsMarcoNo ratings yet

- HTWT415021 - enDocument1 pageHTWT415021 - enMarcoNo ratings yet

- HS Hge00 000412622QWDocument3 pagesHS Hge00 000412622QWMarcoNo ratings yet

- Washer D37 specificationsDocument1 pageWasher D37 specificationsMarcoNo ratings yet

- HS FNT02 00000080aec - DDocument4 pagesHS FNT02 00000080aec - DMarcoNo ratings yet

- HTCM629463 BDocument2 pagesHTCM629463 BMarcoNo ratings yet

- HS FPN02 000000stlec - BDocument5 pagesHS FPN02 000000stlec - BMarcoNo ratings yet

- H1006300MKD11 Sa00qw 02Document8 pagesH1006300MKD11 Sa00qw 02MarcoNo ratings yet

- HTWT410375 QDocument4 pagesHTWT410375 QMarcoNo ratings yet

- HS FWR01 000000staec - CDocument4 pagesHS FWR01 000000staec - CMarcoNo ratings yet

- Heugs 7.04.1113 - A - en - 01Document5 pagesHeugs 7.04.1113 - A - en - 01MarcoNo ratings yet

- H1006300MKD11 Sa00qw 03Document3 pagesH1006300MKD11 Sa00qw 03MarcoNo ratings yet

- H1006300mkd11-Sa00 004 - BomDocument1 pageH1006300mkd11-Sa00 004 - BomMarcoNo ratings yet

- How Chips Are DesignedDocument46 pagesHow Chips Are DesignedAli AhmadNo ratings yet

- Corbin Technical Bulletin Volume 4Document149 pagesCorbin Technical Bulletin Volume 4aikidomoysesNo ratings yet

- Joint Ventures Synergies and BenefitsDocument5 pagesJoint Ventures Synergies and BenefitsleeashleeNo ratings yet

- Excel - Bachelorprojekt - Bertil Theis JørgensenDocument944 pagesExcel - Bachelorprojekt - Bertil Theis JørgensenBertil JørgensenNo ratings yet

- Normalization Castuera BSCS2CDocument8 pagesNormalization Castuera BSCS2CRichard, Jr. CastueraNo ratings yet

- HQ 170aDocument82 pagesHQ 170aTony WellsNo ratings yet

- j00m HD FLV SQL Injection - PyDocument4 pagesj00m HD FLV SQL Injection - PyZeljko PanovicNo ratings yet

- PRACTICA (1) (1) - Páginas-2-4Document3 pagesPRACTICA (1) (1) - Páginas-2-4EDDY POLICARPIO BRAVO HUAMANINo ratings yet

- College of Industrial Technology Bachelor of Technology and Livelihood Education (TLE) CMO. No. 78, S. 2017Document5 pagesCollege of Industrial Technology Bachelor of Technology and Livelihood Education (TLE) CMO. No. 78, S. 2017Industrial TechnologyNo ratings yet

- Ansys Workbench Tutorial: Structural & Thermal Analysis Using The ANSYS Workbench Release 11.0 EnvironmentDocument5 pagesAnsys Workbench Tutorial: Structural & Thermal Analysis Using The ANSYS Workbench Release 11.0 EnvironmentMuhammad HaroonNo ratings yet

- List of COCDocument21 pagesList of COCjoan_padilla2000No ratings yet

- Principles of Marketing Handout 4: Marketing Opportunity and Consumer AnalysisDocument19 pagesPrinciples of Marketing Handout 4: Marketing Opportunity and Consumer AnalysisAsset Dy100% (1)

- Computer Fundamentals: Input-Process-Output ModelDocument7 pagesComputer Fundamentals: Input-Process-Output ModelHarsh Nsf WolfNo ratings yet

- Sap AbapDocument7 pagesSap Abapidrees aliNo ratings yet

- Police Report Hearing RightsDocument7 pagesPolice Report Hearing RightsYatn BangadNo ratings yet

- HistoryDocument13 pagesHistoryMuhamed Zimić ZimaNo ratings yet

- Nursing Grand Rounds Reviewer PDFDocument17 pagesNursing Grand Rounds Reviewer PDFAlyssa Jade GolezNo ratings yet

- Part 1 LEA 4 Law Enforcement Operations and Planning With Crime MappingDocument94 pagesPart 1 LEA 4 Law Enforcement Operations and Planning With Crime Mappingyomaeko CinkoNo ratings yet

- Impact On Cocoon Quality Improvement.1Document10 pagesImpact On Cocoon Quality Improvement.1Naveen NtrNo ratings yet

- Rapidcure: Corrosion Management Products Rapidcure UwDocument1 pageRapidcure: Corrosion Management Products Rapidcure UwHeramb TrifaleyNo ratings yet

- ChecklistDocument2 pagesChecklistKyra AlesonNo ratings yet

- Manual Flowpet 5GDocument56 pagesManual Flowpet 5GRahkmat DanizarNo ratings yet

- Cem-FIL GRC Technical DataDocument91 pagesCem-FIL GRC Technical Datacbler100% (1)

- G.princy Xii - CommerceDocument21 pagesG.princy Xii - CommerceEvanglin .gNo ratings yet

- Global Server Load Balancing: Cns 205-5I: Citrix Netscaler 10.5 Essentials and NetworkingDocument37 pagesGlobal Server Load Balancing: Cns 205-5I: Citrix Netscaler 10.5 Essentials and NetworkingsudharaghavanNo ratings yet

- Crim Cases MidtermsDocument76 pagesCrim Cases MidtermsCoreine Valledor-SarragaNo ratings yet

- Nody D 23 01248 PDFDocument70 pagesNody D 23 01248 PDFLegis FloyenNo ratings yet

- OT Lawsuit CPDDocument20 pagesOT Lawsuit CPDDan LehrNo ratings yet

- International Financial Law Reforms After Global CrisisDocument5 pagesInternational Financial Law Reforms After Global CrisisВладиславNo ratings yet

- Discharging A ClientDocument6 pagesDischarging A ClientNorman Batalla Juruena, DHCM, PhD, RNNo ratings yet

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansFrom EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansRating: 4.5 out of 5 stars4.5/5 (21)

- Cable Supported Bridges: Concept and DesignFrom EverandCable Supported Bridges: Concept and DesignRating: 5 out of 5 stars5/5 (1)

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetFrom EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetRating: 4.5 out of 5 stars4.5/5 (10)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansFrom EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansNo ratings yet

- The Great Bridge: The Epic Story of the Building of the Brooklyn BridgeFrom EverandThe Great Bridge: The Epic Story of the Building of the Brooklyn BridgeRating: 4.5 out of 5 stars4.5/5 (59)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- The Rights of Nature: A Legal Revolution That Could Save the WorldFrom EverandThe Rights of Nature: A Legal Revolution That Could Save the WorldRating: 5 out of 5 stars5/5 (1)

- To Engineer Is Human: The Role of Failure in Successful DesignFrom EverandTo Engineer Is Human: The Role of Failure in Successful DesignRating: 4 out of 5 stars4/5 (137)

- Summary of Neil Postman's Amusing Ourselves to DeathFrom EverandSummary of Neil Postman's Amusing Ourselves to DeathRating: 4 out of 5 stars4/5 (2)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Professional Surveyors and Real Property Descriptions: Composition, Construction, and ComprehensionFrom EverandProfessional Surveyors and Real Property Descriptions: Composition, Construction, and ComprehensionNo ratings yet

- Methodology for Estimating Carbon Footprint of Road Projects: Case Study: IndiaFrom EverandMethodology for Estimating Carbon Footprint of Road Projects: Case Study: IndiaNo ratings yet

- Desperate: An Epic Battle for Clean Water and Justice in AppalachiaFrom EverandDesperate: An Epic Battle for Clean Water and Justice in AppalachiaRating: 4 out of 5 stars4/5 (1)

- Principles of Forensic Engineering Applied to Industrial AccidentsFrom EverandPrinciples of Forensic Engineering Applied to Industrial AccidentsNo ratings yet

- Safety and Intelligent Transport Systems Development in the People’s Republic of ChinaFrom EverandSafety and Intelligent Transport Systems Development in the People’s Republic of ChinaNo ratings yet

- Climate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingFrom EverandClimate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingNo ratings yet

- The Finite Element Method: Linear Static and Dynamic Finite Element AnalysisFrom EverandThe Finite Element Method: Linear Static and Dynamic Finite Element AnalysisRating: 5 out of 5 stars5/5 (3)

- Transportation Decision Making: Principles of Project Evaluation and ProgrammingFrom EverandTransportation Decision Making: Principles of Project Evaluation and ProgrammingNo ratings yet